Inicio / Gestión de mantenimiento

Conceptos básicos sobre la generación de una orden de trabajo (OT)

Periodo de las OT (orden de trabajo)

Generar OTs desde el módulo Trabajos en espera de generarles una Orden de trabajo

Seleccionar trabajos y generar OT (orden de trabajo)

Adelantar o posponer actividades

Cálculo de la duración de los trabajos, asignación de responsable y distribución de las cargas de trabajo

Generar OTs desde el módulo Mantenimientos rutinario próximos

Registrar actividades rutinarias realizadas sin OT

Generar OTs desde el módulo Trabajos no rutinarios

Registrar trabajos no rutinarios realizados sin OT

Generar OTs desde el módulo de equipos y localizaciones

Equipos y localizaciones fuera de servicio

Asignar responsable a una orden de trabajo

Conceptos básicos sobre la generación de una orden de trabajo (OT)

La generación de órdenes de trabajo es un proceso automático que se lleva a cabo cuando el usuario presiona el comando Generar órdenes de trabajo.

Para ello, debe seleccionar primero los trabajos o actividades que desee incluir en una orden de trabajo. Por trabajos deben entenderse actividades de mantenimiento rutinario previamente registradas en un plan de mantenimiento ligado a un equipo y/o Trabajos no rutinarios previamente registrados.

Antes de generar una OT de un trabajo no rutinario (ej. correctivo), éste debe registrarse en el módulo Trabajos no rutinarios. Antes de generar una OT de un trabajo rutinario, es necesario crear un plan de mantenimiento y ligar el plan con al menos un equipo o localización.

Al Generar órdenes de trabajo, el sistema incluye en una orden de trabajo los trabajos seleccionados y genera un número de folio consecutivo para la orden de trabajo. El número de folio permite dar seguimiento a cada orden de trabajo generada.

Una vez generadas las órdenes de trabajo, la administración, control, actualización y seguimiento de las órdenes de trabajo generadas se lleva a cabo en el módulo Órdenes de Trabajo.

Por versatilidad y facilidad para el usuario, existen diferentes rutas para la generación de órdenes de trabajo. La Opción 1 es el proceso habitual recomendado, sin embargo, existen situaciones en las que resulta más conveniente y sencillo tomar rutas alternativas.

| Rutas para la Generación de Órdenes de Trabajo | |||

|---|---|---|---|

| PASO 1 | PASO 2 | PASO 3 | PASO 4 |

| Opción 1 (Recomendada) | |||

| En el menú principal seleccione:

Trabajos en espera de generarles una OT Muestra TODOS LOS EQUIPOS Y LOCALIZACIONES con actividades rutinarias y no rutinarias que deben realizarse en el periodo. De igual forma muestra todas las actividades que deben realizarse en el periodo a cada uno de los equipos o inmuebles mostrados. |

Seleccione las actividades y presione Generar OT

(Utilice la herramienta de filtro para mostrar exclusivamente actividades que cumplan con cierta condición) |

||

| Opción 2 | |||

| En el menú principal seleccione:

Muestra el catálogo de equipos. |

Seleccione los equipos a los que desea generales una OT.

(Utilice la herramienta de filtro para auxiliarse a hacer la selección de equipos) |

En el submenú seleccione:

Trabajos en espera de generarles OT Muestra LOS EQUIPOS SELECCIONADOS y las actividades rutinarias y no rutinarias que deben realizarse a dichos equipos en el periodo. |

Seleccione las actividades y presione la herramienta Generar OT. |

| Opción 3 | |||

| En el menú principal seleccione:

Muestra el catálogo de localizaciones. |

Seleccione las localizaciones a las que desea generales una OT.

(Utilice la herramienta de filtro para auxiliarse a hacer la selección de localizaciones) |

En el submenú seleccione:

Trabajos en espera de generarles OT Muestra LAS LOCALIZACIONES SELECCIONADAS y las actividades rutinarias y no rutinarias que deben realizarse a dichas localizaciones en el periodo. |

Seleccione las actividades y presione la herramienta Generar OT. |

| Opción 4 | |||

| En el menú principal seleccione:

Mantenimientos rutinarios próximos Muestra la fecha del próximo mantenimiento de TODAS LAS ACTIVIDADES DE MANTENIMIENTO RUTINARIO, así como su estado, ya sea en tiempo o atrasada. |

Seleccione un equipo, localización o una actividad. | En el submenú seleccione: | Seleccione las actividades que desea incluir en una orden de trabajo y presione Siguiente. |

| Opción 5 (Para trabajos no rutinarios nuevos) | |||

| En el menú principal seleccione: | Si aún no registra el trabajo no rutinario, proceda a registrarlo y siga las instrucciones en pantalla.

Al finalizar el proceso, el software le preguntará si desea genera una orden de trabajo en ese momento. |

||

| Opción 6 (Para trabajos no rutinarios previamente registrados y aún no incluidos en una OT) | |||

| En el menú principal seleccione:

Muestra la lista de todos los trabajos no rutinarios previamente registrados. |

Seleccione el trabajo no rutinario para el cual desee generar una OT.

(Utilice las herramientas de filtro para mostrar sólo trabajos atrasados no incluidos aún en una OT) |

En el submenú seleccione: | Siga las instrucciones en pantalla. |

Periodo de las OT (orden de trabajo)

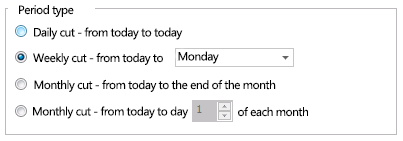

En Opciones de configuración de las Órdenes de Trabajo, el usuario puede establecer el tipo de periodo con el que desea generar sus órdenes de trabajo.

Normalmente el tipo de periodo es un parámetro del sistema que debe mantenerse fijo, sin embargo, puede modificarse en cualquier momento a criterio del administrador.

Se sugiere iniciar la implementación estableciendo el periodo con corte semanal y posteriormente, de acuerdo a las necesidades del usuario, podrá modificar el tipo de periodo.

Corte diario – La generación de órdenes de trabajo se realiza en forma diaria, así como la actualización de trabajos realizados y cierre de las mismas.

Corte semanal (Recomendado) – La generación de órdenes de trabajo se realiza una vez a la semana y en ellas se plasman todas las actividades que deben realizarse en la semana. Al final o en el transcurso de la semana, se van actualizando los trabajos realizados en el sistema.

Corte mensual – La generación de órdenes de trabajo se realiza una vez al mes y en ellas se plasman todas las actividades que deben realizarse en el mes. Al final o en el transcurso del mes, se van actualizando los trabajos realizados en el sistema.

Generar OTs desde el módulo Trabajos en espera de generarles una Orden de trabajo

En este módulo se presentan todos los trabajos, rutinarios y no rutinarios que deben realizarse en el periodo. Para la generación automática de las órdenes de trabajo de todos los trabajos que deben realizarse en el periodo, recomendamos acceder a este módulo.

El sistema calcula automáticamente la fecha de los próximos mantenimientos de cada actividad, con base en la frecuencia con que debe realizarse la actividad y la fecha en que ésta se realizó por última vez.

PRÓXIMO MANTENIMIENTO RUTINARIO

Ejemplo:

| PARTE | ACTIVIDAD | FECHA DEL ÚLTIMO MANTENIMIENTO | FRECUENCIA | FECHA DEL PRÓXIMO MANTENIMIENTO (Calculada por el MP) |

|---|---|---|---|---|

| MOTOR/ BANDA Y POLEAS | REVISAR, TENSAR Y ALINEAR | 17 Abril 2015 | Cada 6 meses | 17 Octubre 2015 |

En el módulo Trabajos en espera de generarles una OT, se presenta una lista con todas las actividades cuya fecha del próximo mantenimiento coincide con el periodo actual, es decir, en el día, en la semana o en el mes actual. De igual forma, se presentan en la lista las actividades cuyos mantenimientos se rigen por lecturas, cuando la fecha estimada de realización coincida con el periodo, basada en la última lectura de uso registrada y el promedio de uso mensual estimado.

En el listado, aparecen tanto actividades rutinarias como actividades no rutinarias programadas para realizarse en el periodo.

Desde esta ventana, el usuario podrá seleccionar las actividades que desee incluir y generar su orden de trabajo para que sean atendidas físicamente por el personal de mantenimiento.

Cabe mencionar que en el listado no aparecerán actividades de equipos o localizaciones que estén fuera de servicio durante el periodo.

Seleccionar trabajos y generar OT (orden de trabajo)

Para generar una orden de trabajo, el usuario deberá seleccionar primero las actividades cuya fecha del próximo mantenimiento coincide con el periodo actual y que desee incluir en una orden de trabajo. Una vez seleccionadas bastará con presionar la herramienta Generar OT para que el sistema les genere una orden de trabajo con un número de folio consecutivo.

Al generarles su orden de trabajo, las actividades seleccionadas dejan de aparecer en la lista de Trabajos en espera de generarles una OT y su control, administración y seguimiento pasa a partir de ese momento al módulo de Órdenes de Trabajo.

Una vez generadas las órdenes de trabajo correspondientes e incluidas todas las actividades en su correspondiente orden de trabajo, la lista de Trabajos en espera de generarles una OT quedará vacía, ya que todas las actividades por atender en el periodo estarán contenidas en una o varias órdenes de trabajo.

Por lo tanto, será responsabilidad del administrador del mantenimiento, entrar al módulo Trabajos en espera de generarles una OT por lo menos una vez al inicio del periodo y generar las órdenes de trabajo correspondientes para los trabajos que en la lista se presenten.

Si por alguna razón no desea generar una orden de trabajo para ciertas actividades que se presenten en la lista, podrá optar por posponer la fecha de su realización. Una vez generadas todas las órdenes de trabajo del periodo, el administrador de mantenimiento podrá avocarse a su administración y seguimiento en el módulo Órdenes de Trabajo.

Utilice las herramientas de filtro para generar OTs agrupadas por especialidad.

Utilice las herramientas de filtro para marcar y generar las OTs de actividades que deban atenderse con mayor prioridad.

La herramienta de filtro permite filtrar el listado de actividades para escoger de entre todo el listado de actividades que deben atenderse, por ejemplo aquellas que a juicio del administrador del mantenimiento deban atenderse con mayor prioridad, en función de su atraso, prioridad de la actividad, etc.. Otro ejemplo de la funcionalidad de la herramienta de filtro podría consistir en filtrar por cierta especialidad de la actividad y generar órdenes de trabajo agrupadas por especialidad.

Adelantar o posponer actividades

Cuando el administrador requiera cambiar la fecha de realización de las actividades de mantenimiento, ya sea, adelantar o atrasar actividades por algún motivo, podrá hacerlo en el módulo de Trabajos en espera de generarles una OT.

Para posponer las actividades, el administrador deberá seleccionar las actividades que requiere que se realicen en otro momento, y una vez seleccionadas presionar la herramienta Posponer actividad al siguiente periodo. Las actividades seleccionadas serán eliminadas del listado de Trabajos en espera de generarles una OT y volverán a mostrarse cuando inicie el siguiente periodo.

En caso que el usuario necesite modificar la fecha del mantenimiento a un día en especifico, podrá realizarlo con la herramienta Adelantar/posponer actividad. Al utilizar esta herramienta podrá cambiar los trabajos a una fecha especifica en la que requiera que se realicen. De esta forma las actividades serán eliminadas del listado, hasta el periodo de la nueva fecha programada.

Cuando se pospone manualmente la fecha de realización de una actividad, el sistema permite dejar asentado el motivo del cambio en la programación, mismo que podrá consultarse en cualquier momento.

Dentro del módulo Mantenimientos rutinarios próximos podrá Adelantar o posponer las actividades de todos los equipos o inmuebles con un plan de mantenimiento ligado.

En la ventana “Adelantar/Posponer actividades” el sistema habilita la edición múltiple de las fechas y lecturas de las actividades del equipo previamente seleccionado. Esto permite seleccionar varias celdas y Asignar el mismo valor ya sean fechas o lecturas.

Si necesita recorrer la fecha de la actividad un número exacto de días utilice la herramienta Adelantar/Posponer un número de días.

Cálculo de la duración de los trabajos, asignación de responsable y distribución de las cargas de trabajo

En el módulo Trabajos en espera de generarles una OT el administrador selecciona las actividades que quiere incluir en una orden de Trabajo. La herramienta consultar duración calcula el tiempo que tomará realizar las actividades en base al tiempo estimado previamente registrado en el plan de mantenimiento, permitiendo gestionar la duración estimada de la OT previo a su creación.

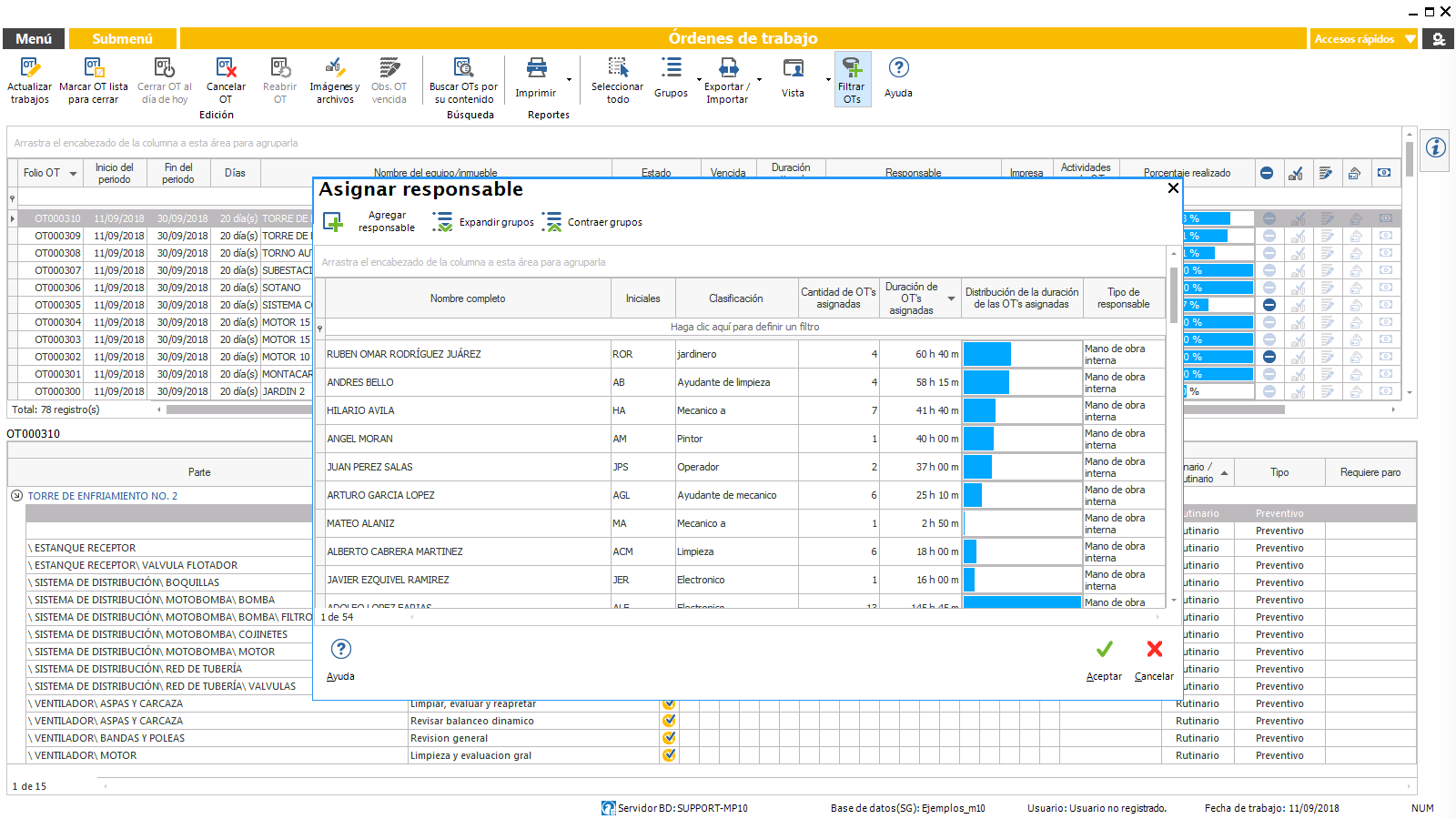

Al crear la orden de trabajo, el MP nos permite asignar un responsable para realizar dicha OT. Esta herramienta muestra el catálogo de Mano de obra y de Proveedores de servicios, del cual el usuario podrá elegir al responsable.

Al momento de asignar responsables a las órdenes de trabajo, el MP presenta una gráfica que indica la cantidad y duración de órdenes de trabajo asignadas a cada responsable o proveedor externo de servicios, ayudando así a balancear la distribución de las cargas de trabajo.

Generar OTs desde el módulo Mantenimientos rutinario próximos

Desde este módulo, podemos generar órdenes de trabajo de cualquier trabajo rutinario, sin importar si su fecha programada coincide o no con el periodo actual.

La funcionalidad del sistema nos permite generar órdenes de trabajo para actividades que su próximo mantenimiento no corresponde al periodo actual. Es decir, podrá generar una orden de trabajo de cualquier actividad de mantenimiento próximo de cualquier equipo o inmueble cuando así lo desee. El administrador podrá generar éstas órdenes de trabajo desde el módulo Mantenimientos rutinarios próximos.

Al abrir el módulo se observa una lista de todos los equipos e inmuebles con un plan de mantenimiento ligado. Aquí se observa la fecha programada para realizar cada una de las actividades que conforman el mantenimiento.

Para generar una orden de trabajo, utilizar la herramienta Generar OT de las actividades que se desean realizar el día de hoy ubicada en el Submenú.

Se mostrará una lista de todos los equipos e inmuebles junto con las actividades de mantenimiento próximo que no se encuentren dentro de una orden de trabajo. De la lista anterior el usuario deberá seleccionar los trabajos que desee se realicen en este momento e incluyan en una orden de trabajo. Lo anterior generará una orden de trabajo cuya administración pasará al módulo de órdenes de trabajo.

Registrar actividades rutinarias realizadas sin OT

Cuando una actividad se realizó sin antes encontrarse dentro de una orden de trabajo, el usuario puede registrar estas actividades como realizadas. De esta forma, si el personal de mantenimiento realizó una actividad a la que no se le generó una OT previamente, al registrarla como realizada, el sistema calculará su mantenimiento próximo a partir de esta fecha de acuerdo a su plan de mantenimiento.

Para registrar una actividad como realizada, el usuario deberá ingresar al módulo de Mantenimientos rutinarios próximos. Al abrir el módulo se observará una lista de todos los equipos e inmuebles con un plan de mantenimiento ligado. Deberá utilizar la herramienta Registrar actividades realizadas sin OT ubicada en el Submenú y seleccionar de la lista de trabajos los ya realizados.

Lo anterior generará una orden de trabajo con folio consecutivo en la que se marcaran todas las actividades dentro de esta orden como ya realizadas. La administración de esta orden de trabajo pasará al módulo Órdenes de trabajo.

Generar OTs desde el módulo Trabajos no rutinarios

Desde este módulo, podemos generar la orden de trabajo de cualquier trabajo no rutinario previamente registrado, sin importar si su fecha programada coincide o no con el periodo actual.

Al registrar un trabajo un trabajo de mantenimiento no rutinario, el sistema da la opción de crear la orden de trabajo en ese momento.

Si al momento de agregar o registrar un trabajo no rutinario decidió no crear su orden de trabajo en ese momento, desde el Submenú del módulo Trabajos no rutinarios, es posible generar la orden de trabajo de cualquiera de los trabajos que se encuentren registrados en dicho módulo, independientemente de su fecha programada.

Registrar trabajos no rutinarios realizados sin OT

En la práctica, es común que algunos trabajos por premura o cualquier otra situación se realicen sin haber generado una orden de trabajo previa. Para control histórico de dichos trabajos, el sistema permite registrar trabajos no rutinarios que se realizaron sin una OT. O bien, si el trabajo ya se encontraba registrado y se realizó sin antes haber generado una OT, desde el Submenú del módulo Trabajos no rutinarios existe la acción de indicar que el trabajo se realizó sin una OT. En estos casos, se genera una orden de trabajo con un número de folio consecutivo y la marca como realizada, permitiendo así la consulta de todos los trabajos realizados.

Generar OTs desde el módulo de equipos y localizaciones

Otra forma de generar órdenes de trabajo es a través de los módulos Equipos y Localizaciones/inmuebles.

Esta ruta es la opción recomendada cuando deseamos generar las órdenes de trabajo de un equipo específico o de una selección de equipos ya que podemos aprovechar todas las opciones de filtro que éste módulo ofrece para ubicar y seleccionar los equipos cuyas órdenes de trabajo deseamos generar.

Al generar órdenes de trabajo desde el módulo de Equipos, será fácil seleccionar los equipos que cumplan con cierta condición, por ejemplo de localización, y generar una orden de trabajo que contenga todos los trabajos que deben realizarse en el periodo a los equipos ubicados en dicha localización.

Seleccione uno o varios equipos del catálogo de Equipos y enseguida utilice la acción Trabajos en espera de generarles una OT del submenú de dicho módulo. Acto seguido se muestra una lista de las actividades de los equipos seleccionados que deben realizarse en el periodo. Seleccione las actividades que desea incluir en una orden de trabajo y presione la herramienta Generar OT.

El MP permite incluir varios equipos seleccionados en una misma orden de trabajo, si así lo desea.

Equipos y localizaciones fuera de servicio

El sistema permite suspender de manera temporal la programación de trabajos de mantenimiento rutinario de equipos y localizaciones que se encuentren fuera de servicio.

Al marcar los equipos o localizaciones fuera de servicio, el tiempo se congela para estos. Es decir, las fechas de mantenimientos próximos que se tenían inicialmente programadas, las recalcula, desplazándolas un periodo de tiempo igual al tiempo que estarán fuera de servicio.

Para establecer uno o varios equipos fuera de servicio, seleccione el o los equipos deseados en el módulo Equipos y posteriormente seleccione la acción del submenú Equipos fuera de servicio.

En la ventana Establecer o modificar estado de los equipos fuera de servicio seleccione un equipo y haga clic en la herramienta Agregar (poner) equipo fuera de servicio. Indique el periodo que el equipo estará fuera de servicio y haga clic en Aceptar. Si el equipo tiene actividades controladas por lecturas, será necesario actualizar lecturas.

No podrá poner el equipo fuera de servicio si hay actividades del equipo incluidas en una OT abierta, o bien, si el equipo no se ha ligado a un plan de mantenimiento.

Para poner localizaciones fuera de servicio el procedimiento es el mismo pero desde el módulo de Localizaciones/immuebles.

Asignar responsable a una orden de trabajo

En el módulo Órdenes de Trabajo podrá asignar y/o modificar el responsable de una o múltiples órdenes de trabajo. Para esto deberá seleccionar las órdenes de trabajo del listado y seleccionar la herramienta Asignar responsable del submenú.

Responsable es la persona a cargo de cada orden de trabajo. En muchas ocasiones el responsable es la misma persona que realiza físicamente los trabajos, sin embargo, puede no siempre ser así.

En el módulo Mano de Obra podemos dar de alta un catálogo de mano de obra en donde se registra el nombre y la especialidad de todo el personal de mantenimiento, incluyendo a los responsables. Cuando asignamos un responsable a una o varias órdenes de trabajo, el sistema totaliza el tiempo estimado para realizar los trabajos contenidos en cada orden de trabajo y lo acumula al responsable asignado. Lo anterior permite conocer gráficamente la distribución de la duración de las órdenes de trabajo asignadas al personal, ayudando al administrador de mantenimiento a balancear las cargas de trabajo. De igual forma podremos conocer la cantidad de OTs abiertas asignadas a cada uno de ellos al momento de asignar los trabajos.

ASIGNAR RESPONSABLE A UNA ORDEN DE TRABAJO

Para asignar un responsable, la orden de trabajo debe estar abierta.

Ahora bien, el sistema permite llevar control del tiempo del personal de mantenimiento invertido en las diferentes órdenes de trabajo. En el módulo Bitácora de mano de obra el usuario podrá registrar manualmente el tiempo invertido de las diferentes personas que intervinieron en cada orden de trabajo, a modo que para una misma orden de trabajo, podremos registrar la participación de diferentes personas.

En el módulo de Análisis de Información, podremos obtener gráficas referentes al tiempo trabajado o reportado por el personal de mantenimiento en un periodo determinado.

Para simplificar el registro de la mano de obra consumida, existe la opción de que se genere automáticamente el consumo del responsable asignado a la OT al momento de cerrarla, partiendo de los tiempos estimados de las diferentes actividades contenidas en la OT. Si desea generar automáticamente el consumo del tiempo del responsable asignado, vaya a opciones de configuración y marque la casilla correspondiente.

¿No encuentras la respuesta a tus dudas o preguntas?

Opcionalmente ofrecemos cursos de capacitación

Nuestras opciones flexibles de capacitación online y presenciales te brindarán todo el conocimiento necesario para comprender e implementar tu software de mantenimiento.