Inicio / Gestión de mantenimiento

Temas relacionados

▸ Introducción a planes de mantenimiento

▸ Elementos básicos de un plan de mantenimiento (Partes, actividades y frecuencia)

▸ Submenú del catálogo de planes de mantenimiento

▸ Agregar un plan de mantenimiento

▸ Partes y actividades del plan

▸ Notas y archivos adjuntos del plan

▸ Agregar otro plan de mantenimiento igual

▸ Editar un plan de mantenimiento

▸ Eliminar un plan de mantenimiento

▸ Agregar partes

▸ Editar partes

▸ Eliminar partes

▸ Copiar y pegar partes

▸ Insertar un plan de mantenimiento dentro de otro

▸ Agregar actividades

▸ Editar actividades

▸ Frecuencia de las actividades

▸ Prioridad de las actividades

▸ Duración de las actividades

▸ Paro del equipo

▸ Clasificación de las actividades

▸ Actividades que implican la toma de una medición (Mantenimiento predictivo)

▸ Procedimiento para realizar las actividades

▸ Notas de seguridad, imágenes y archivos adjuntos de las actividades

▸ Requisitos para cerrar o incluir las actividades en una OT

▸ Eliminar actividades

▸ Copiar y pegar actividades

Ligar planes de mantenimiento

El mantenimiento programado del equipo o localización, comienza a partir de la asociación de un equipo con su respectivo plan de mantenimiento.

Para comenzar la programación del mantenimiento rutinario de un equipo o una localización, estos deberán ligarse primero con el plan de mantenimiento que les corresponda.

Para controlar el mantenimiento rutinario, es necesario ligar cada equipo o localización con un plan de mantenimiento, ya que el plan de mantenimiento (maestro) es el que contiene la información acerca de las actividades rutinarias que deben realizarse.

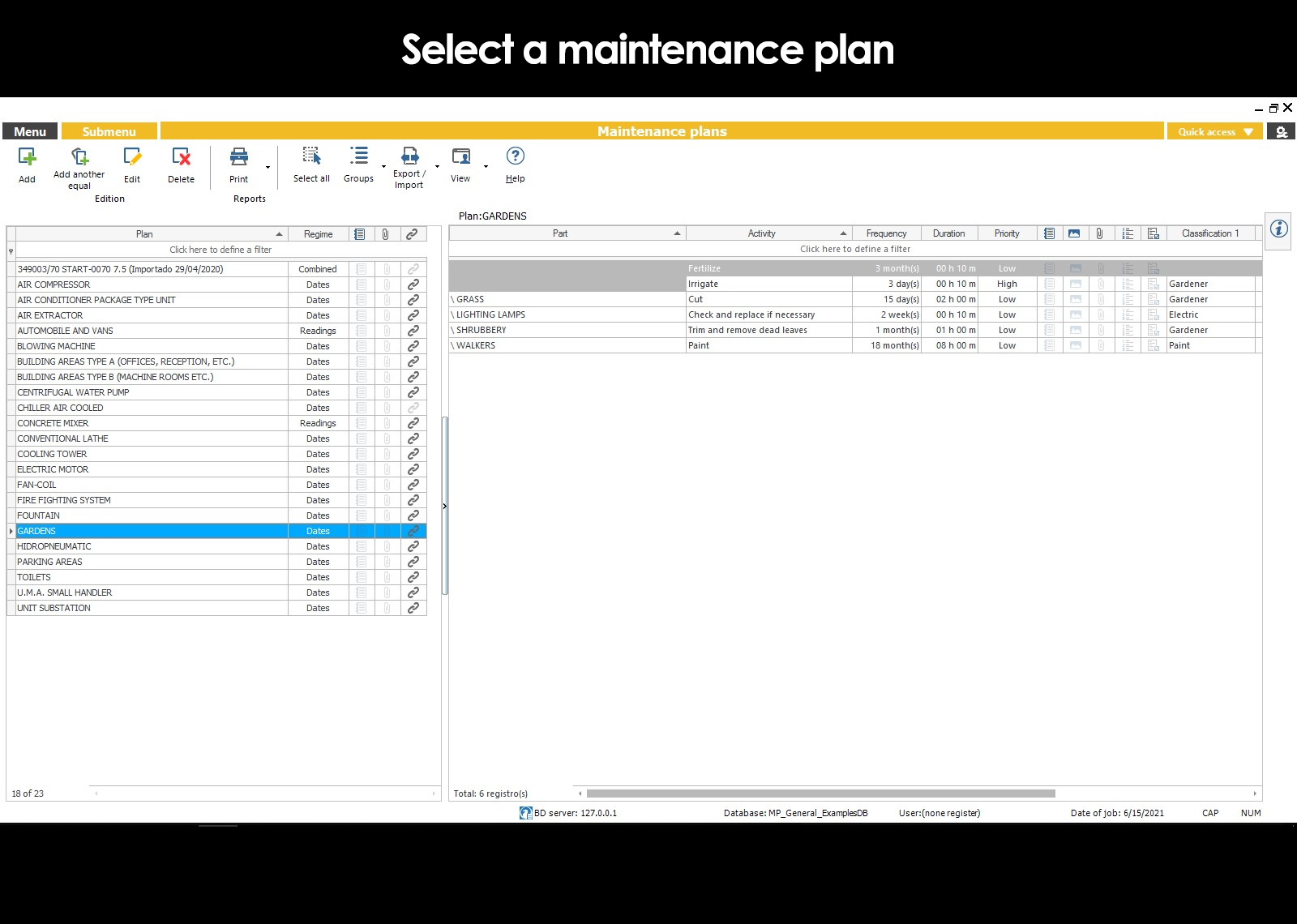

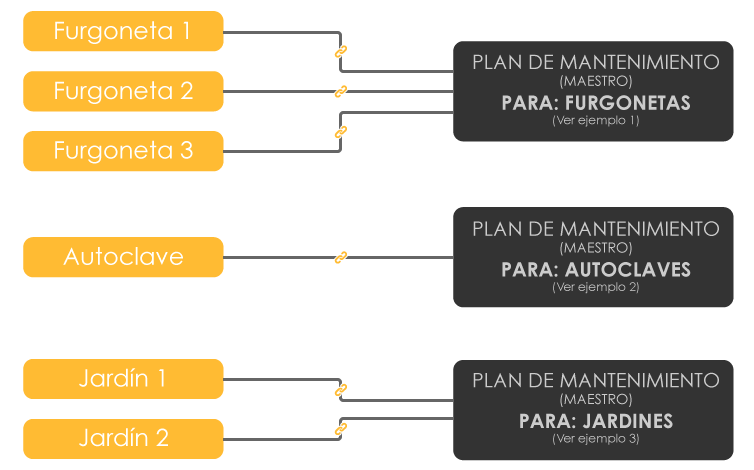

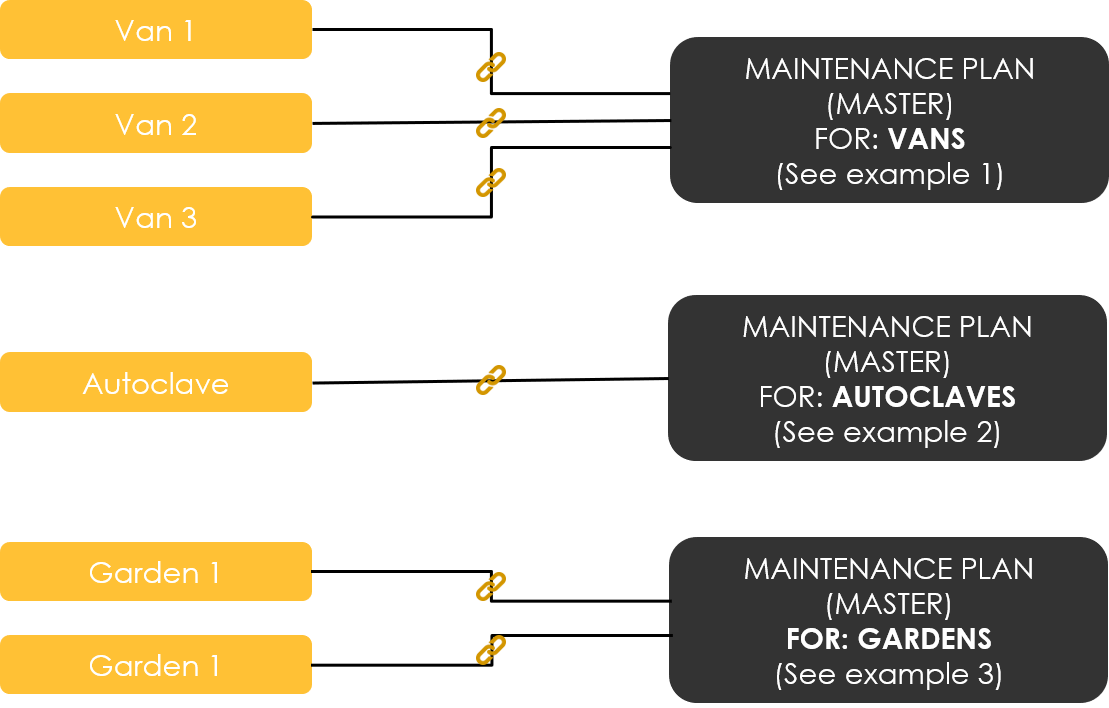

Un plan de mantenimiento puede utilizarse para regir el mantenimiento rutinario de varios equipos o localizaciones afines al plan. Esto evita la necesidad capturar el mismo plan varias veces para equipos o localizaciones afines.

Ejemplo de liga de equipos y localizaciones con planes de mantenimiento.

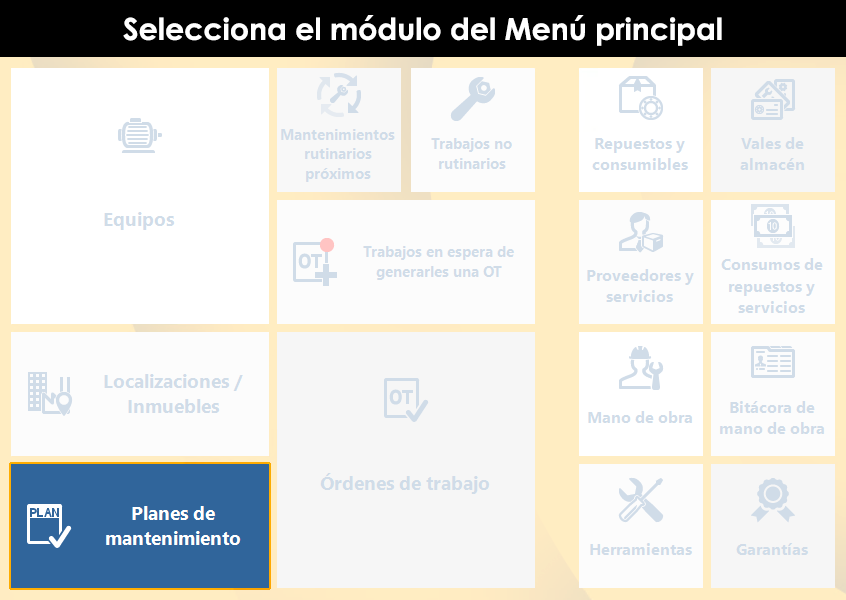

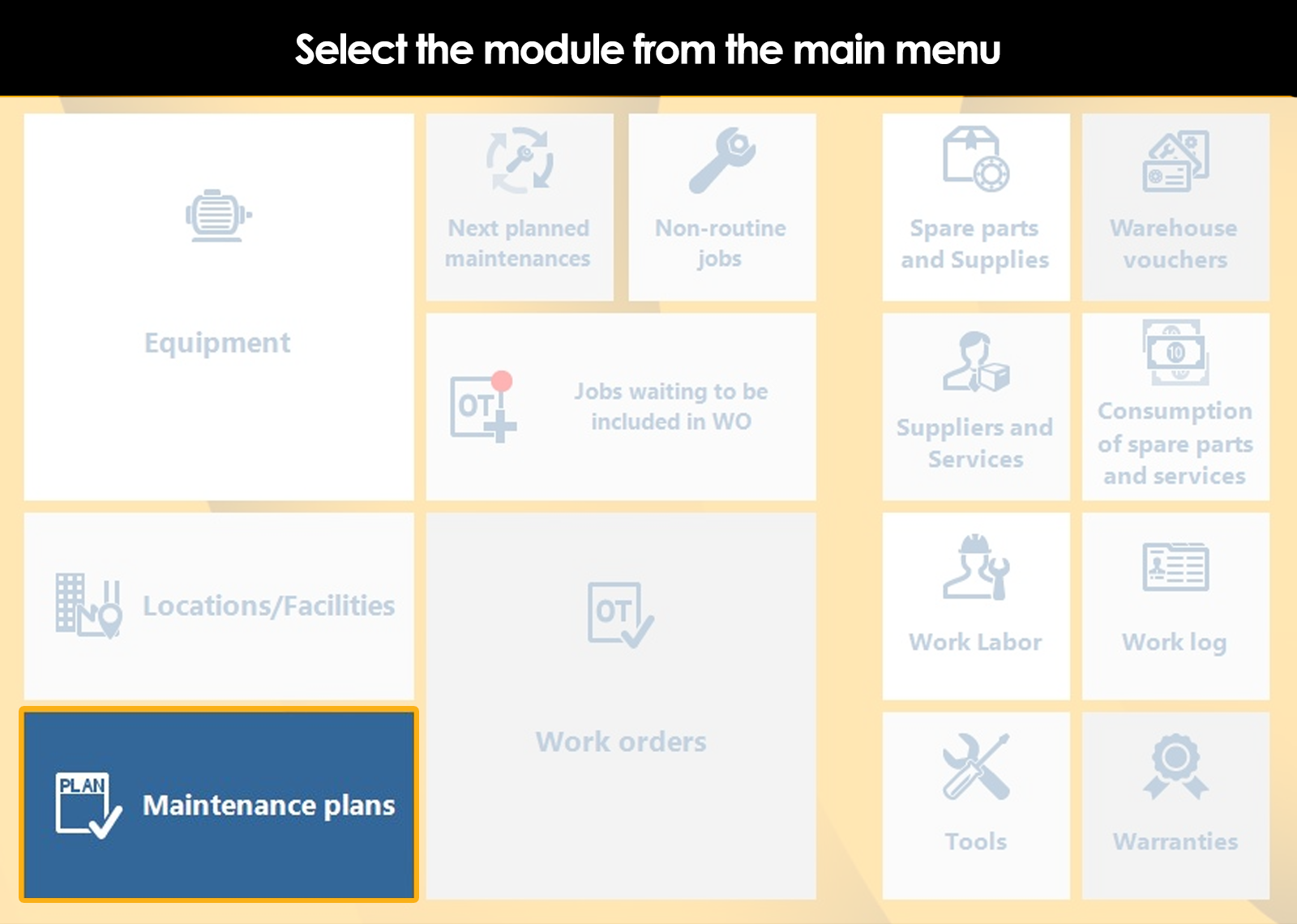

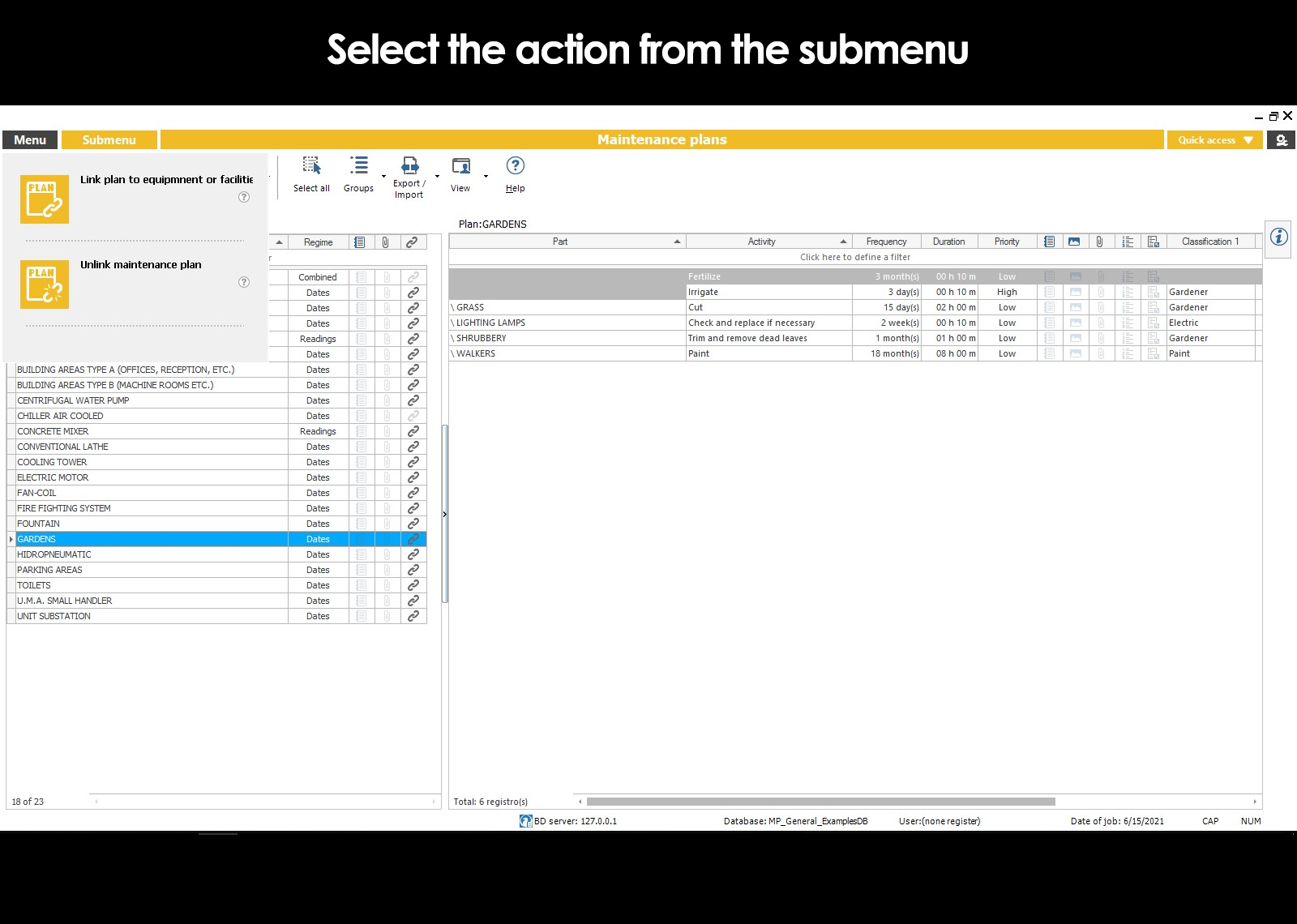

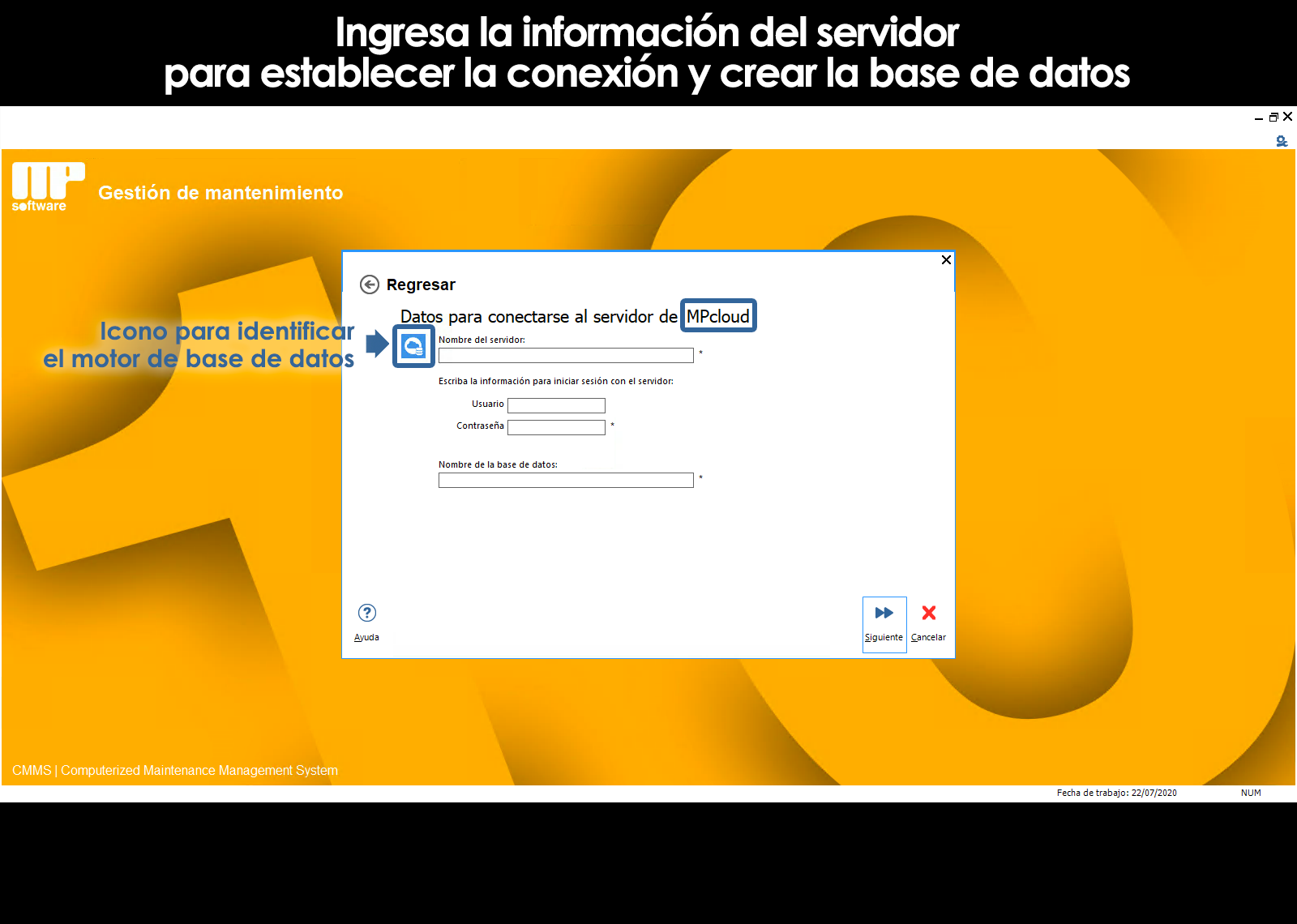

Para ligar un plan de mantenimiento a equipos o localizaciones, seleccione en el catálogo de planes, el plan que desea ligar a sus equipos o localizaciones y a continuación haga clic sobre la acción Ligar plan de mantenimiento a equipos o localizaciones del submenú.

Marque los equipos o localizaciones que desea ligar al plan anteriormente seleccionado y haga clic en Siguiente. Si está ligando un plan de mantenimiento que contiene actividades controladas por lecturas, el sistema solicitará teclear la última lectura conocida del equipo y su promedio de uso mensual para finalizar con la liga.

De igual manera es posible ligar planes de mantenimiento a equipos o localizaciones desde sus respectivos módulos. Seleccione uno o más equipos o localizaciones según el módulo en que se encuentre, haga clic en el submenú Ligar plan de mantenimiento y siga las instrucciones en pantalla.

En la columna Plan asignado, el usuario puede ingresar en cada celda el nombre del plan que desea asignar al equipo. También puede seleccionar varios registros de la lista y asignarles el mismo plan con el botón Asignar plan a equipos seleccionados.

Ligar un plan de mantenimiento con actividades con régimen de lecturas

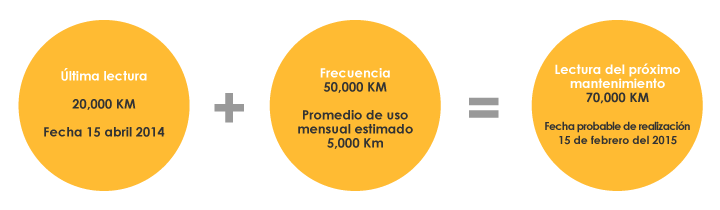

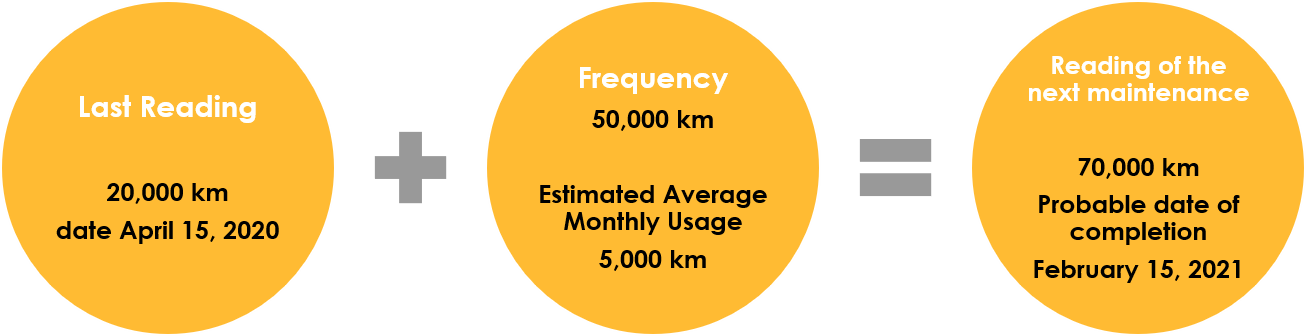

Hemos visto que la frecuencia con que debe realizarse una actividad se puede establecer por tiempo o por lecturas (Ejemplo kilómetros, horas de uso, piezas producidas etc.).

Cuando una actividad de mantenimiento se controla por el régimen de lecturas o mixto, el control es más preciso ya que depende directamente del uso del equipo y no solamente del tiempo transcurrido. Sin embargo, el control por lecturas y mixto resulta un poco más complejo, ya que obliga al usuario a registrar periódicamente la lectura de uso que marque un odómetro, reloj contador de horas, etc. De igual forma, para poder pronosticar una fecha tentativa de realización de la actividad, es necesario indicar también en estos casos un promedio de uso mensual estimado.

Por lo anterior, al ligar un plan de mantenimiento controlado por lecturas, el sistema solicita al usuario que teclee la última lectura conocida del equipo y su promedio de uso mensual. Para más información respecto al control por lecturas presione aquí.

Desligar planes de mantenimiento

Al momento de desligar un plan de mantenimiento de un equipo o localización, se eliminará el historial de mediciones, recursos (mano de obra, servicios externos y herramientas) y lecturas asociadas a ellos y no será posible registrar nuevos valores hasta ligar nuevamente un plan.

Desde el catálogo planes de mantenimiento, seleccione el plan de mantenimiento que desea desligar del equipo o localización y a continuación haga clic en la acción Desligar plan de mantenimiento del submenú.

Aparecerá una lista con los equipos o localizaciones que están ligados al plan previamente seleccionado. Marque el equipo o localización que desee desligar y luego haga clic en Desligar plan.

Nota: Para desligar un plan de mantenimiento deberá asegurarse que ninguna de las actividades del plan asignado al equipo o localización se encuentre en una OT abierta. Usted podrá seguir registrando mantenimientos no rutinarios en los equipos o localizaciones que no tengan plan asignado.

Alertas relacionadas con planes de mantenimiento

Ligar equipos y localizaciones con sus respectivos planes de mantenimiento es fundamental para el control del mantenimiento rutinario. No basta con agregar equipos y estructurar planes de mantenimiento en el sistema, es muy importante asociarlos para definir el arranque de los trabajos de mantenimiento y la programación de las fechas próximas en que se realizarán cada una de las actividades que incluimos en el plan. Por esta razón, el sistema cuenta con las siguientes alertas:

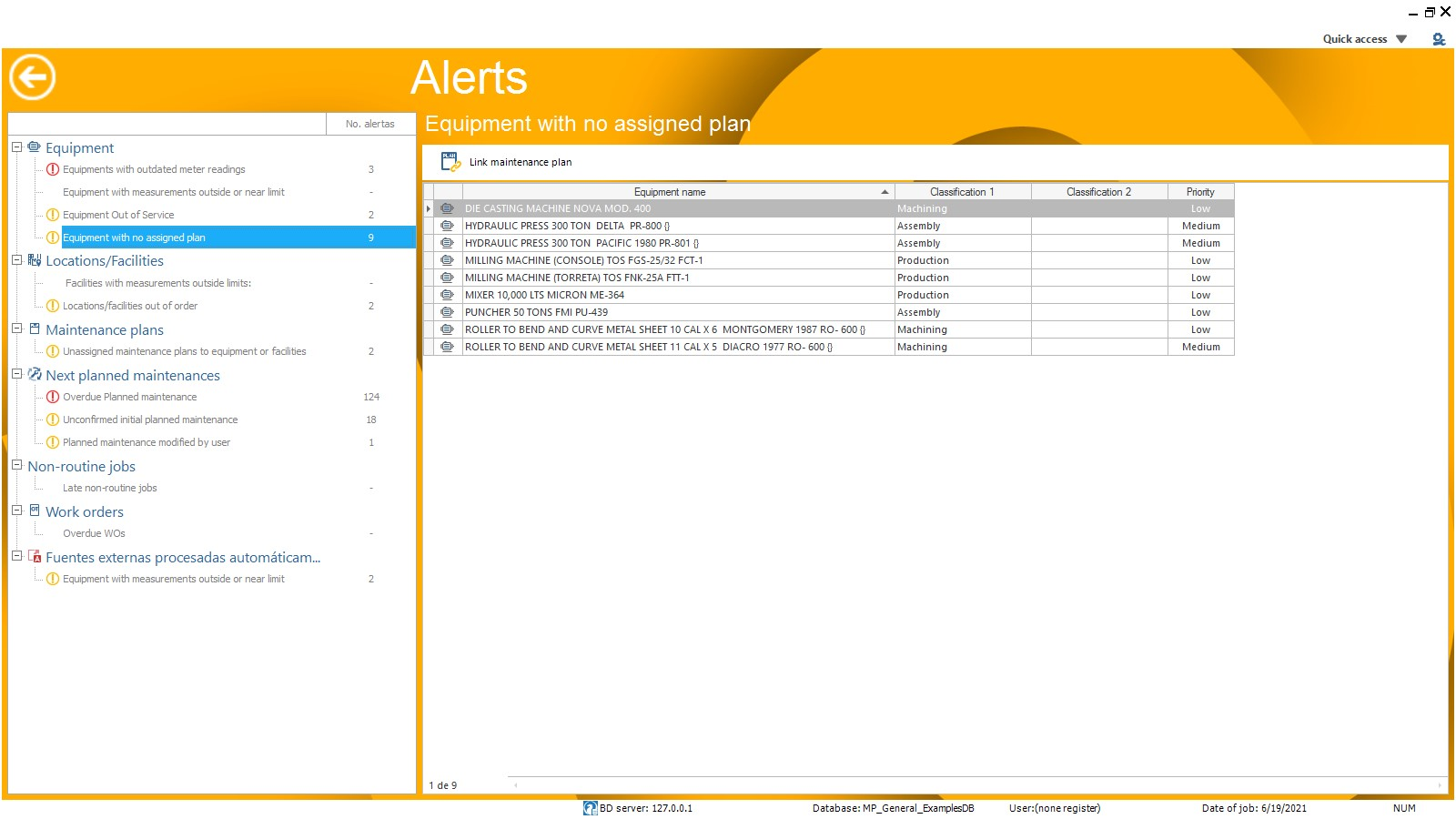

Alerta de equipos sin plan asignado

Muestra un listado de todos los equipos que no se han asociado con algún plan de mantenimiento.

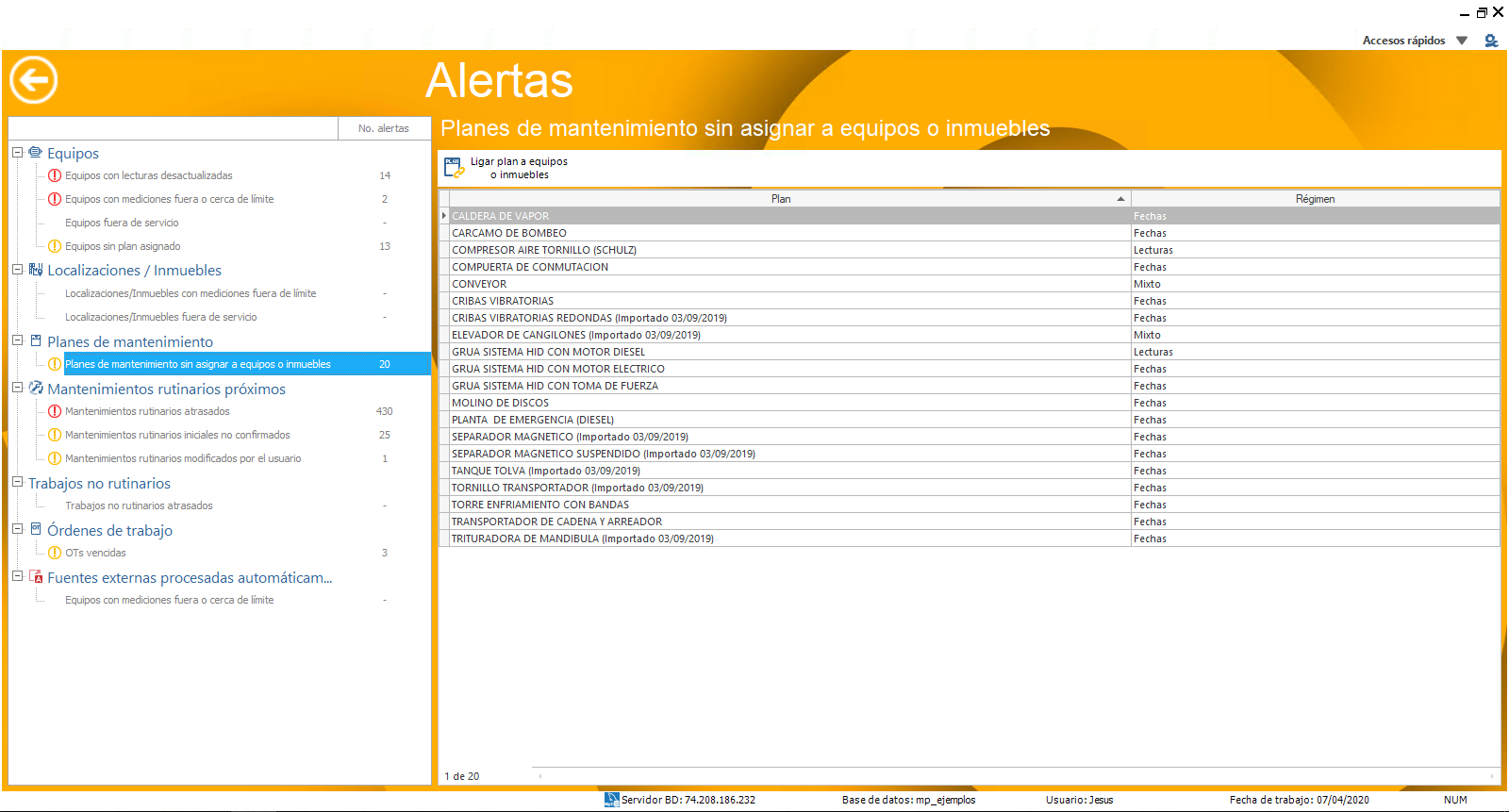

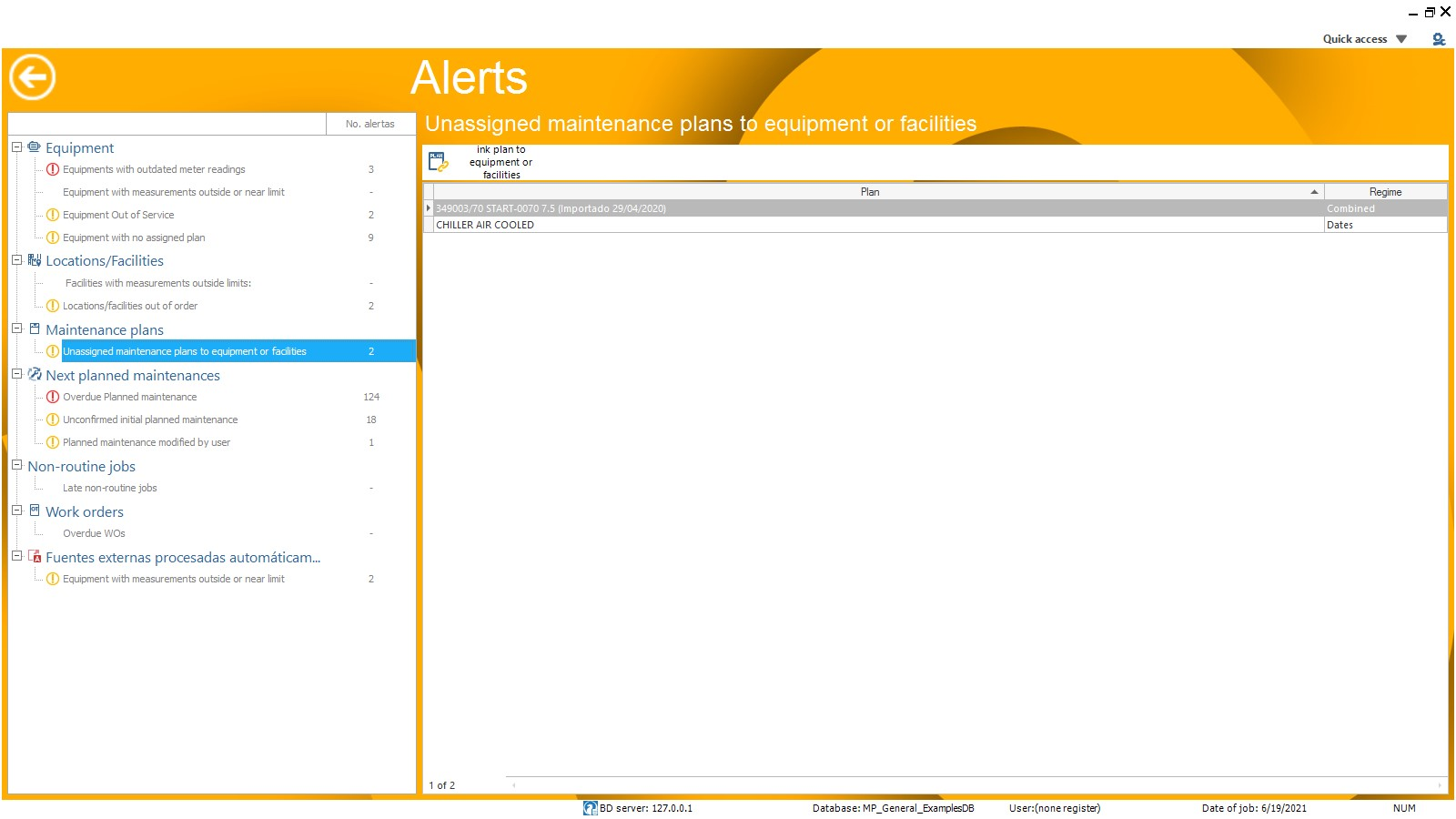

Alerta de planes de mantenimiento sin asignar a un equipo o localización

Muestra un listado de todos los planes de mantenimiento que no han sido asociados con equipos o localizaciones.

¿No encuentras la respuesta a tus dudas o preguntas?

Opcionalmente ofrecemos cursos de capacitación

Nuestras opciones flexibles de capacitación online y presenciales te brindarán todo el conocimiento necesario para comprender e implementar tu software de mantenimiento.