Inicio / Gestión de mantenimiento

Temas relacionados

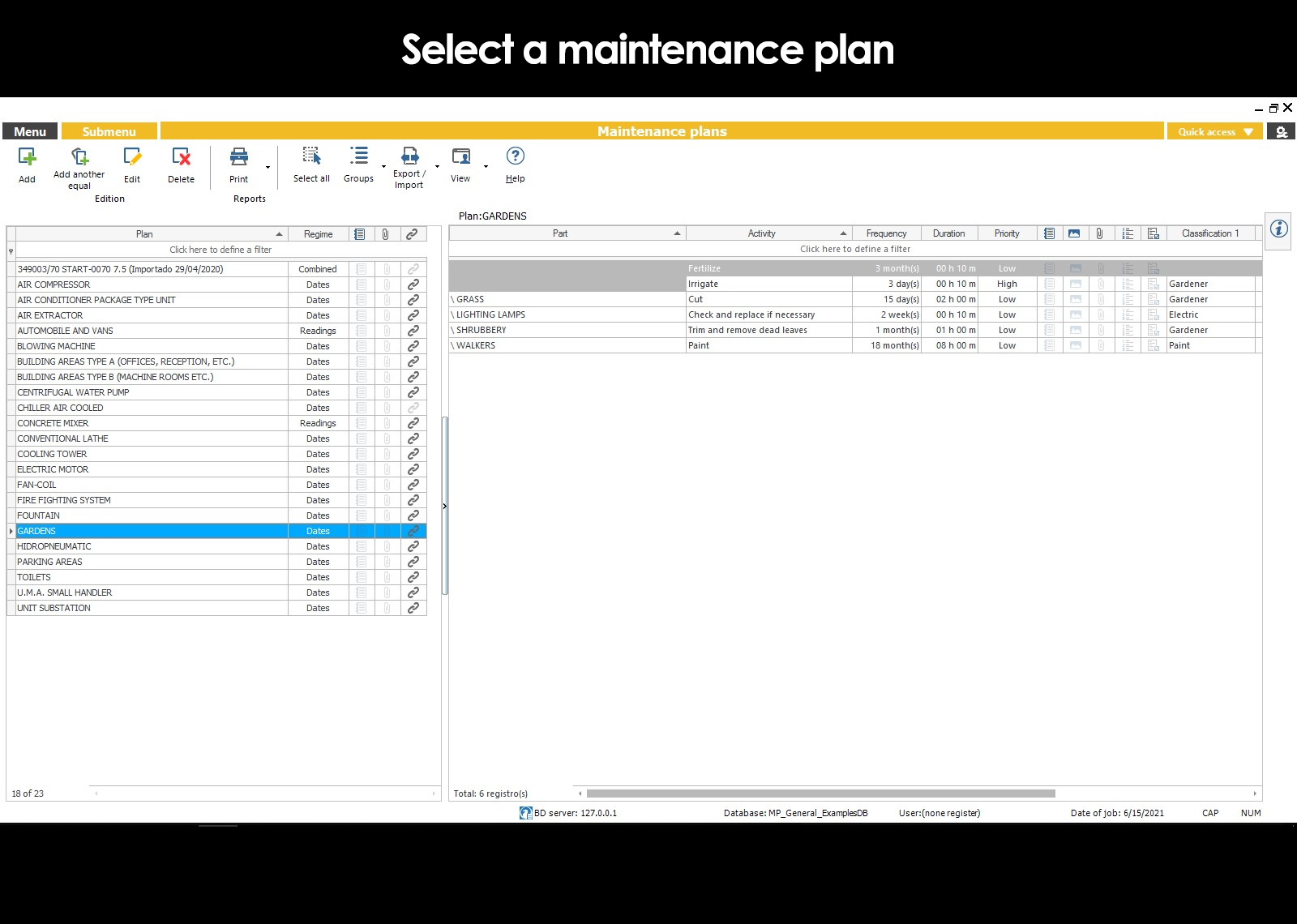

▸ Agregar un plan de mantenimiento

▸ Partes y actividades del plan

▸ Notas y archivos adjuntos del plan

▸ Agregar otro plan de mantenimiento igual

▸ Editar un plan de mantenimiento

▸ Eliminar un plan de mantenimiento

▸ Agregar partes

▸ Editar partes

▸ Eliminar partes

▸ Copiar y pegar partes

▸ Insertar un plan de mantenimiento dentro de otro

▸ Agregar actividades

▸ Editar actividades

▸ Frecuencia de las actividades

▸ Prioridad de las actividades

▸ Duración de las actividades

▸ Paro del equipo

▸ Clasificación de las actividades

▸ Actividades que implican la toma de una medición (Mantenimiento predictivo)

▸ Procedimiento para realizar las actividades

▸ Notas de seguridad, imágenes y archivos adjuntos de las actividades

▸ Requisitos para cerrar o incluir las actividades en una OT

▸ Eliminar actividades

▸ Copiar y pegar actividades

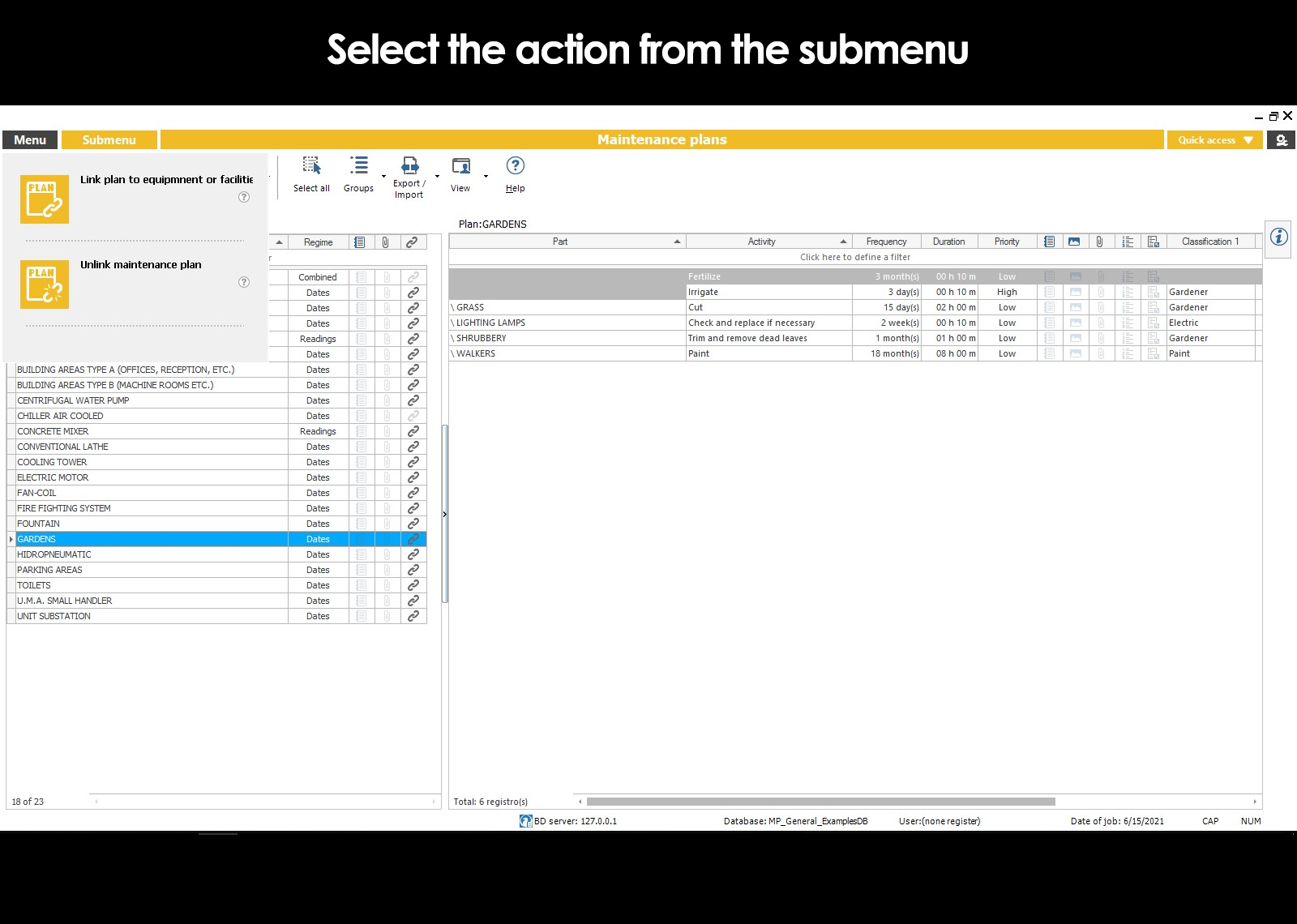

▸ Ligar planes de mantenimiento

▸ Ligar un plan de mantenimiento con actividades con régimen de lecturas

▸ Desligar planes de mantenimiento

▸ Alerta de equipos sin plan ligado

▸ Alerta de planes de mantenimiento sin asignar a un equipo o localización

Introducción a planes de mantenimiento

Una parte fundamental para el control del mantenimiento rutinario es la formación de planes o rutinas de mantenimiento.

Los planes o rutinas de mantenimiento son modelos que contienen la información respecto a las actividades de mantenimiento rutinario que deben realizarse a los equipos. Las actividades de mantenimiento rutinario generalmente consisten en acciones enfocadas a prevenir fallas y se realizan en forma cíclica y repetitiva con una frecuencia determinada.

Elementos básicos de un plan de mantenimiento (Partes, actividades y frecuencia)

Un plan de mantenimiento se compone de tres elementos básicos:

| PLAN DE MANTENIMIENTO | ||

|---|---|---|

| PARTES | ACTIVIDADES | FRECUENCIA |

| Las partes del equipo. | Las actividades rutinarias que deben realizarse a cada una de las partes. | La frecuencia con que deben realizarse cada una de las actividades. |

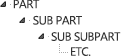

Para definir las partes de un equipo, el sistema maneja una estructura arbolar.

|

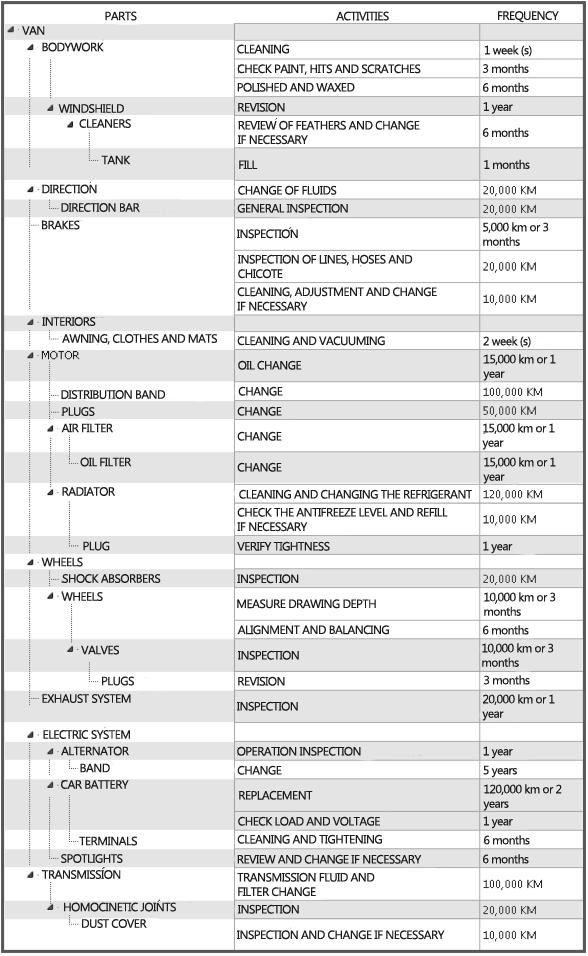

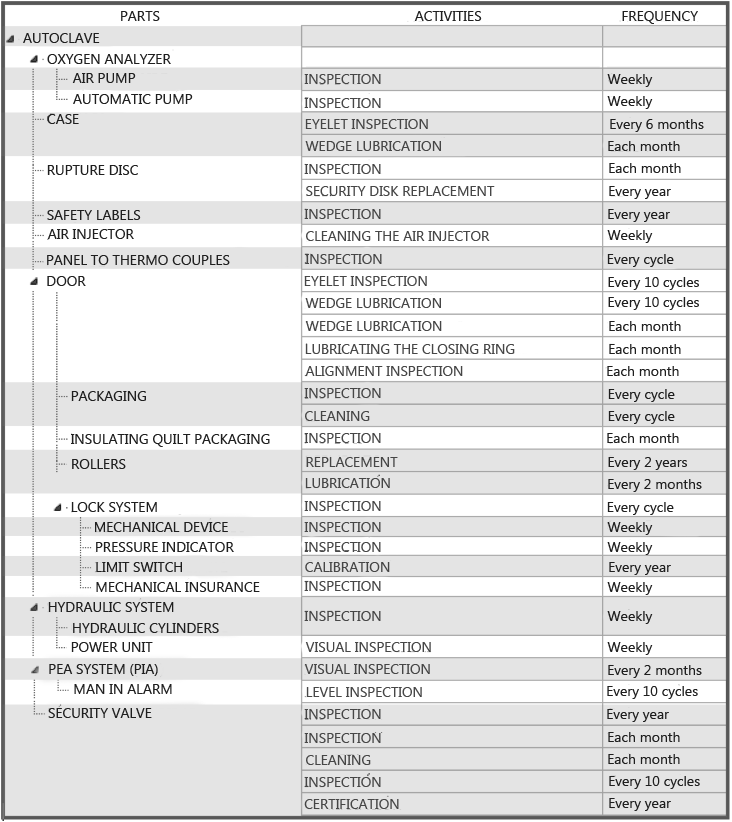

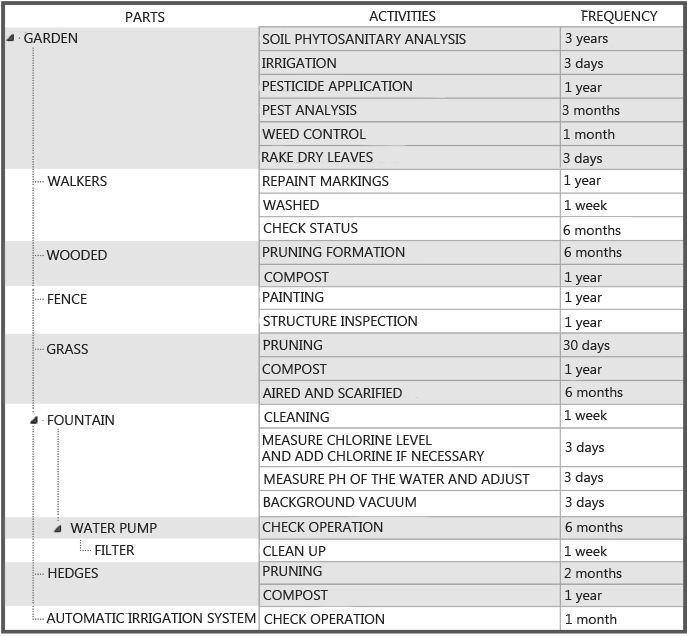

Ejemplo:

|

Frecuencia con base en fechasEn una actividad de mantenimiento controlada con base en fechas, la frecuencia con que debe realizarse la actividad se establece en función del tiempo transcurrido. (Ejemplo, diario, cada semana, cada 15 días, cada 3 meses, cada 2 años, etc.) Frecuencia con base en lecturasEn una actividad de mantenimiento controlada con base en lecturas, la frecuencia con que debe realizarse la actividad se establece en función del uso del equipo. (Ejemplo, kilómetros recorridos, horas de uso, unidades producidas, cantidad de encendidos, ciclos, etc.) Frecuencia mixtaEn una actividad de mantenimiento mixta, la frecuencia con que debe realizarse la actividad se establece en función del uso del equipo o el tiempo, lo que suceda primero. (Ejemplo, cada 15,000 kilómetros o 12 meses, lo que suceda primero) |

Un plan de mantenimiento se compone de tres elementos básicos:

| PLAN DE MANTENIMIENTO | ||

|---|---|---|

| PARTES | ACTIVIDADES | FRECUENCIA |

| Las partes del equipo. | Las actividades rutinarias que deben realizarse a cada una de las partes. | La frecuencia con que deben realizarse cada una de las actividades. |

| Para definir las partes de un equipo, el MP maneja una estructura arbolar.

|

Ejemplo:

|

Frecuencia con base en fechasEn una actividad de mantenimiento controlada con base en fechas, la frecuencia con que debe realizarse la actividad se establece en función del tiempo transcurrido. (Ejemplo, diario, cada semana, cada 15 días, cada 3 meses, cada 2 años, etc.) Frecuencia con base en lecturasEn una actividad de mantenimiento controlada con base en lecturas, la frecuencia con que debe realizarse la actividad se establece en función del uso del equipo. (Ejemplo, kilómetros recorridos, horas de uso, unidades producidas, cantidad de encendidos, ciclos, etc.) Frecuencia mixtaEn una actividad de mantenimiento mixta, la frecuencia con que debe realizarse la actividad se establece en función del uso del equipo o el tiempo, lo que suceda primero. (Ejemplo, cada 15,000 kilómetros o 12 meses, lo que suceda primero) |

El usuario es quien estructura los planes de mantenimiento de sus equipos con base en su experiencia o recomendación de los fabricantes de los mismos

Por lo anterior, el sistema es un programa de aplicación general que puede implementarse en cualquier empresa, sin importar los tipos de equipos o localizaciones con los que cuente. Podemos crear planes de mantenimiento rutinario para equipos y para localizaciones o inmuebles.

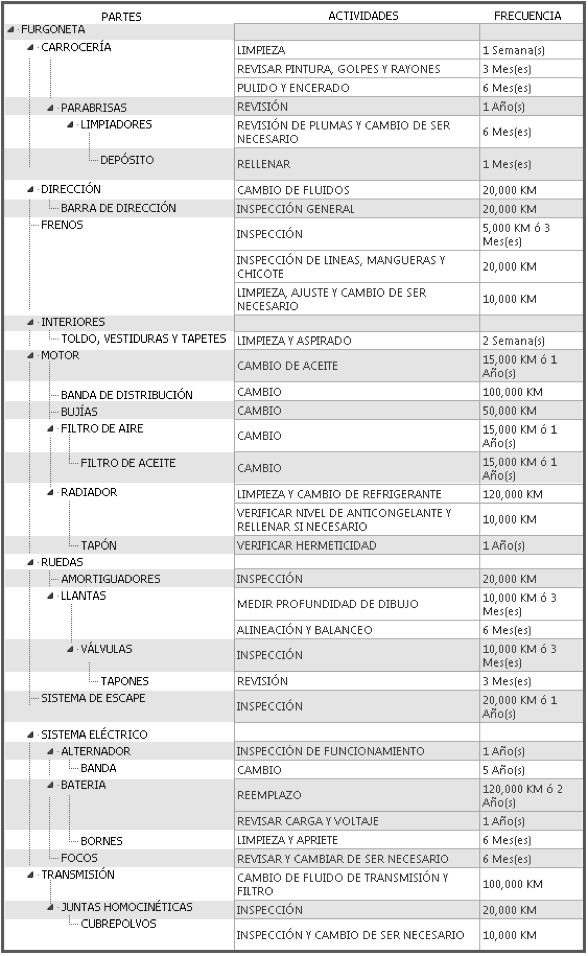

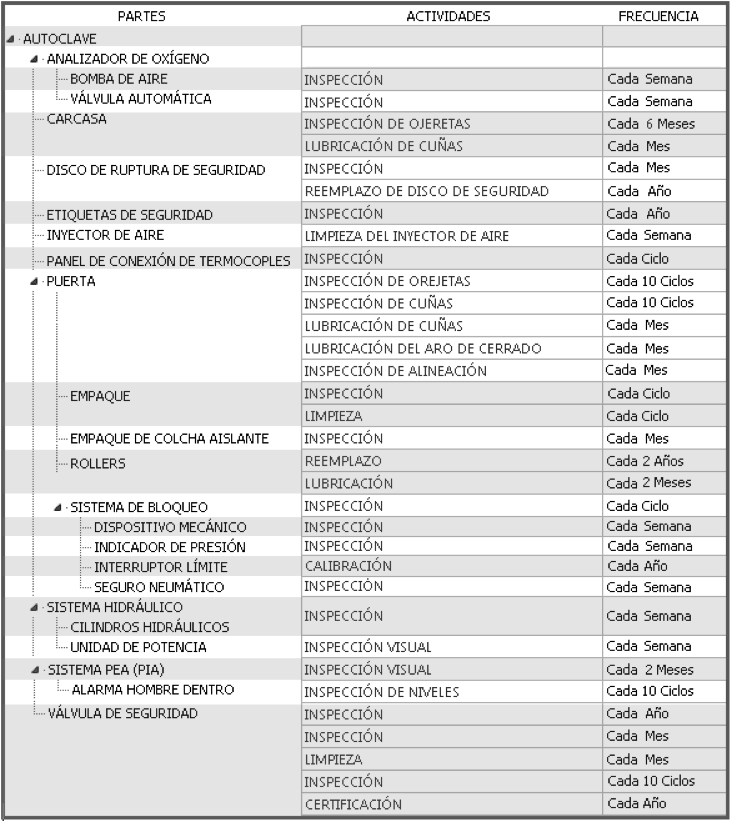

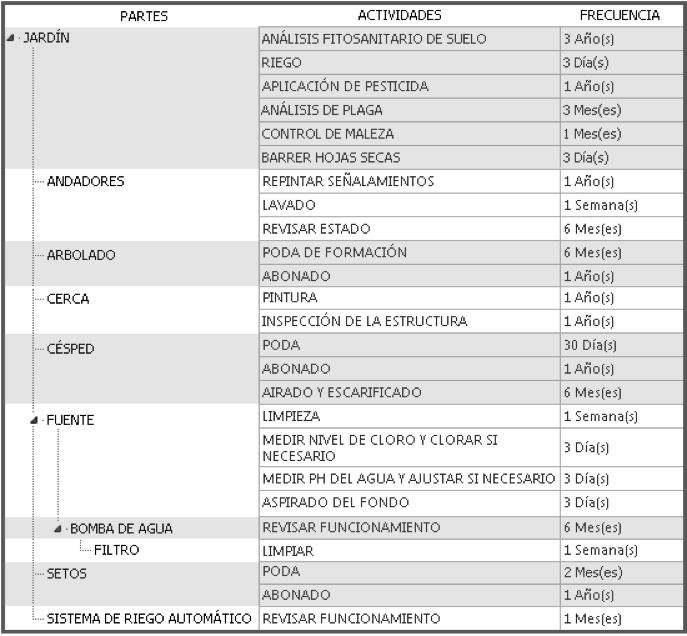

Ejemplos de planes de mantenimiento:

Planificar actividades de mantenimiento preventivo genera ahorros de capital, garantiza un mayor tiempo de servicio de las instalaciones, equipos y maquinaria, aportando valor a la empresa y mayor confiabilidad

¿No encuentras la respuesta a tus dudas o preguntas?

Opcionalmente ofrecemos cursos de capacitación

Nuestras opciones flexibles de capacitación online y presenciales te brindarán todo el conocimiento necesario para comprender e implementar tu software de mantenimiento.