Inicio / Inventario de repuestos

Temas relacionados

▸ Introducción a niveles de inventario, abastecimiento y requisiciones

▸ Métodos de cálculo para la cobertura

▸ Qué método de cálculo para la cobertura es conveniente utilizar

▸ Edición de la rotación para el cálculo de la cobertura

▸ Cálculo de la rotación con base en los movimientos de salida

▸ Cálculo óptimo de los niveles de inventario con base en la rotación

▸ Generación del flujo de recursos para el cálculo de la cobertura

▸ Entendiendo el calendario de cobertura

▸ Generación de requisiciones

▸ Ajuste de las cantidades en pedido

Edición de los niveles de inventario y el tiempo de procuramiento

Los niveles de inventario y el tiempo de procuramiento se pueden especificar desde diferentes módulos en el Inventario de Repuestos.

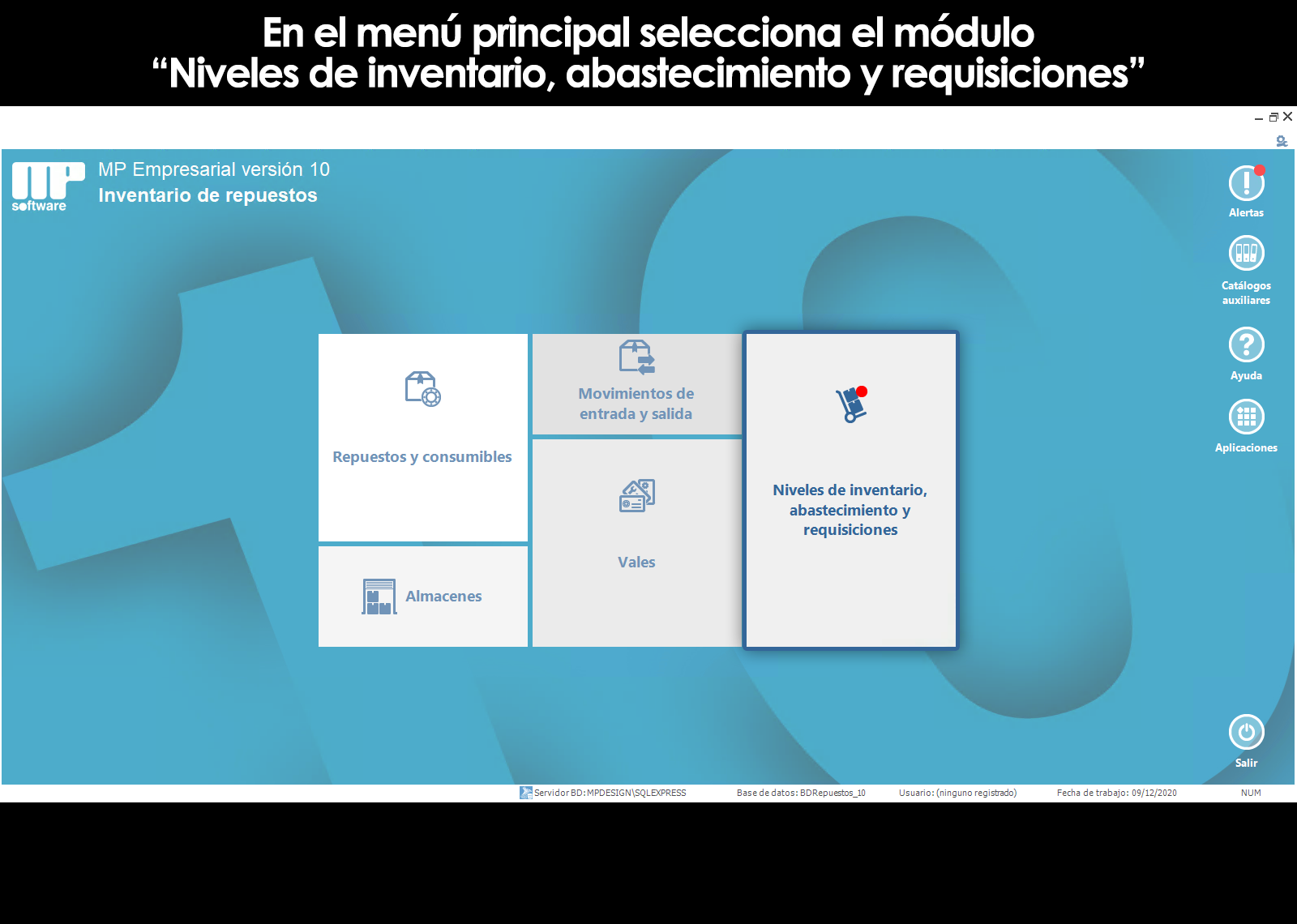

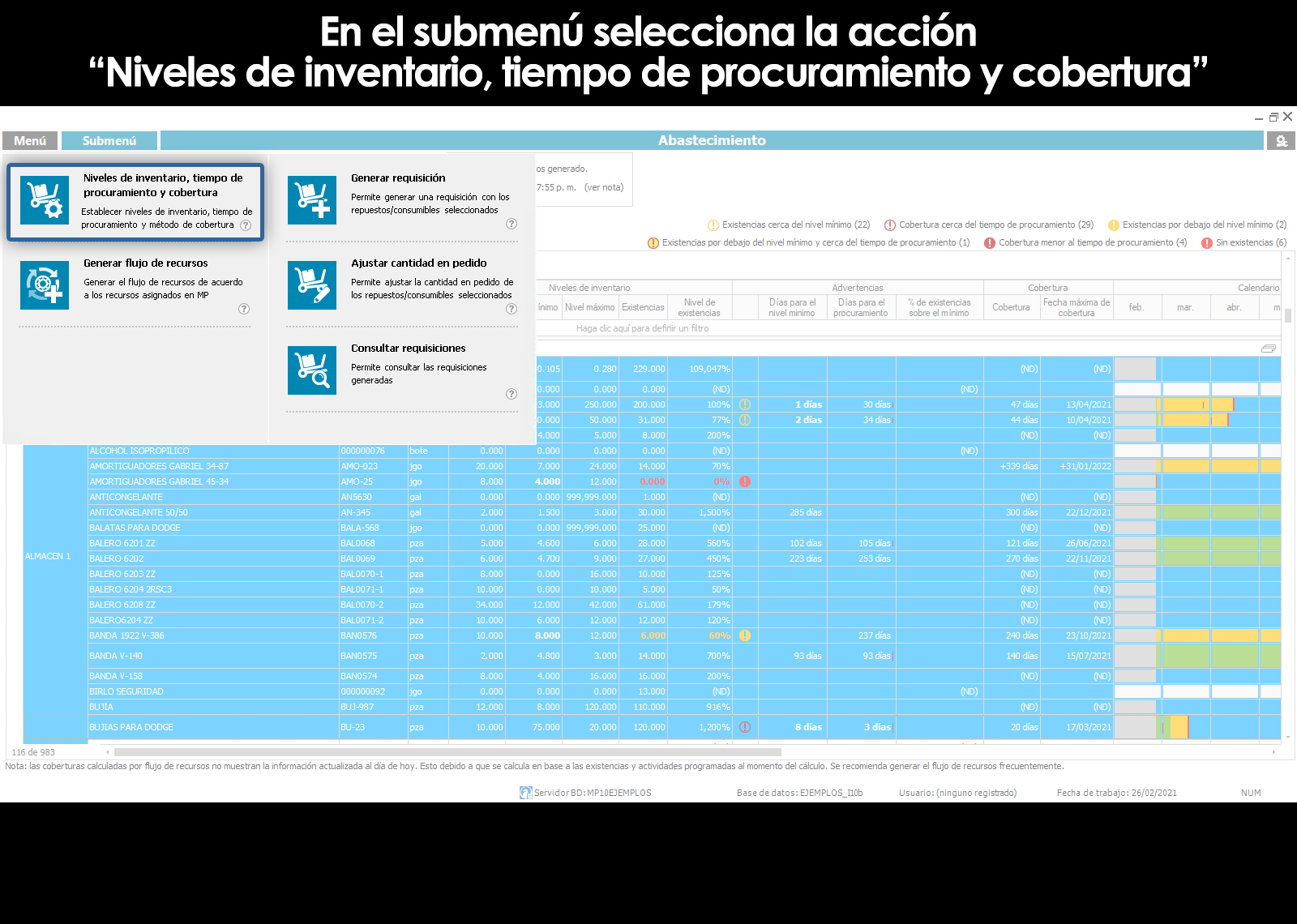

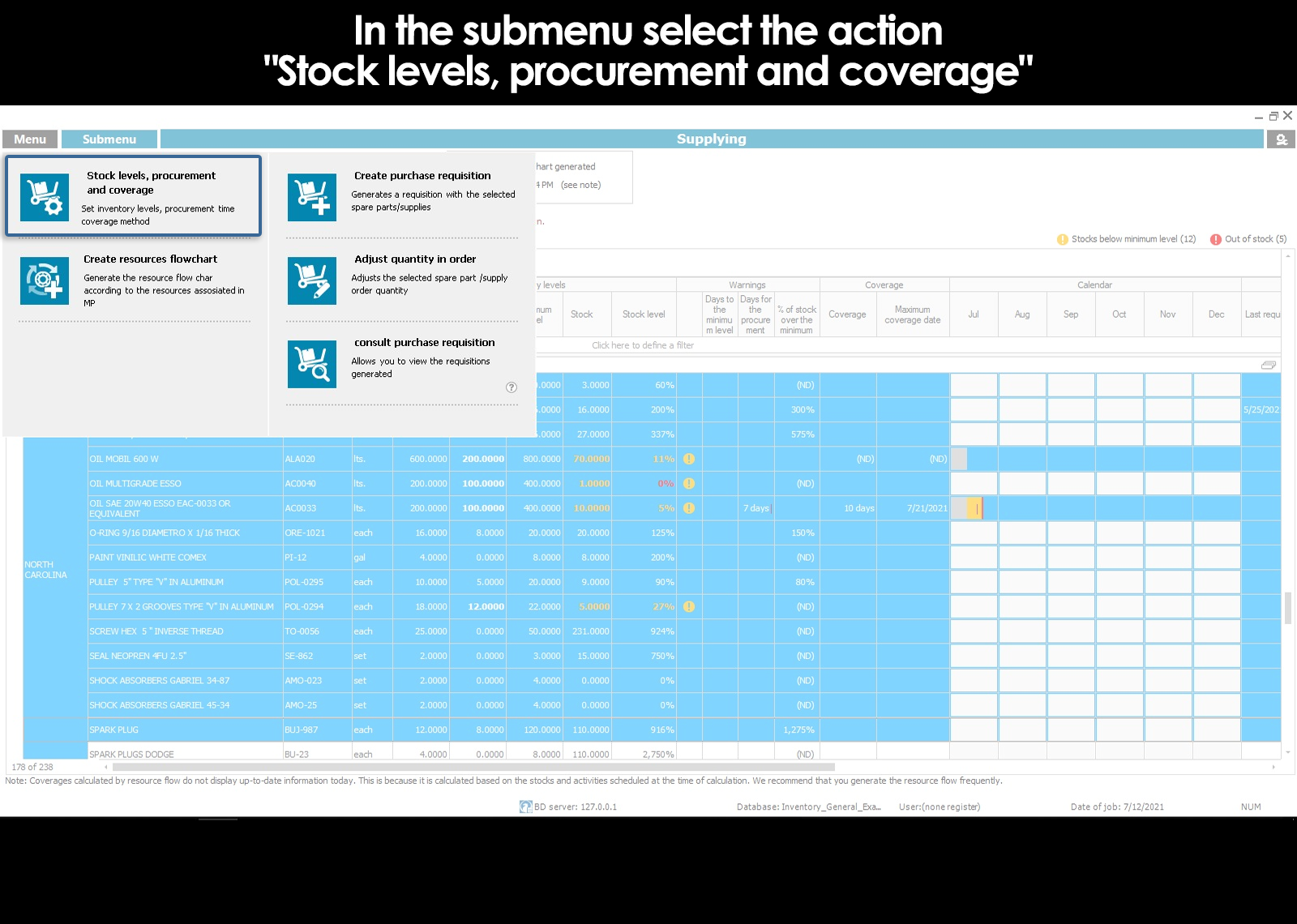

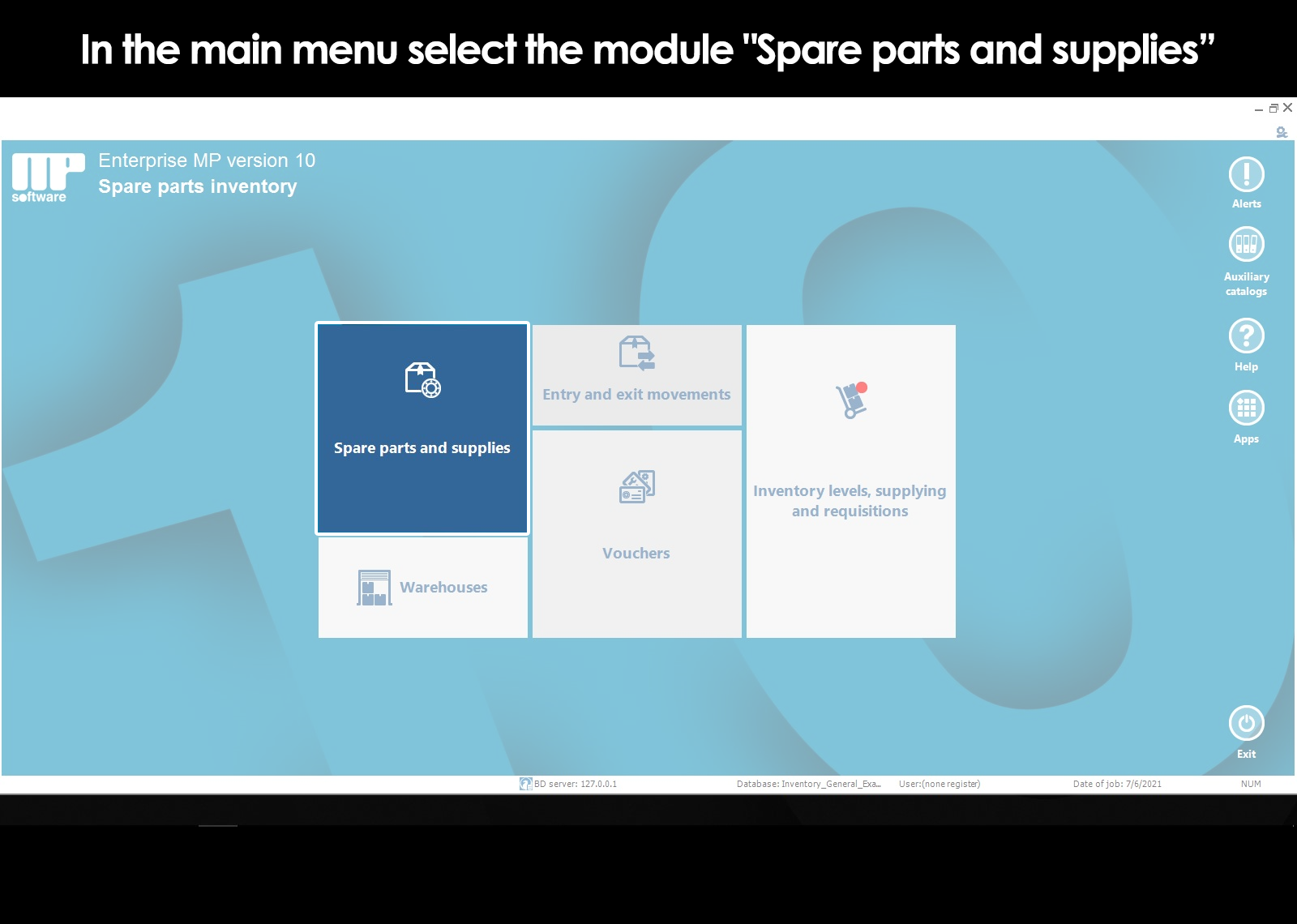

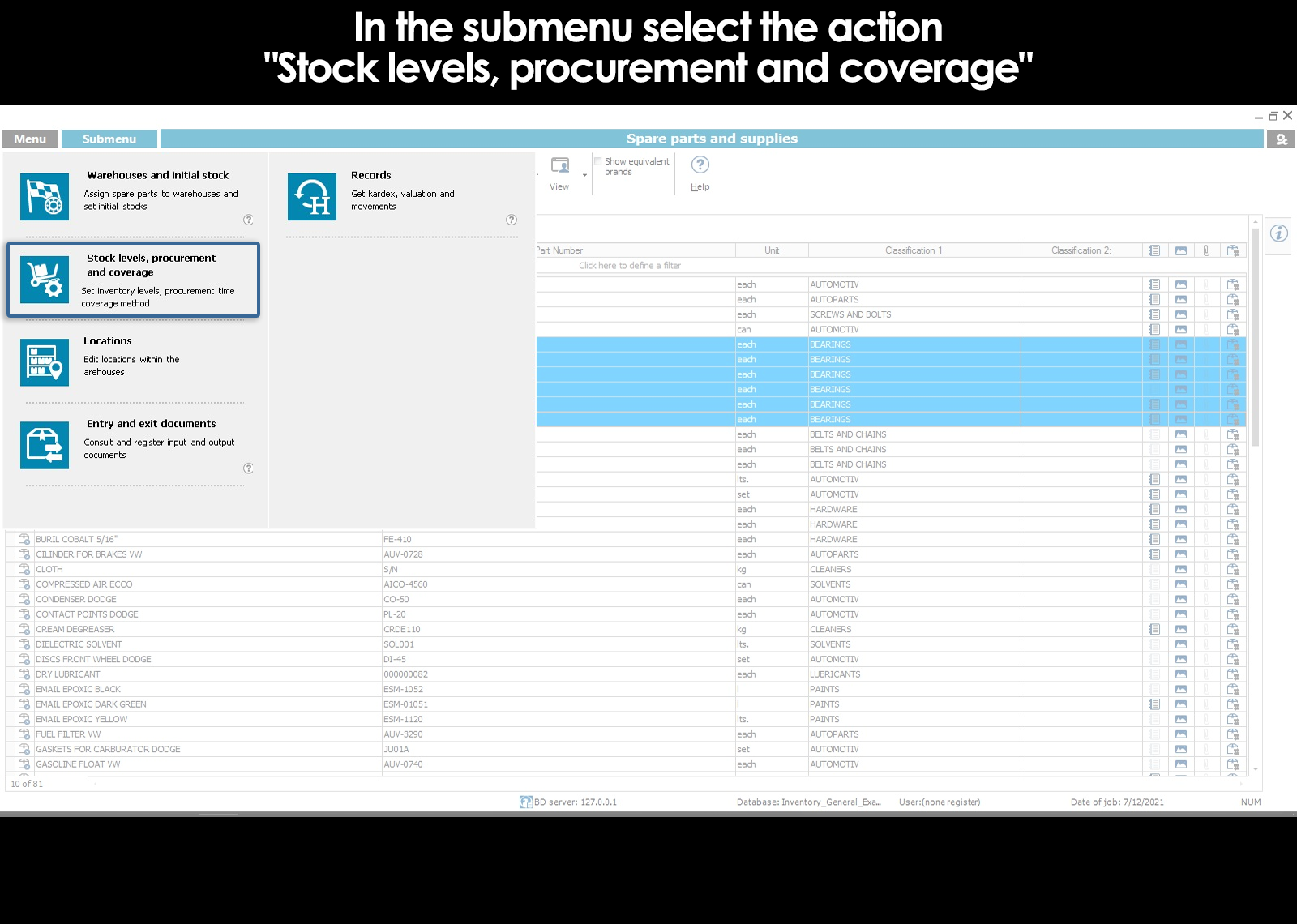

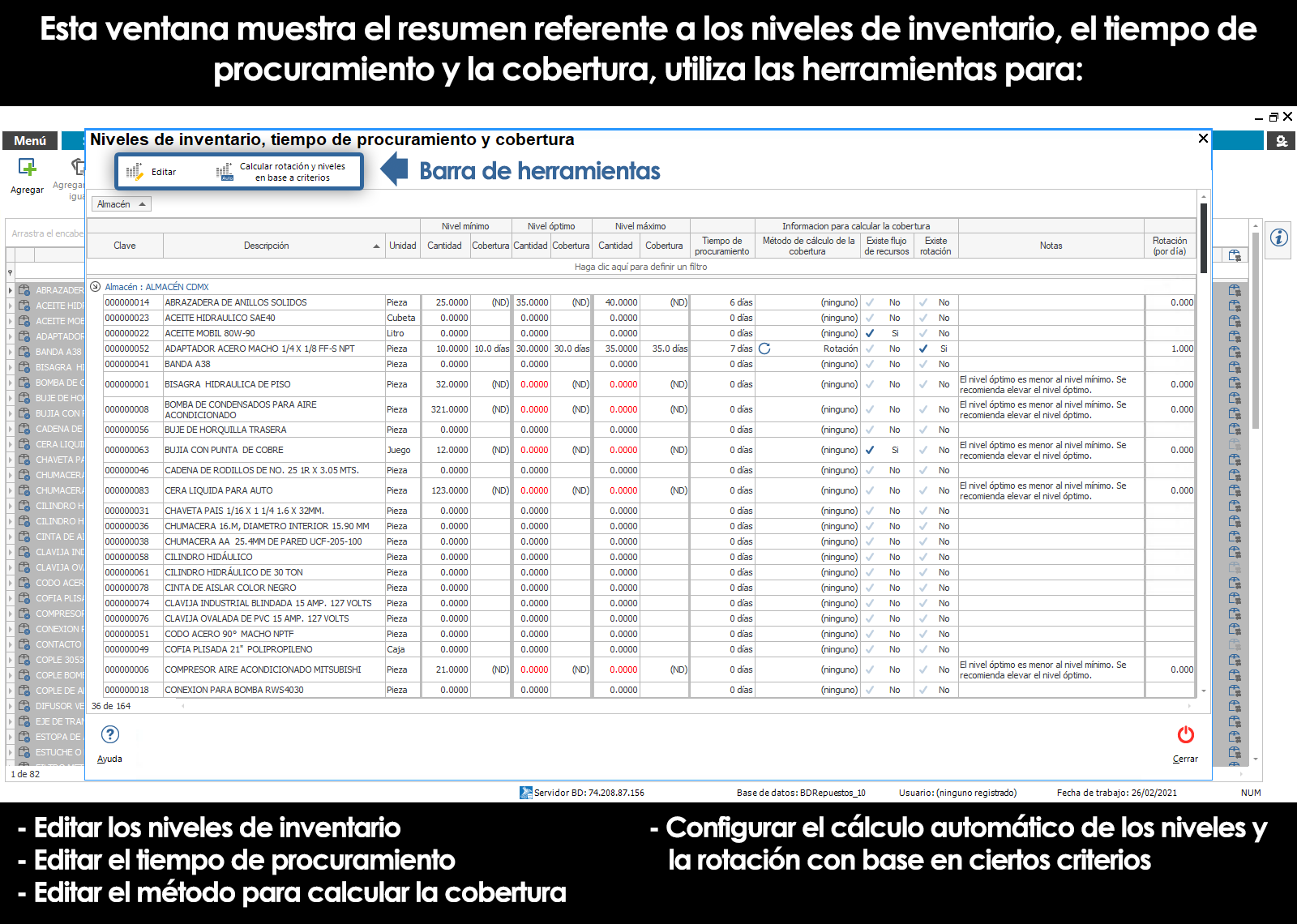

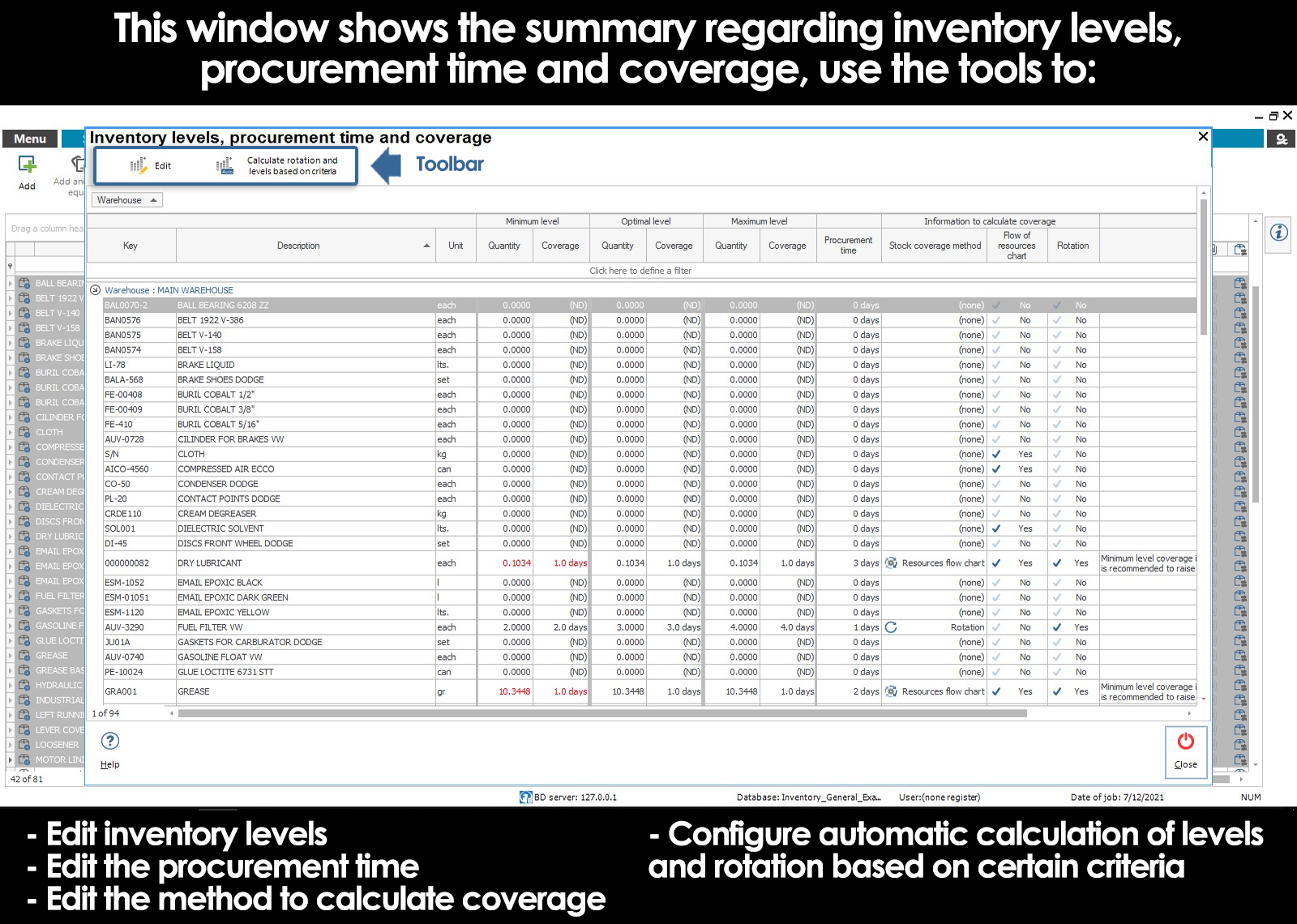

1. Desde el submenú en el módulo de Niveles de inventario, abastecimiento y requisiciones

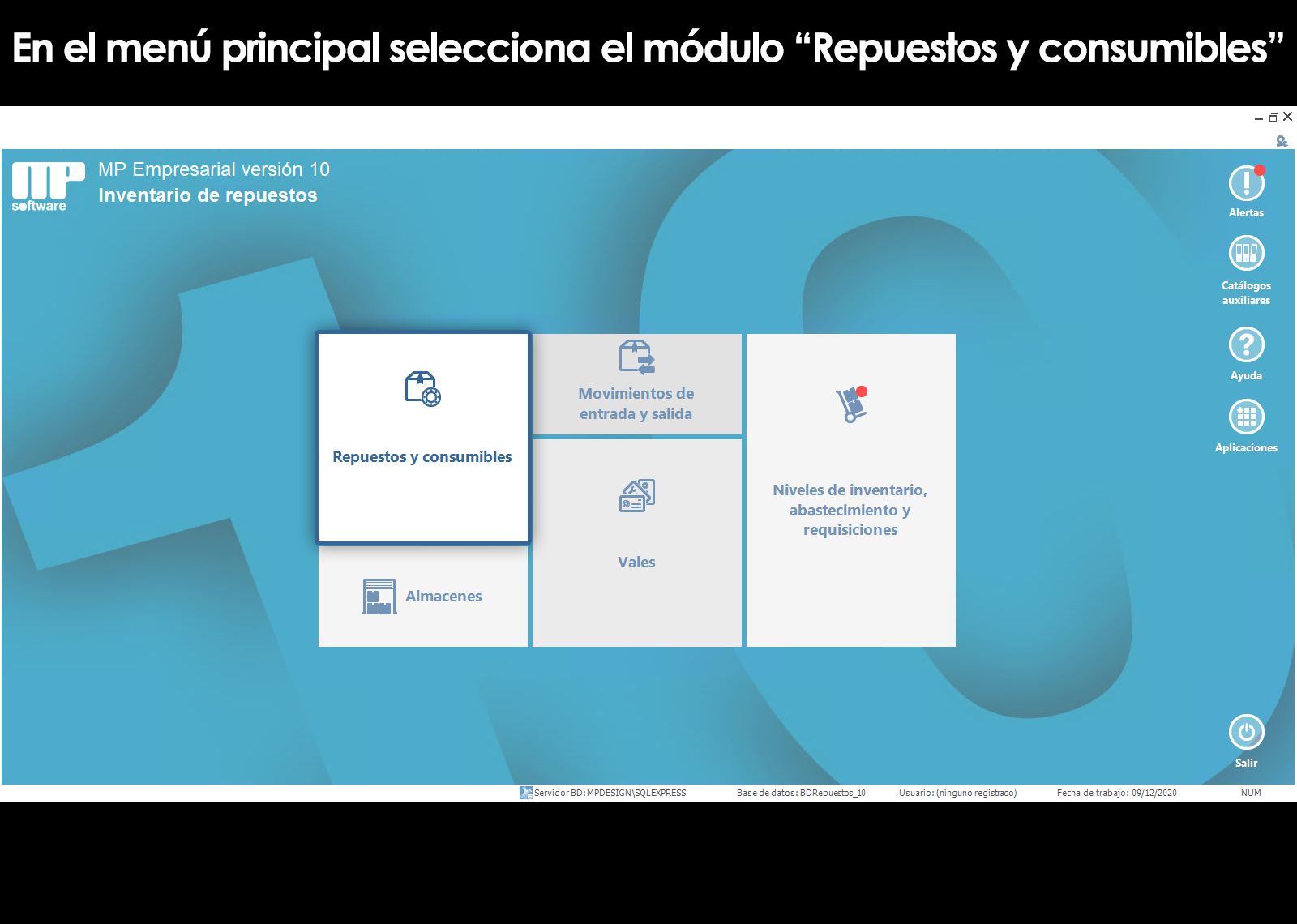

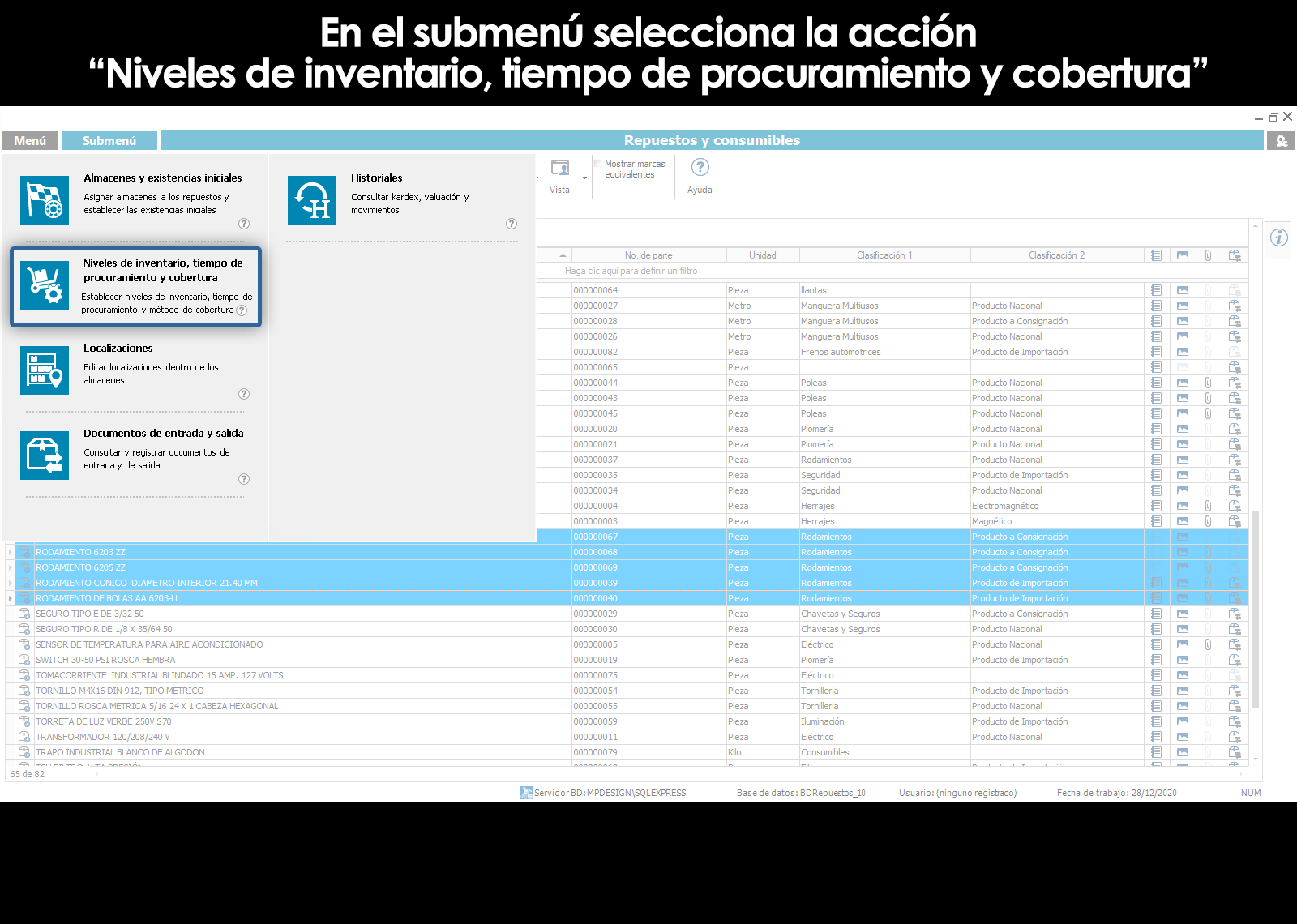

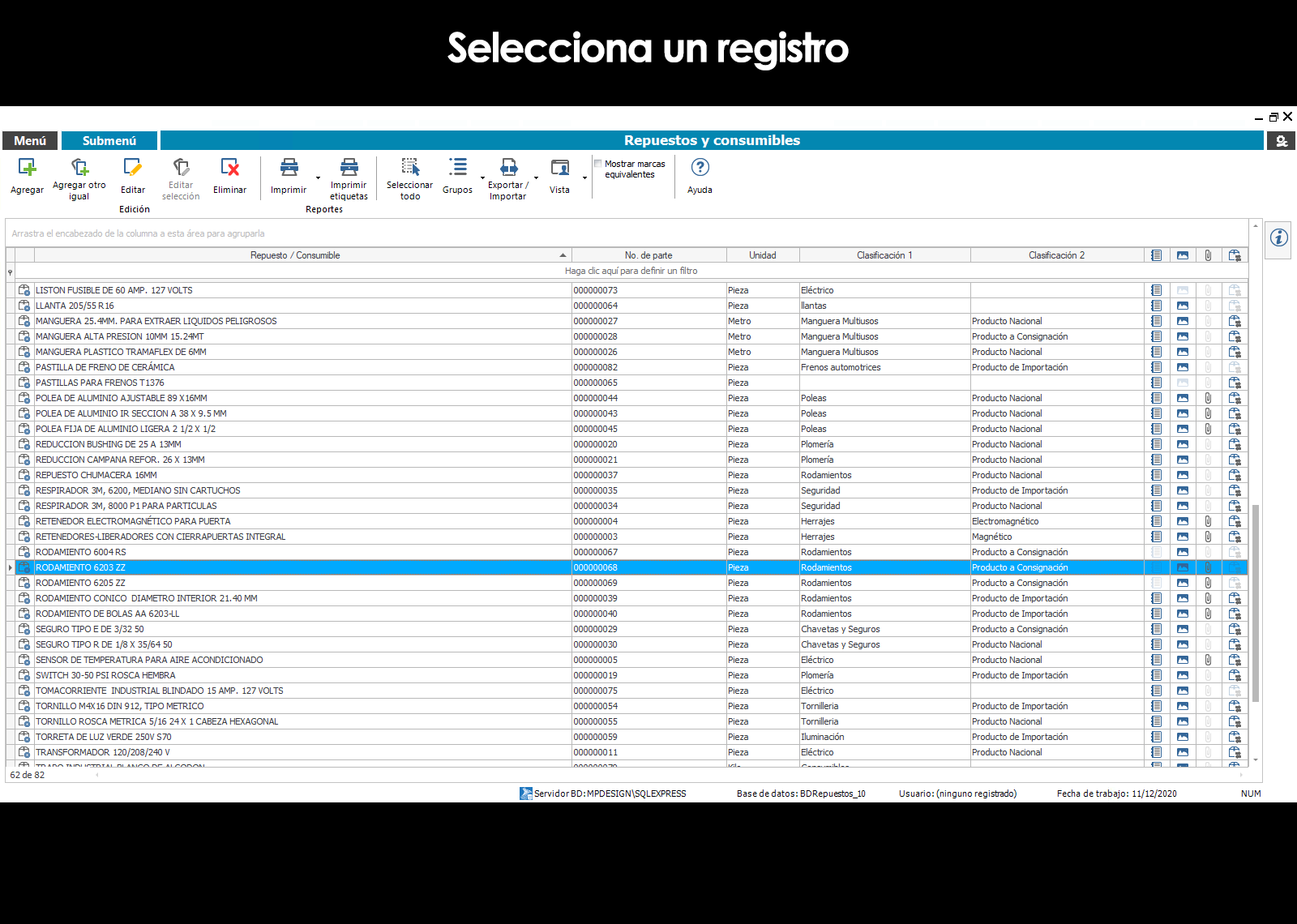

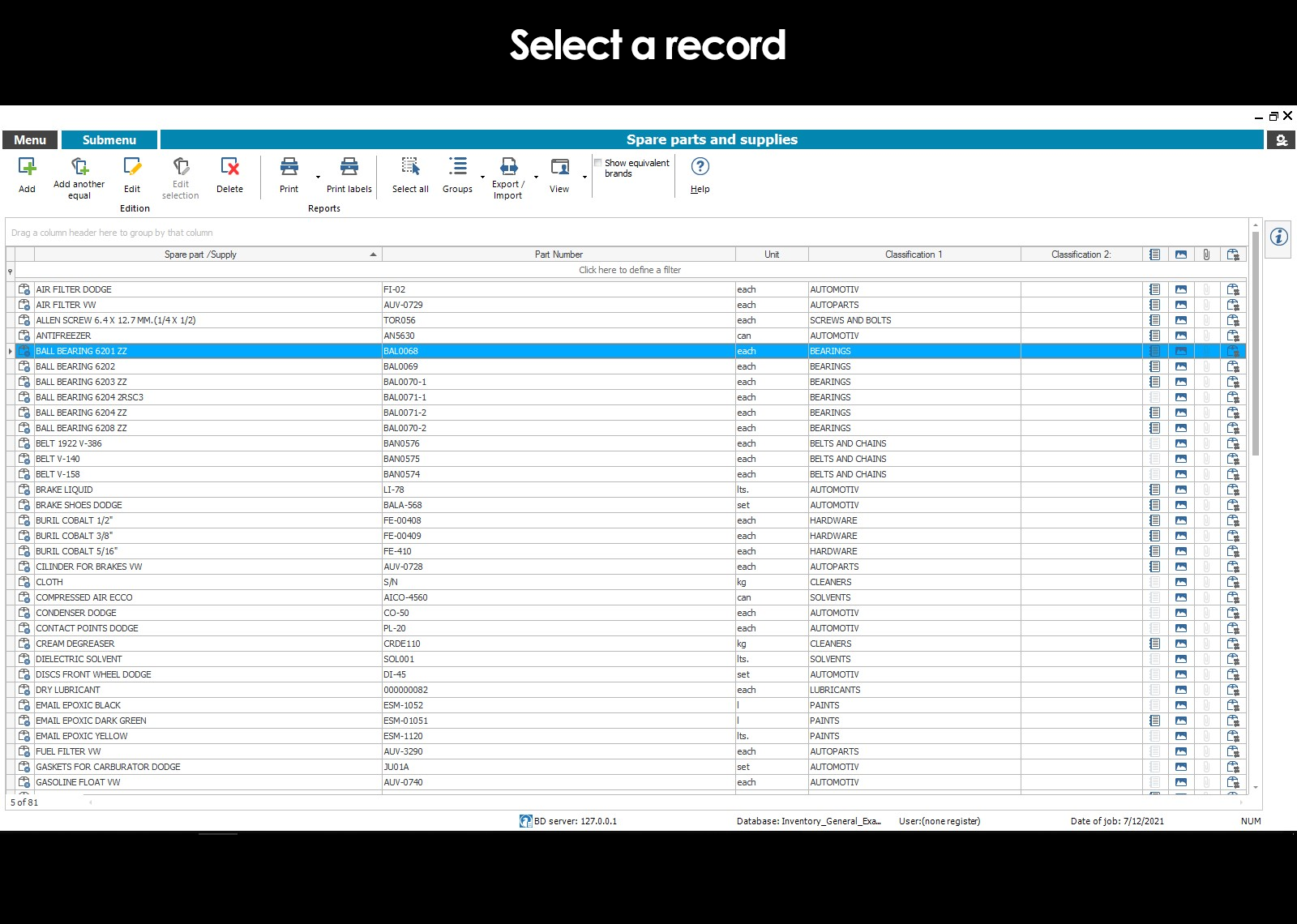

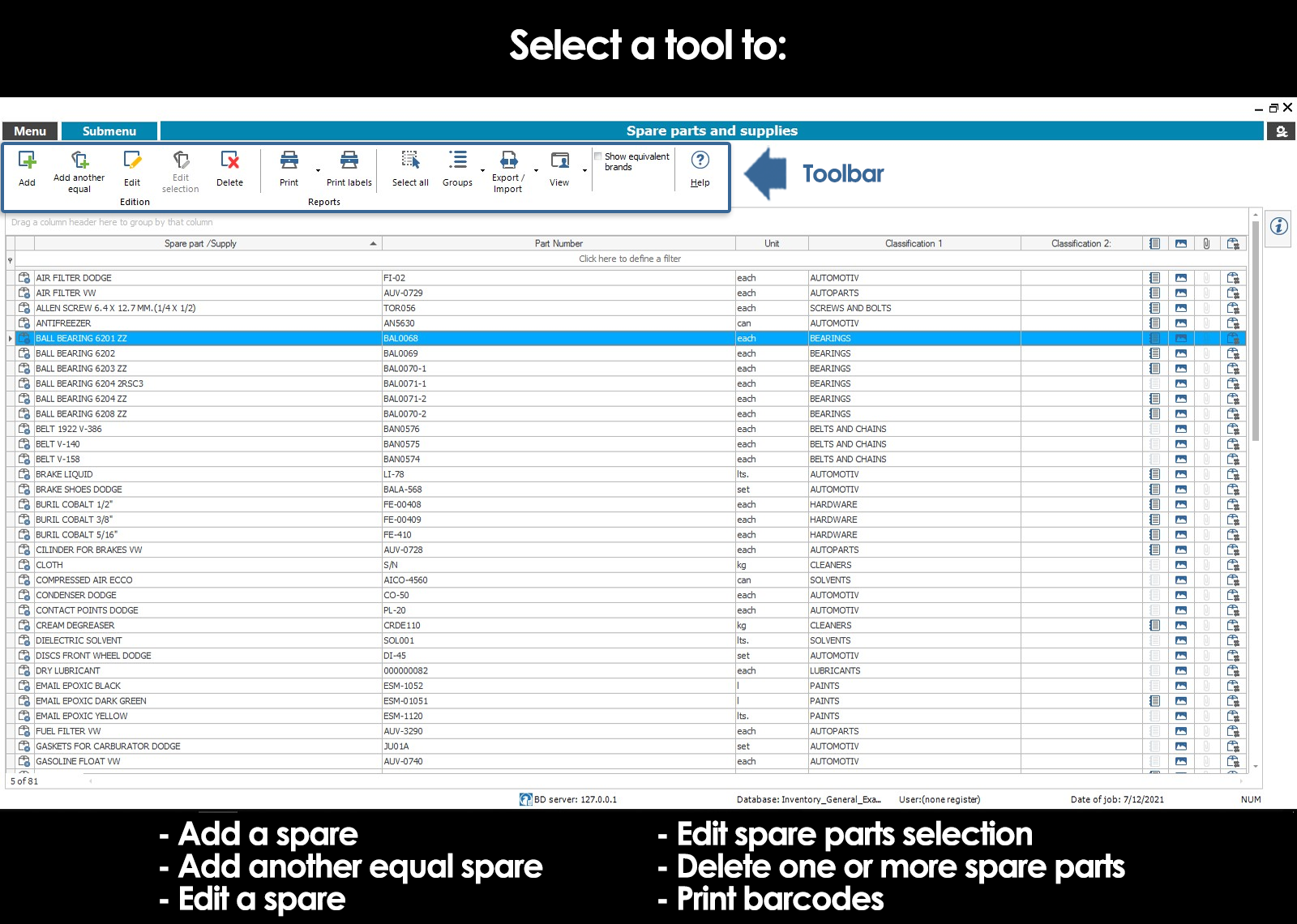

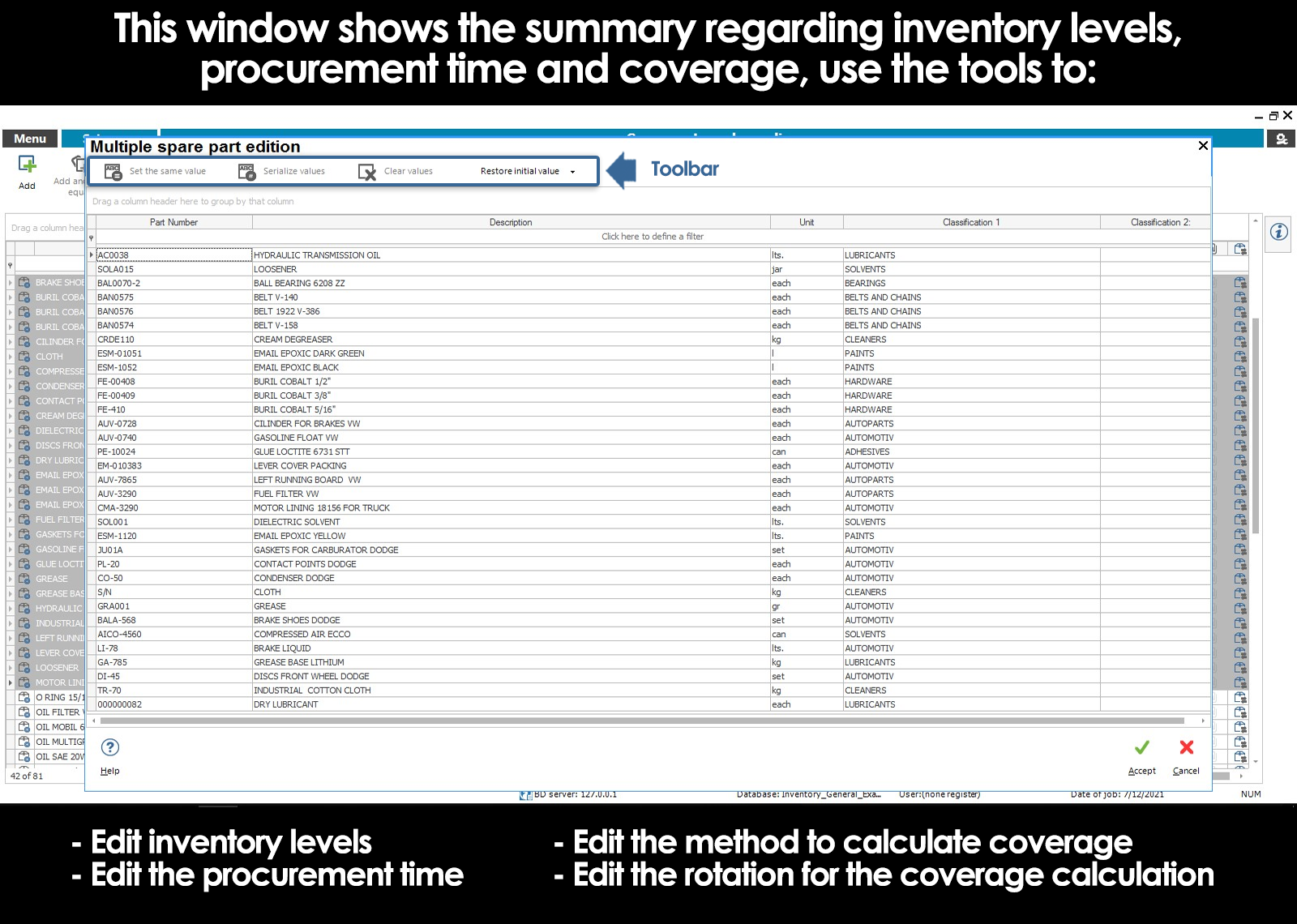

2. Desde el submenú en el módulo de Repuestos y consumibles

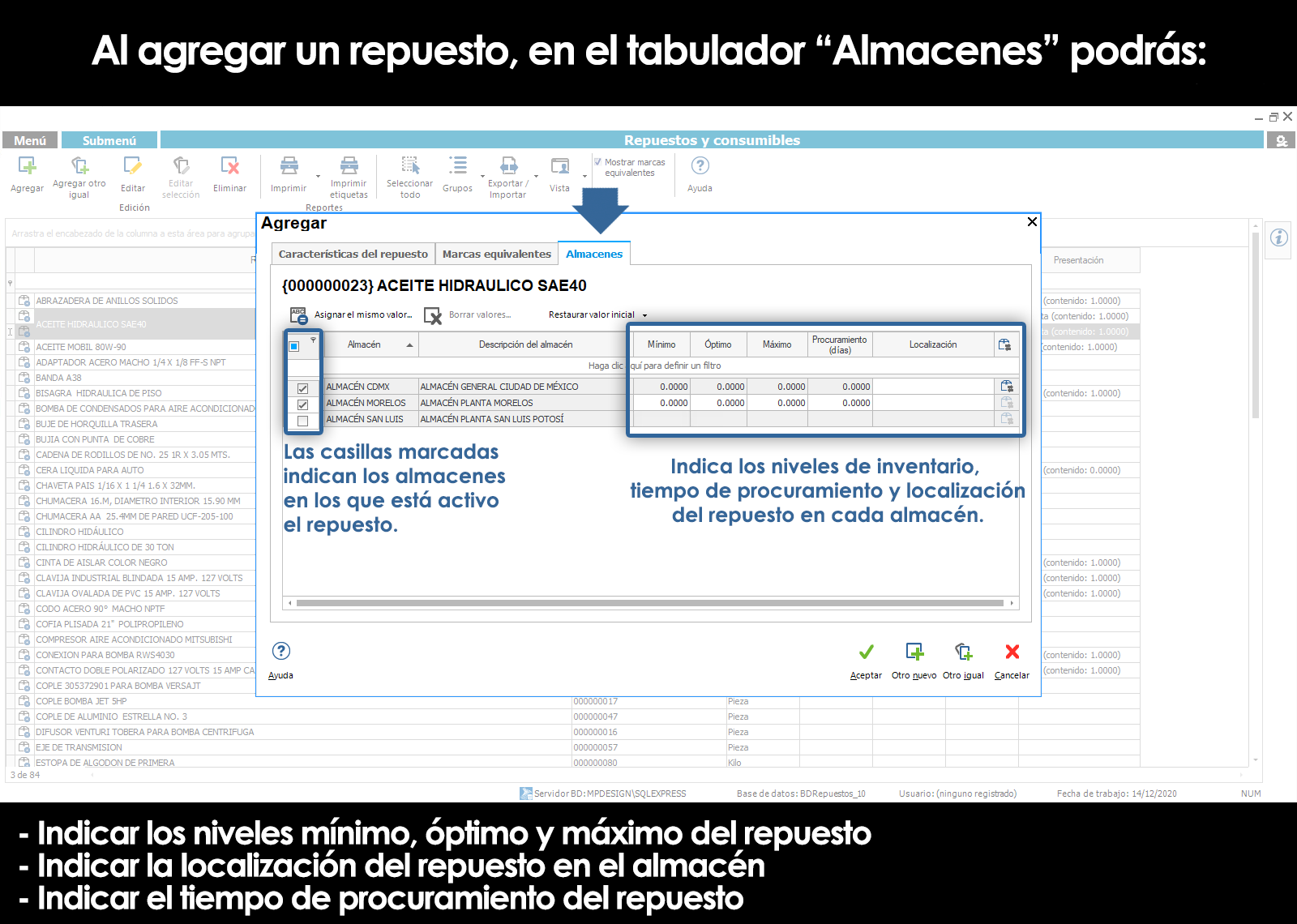

3. En el módulo de Repuestos y consumibles, al agregar o editar un repuesto o consumible en el tabulador Almacenes.

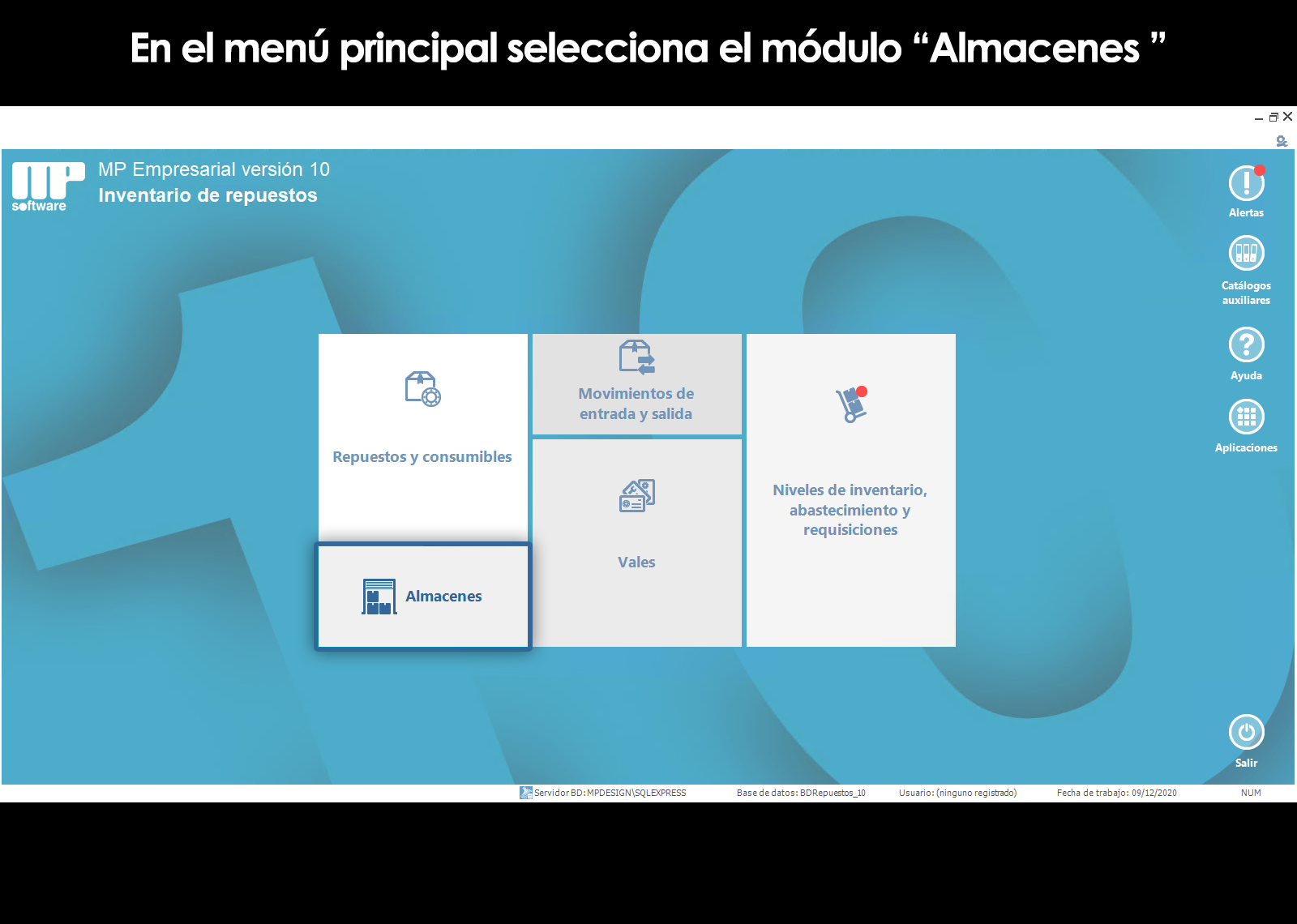

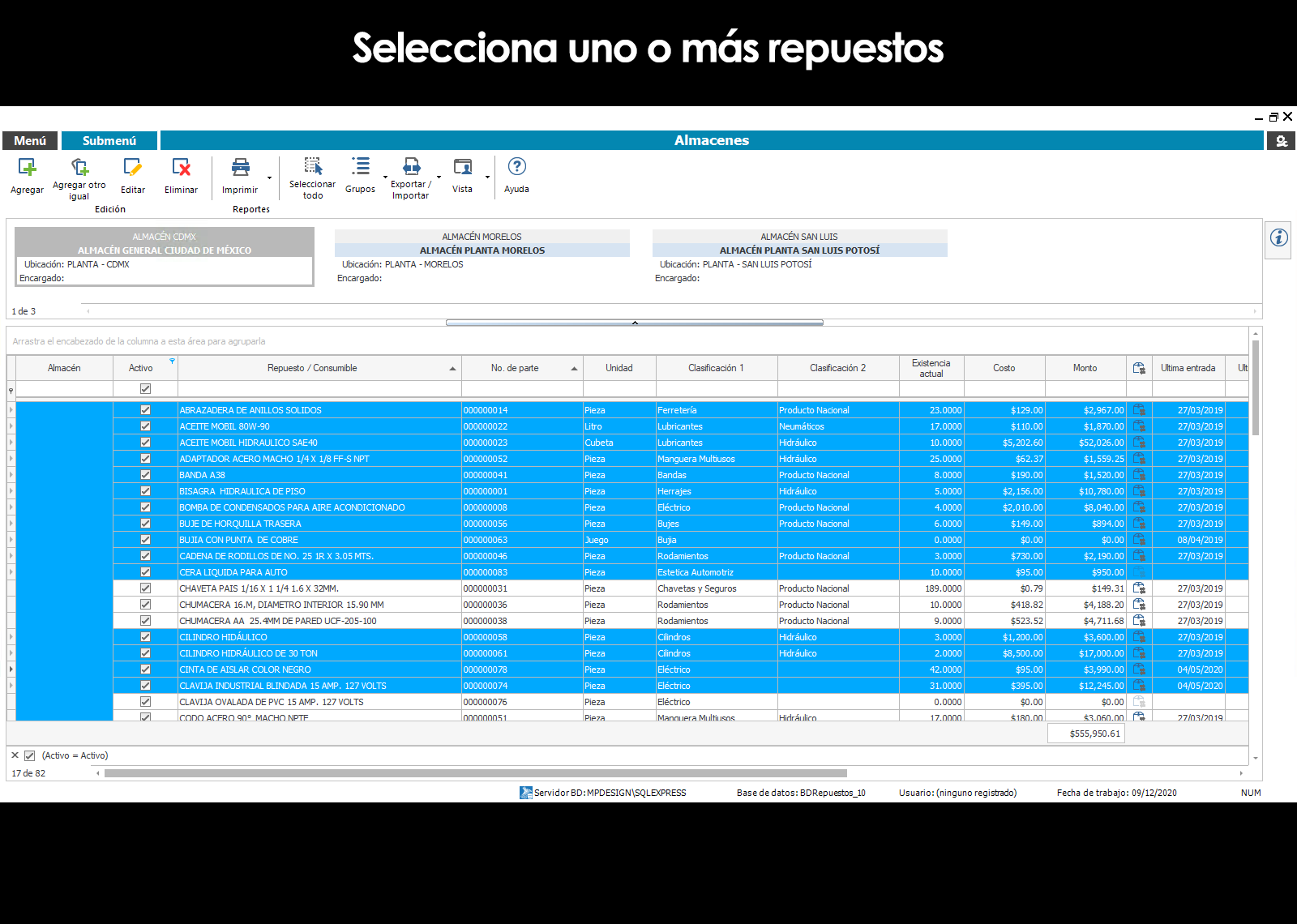

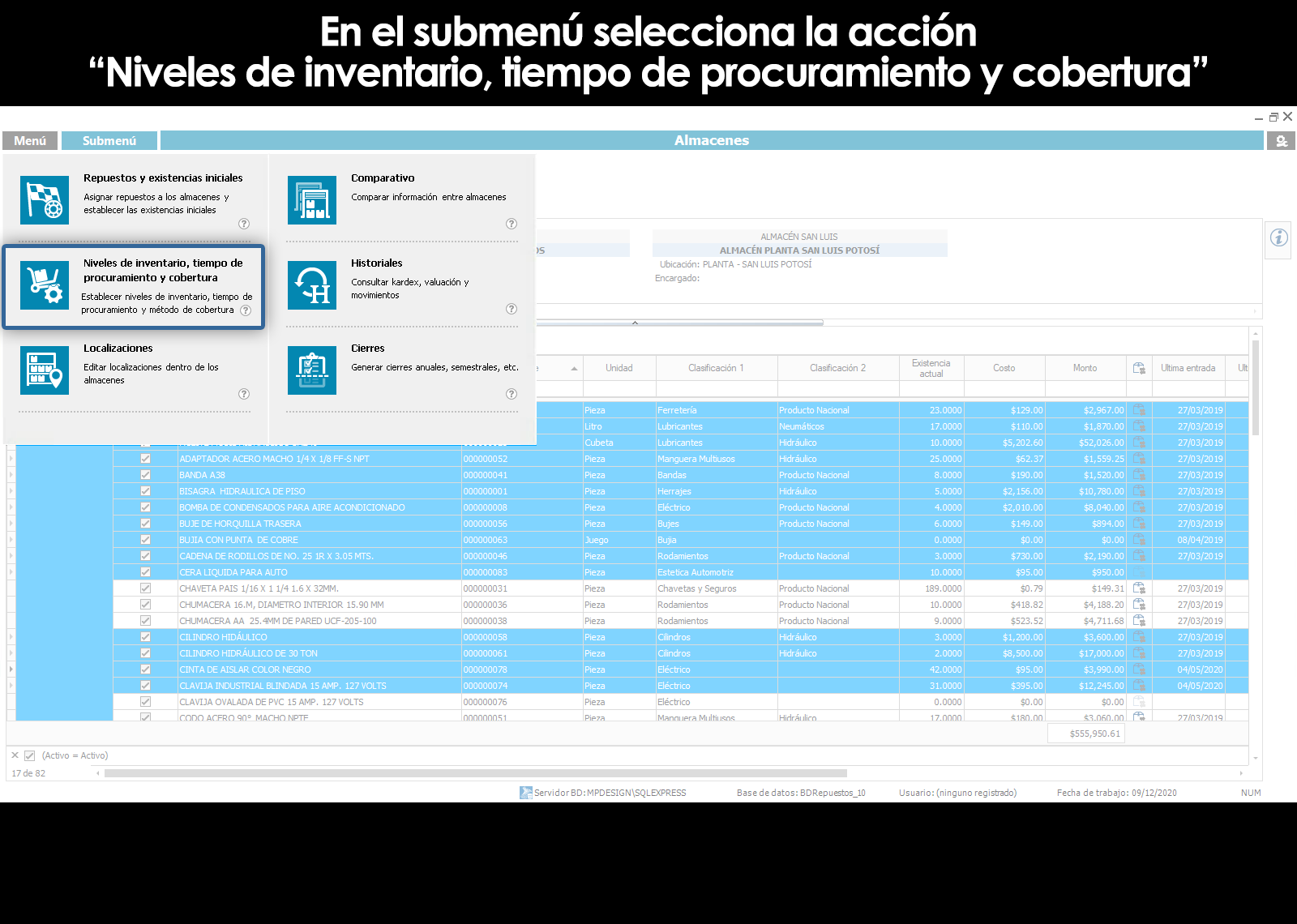

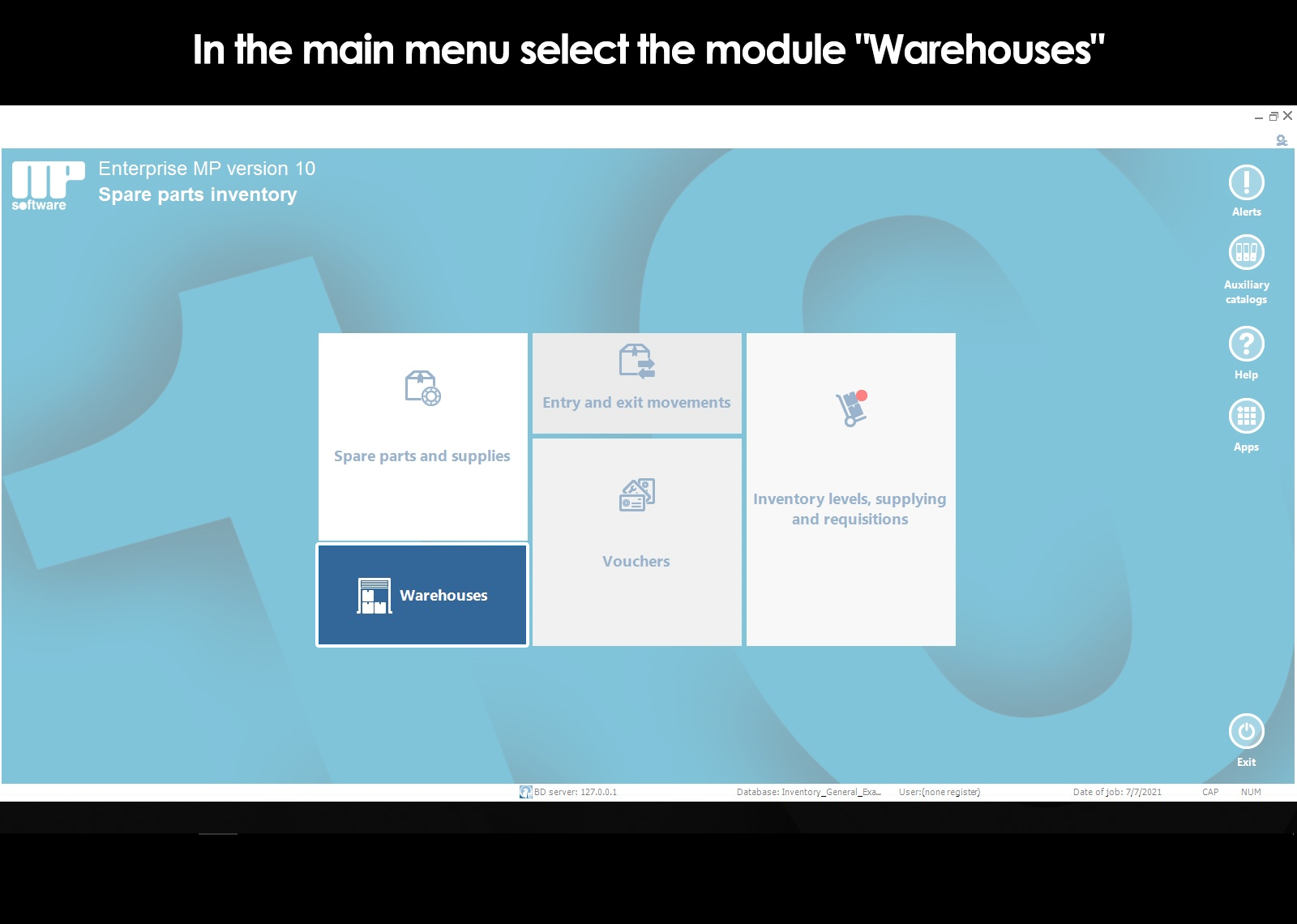

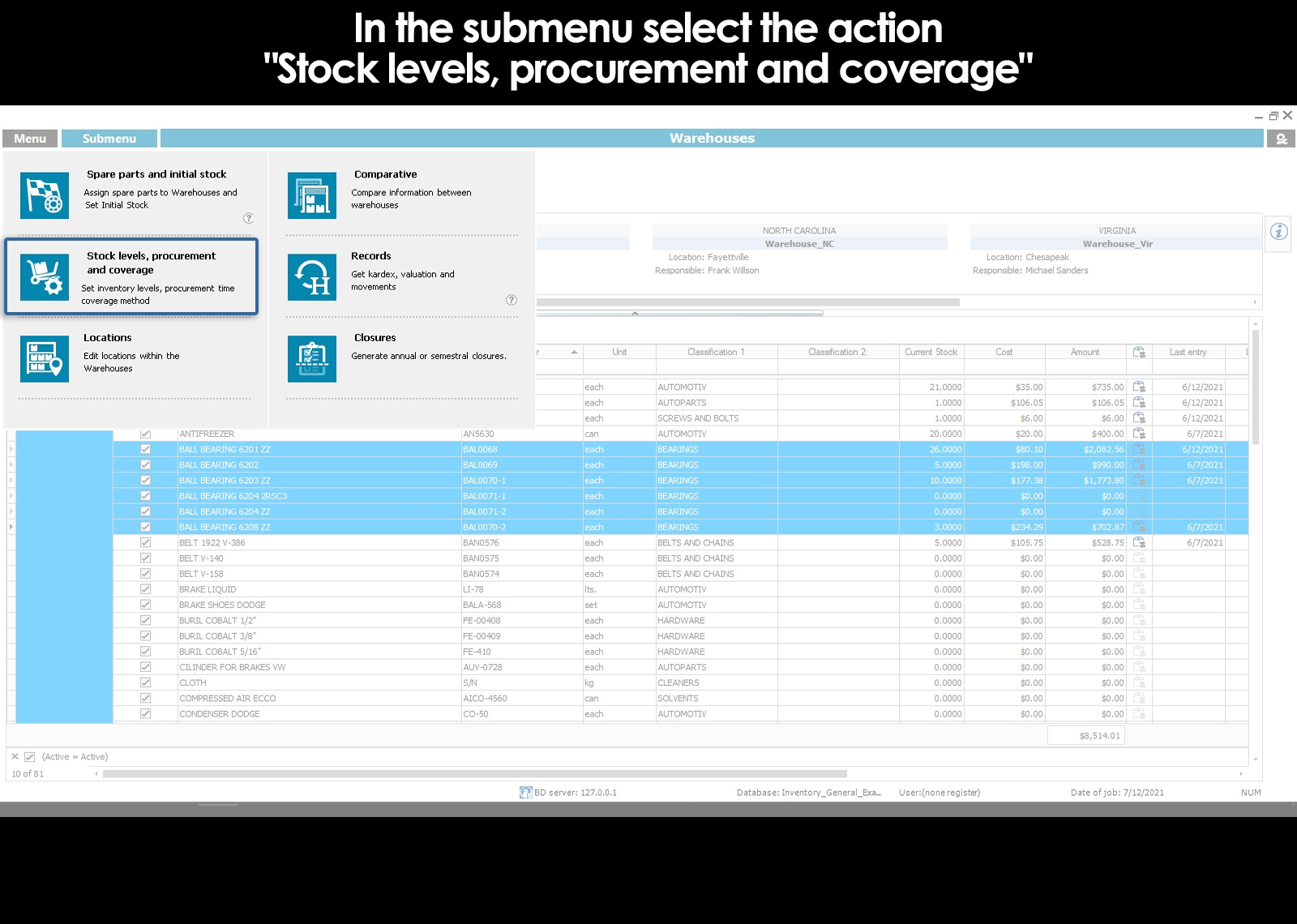

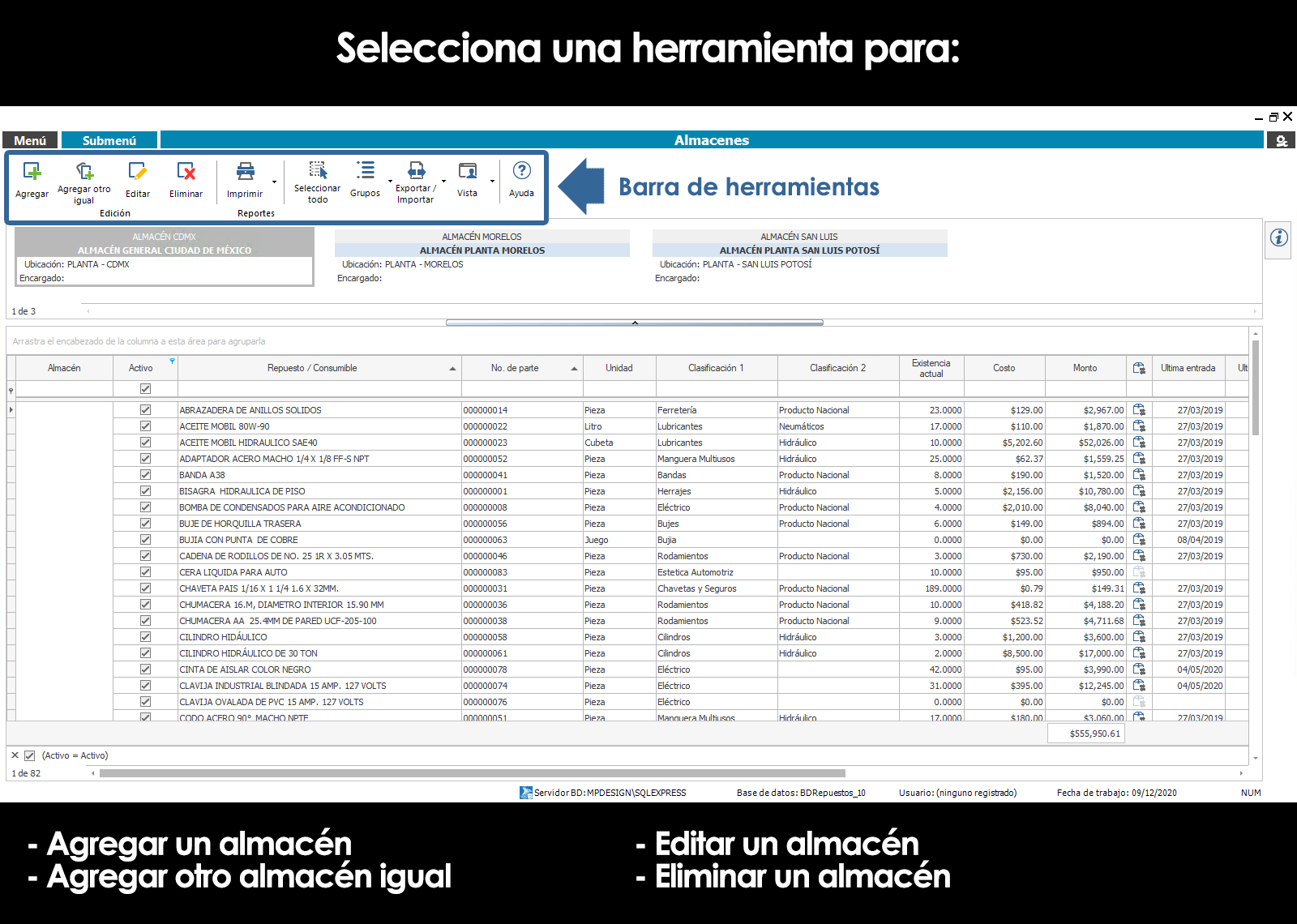

4. Desde el submenú en el módulo de Almacenes.

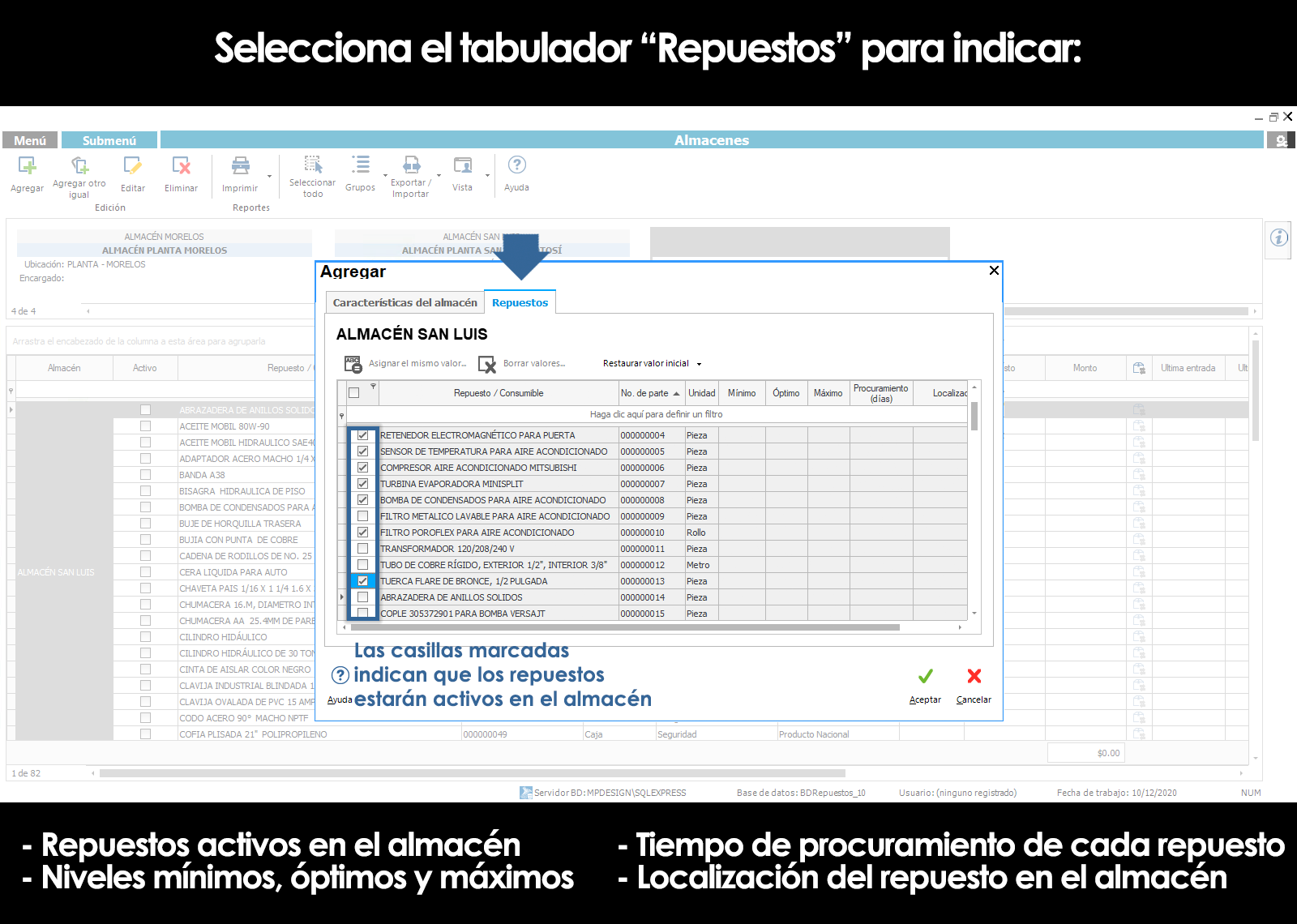

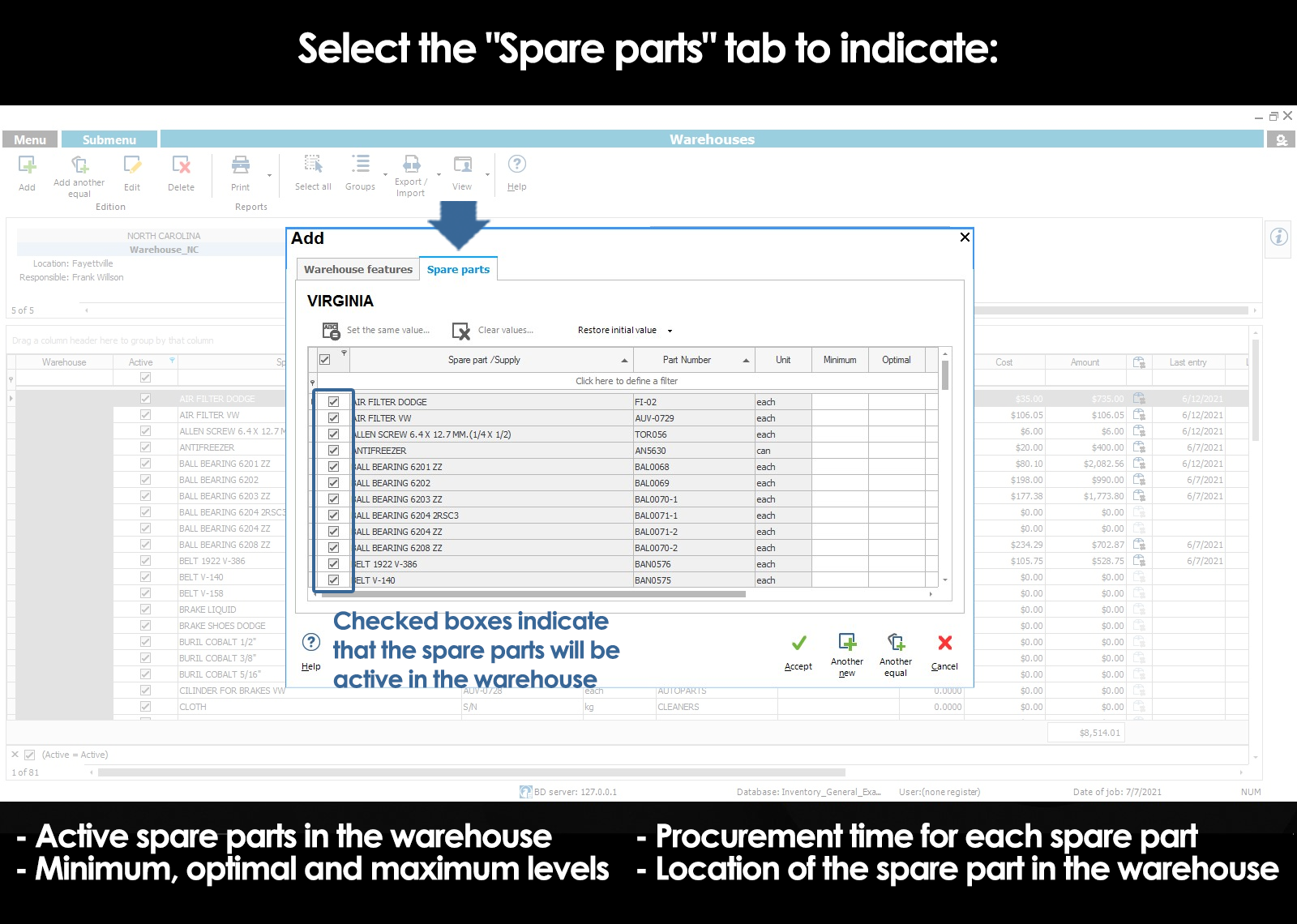

5. En el módulo de almacenes, al agregar o editar un almacén en el tabulador Repuestos

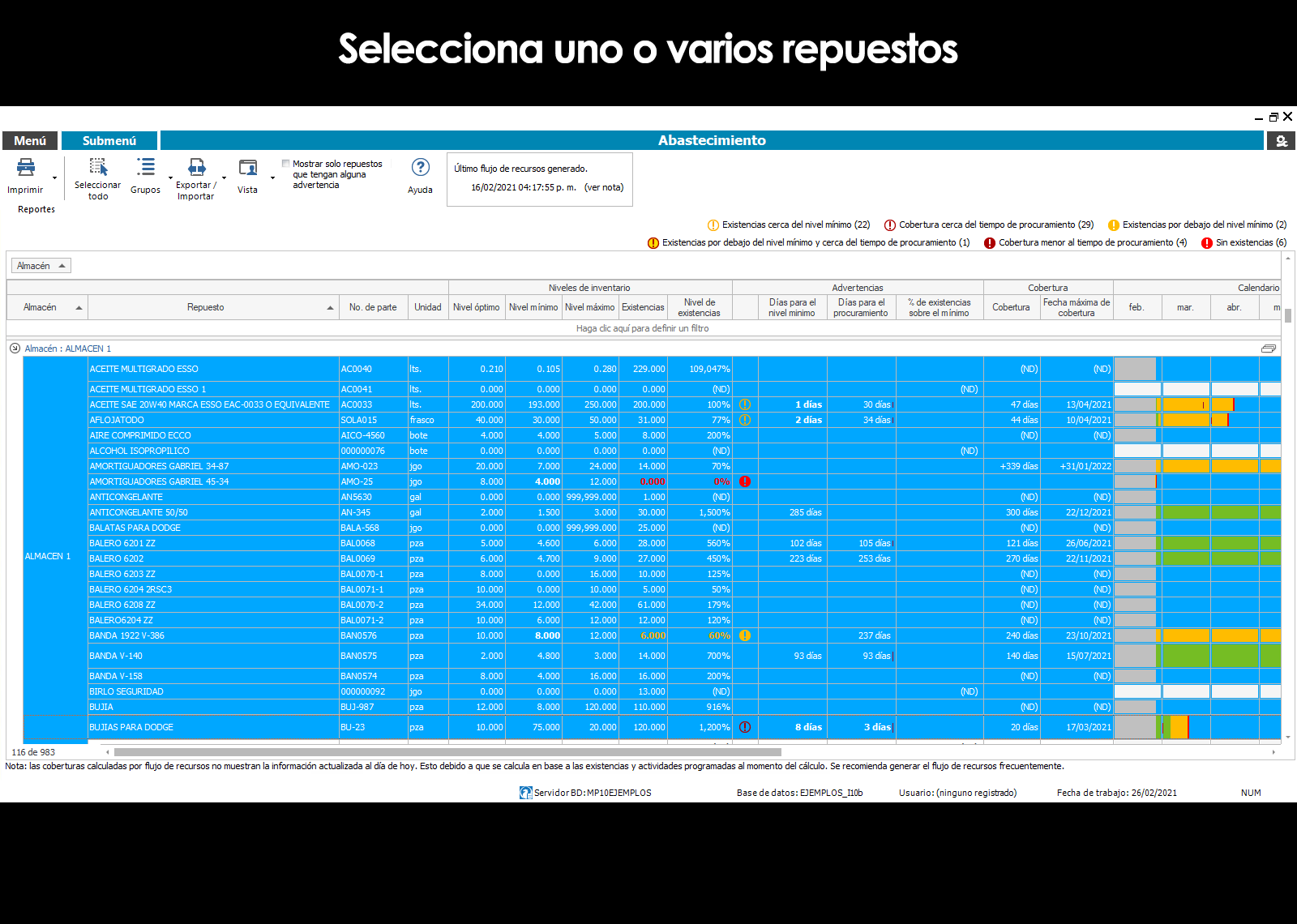

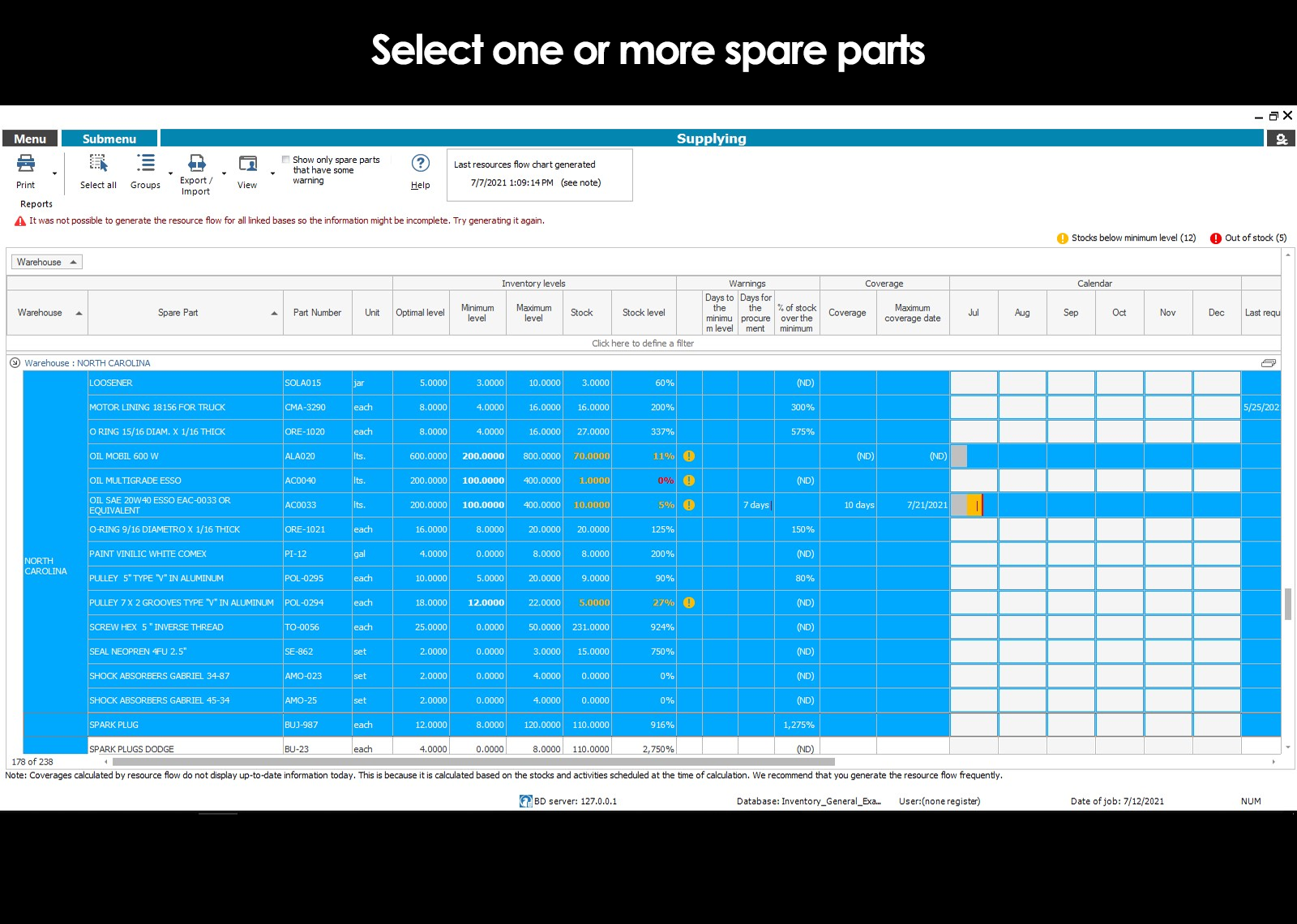

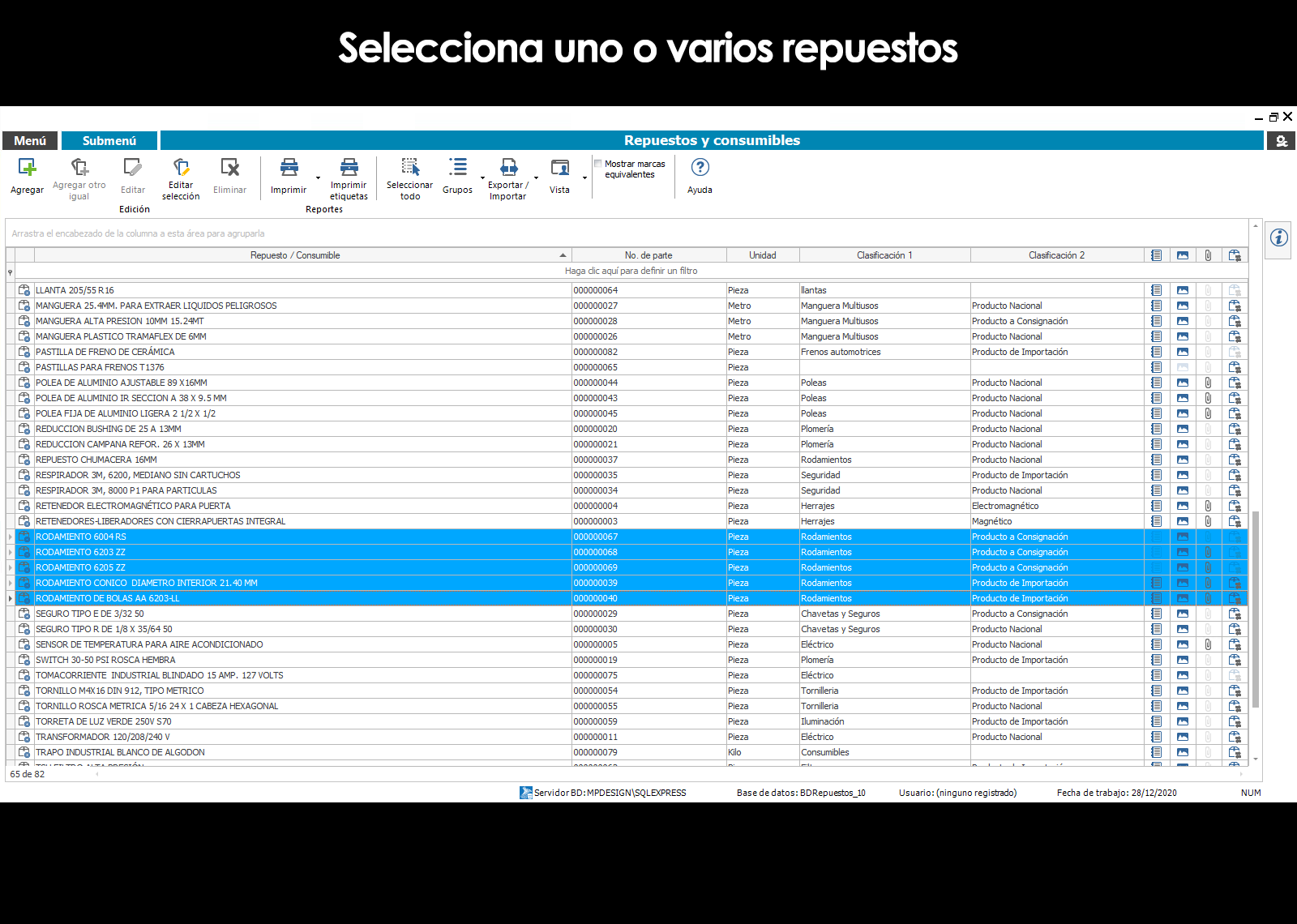

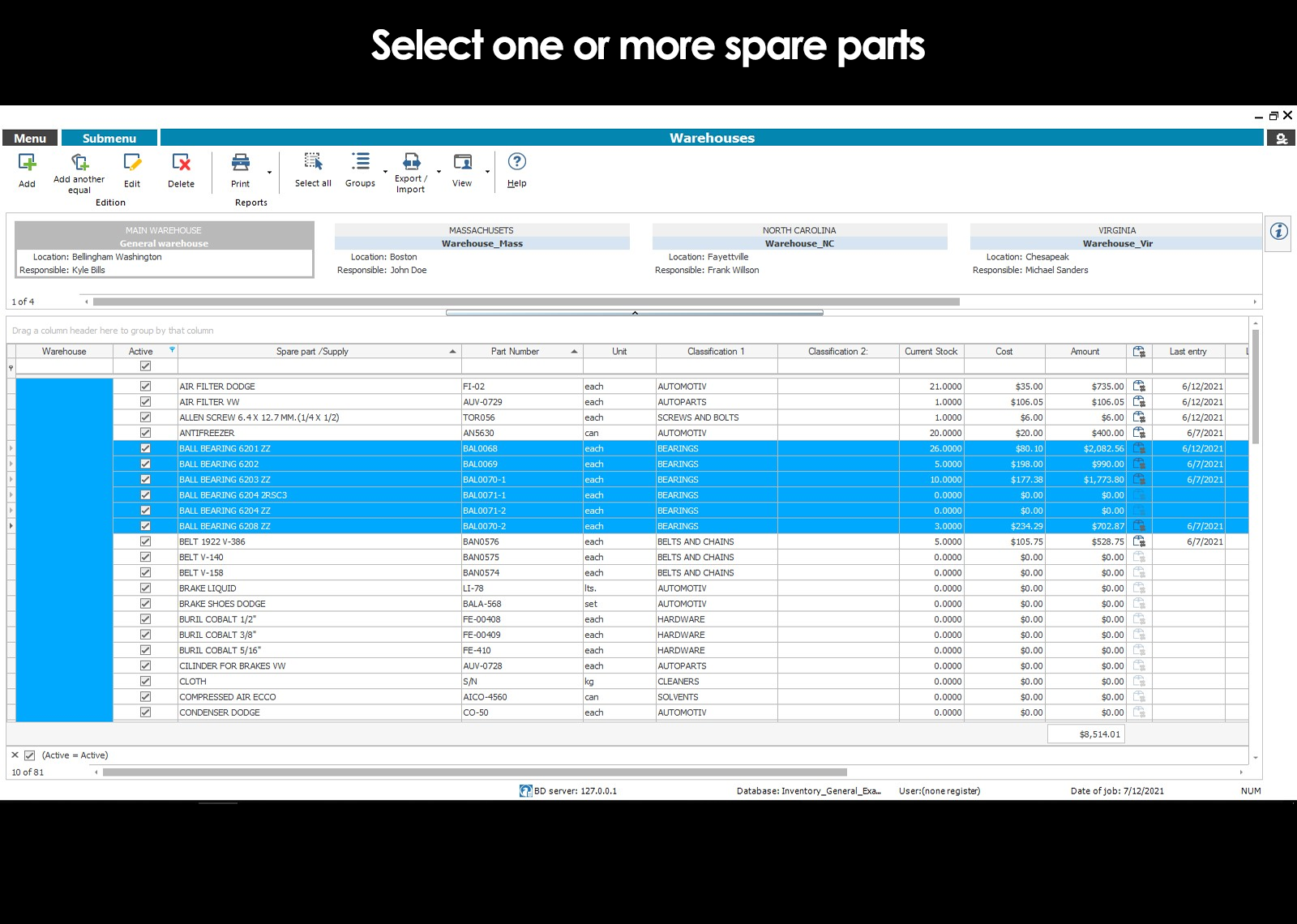

Previamente se podrá haber elegido un solo repuesto, o bien, una selección de repuestos.

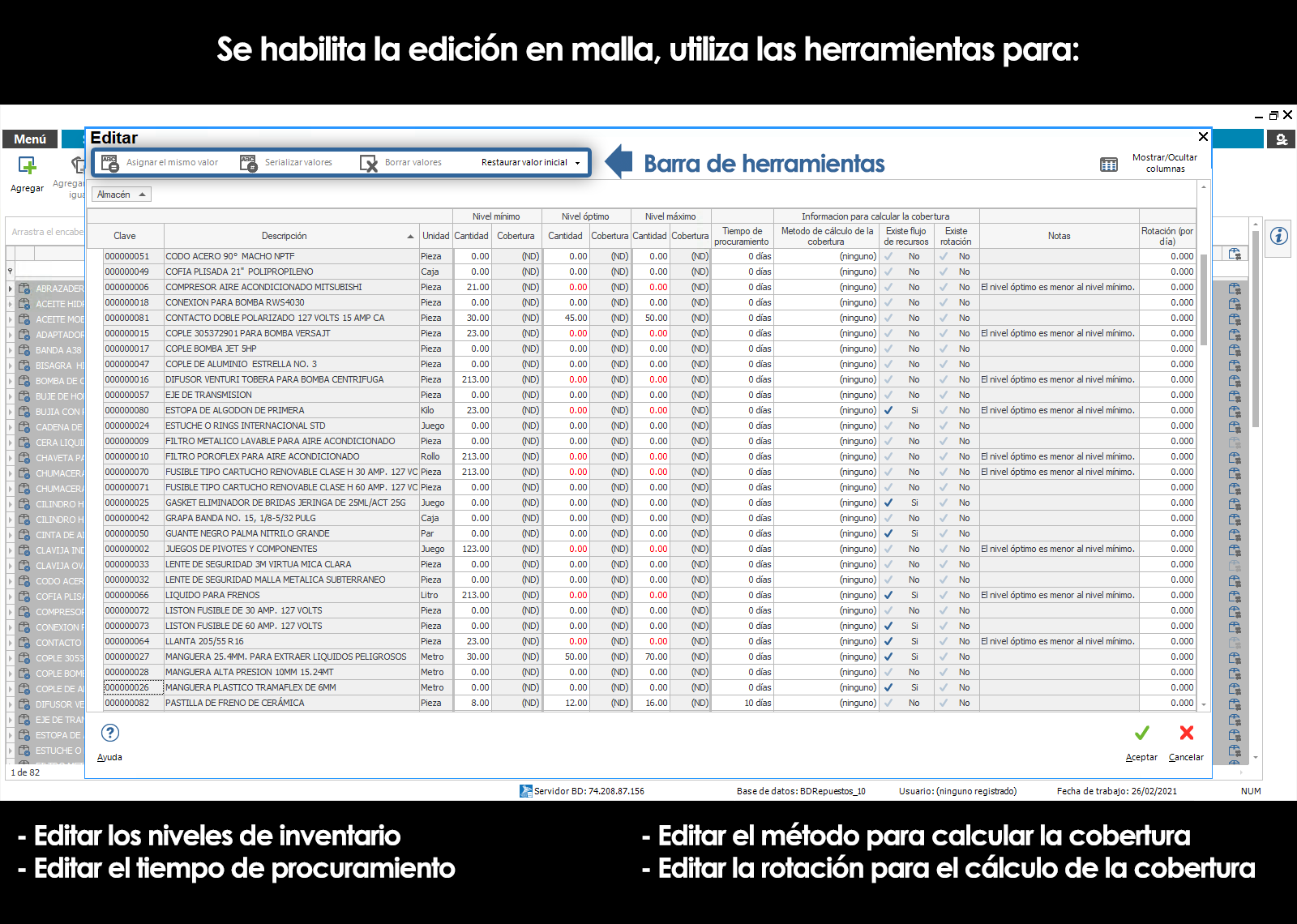

Al presentarse la pantalla, debes dar clic en el botón editar en la barra de herramientas.

Nivel mínimo: se refiere al punto donde se sugiere realizar nuevamente un reabastecimiento de material. Definir correctamente este nivel es esencial para no llegar a quedarnos sin existencias.

- Un valor bajo puede ocasionar que seguido nos quedemos sin existencias.

- Un valor alto hace que el costo de nuestro inventario sea elevado.

- Se sugiere contemplar en ocasiones la problemática para adquirir el artículo, el costo del repuesto, o lo grave que puede ser una falla en los equipos y no contar con existencias del repuesto.

Nivel óptimo: es al nivel al cual deseamos llegar al hacer una compra. Por lo general las existencias fluctúan entre 0 y el nivel óptimo.

Nivel máximo: es el nivel el cual se sugiere nunca rebasar. Este nivel puede estar definido muchas veces por el costo del repuesto o por el espacio que se necesita para almacenarlo entre otros.

Tiempo de procuramiento: es el tiempo que tarda en llegar un repuesto, desde que se genera una requisición, hasta que se recibe en nuestro almacén. Para establecer correctamente este tiempo debemos considerar el tiempo que nos toma a nosotros internamente como compañía hasta que se genera el pedido, el tiempo que tarda el proveedor en enviarnos el producto y el tiempo quizá del transportista entre otros.

El tiempo de procuramiento es crítico, ya que, si elaboramos una requisición rebasado este tiempo, es probable que llegue el punto en que nos quedemos sin existencias aún habiendo hecho anticipadamente un pedido.

Se recomienda en lo posible que, al establecer los niveles mínimos de los repuestos y consumibles, la cobertura en tiempo de lo que nos abarcarían estas existencias siempre sea mayor al tiempo de procuramiento de cada uno de los productos. Esto con la finalidad de evitar contratiempos. Más adelante hablaremos sobre el tiempo de cobertura de los repuestos.

¿No encuentras la respuesta a tus dudas o preguntas?

Opcionalmente ofrecemos cursos de capacitación

Nuestras opciones flexibles de capacitación online y presenciales te brindarán todo el conocimiento necesario para comprender e implementar tu software de mantenimiento.