Inicio / Gestión de mantenimiento

Navegando desde el módulo de alertas

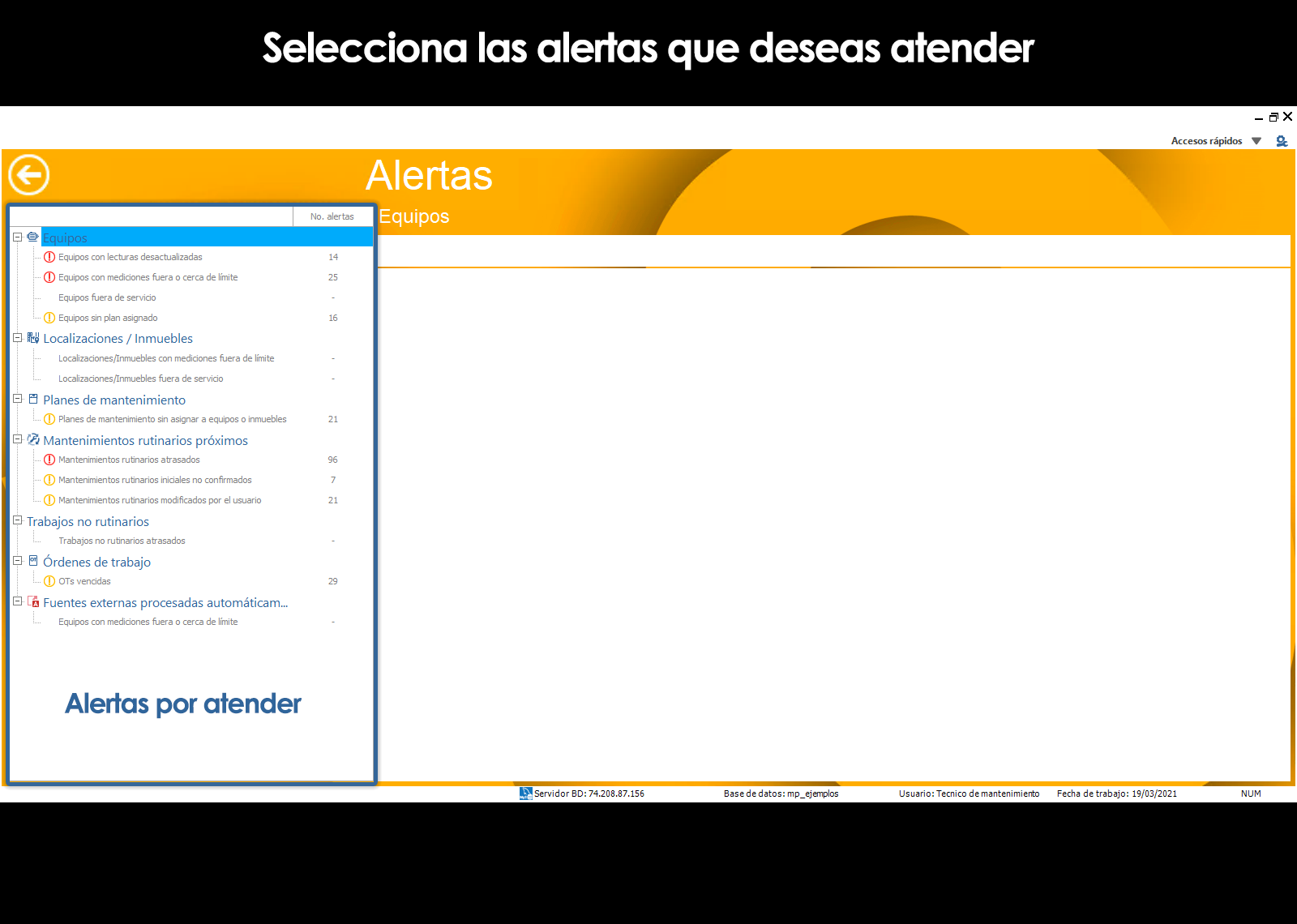

Accesa al módulo de alertas para saber lo que tienes que atender

Alerta de equipos con lecturas desactualizadas

Alerta de equipos con mediciones fuera o cerca de límite

Alerta de equipos fuera de servicio

Alerta de equipos sin plan asignado

Alerta de planes de mantenimiento sin asignar a equipos o inmuebles

Alerta de mantenimientos rutinarios atrasados

Alerta de mantenimientos rutinarios iniciales no confirmados

Alerta de mantenimientos rutinarios modificados por el usuario

Alerta de trabajos no rutinarios atrasados

Alerta de órdenes de trabajo vencidas

Alerta de equipos con mediciones provenientes de fuentes externas fuera o cerca de límite

Accesa al módulo de alertas para saber lo que tienes que atender

El sistema de mantenimiento cuenta con un módulo de alertas con la finalidad de informar sobre los aspectos relevantes del mantenimiento que necesitan ser atendidos.

El módulo de alertas constituye una forma práctica para navegar por el programa.

Desde el módulo de alertas podrás dirigirte directamente a todo aquello que debes atender

El acceso al módulo de alertas se encuentra en el menú principal del sistema.

En el módulo de alertas podrás consultar y atender:

Alerta de equipos con lecturas desactualizadas

Alerta de equipos con mediciones fuera o cerca de límite

Alerta de equipos fuera de servicio

Alerta de equipos sin plan asignado

Alerta de planes de mantenimiento sin asignar a equipos o inmuebles

Alerta de mantenimientos rutinarios atrasados

Alerta de mantenimientos rutinarios iniciales no confirmados

Alerta de mantenimientos rutinarios modificados por el usuario

Alerta de trabajos no rutinarios atrasados

Alerta de órdenes de trabajo vencidas

Alerta de equipos con mediciones provenientes de fuentes externas fuera o cerca de límite

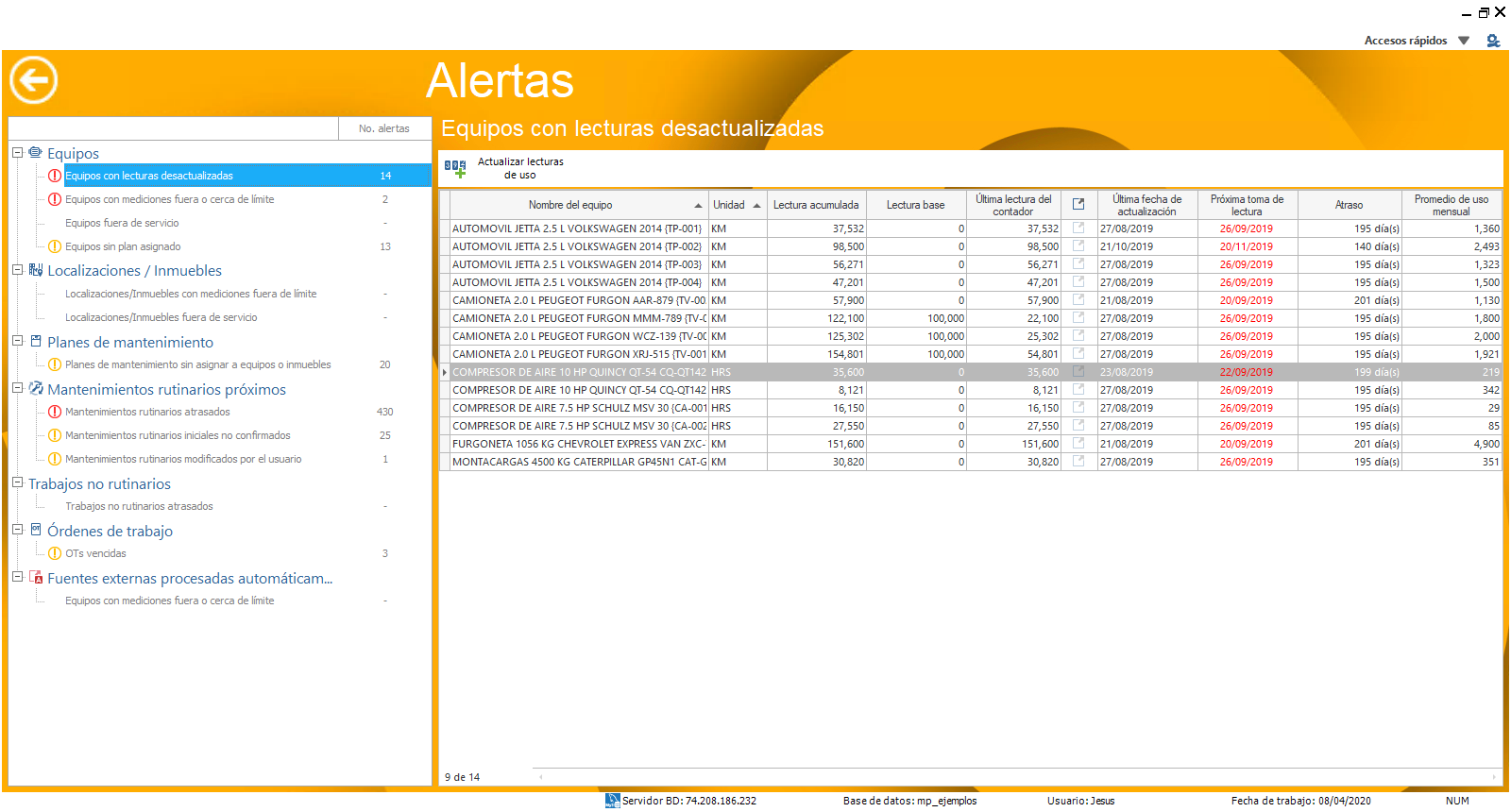

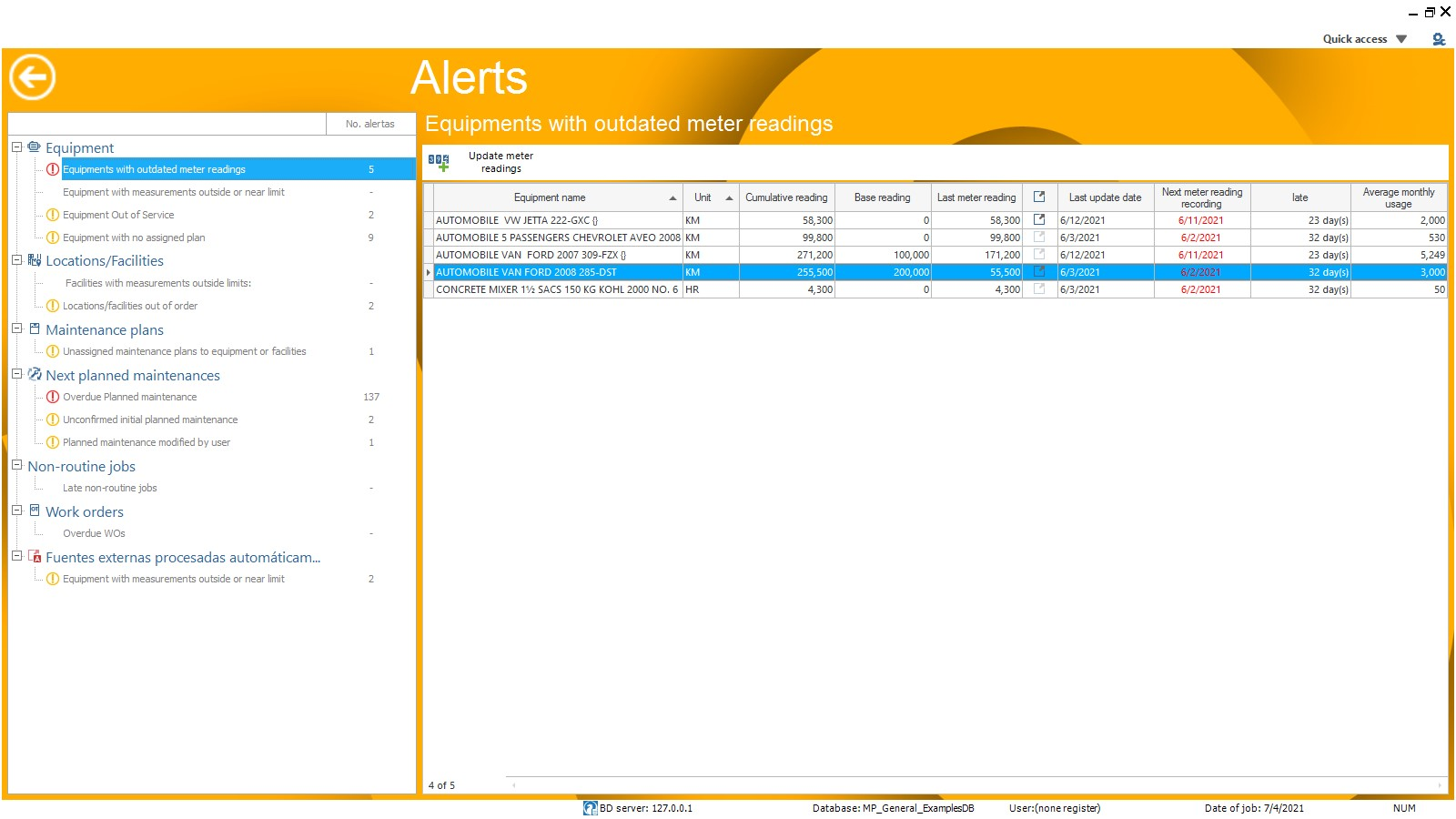

Alerta de equipos con lecturas desactualizadas

Si te aparece una alerta indicando que tienes equipos con lecturas desactualizadas, accesa al módulo. Se mostrarán todos los equipos que requieren actualizar sus lecturas. Desde el módulo podrás actualizar la lectura de todos los equipos que lo requieran.

MÓDULO DE ALERTAS (EQUIPOS CON LECTURAS DESACTUALIZADAS)

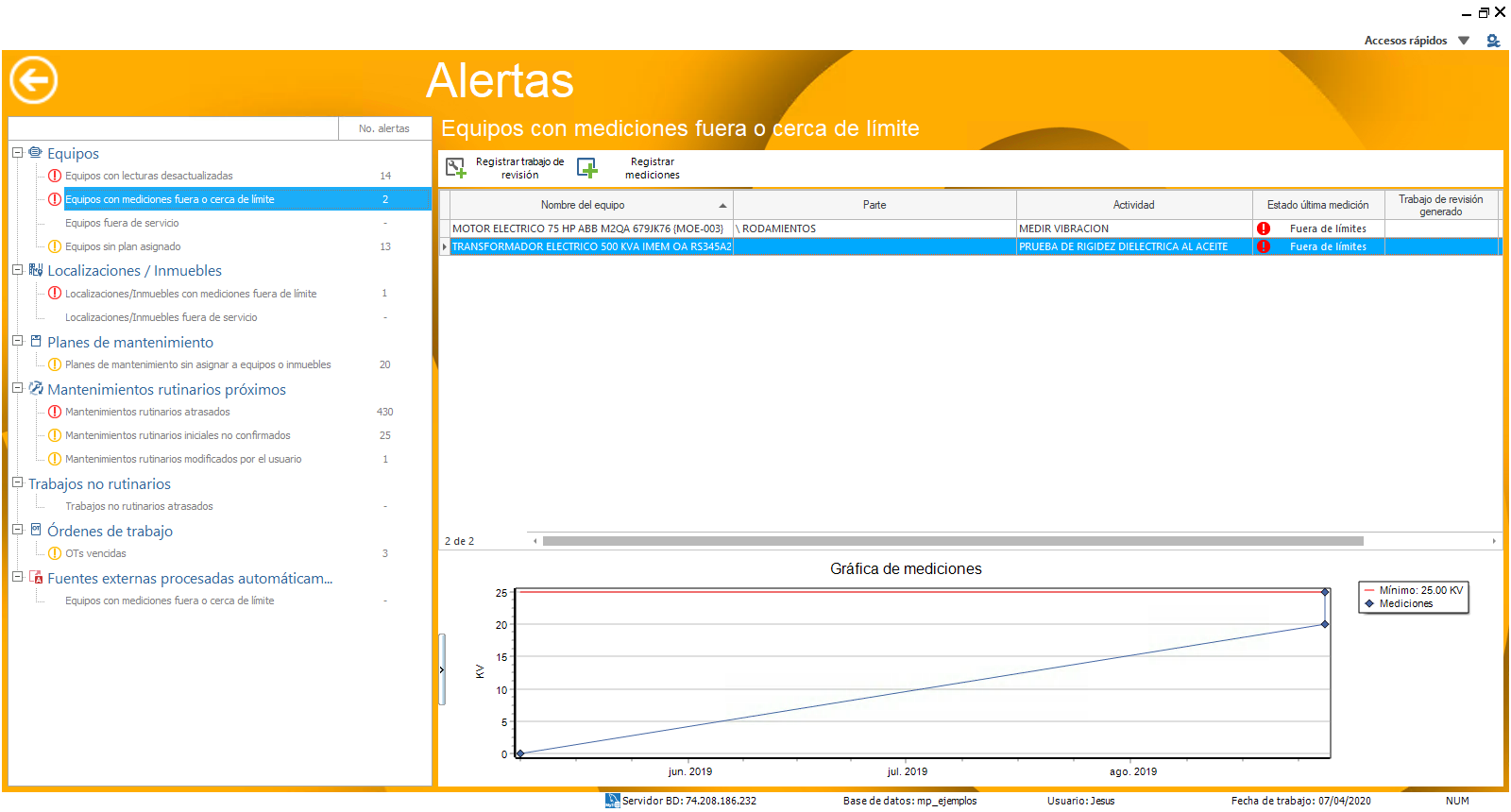

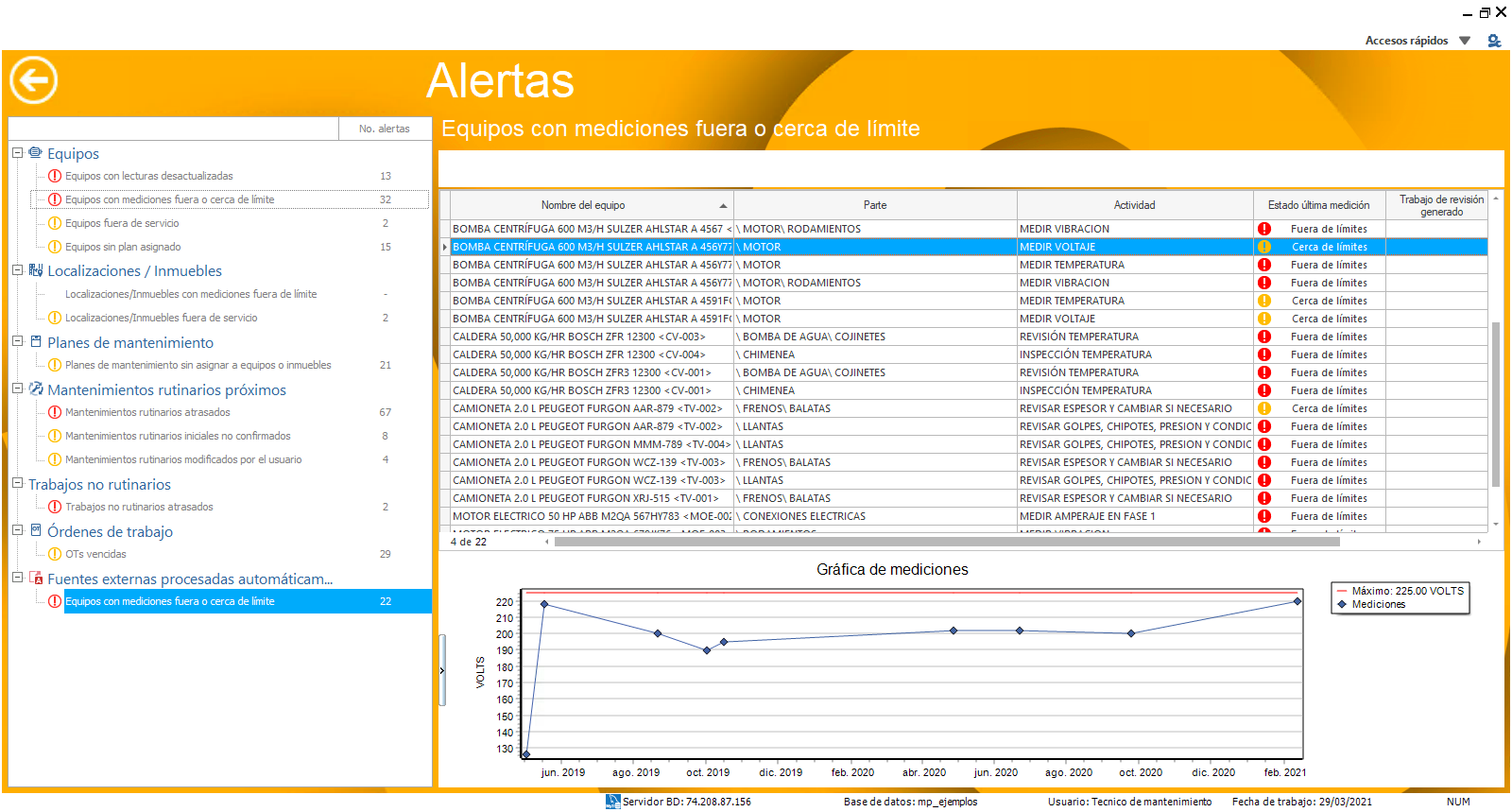

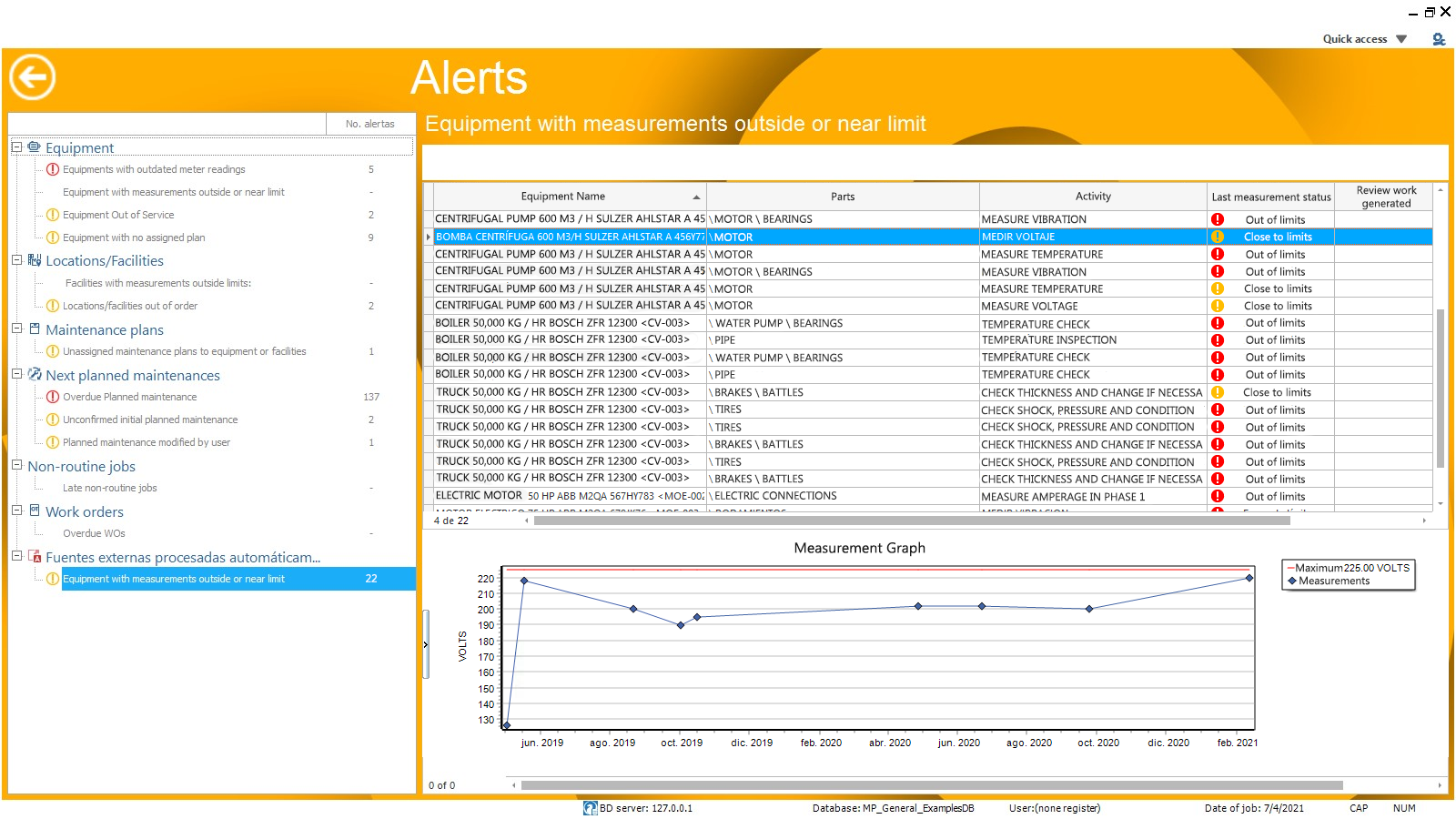

Alerta de equipos con mediciones fuera o cerca de límite

Si te aparece una alerta indicando que tienes equipos con mediciones fuera o cerca de límites accesa al módulo. Se mostrarán todos los equipos que tienen una medición fuera o cercana a los límites.

Desde este módulo podrás registrar una nueva medición. Si la nueva medición está dentro de los límites automáticamente el equipo dejará de aparecer en la lista. De igual forma podrás generar un reporte para que el equipo sea atendido. Una vez reparada la anomalía, deberás registrar una nueva medición y cuando ésta esté dentro de los límites el equipo dejará de aparecer en la lista.

MÓDULO DE ALERTAS (EQUIPOS CON MEDICIONES FUERA O CERCA DE LÍMITES)

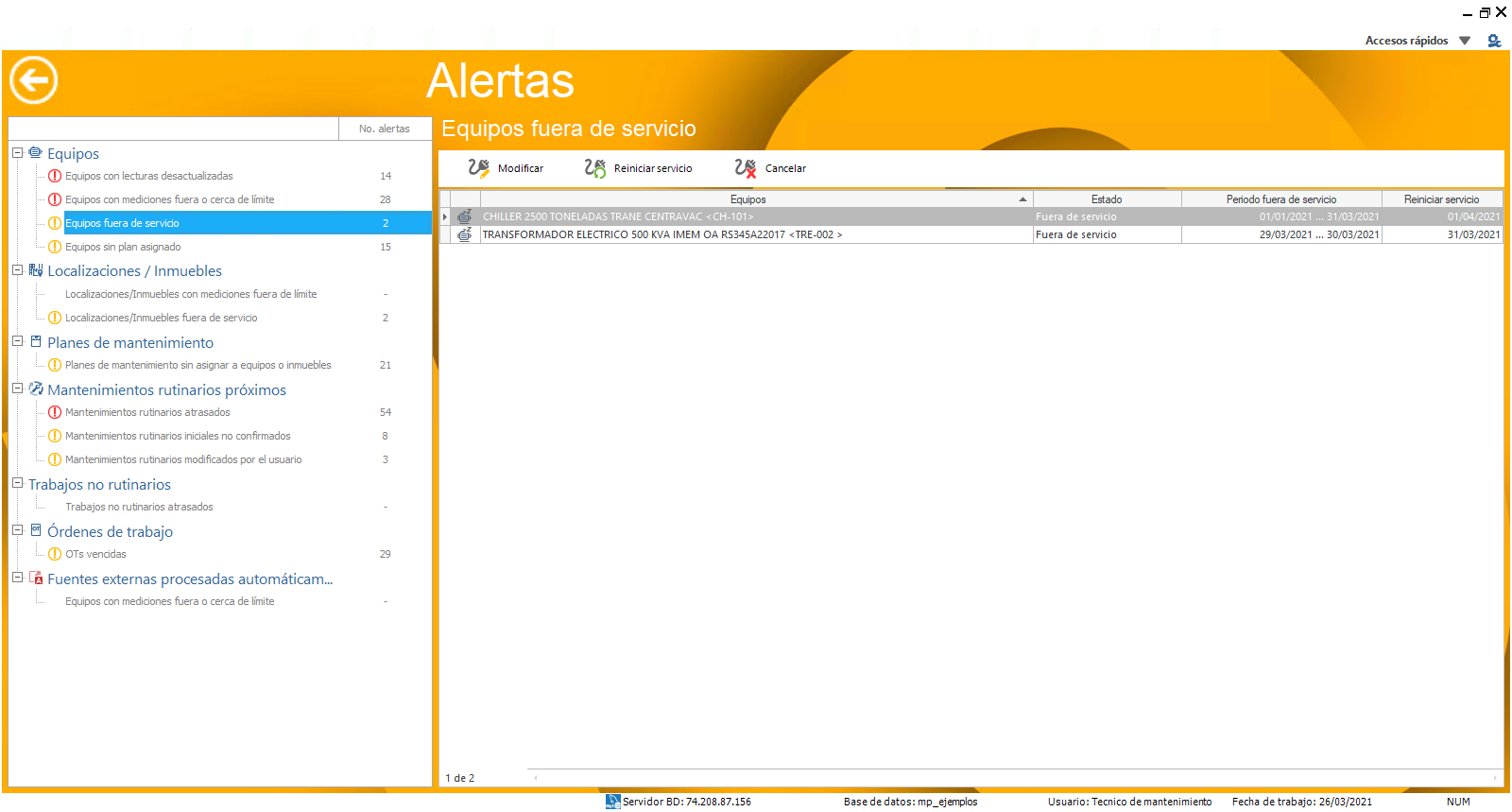

Alerta de equipos fuera de servicio

En esta sección se muestran todos los equipos que han sido marcados como fuera de servicio, desde aquí, podemos modificar la fecha en que se pondrán nuevamente en marcha, indicar que reiniciará su servicio, o bien, cancelar el estado fuera de servicio.

Es importante recordar que al marcar los equipos o localizaciones fuera de servicio, las fechas de mantenimientos próximos que se tenían inicialmente programadas, el sistema las recalcula, desplazándolas un periodo de tiempo igual al tiempo que estarán fuera de servicio.

Alerta de equipos sin plan asignado

Una parte fundamental para el control del mantenimiento rutinario es la formación de planes o rutinas de mantenimiento.

Los planes o rutinas de mantenimiento son modelos que contienen la información respecto a las actividades de mantenimiento rutinario que deben realizarse a los equipos. Las actividades de mantenimiento rutinario generalmente consisten en acciones enfocadas a prevenir fallas y se realizan en forma cíclica y repetitiva con una frecuencia determinada.

Para controlar el mantenimiento rutinario, es necesario ligar cada equipo o localización con un plan de mantenimiento, ya que el plan de mantenimiento (maestro) es el que contiene la información acerca de las actividades rutinarias que deben realizarse.

Si te aparece una alerta indicando que tienes equipos sin plan asignado, deberás entrar al módulo para ligar los equipos con un plan de mantenimiento.

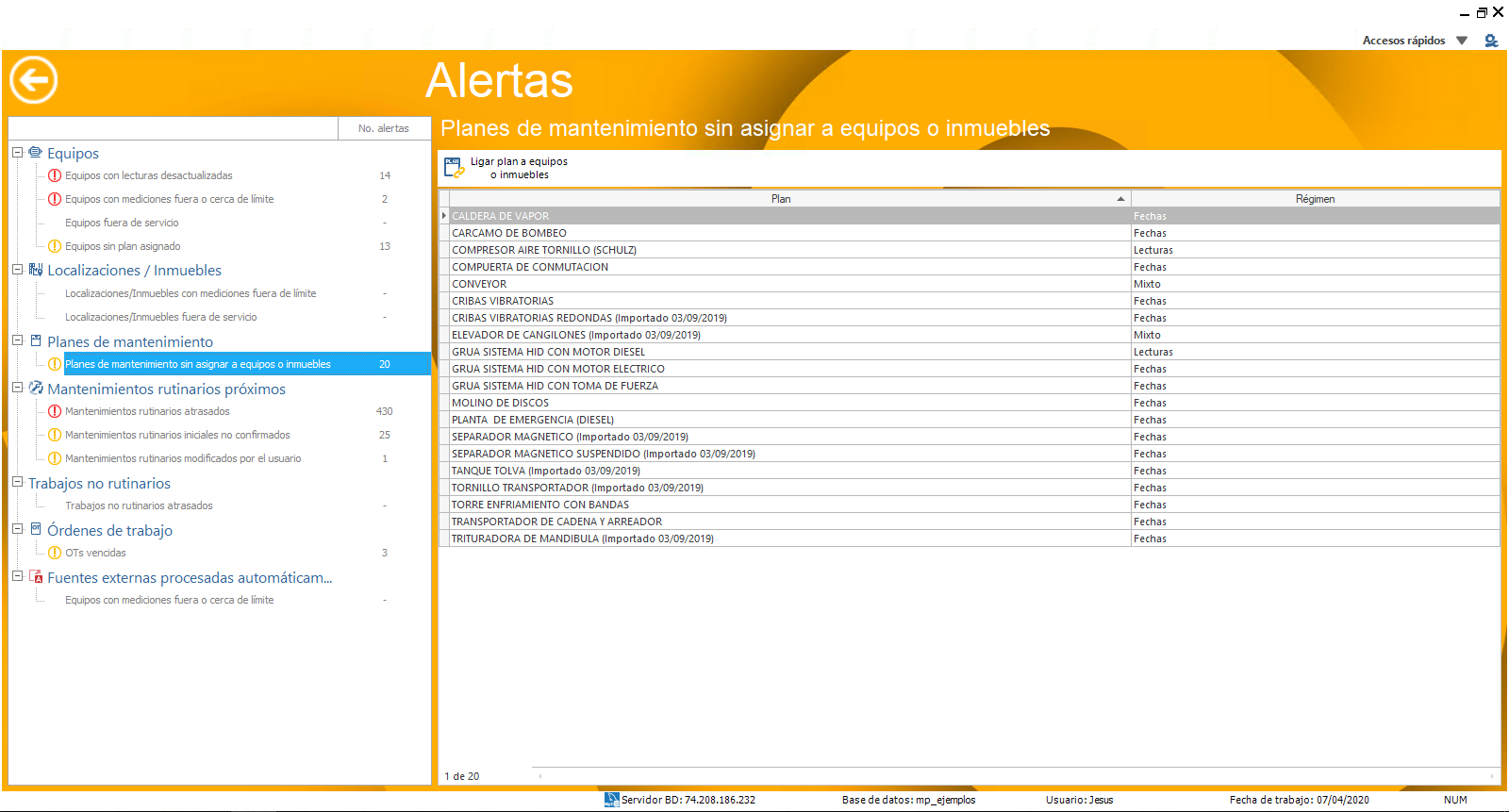

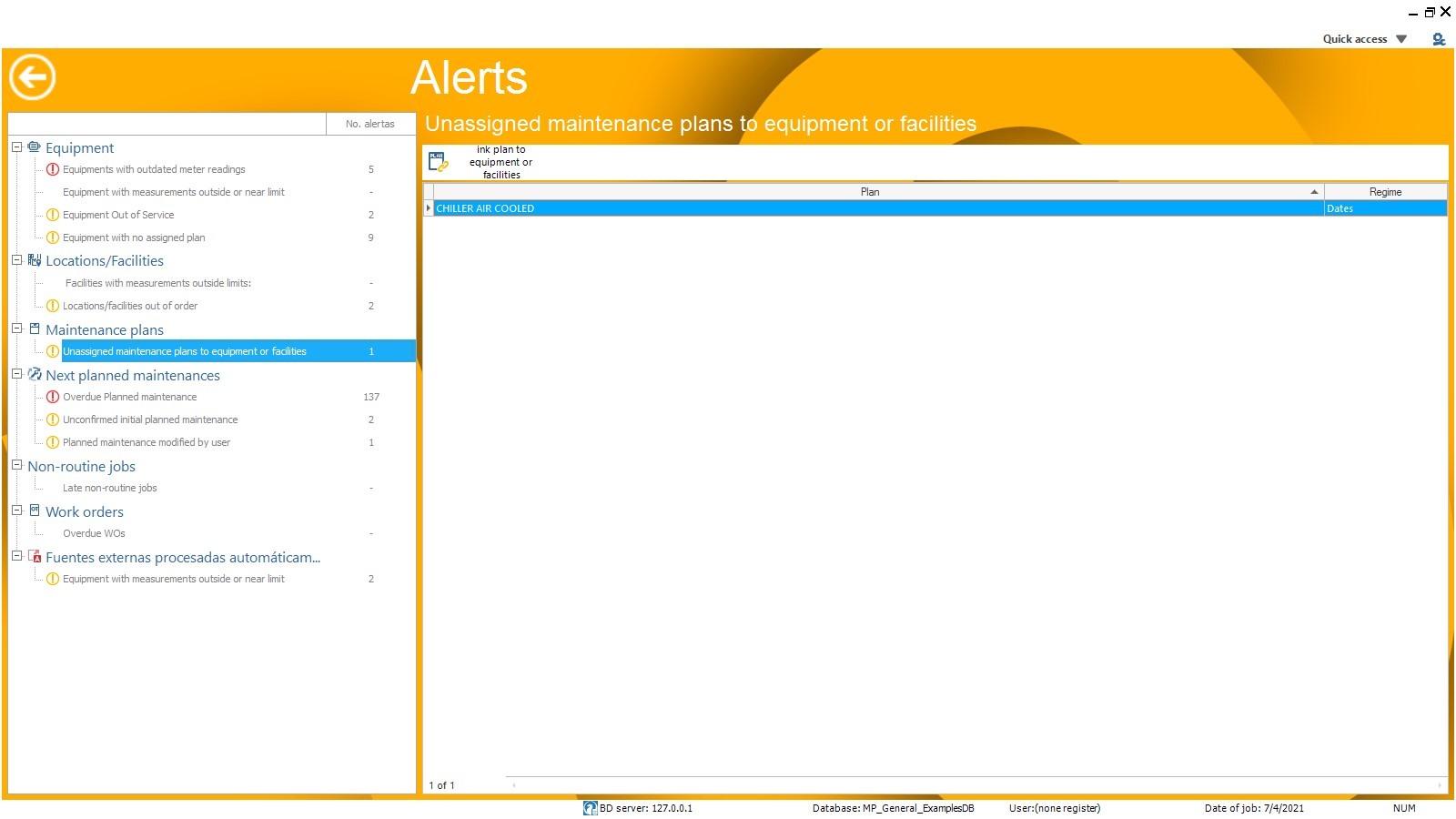

Alerta de planes de mantenimiento sin asignar a un equipo o localización

Una parte fundamental para el control del mantenimiento rutinario es la formación de planes o rutinas de mantenimiento.

Los planes o rutinas de mantenimiento son modelos que contienen la información respecto a las actividades de mantenimiento rutinario que deben realizarse a los equipos. Las actividades de mantenimiento rutinario generalmente consisten en acciones enfocadas a prevenir fallas y se realizan en forma cíclica y repetitiva con una frecuencia determinada.

Para controlar el mantenimiento rutinario, es necesario ligar cada equipo o localización con un plan de mantenimiento, ya que el plan de mantenimiento (maestro) es el que contiene la información acerca de las actividades rutinarias que deben realizarse.

Si te aparece una alerta indicando que tienes planes de mantenimiento que no han sido asociados con equipos o localizaciones, accesa el módulo para ligar con un equipo o localización los planes de mantenimiento que tienes aún sin asociar.

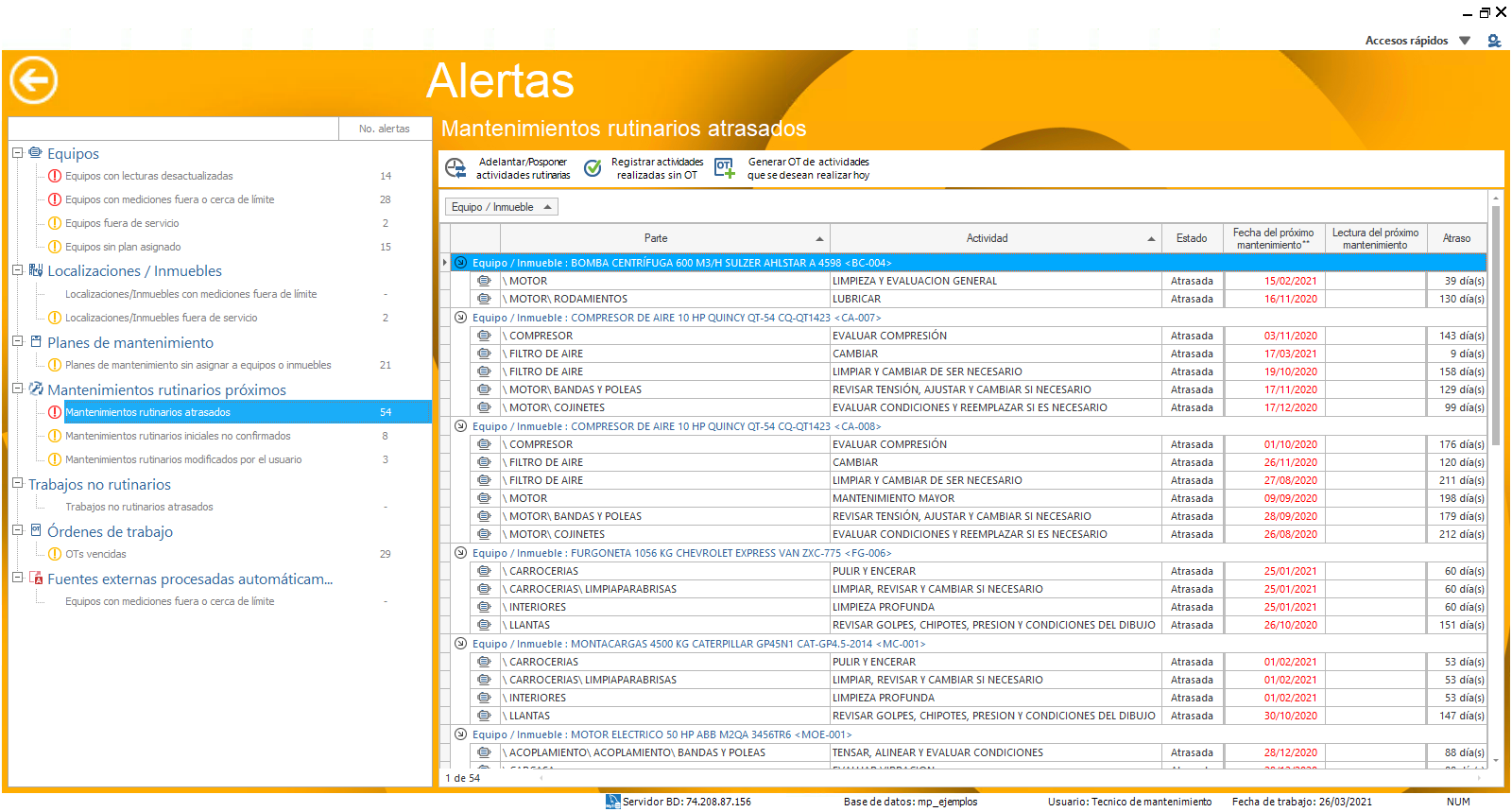

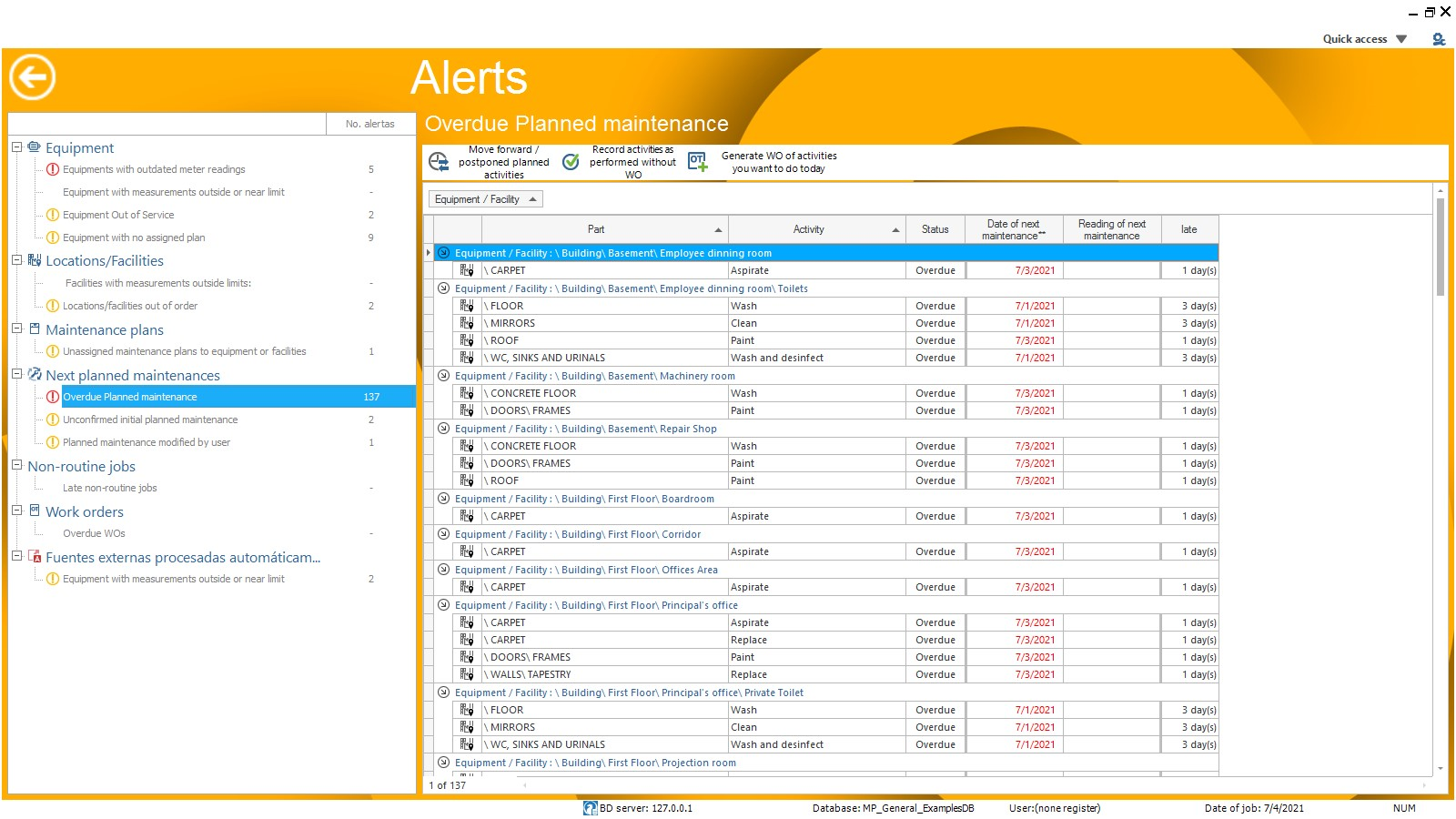

Alerta de mantenimientos rutinarios atrasados

Si te aparece una alerta indicando que tienes mantenimientos rutinarios atrasados, accesa al módulo. Se mostrará una lista con todos los mantenimientos rutinarios atrasados agrupados por equipo o inmueble, indicando la fecha que se tenía pogramada para realizar la actividad, así como los días de atraso.

Desde este módulo podrás adelantar o posponer las actividades, registrar las actividades realizadas sin OT y generar OT’s de las actividades que desees realizar en ese momento.

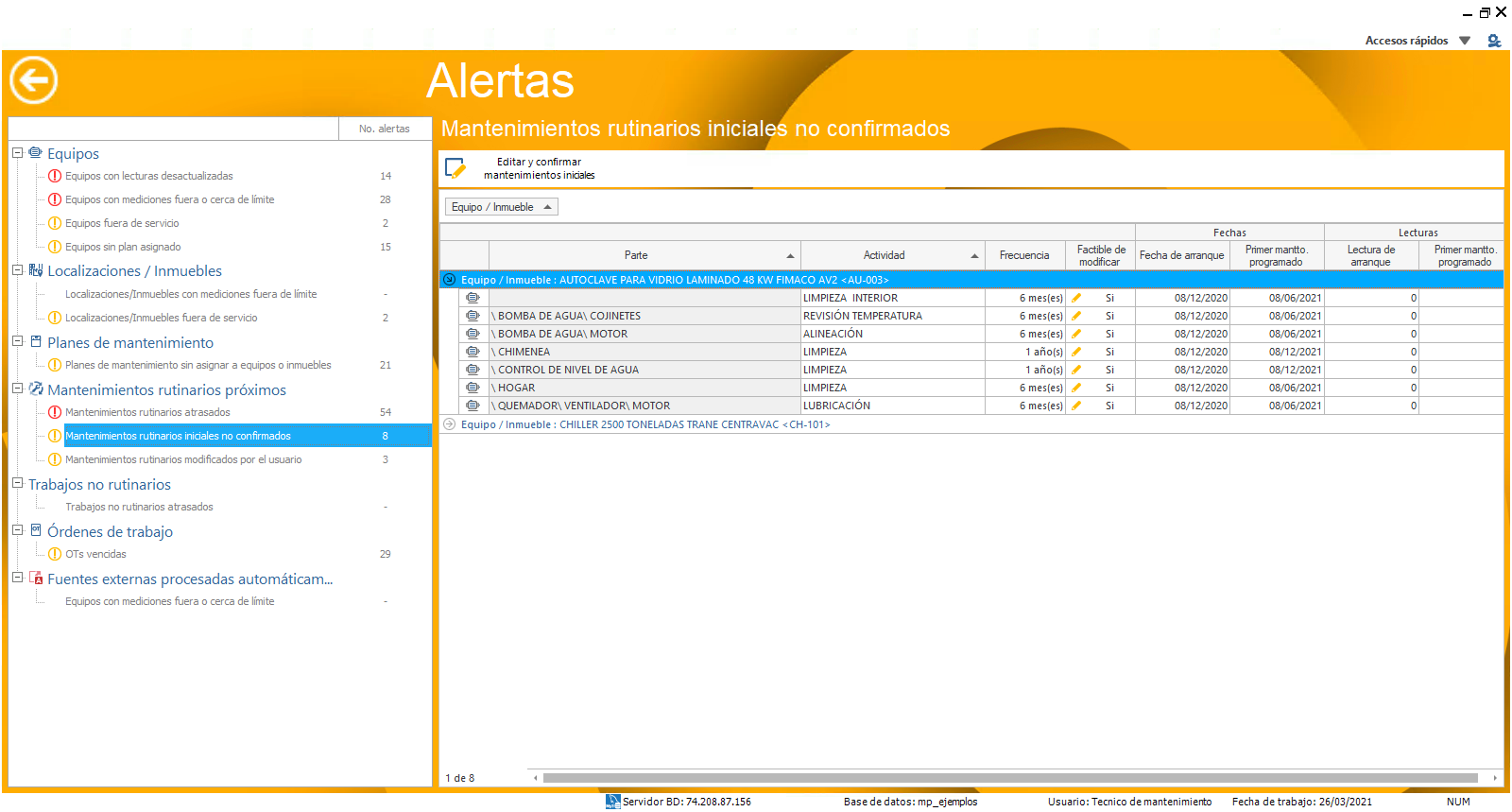

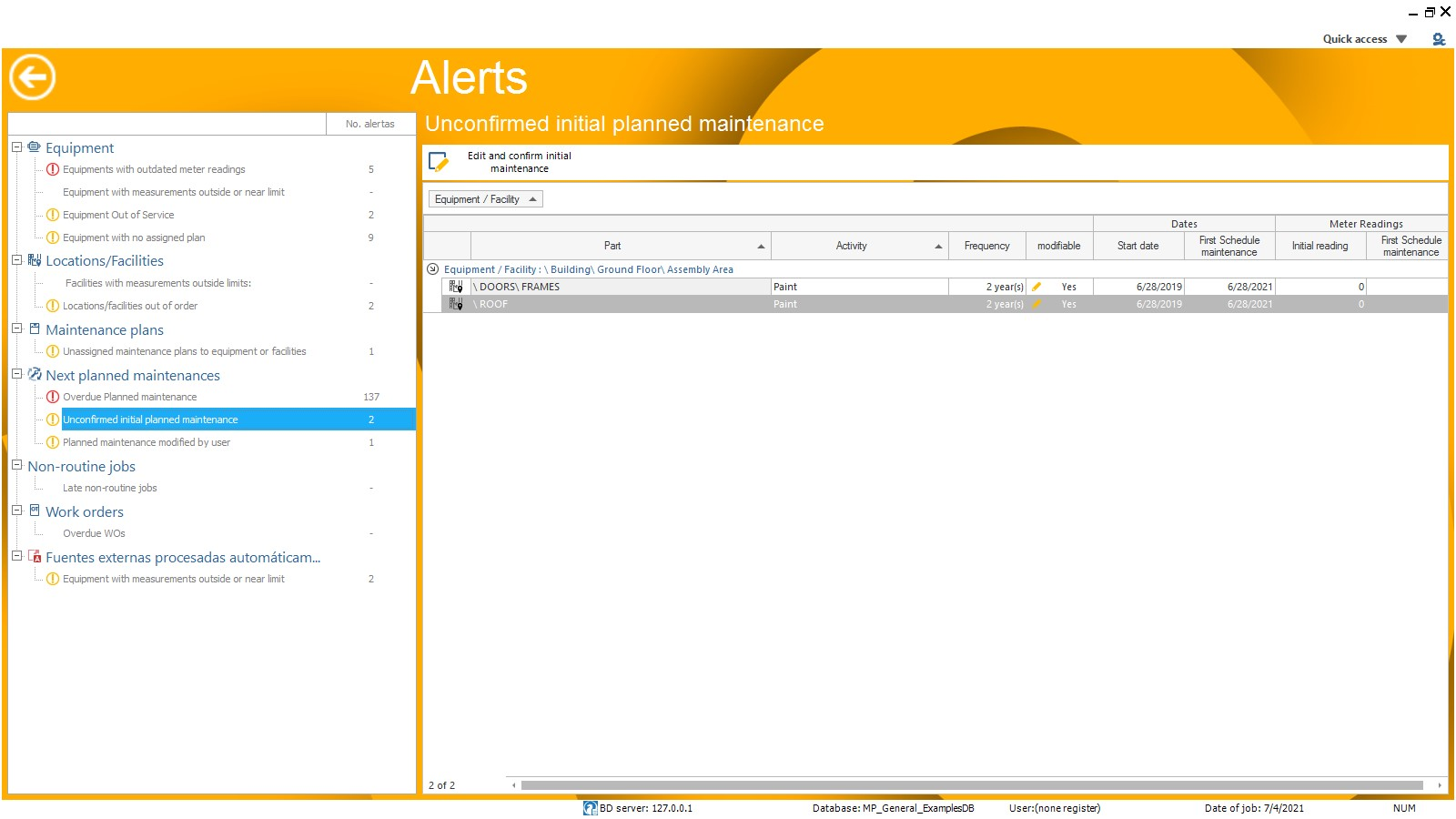

Alerta de mantenimientos rutinarios iniciales no confirmados

Si te aparece una alerta indicando que tienes mantenimientos rutinarios iniciales no confirmados, accesa al módulo. Se mostrarán los equipos cuyos mantenimientos rutinario iniciales (fechas de arranque o lecturas de arranque) no han sido confirmados. Desde este módulo podrás editar y confirmar los mantenimientos iniciales.

Al confirmar los mantenimientos iniciales o fechas de arranque, el usuario deja asentado en el sistema que ha revisado las fechas o lecturas de arranque y que por lo tanto, se puede proceder a generar las órdenes de trabajo. Esto resulta importante, ya que una vez que se incluye una actividad en una orden de trabajo, ya no será factible modificar sus mantenimientos iniciales o fechas de arranque.

La finalidad de esta confirmación es garantizar que el sistema arranca con información real que corresponda a los últimos mantenimientos realizados físicamente a los equipos, sin embargo, si el usuario no confirma, podrá proseguir con la elaboración de órdenes de trabajo con las fechas o lecturas de arranque que se tengan registradas.

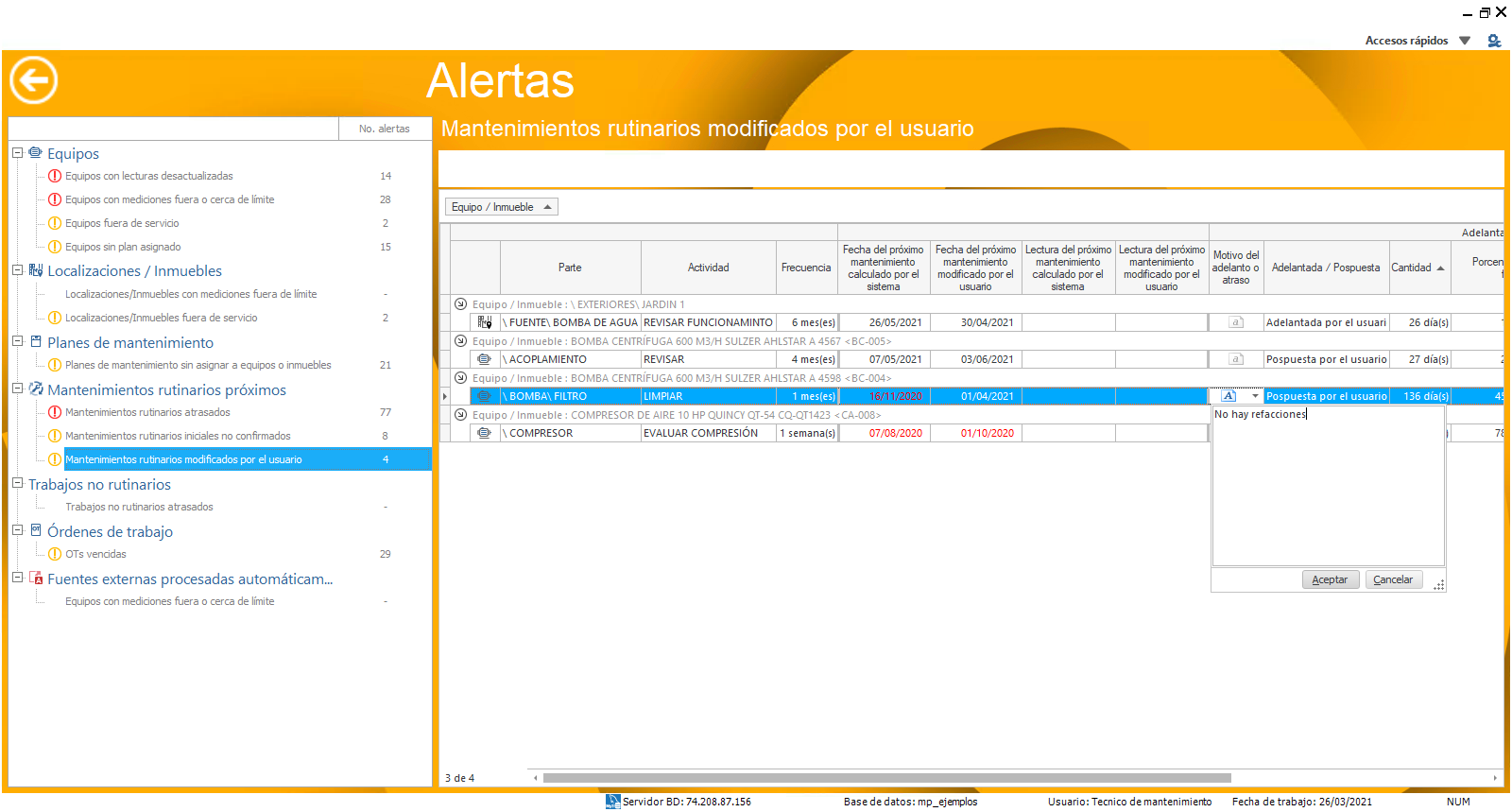

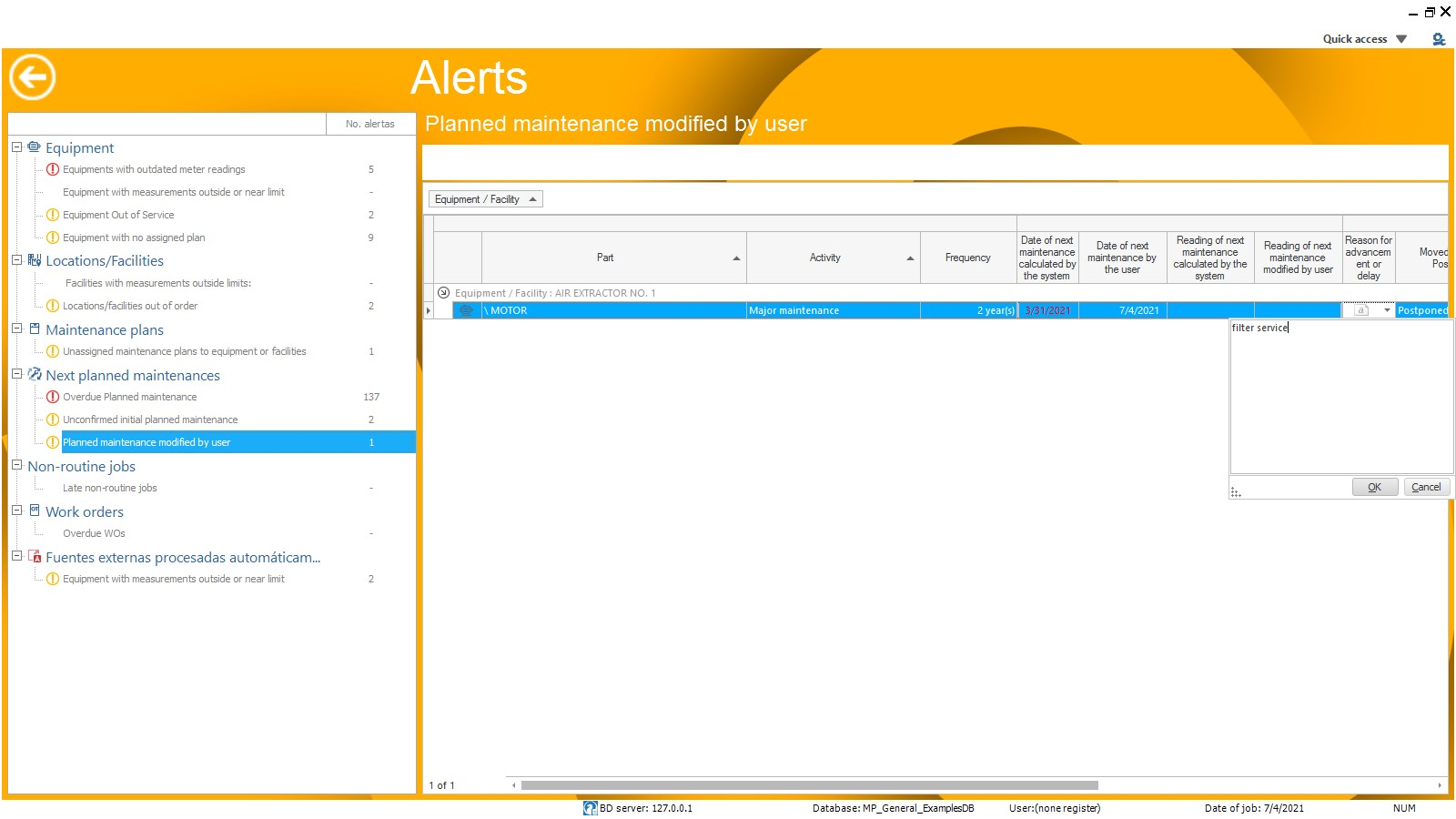

Alerta de mantenimientos rutinarios modificados por el usuario

Si te aparece una alerta indicando que existen Mantenimientos rutinarios modificados por el usuario, accesa al módulo. Se mostrarán todas las actividades cuyas fechas de próximo mantenimiento hayan sido adelantadas o pospuestas por un usuario. Podrás consultar la fecha o lectura del próximo mantenimiento que había calculado el sistema, la fecha o lectura editada por el usuario, así como el motivo descrito por el usuario para justificar la modificación.

Alerta de trabajos no rutinarios atrasados

Si te aparece una alerta indicando que existen Trabajos no rutinarios atrasados, accesa al módulo. Se mostrarán todos los trabajos no rutinarios atrasados, mostrando la falla reportada, la fecha en que se reportó la falla, la fecha que se tenía pogramada para realizar la actividad, así como los días de atraso. Desde este módulo podrás editar el trabajo no rutinario seleccionado.

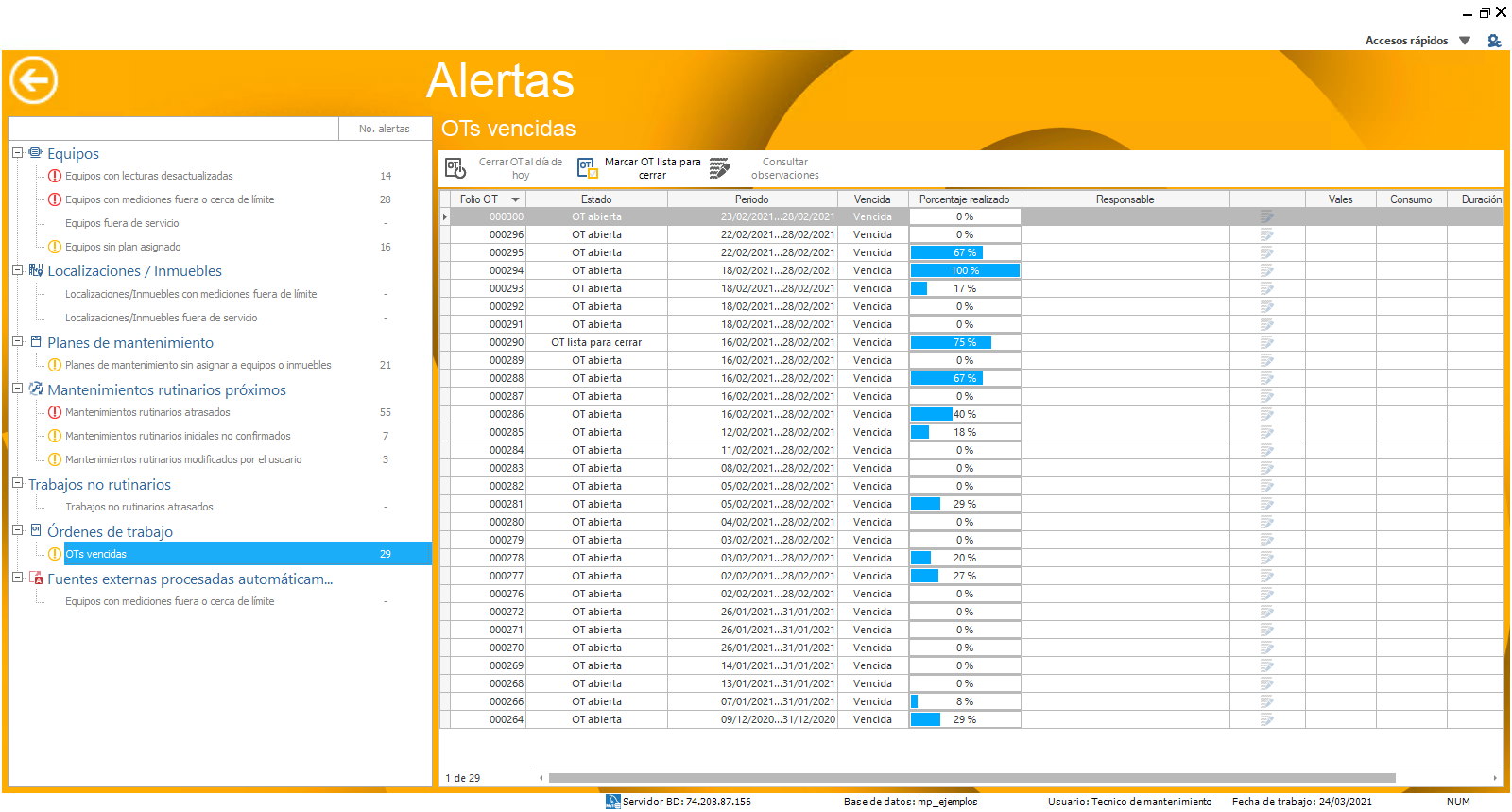

Alerta de órdenes de trabajo vencidas

Si te aparece una alerta indicando que existen Órdenes de trabajo vencidas, accede al módulo. Se mostrarán las órdenes de trabajo vencidas que han excedido la tolerancia en días para ser actualizadas y cerrarlas. Desde este módulo podrás marcar dichas órdenes como listas para cerrar y/o cerrarlas, a modo de no estar acarreando OTs vencidas por demasiado tiempo.

En opciones de configuración el usuario establece dicha tolerancia de acuerdo a su propio criterio.

Alerta de equipos con mediciones provenientes de fuentes externas fuera o cerca de límite

Si te aparece una alerta indicando que tienes mediciones provenientes de fuentes externas fuera o cercanas a límites, accesa al módulo. Se mostrarán todos los equipos que tienen una medición fuera o cercana a los límites.

Desde este módulo podrás generar un reporte para que el equipo sea atendido. Una vez reparada la anomalía, deberás registrar una nueva medición y cuando ésta esté dentro de los límites el equipo dejará de aparecer en la lista.

¿No encuentras la respuesta a tus dudas o preguntas?

Opcionalmente ofrecemos cursos de capacitación

Nuestras opciones flexibles de capacitación online y presenciales te brindarán todo el conocimiento necesario para comprender e implementar tu software de mantenimiento.