Home / Inventory of spare parts

What is physical inventory?

The program inventory of spare parts has a powerful tool to facilitate the conduct of physical inventories.

Physical inventory is a manual count of the products in a store.

It is necessary to do it every certain time, so that you can identify, review, and compare the stocks that are registered with the that there really is. That is to say, a physical inventory is used to compare the actual stock with the amounts that are on the program of inventory of spare parts.

The purpose of a physical inventory is:

- Calculate what items to match in number and which are not

- To locate the possible origins of the descuadre

- Detect leaks and broken items or defective

Given that you can't stop the maintenance work in a company, close the store of spare parts by one or several days to perform the physical inventory is not an option.

The tool included with the program inventory of spare parts for the completion of the physical inventory is extremely practical, as it allows you to perform the count by parts, without interfering in the store.

Generate new physical inventory

The process for conducting a physical inventory from the inventory of spare parts, begins with the creation of a document physical inventory that contains the spare parts that are going to be inventory. It could be for example, spare parts located in a hallway or shelf particular.

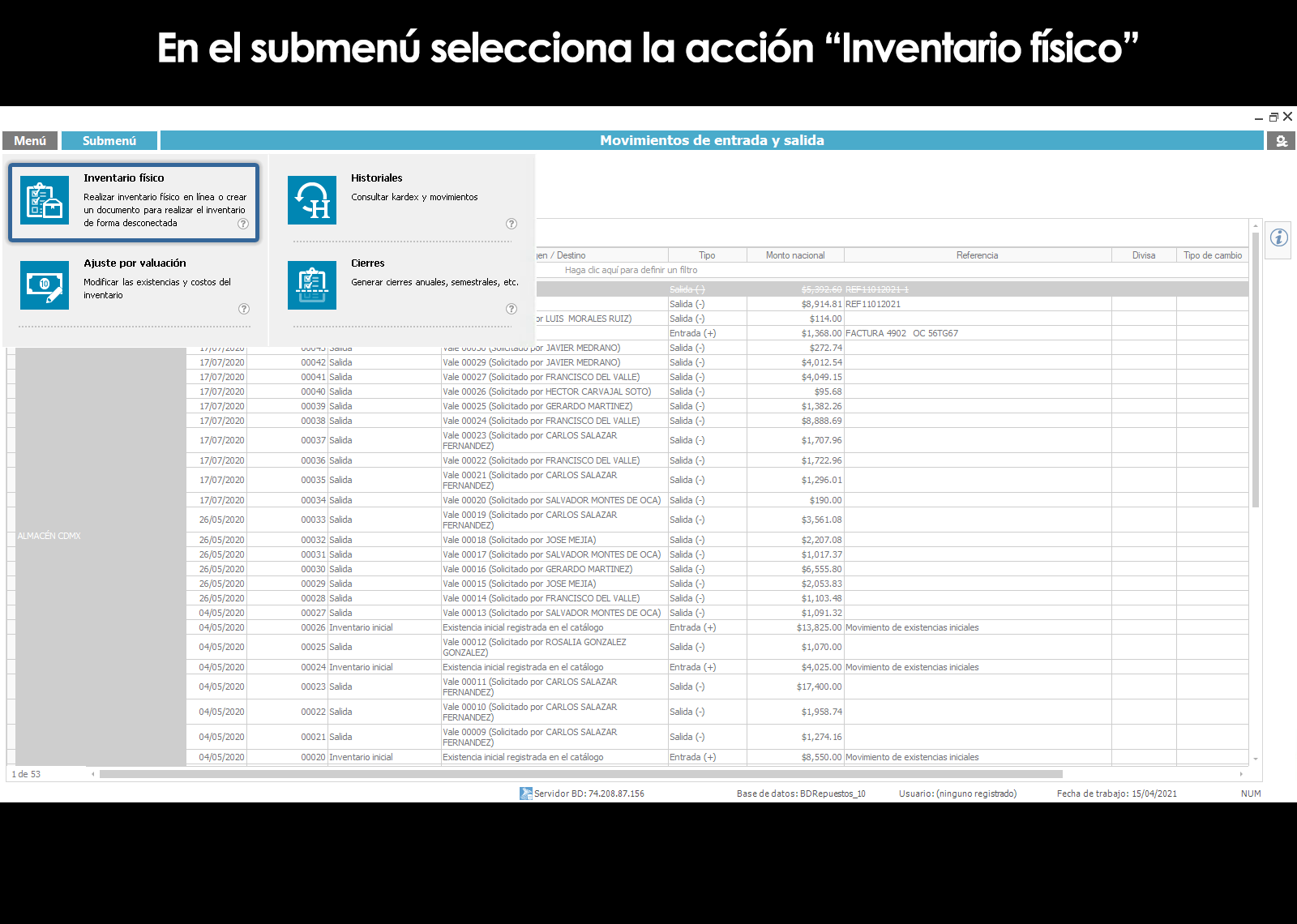

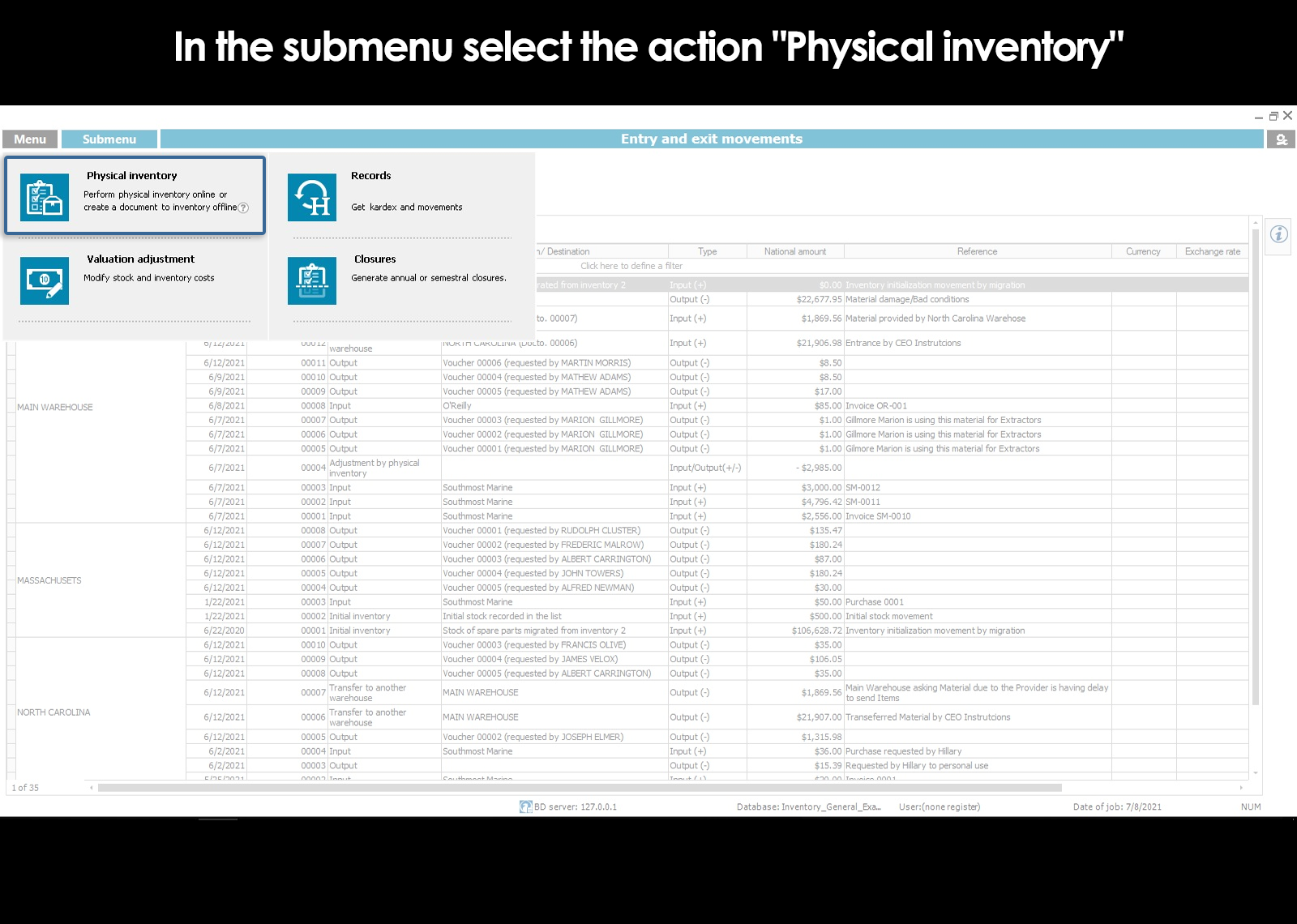

To create a new document physical inventory, log in to the tool physical inventory located in the submenu of the module movements of input and output the program of inventory of spare parts.

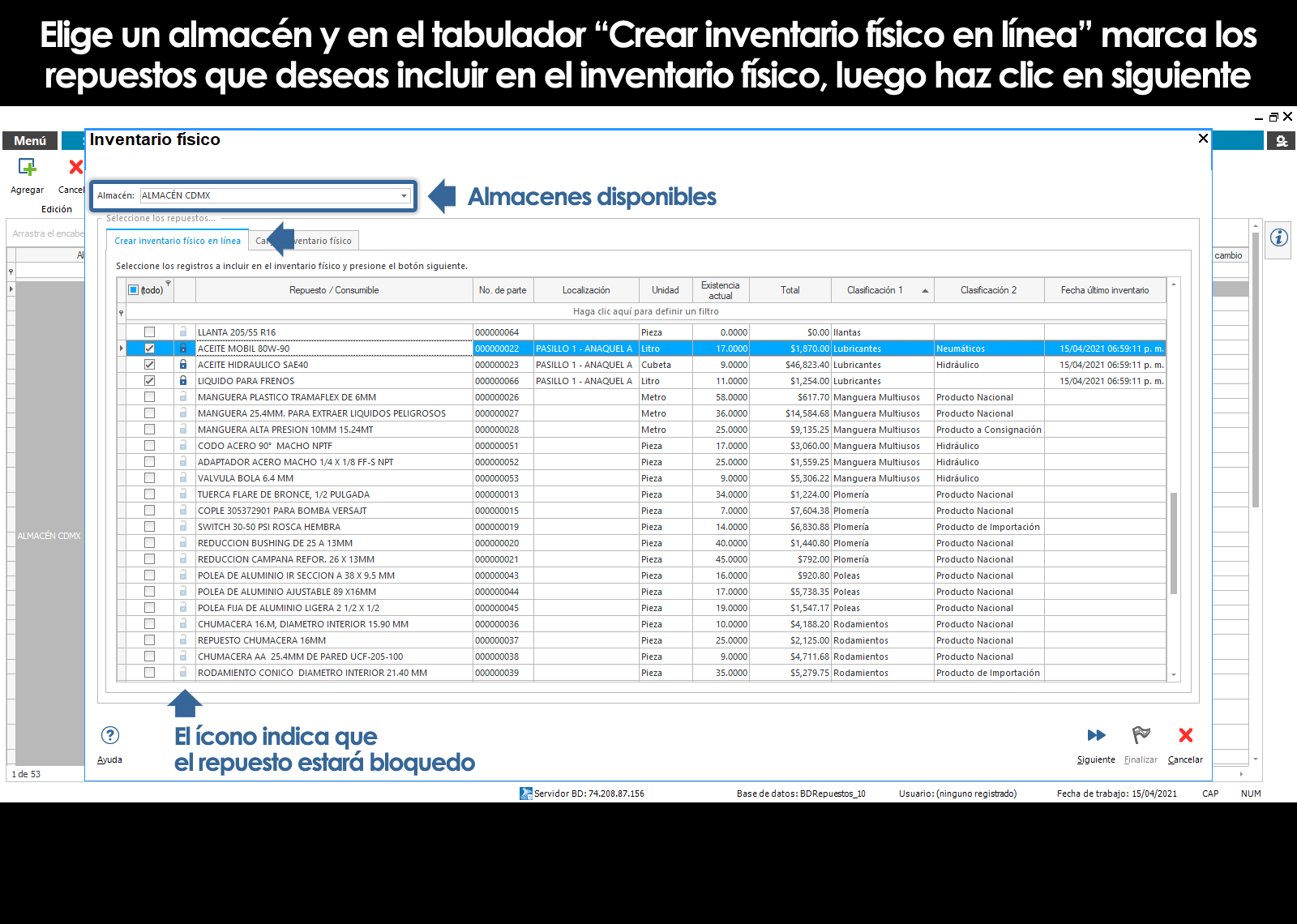

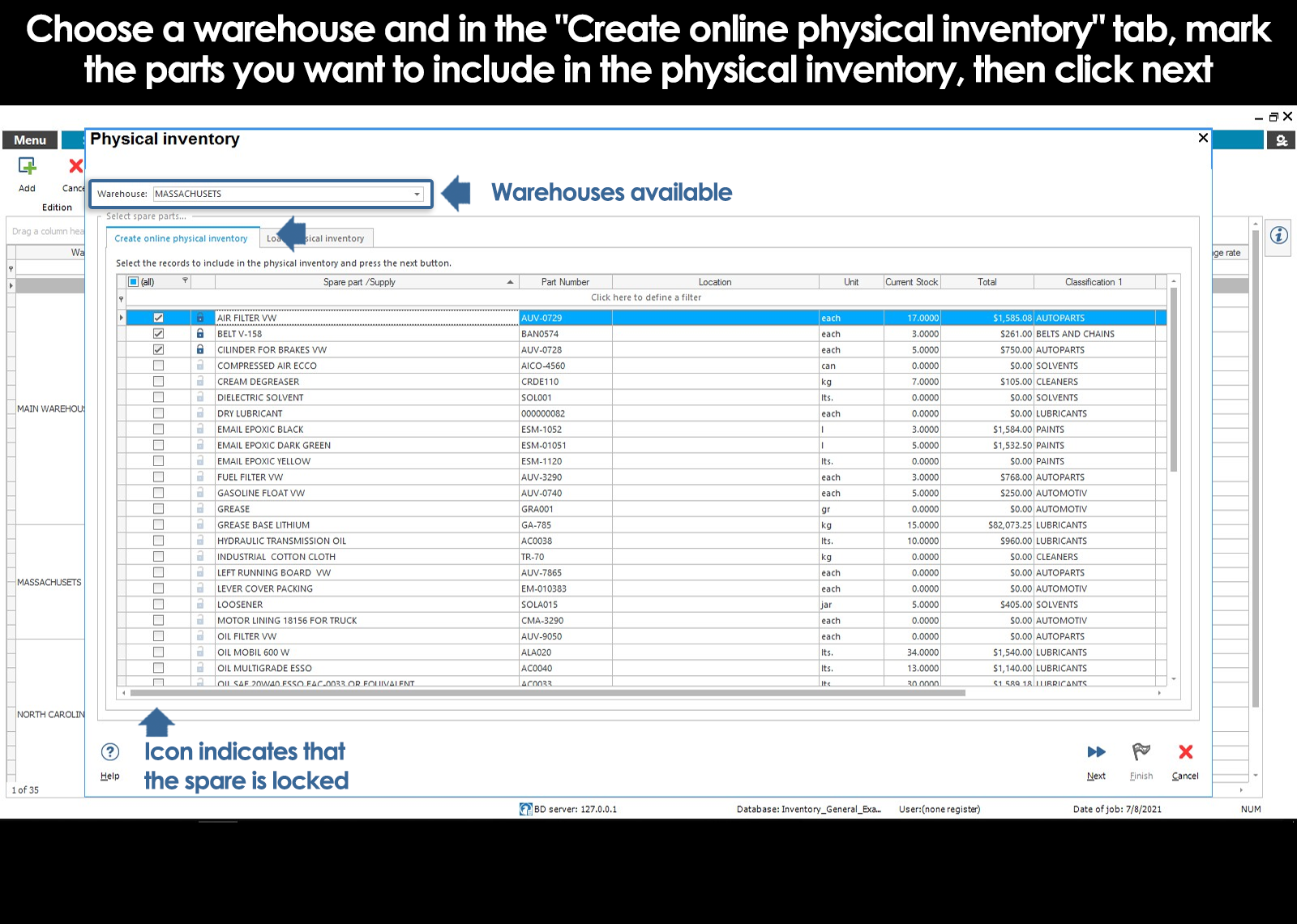

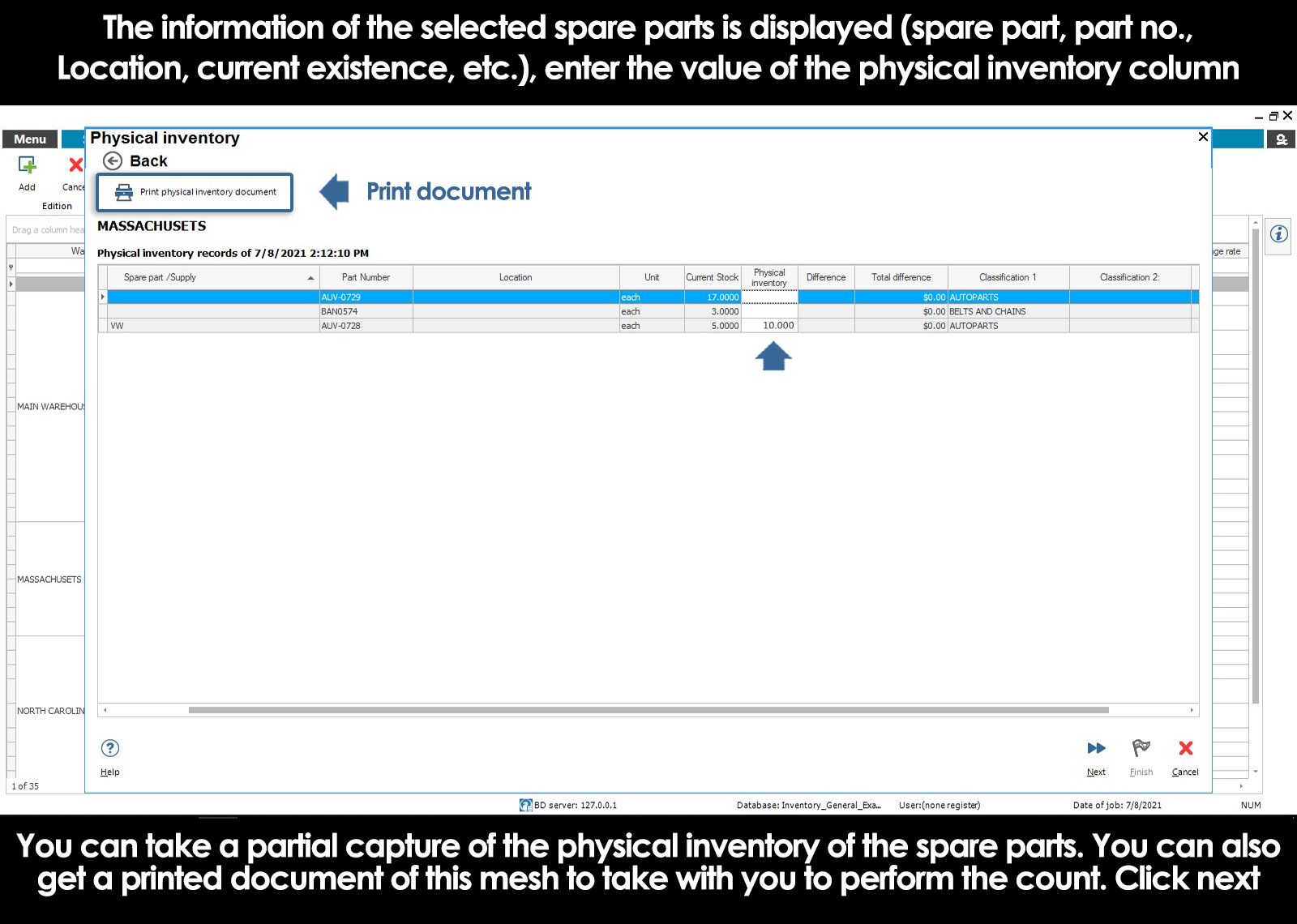

The program will prompt you to enter the store, and the parts that you want to inventory by checking the selection box. You can print a list of the spare parts inventory to give to the person in charge of such a count.

The parts that are inside a document physical inventory are blocked by the system. However, if the wholesaler is required or have the need to make a move out you can do this and in auto the system will low the replacement of the product listing to inventory and inventariarlo later.

The next step is to register in the program data obtained in the physical count.

Once you have registered the physical count total or partial will be able to go, releasing the parts that have already been inventoried. Spare parts released will disappear from the list.

You can also save the progress in the physical inventory, and resume it later, using the tool “Load physical inventory”.

Free spare parts are inventoried and create movements of adjustment

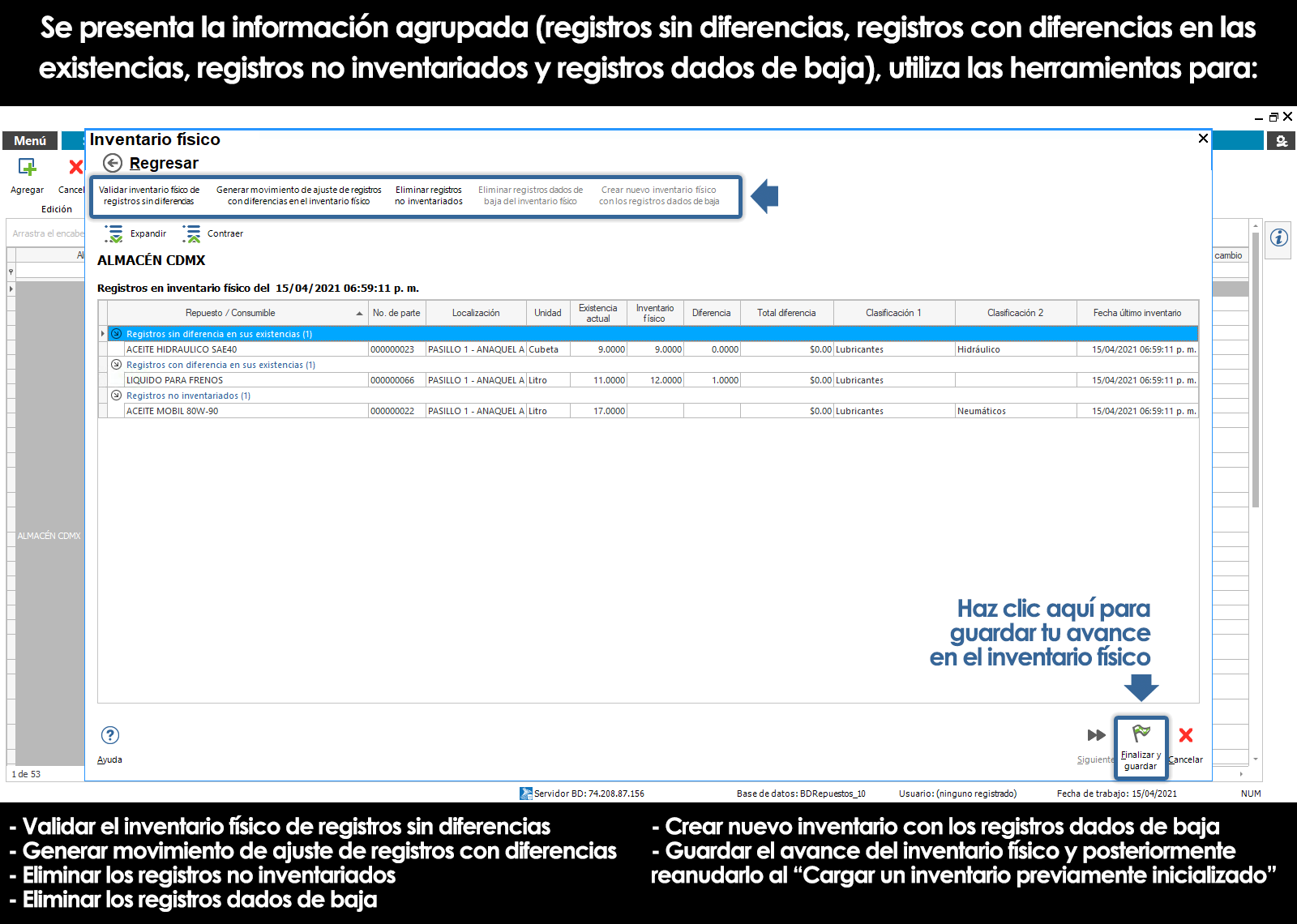

As you're registering the stock a result of the physical count, spare parts and consumables are grouped in 4 categories:

| Category | Action to perform |

|---|---|

| 1. RECORDS WITH NO DIFFERENCES IN THEIR INVENTORY |

|

| The physical count is equal to the amount documented in the program. | Click Validate inventory physical records without differences.

All the parts already inventoried, and that showed no differences will be released and removed from the list. |

| 2. RECORDS WITH DIFFERENCES IN THEIR INVENTORY | |

| The physical count is different to the amount that is documented in the program. | Click Generate movements of setting records with differences in their inventory

It will generate a movement of adjustment to match the stocks of the program with the physical stock. The movements of setting uses the costing method default to calculate the amount of the movement. The parts involved will be released and removed from the list. |

| 3. RECORDS ARE NOT INVENTORIED | |

| Are spare parts, or consumables that have not been counted physically but are included in the document physical inventory. | Performs the count and record the data obtained, or, click on Delete records not inventoried to remove the spare parts list and set them free. |

| 4. RECORDS TERMINATED | |

| A spare is removed from the document physical inventory when it generates a movement of the input or output that involves such a replacement. Even when the parts are locked by the system when it is in a document of the physical inventory, the carrying out of maintenance work can't stop, because of this, when you generate a movement with products that are inventorying, the program displays an alert and informs you that the spare is located in physical inventory. If the wholesaler decides to continue with the movement, the system will low the replacement of the document physical inventory. | Click Delete records released low to remove the spare parts list and set them free, or, press Create a physical inventory with the records given to low to remove them from the list and generate a new document physical inventory with the parts that were of low inventory. |

When the list of spare parts of the document physical inventory is empty, you're done with the physical inventory.

For each spare inventory shall be recorded the date and time that is registered in the system your last physical count.

By clicking End and save you'll be able to save the progress in the physical inventory, and resume it later, using the tool “Load physical inventory”.

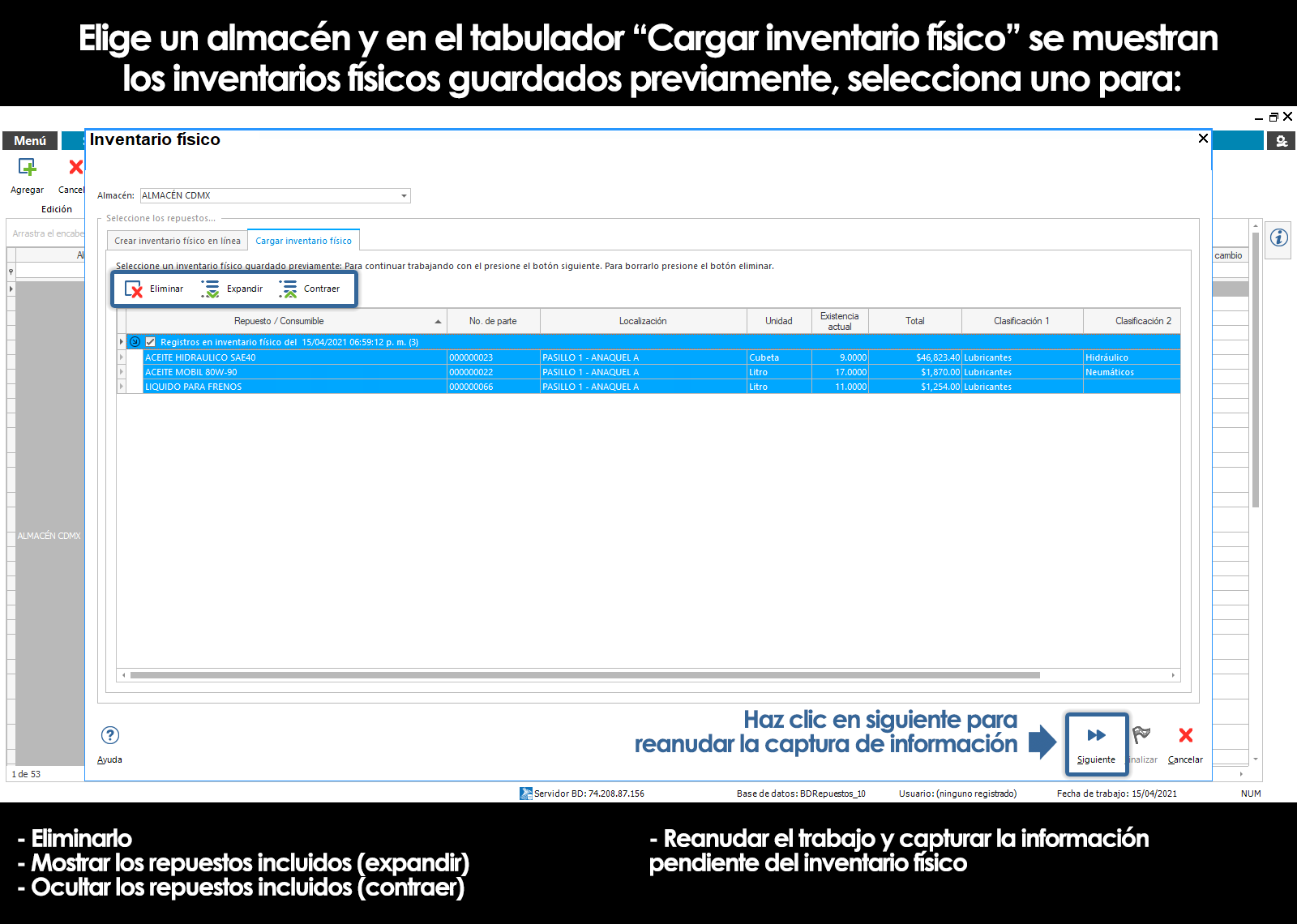

Upload physical inventory previously initiated

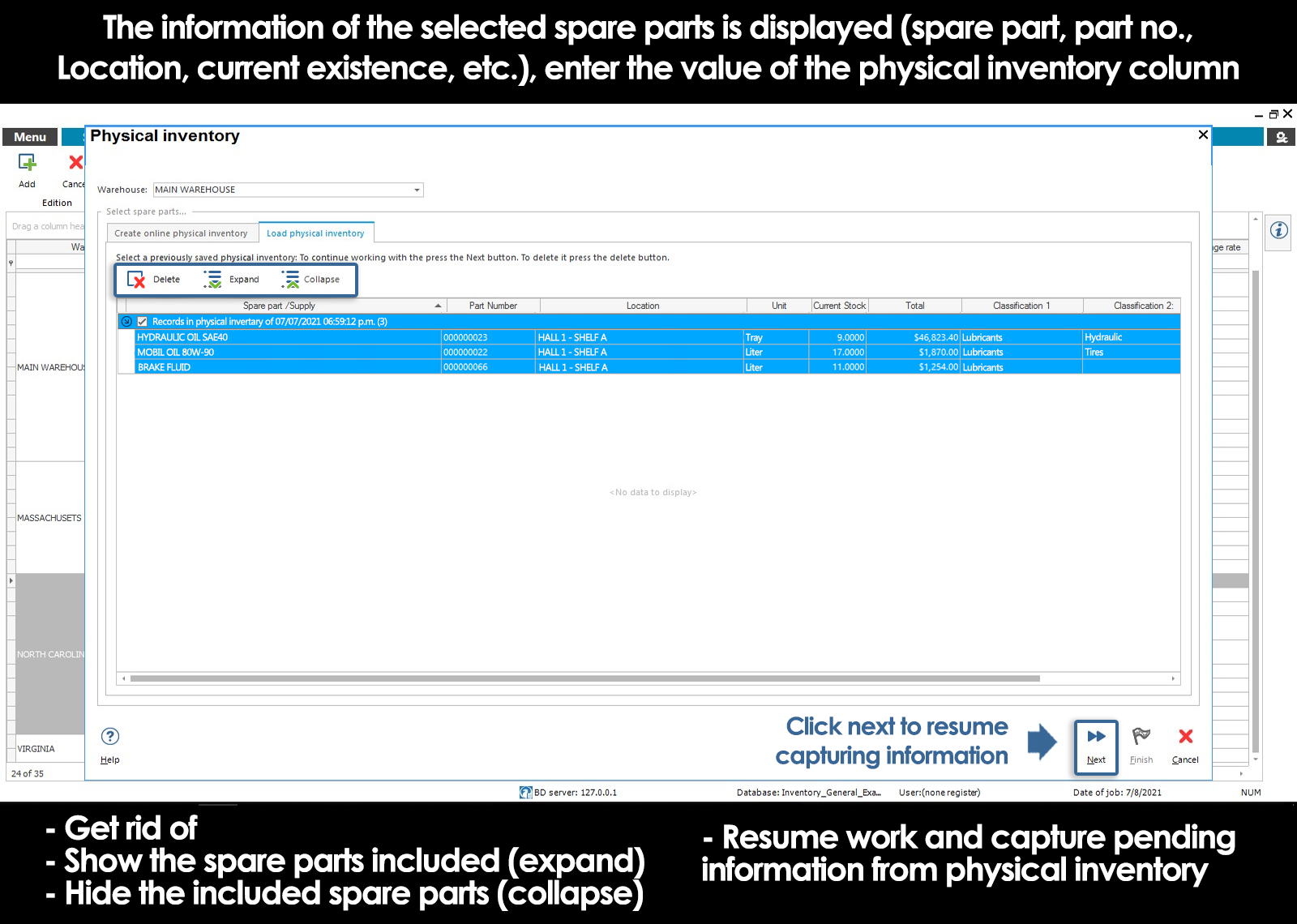

The physical inventory you can do by parts, that is to say, you can capture the information of a group of parts, save the information and continue to work in the physical inventory at another time. Also when you perform a physical inventory manual filling of the printed document, you must enter the inventory previously initialized corresponding to input the information into the system.

Within the tool physical inventoryselect the tab upload physical inventory previously initialized, which is located at the top of the screen. This tab displays all the documents of physical inventory that are open. Physical inventories are grouped by start date. When the group is expanded, you will see the parts that are contained in this inventory.

Select the inventory you want to load and press following it will display the mesh modifiable to continue capturing the physical inventory.

Can't find the answer to your doubts or questions?

Additionally, we offer training courses

Our flexible options of online training and face-to-face will provide you with all the knowledge necessary to understand and implement your software maintenance.