Introduction to routine maintenance next

The date of the next maintenance is calculated based on the date of the last maintenance that we have on record, and the frequency with which it must be performed each activity.

Example:

| PART | ACTIVITY | DATE OF LAST MAINTENANCE | FREQUENCY | DATE OF THE NEXT MAINTENANCE (Calculated) |

|---|---|---|---|---|

| MOTOR/ BELT AND PULLEYS | CHECK, TIGHTEN AND ALIGN | 17 April 2025 | Every 6 months | 17 October 2025 |

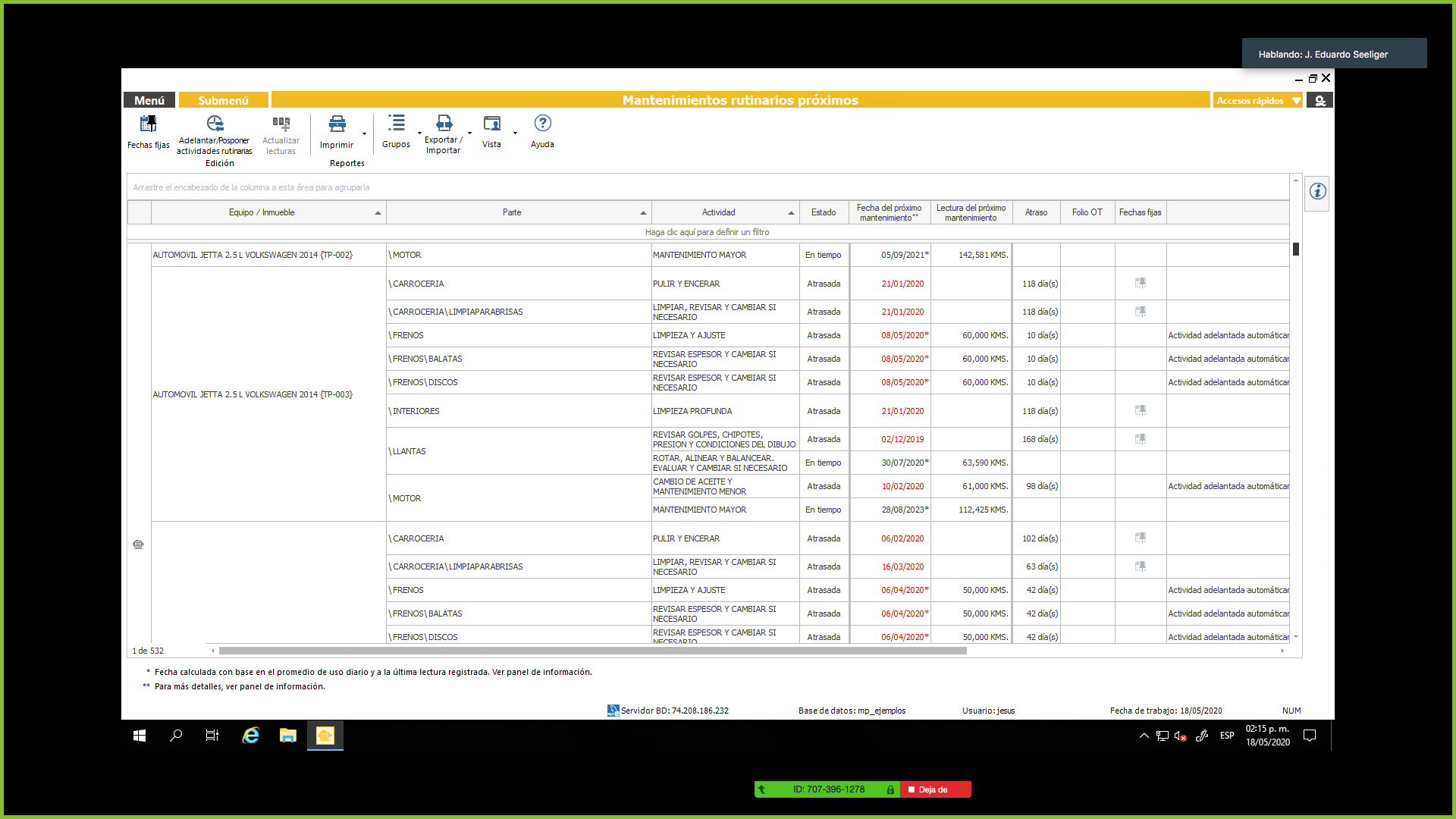

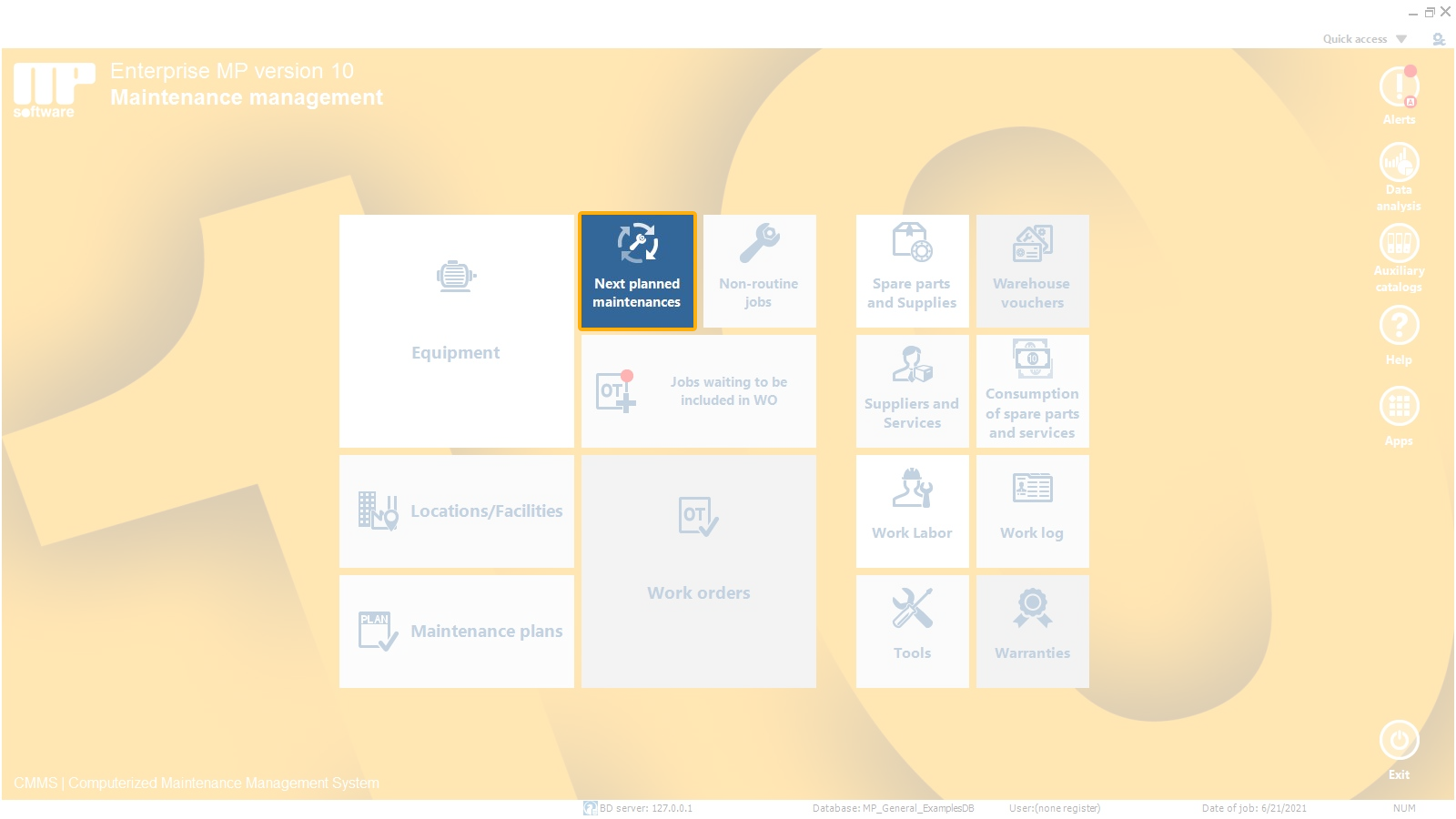

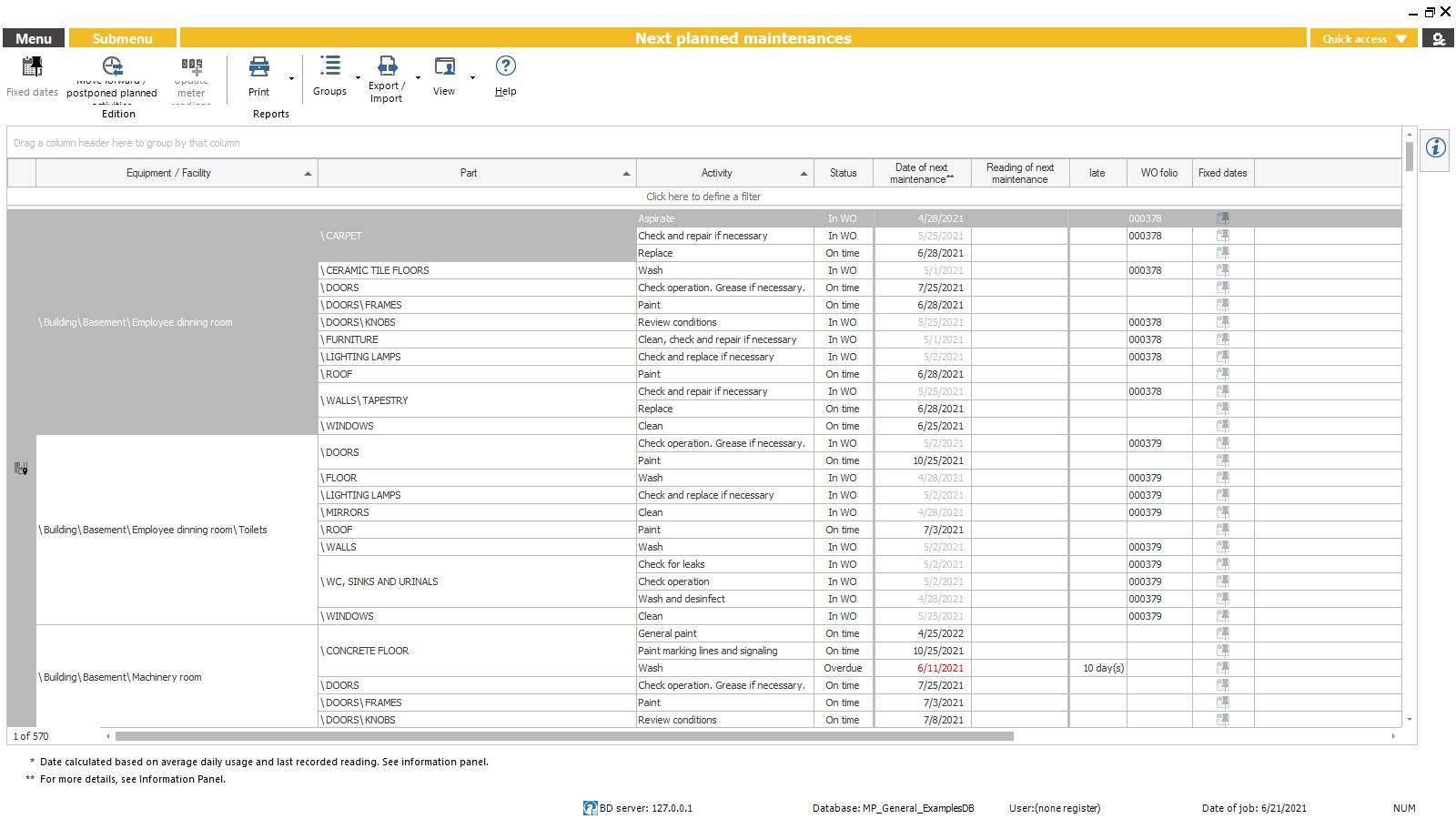

In the module Routine maintenance next you can find the dates or readings of the next maintenance of all equipment or locations that are linked to a maintenance plan.

Open the information panel to check the detail of the calculation of the next routine maintenance.

In this module, in addition you can generate work orders, advance or postpone activities, set dates, record activities without a work order.

It is important to know that a delay or advance the date of completion of the maintenance work that generates automatic adjustments in the dates of maintenance subsequent.

However, if you do not want the dates of the next maintenance is desfasen or walk around for delays or advances in the realization of the activities, use the tool Fixed Dates to indicate that you want to force to make a fixed day determined. This tool is located in the module Routine maintenance next.

For the case of activities controlled by the regime of readings, the edit the activitythe user can also indicate to the MARKER that you want to force their realization in exact multiples.

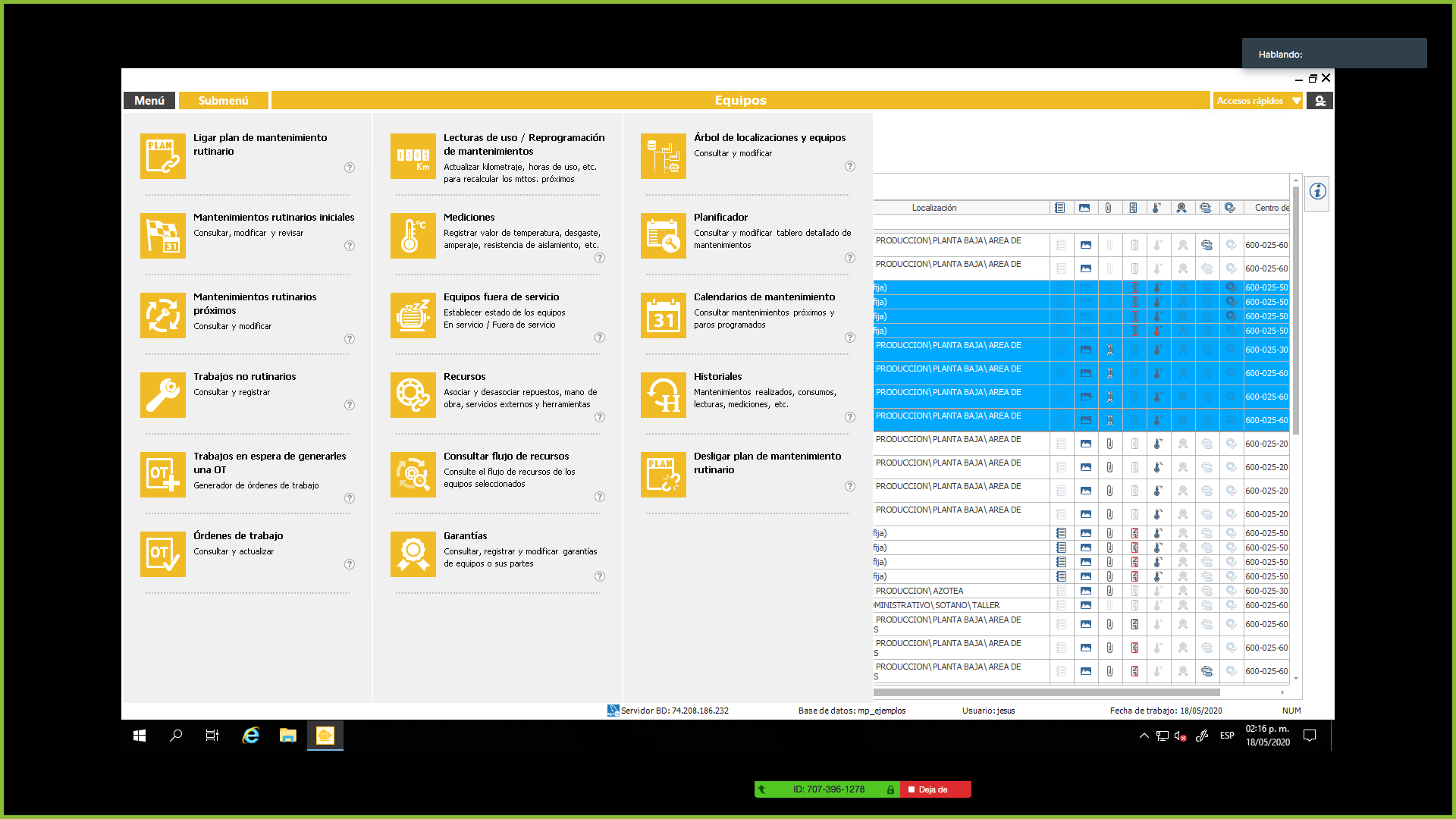

Routine maintenance initial

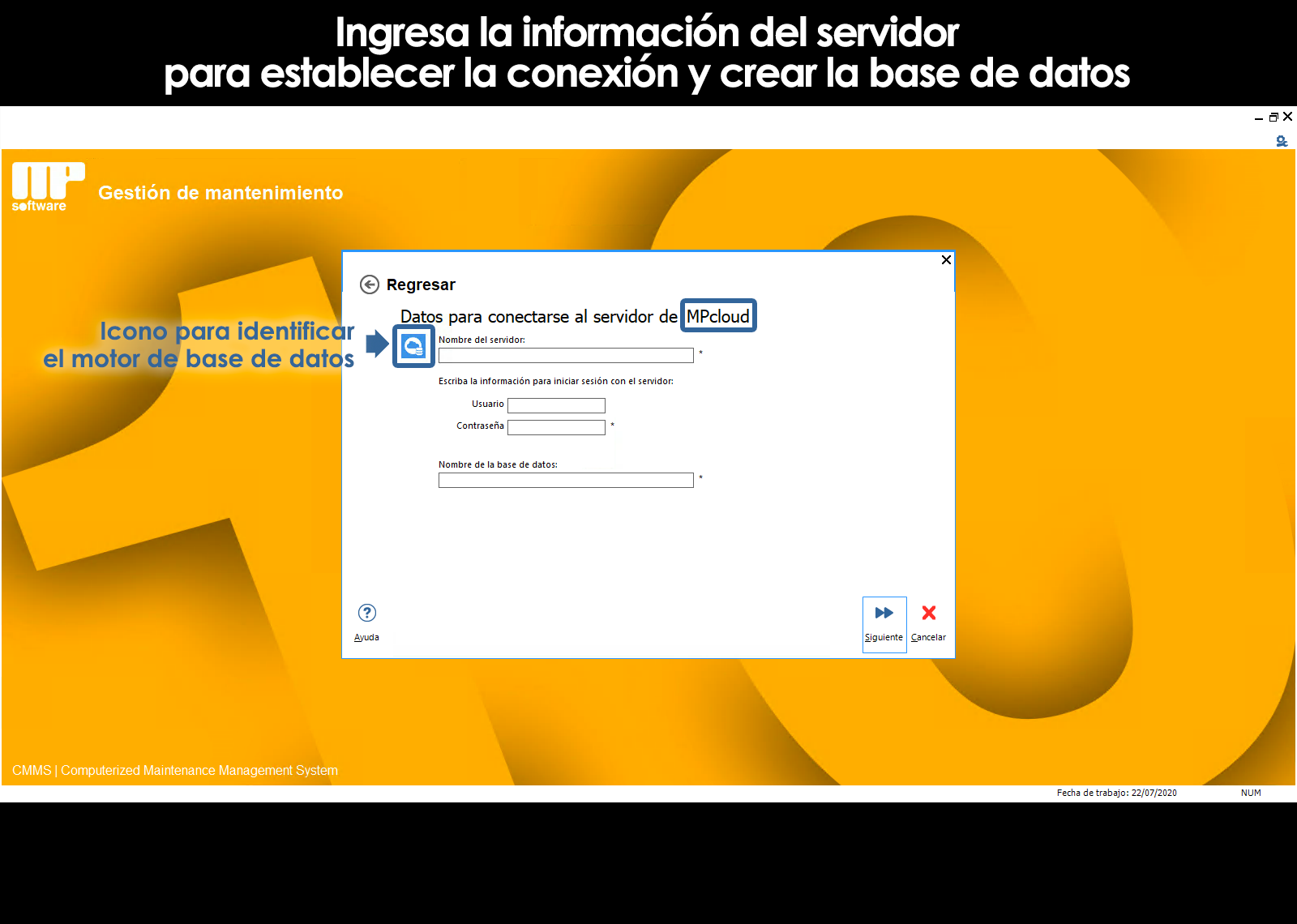

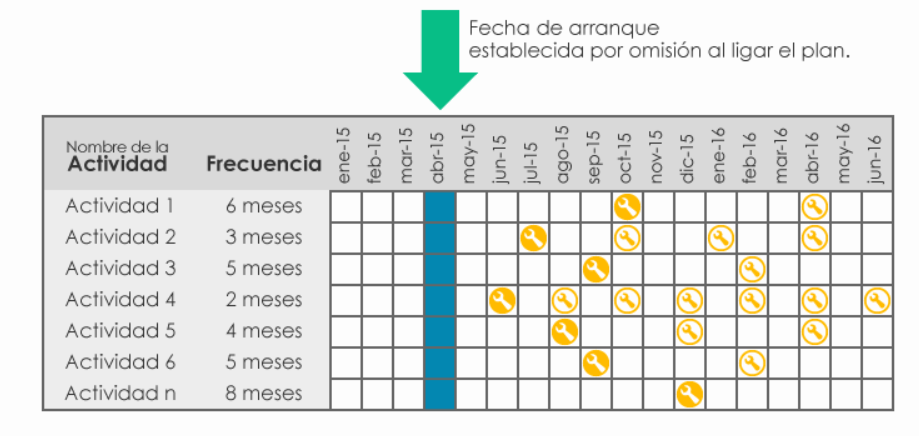

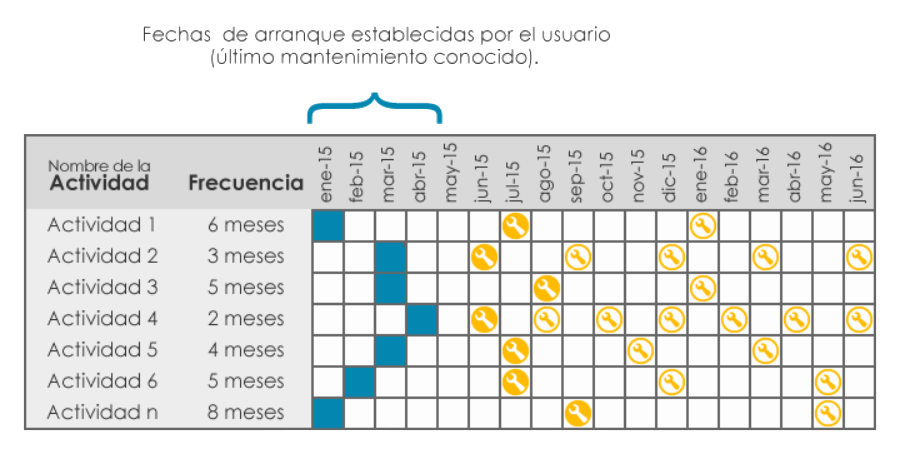

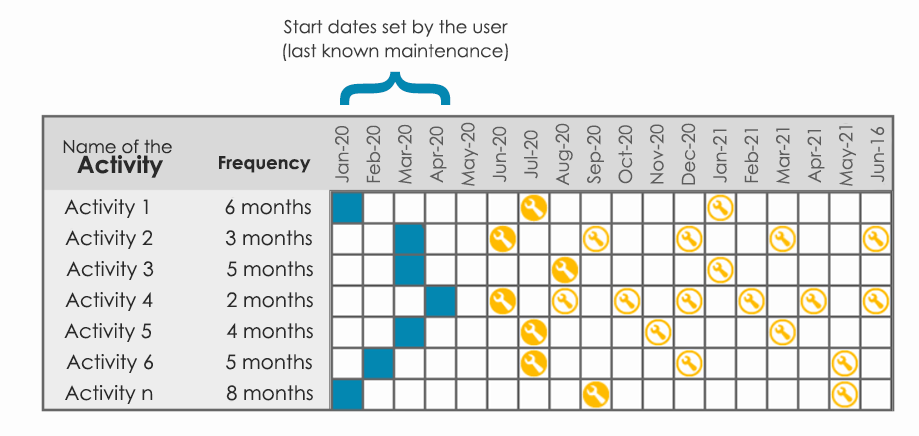

When we started the schedule of routine maintenance of a computer, the system does not have a record of the last maintenance carried out, which leads us to the need of manually indicate the date of the last maintenance of the knowledge. On that date it will automatically calculate the date of the next maintenance.

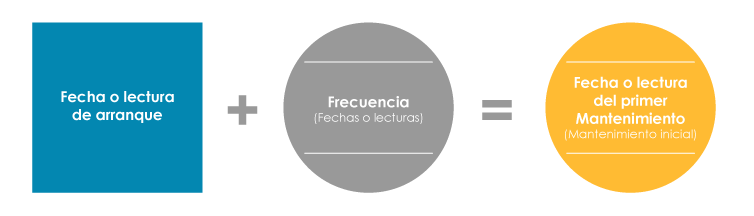

The date or read the boot is the date or reading from which begins the programming of each of the activities of routine maintenance.

DATE OF FIRST MAINTENANCE

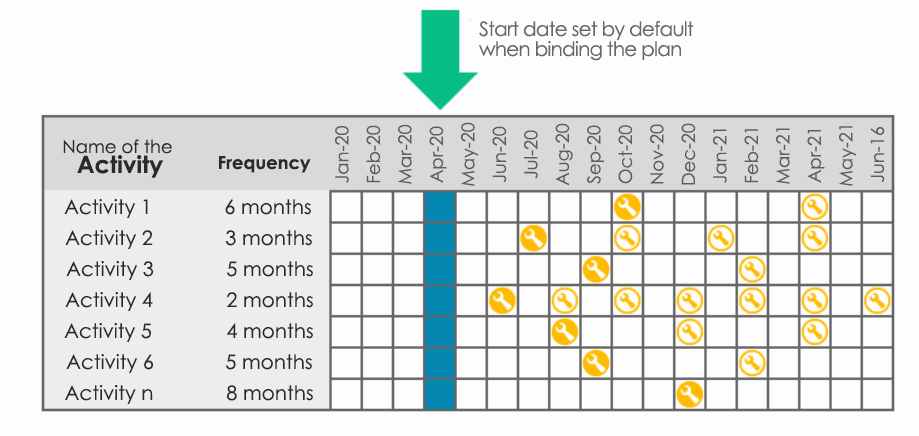

Note: By default, the system sets the date on which the league of the team with your maintenance plan, as the date of starting.

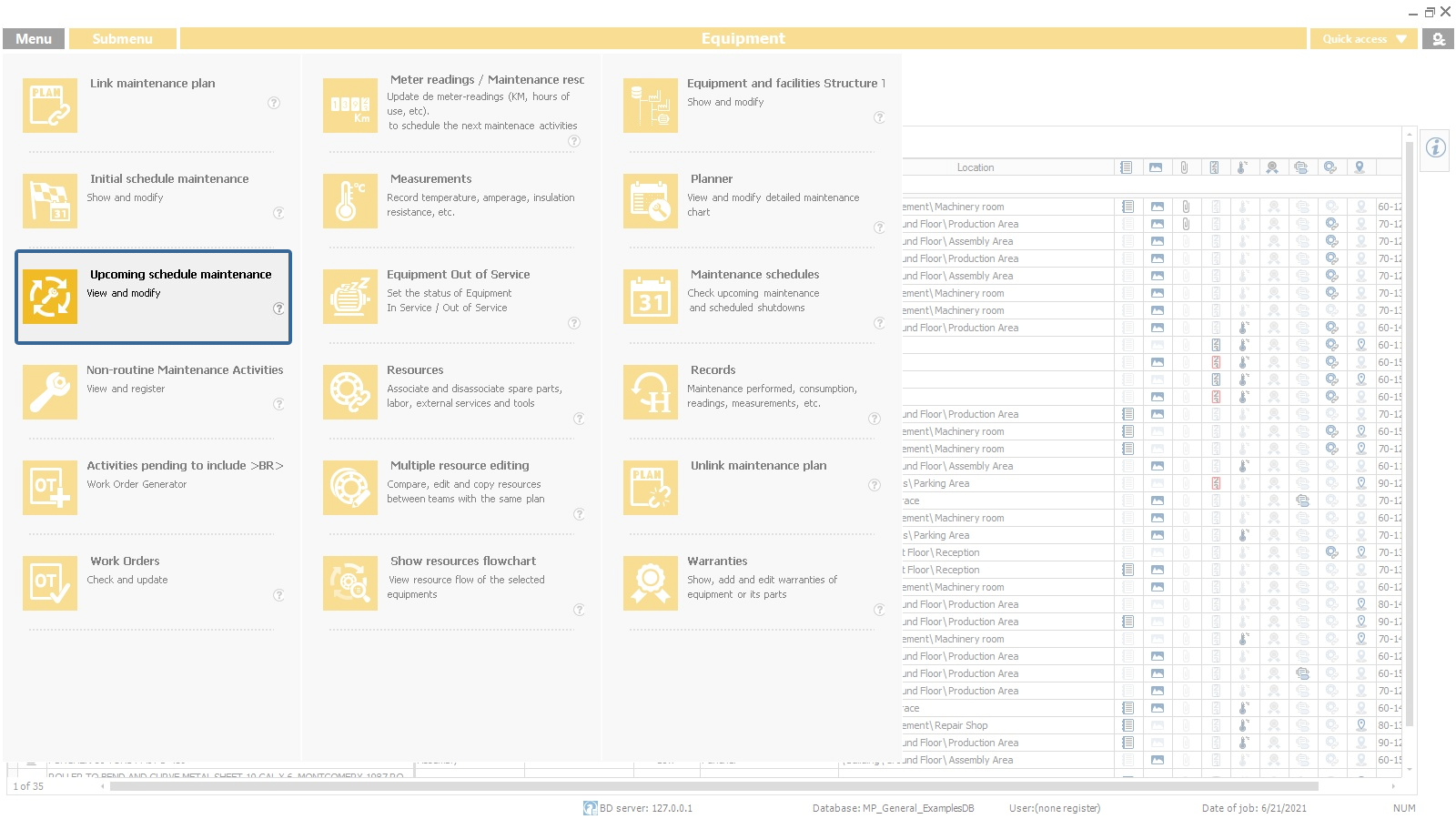

Edit routine maintenance initial

If the user knows the date or read when it is performed for the last time maintenance, through the submenu Routine maintenance initial you can specify a date or reading boot different for each activity.

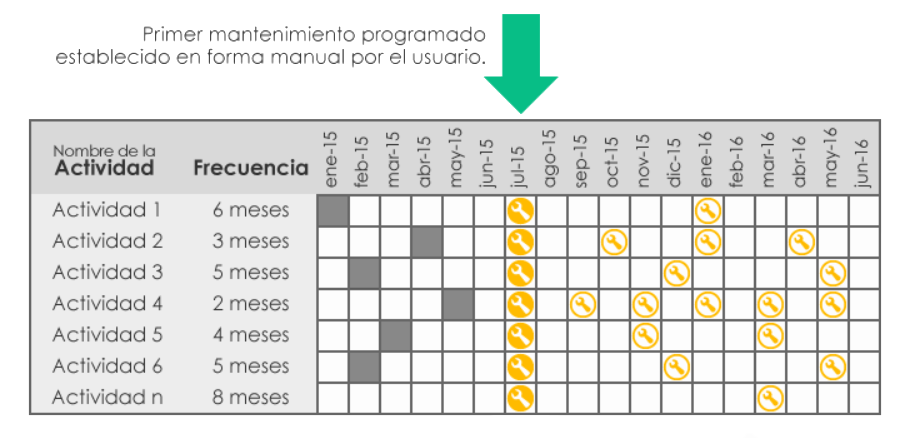

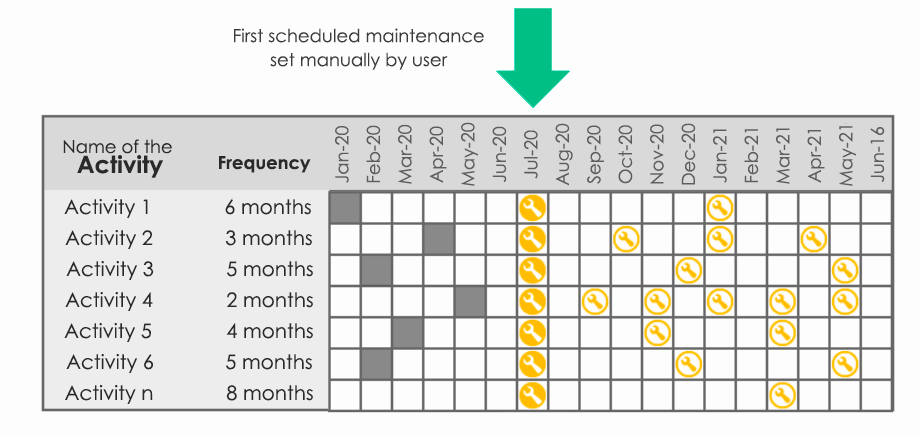

There is also the possibility that the user wants to set a date manually to the first scheduled maintenance. In the same way with through the submenu Routine maintenance initial you can edit manually the date of the first scheduled maintenance. In this case, it will be set only as a reference, the date of start as the first scheduled maintenance to be performed on the date set by the user.

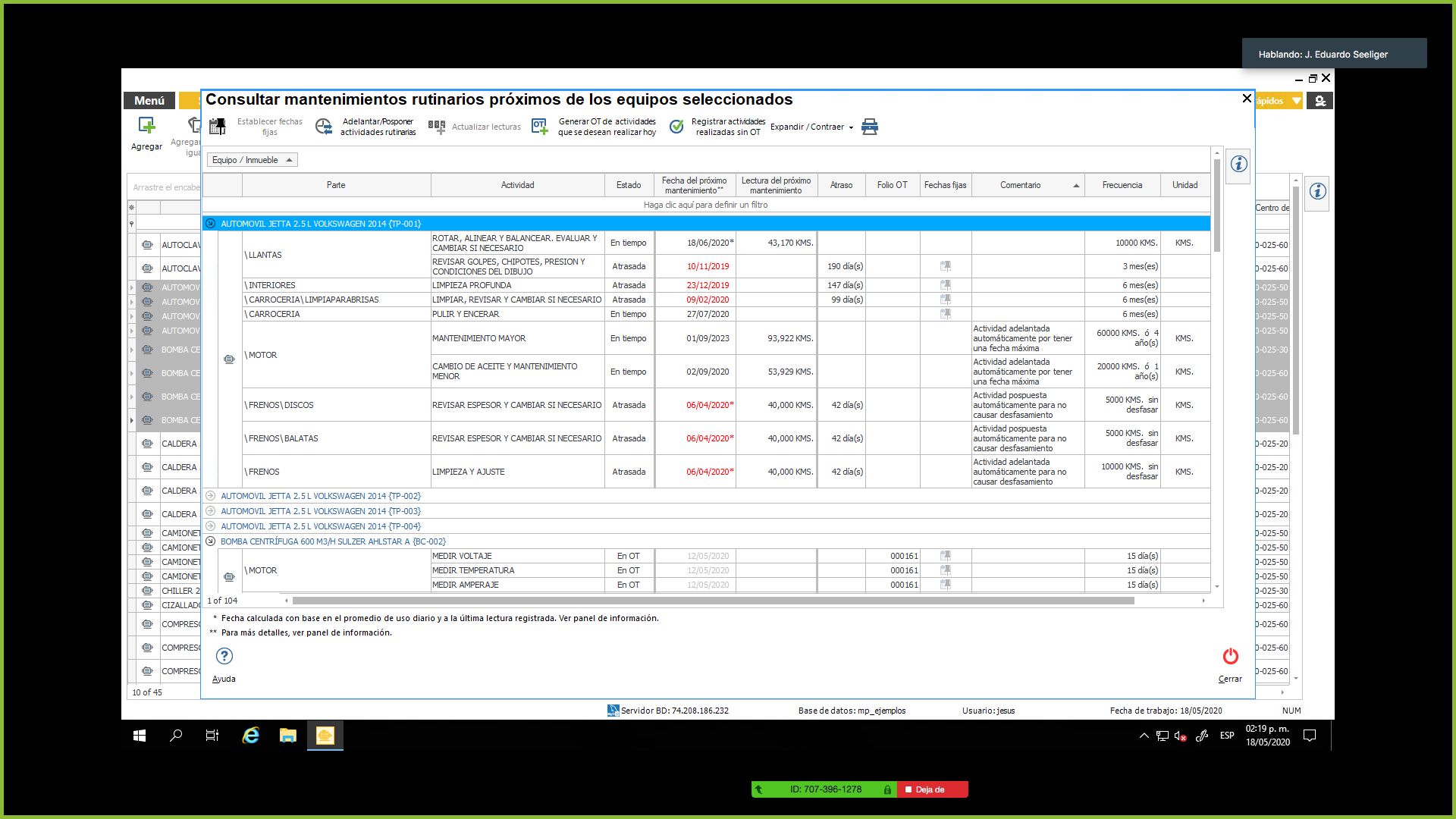

In the window “Edit and confirm maintenance initial” to enable the editing directly in the mesh of information. This allows you to select multiple cells, and set the same date to the selection using the tool To assign the same value.

Routine maintenance initial feasible to modify

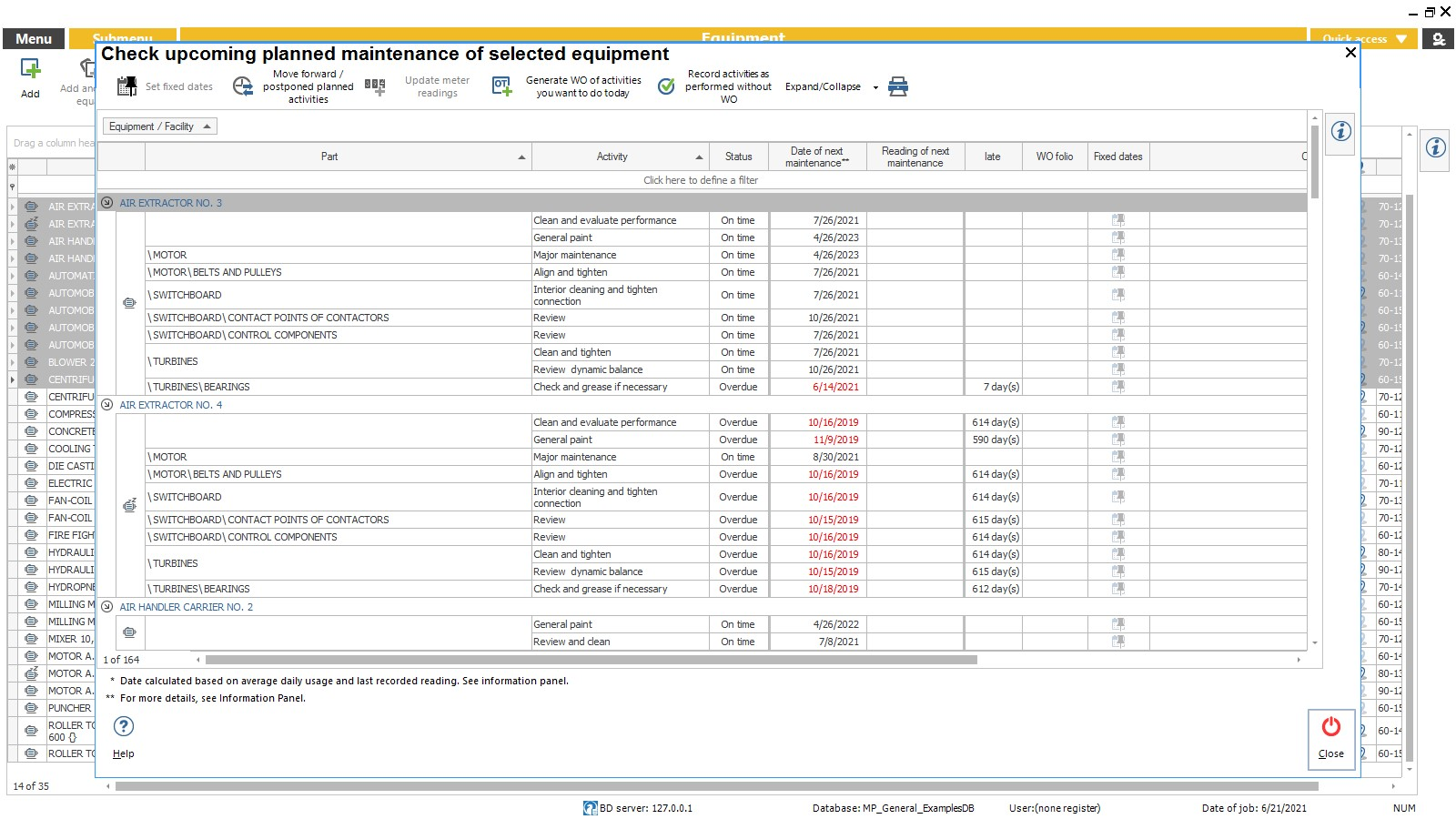

The edition of the dates or readings boot is performed only once when you start the programming of maintenance of a computer. Once you have approved the maintenance initials or dates of start-up, this process does not re-performed.

Once that is includes an activity in a work order, it will not be feasible to modify their maintenance initials or dates of boot.

The column feasible to modify tells the user about the activities that have not yet been included in a work order, and therefore, it is feasible to editing your maintenance initials or dates of boot.

Confirm routine maintenance initial

The system has a check box that enables the user to give their approval on each of the dates or readings with which to begin the scheduling of maintenance.

To confirm the maintenance initials or dates of start-up, the user leaves settled on the system that has revised the dates or readings boot and therefore, you can proceed to generate the work orders. This is important because as mentioned earlier, a time which includes an activity in a work order, it will not be feasible to modify their maintenance initials or dates of boot.

The purpose of this confirmation is to ensure that the system boots up with real information that corresponds to the last maintenance carried out physically to the equipment, however, if the user does not confirm, you will be able to continue with the preparation of work orders with the dates or readings of boot that have registered. In these cases, simply be presented with a warning message in the Status column of the maintenance initial” to warn the user about this condition.

Can't find the answer to your doubts or questions?

Additionally, we offer training courses

Our flexible options of online training and face-to-face will provide you with all the knowledge necessary to understand and implement your software maintenance MP.