Inicio / Inventario de repuestos

Temas relacionados

▸ Edición de los niveles de inventario y el tiempo de procuramiento

▸ Métodos de cálculo para la cobertura

▸ Qué método de cálculo para la cobertura es conveniente utilizar

▸ Edición de la rotación para el cálculo de la cobertura

▸ Cálculo de la rotación con base en los movimientos de salida

▸ Cálculo óptimo de los niveles de inventario con base en la rotación

▸ Generación del flujo de recursos para el cálculo de la cobertura

▸ Entendiendo el calendario de cobertura

▸ Generación de requisiciones

▸ Ajuste de las cantidades en pedido

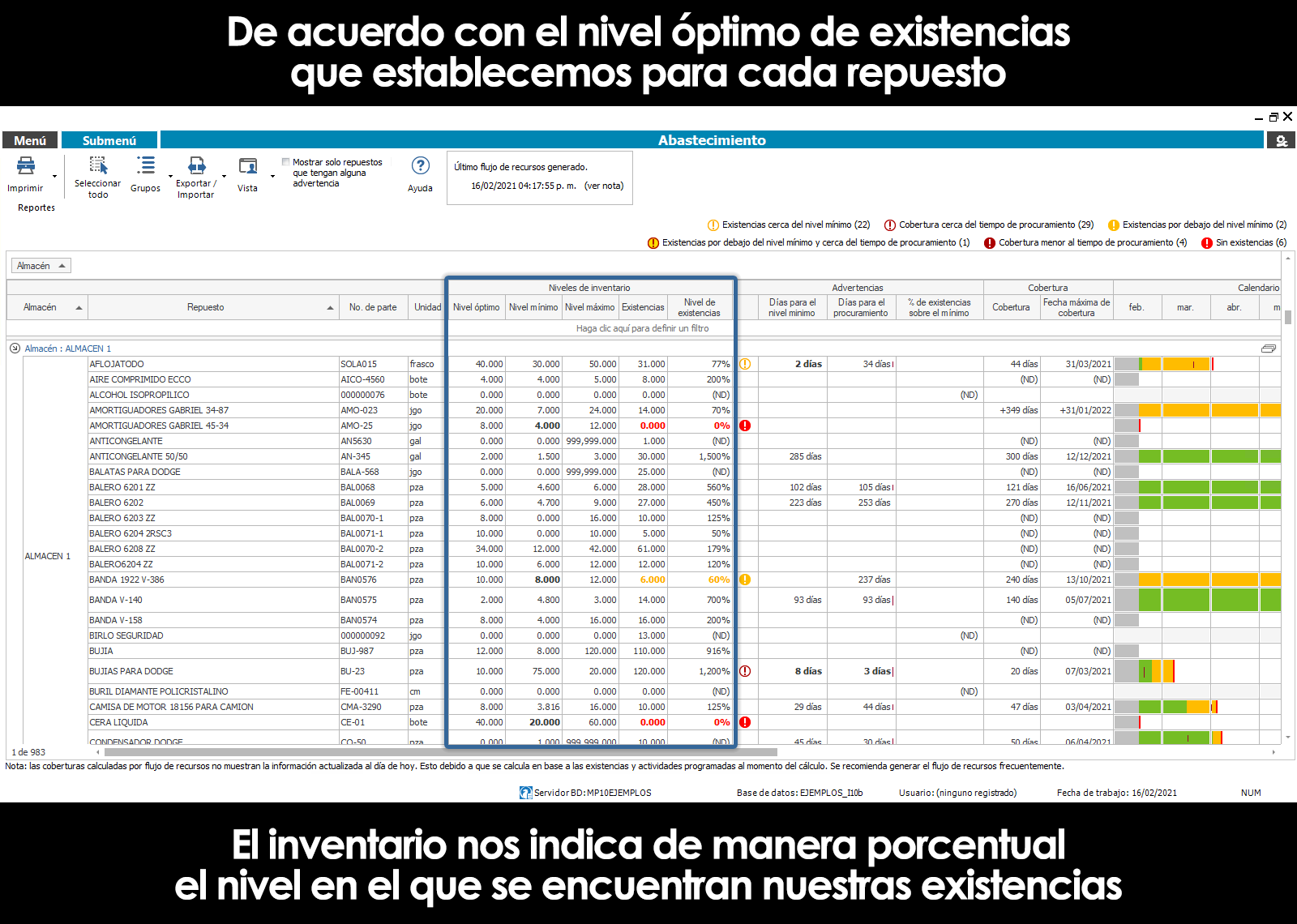

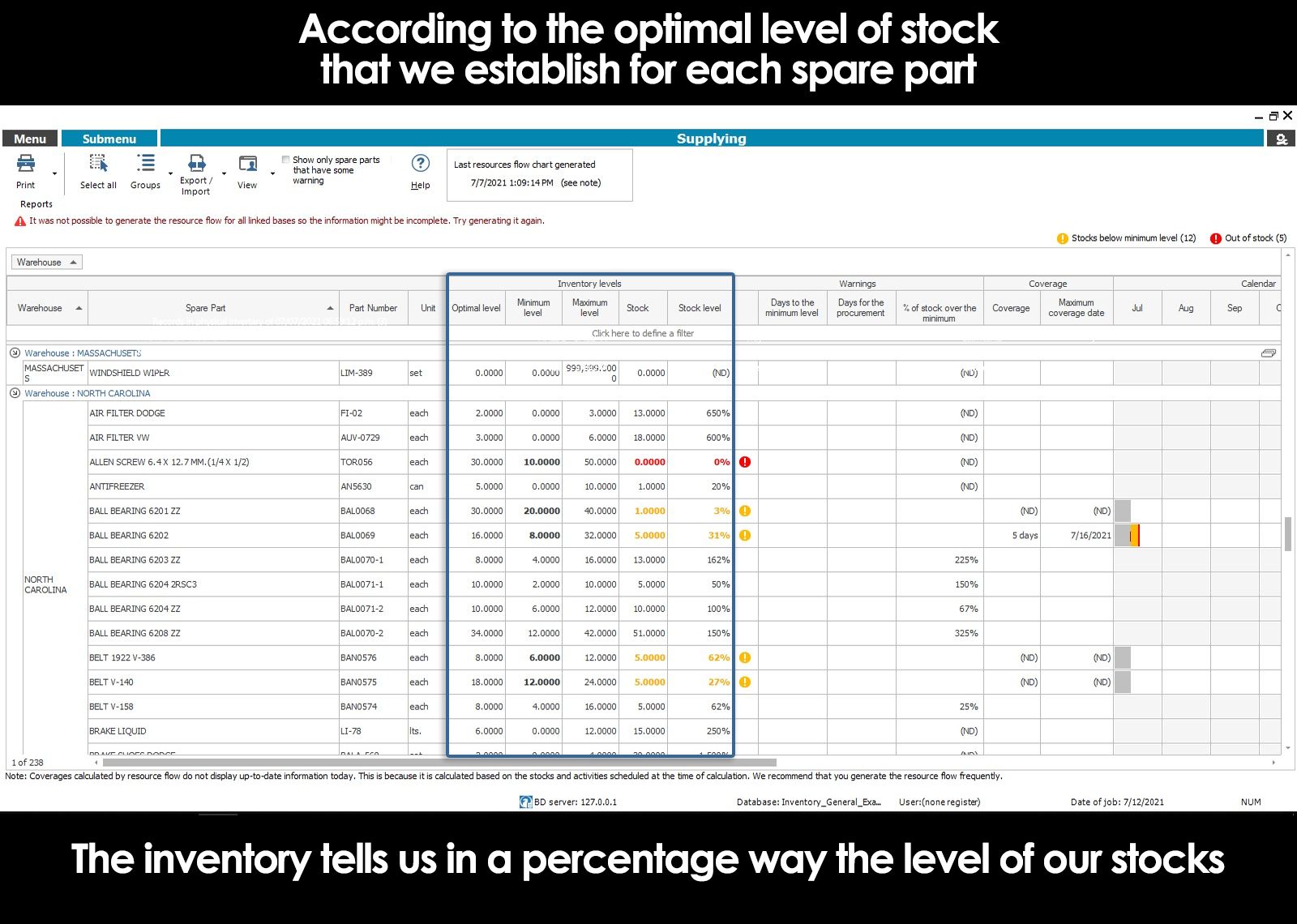

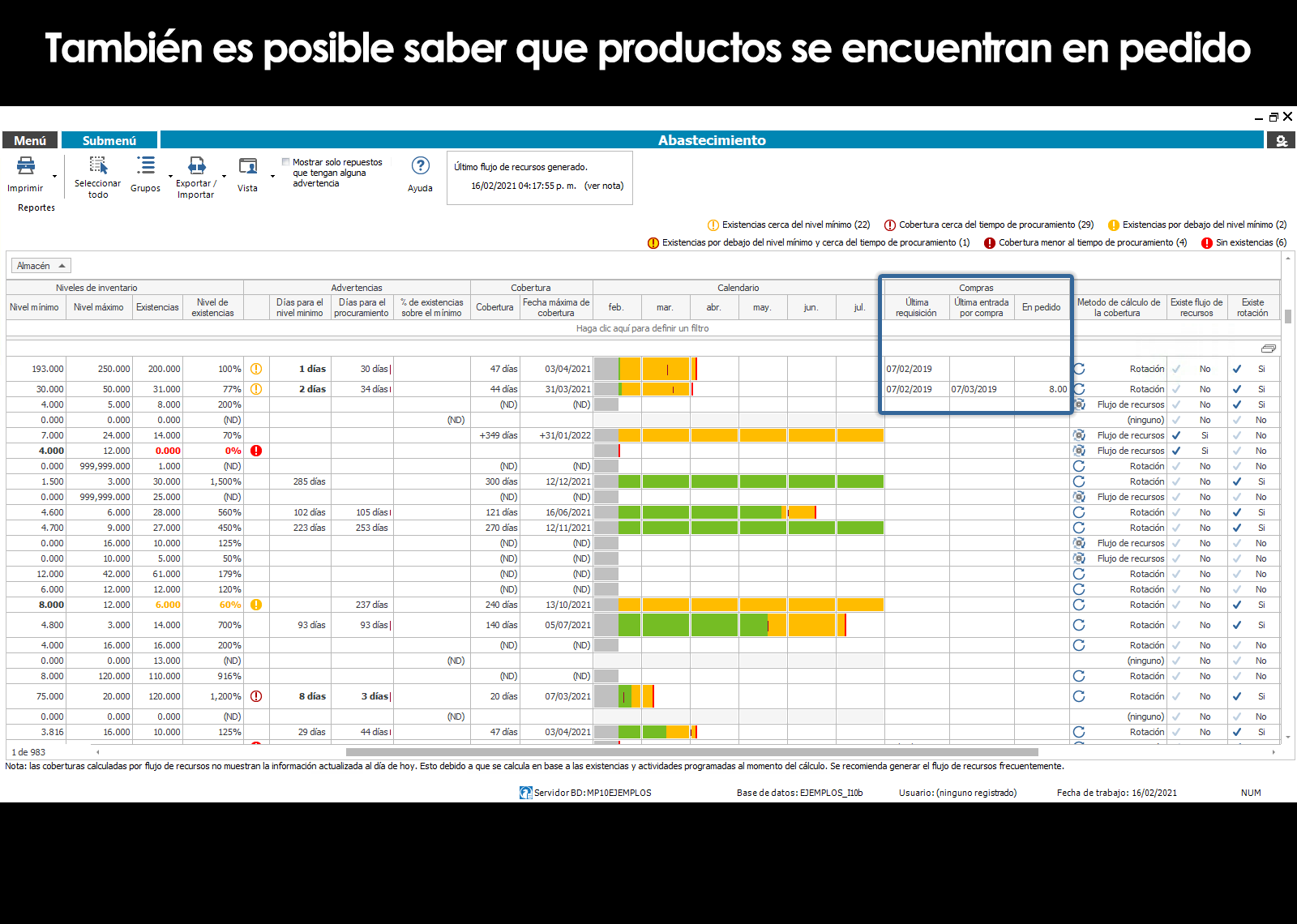

El módulo de niveles de inventario, abastecimiento y requisiciones tiene varias funcionalidades. La primera es conocer de manera gráfica y sencilla los niveles de existencias en las que se encuentra nuestro inventario. De acuerdo con un nivel óptimo de existencias que establecemos para cada repuesto, el inventario nos indica de manera porcentual el nivel en el que se encuentran nuestras existencias, es decir, si estamos ya muy cerca de llegar a 0 o si tenemos suficientes existencias aún.

Este módulo maneja una serie de alertas que nos son muy útiles y que nos avisan con antelación en el momento que ya estamos cerca de llegar a un nivel mínimo de existencias, mismo que establecemos nosotros como un nivel de seguridad. Nos alerta en el momento que estamos por debajo del nivel mínimo, lo que significa que ya debemos comprar más repuestos. De la misma forma nos indica cuando estamos a punto de quedarnos sin existencias y cuando ya estamos en 0.

Todas estas alertas son muy útiles para adelantarnos con la compra de repuestos y evitar, en lo posible, quedarnos sin existencias.

Otro punto importante aquí también es que se considera el tiempo de procuramiento de cada repuesto o consumible, es decir, el tiempo que tarda en llegar el repuesto, desde que se hace el trámite de compra hasta que ingresa a nuestro almacén. Esta referencia es muy importante también ya que, si hacemos una compra de material pasado este punto, es muy probable que nos quedemos en un momento dado sin existencias esperando la llegada de los repuestos.

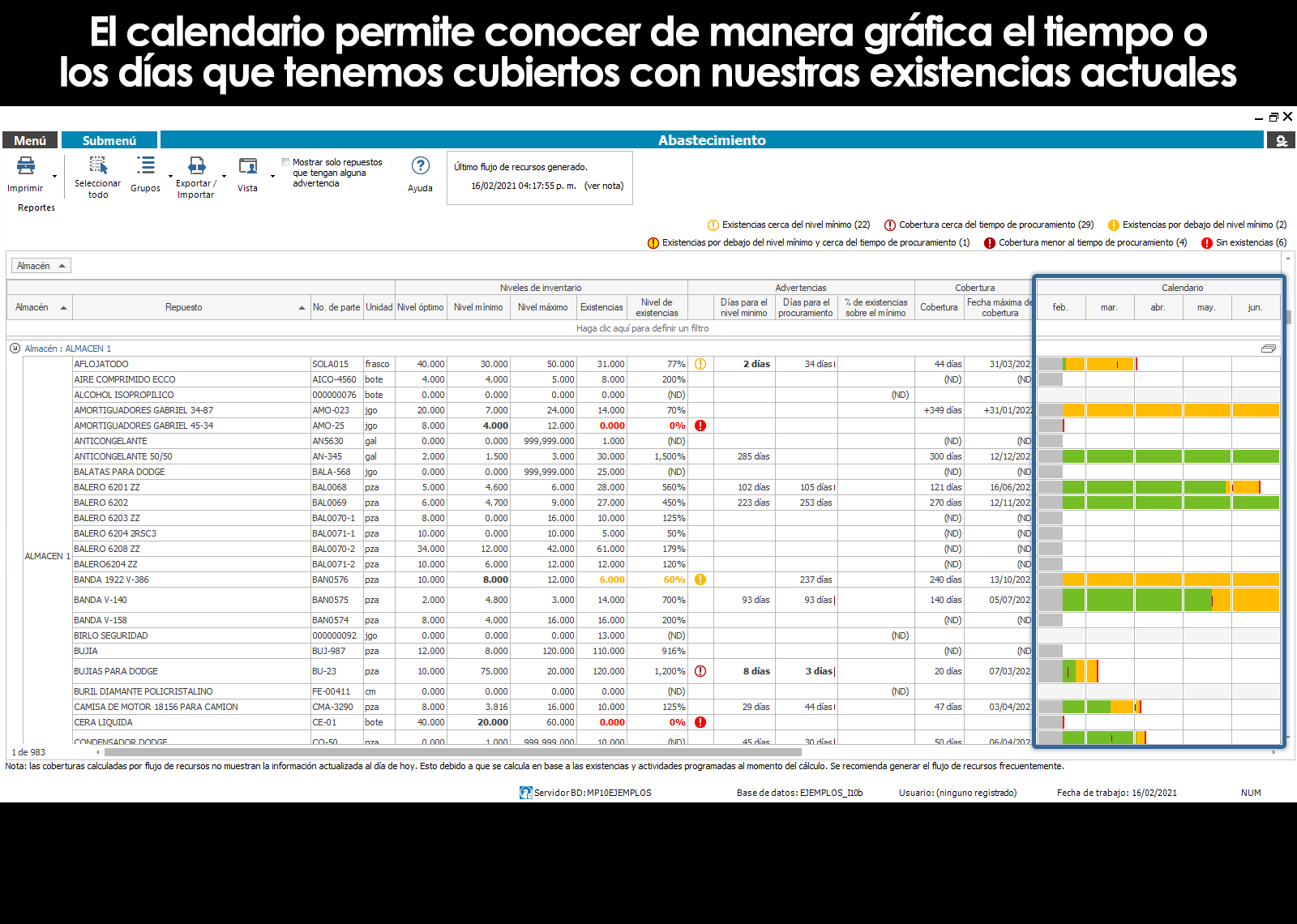

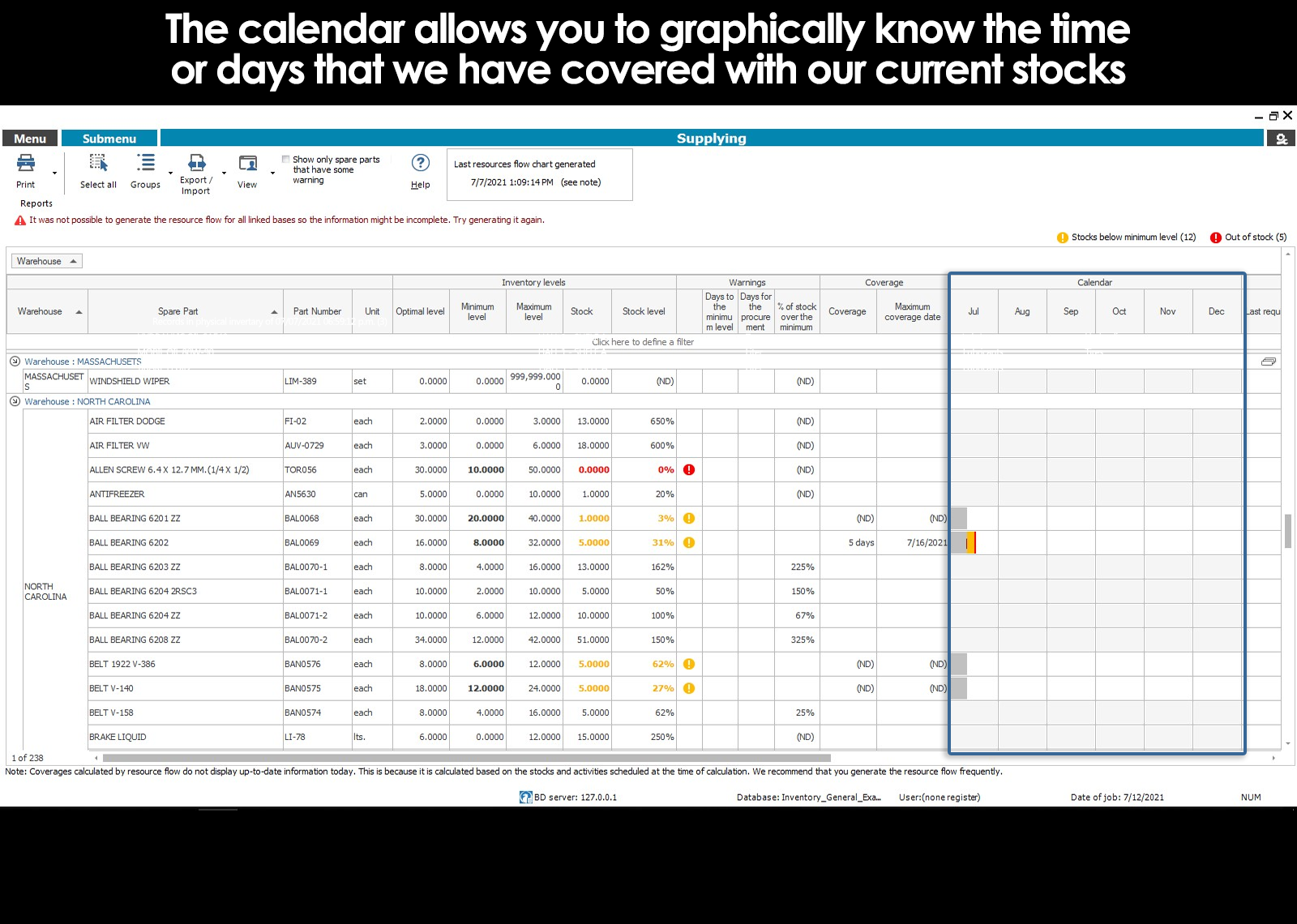

Otra funcionalidad muy interesante en este módulo es poder conocer el tiempo o los días que tenemos cubiertos con nuestras existencias actuales. De acuerdo con el consumo que tiene cada uno de nuestros repuestos y consumibles, es posible estimar como para cuantos días nos va a alcanzar las existencias de cada producto.

Este tiempo se puede calcular de dos diferentes maneras:

- Con base en la rotación o consumo mensual promedio de cada repuesto o consumible, o

- Con base en la programación de los mantenimientos de los equipos donde se utiliza un repuesto determinado.

Más adelante explicaremos las ventajas de utilizar cada uno de los métodos de cálculo.

Esta forma gráfica de visualizar nuestras existencias es muy útil, ya que, de un simple vistazo, podemos saber cuales productos requieren nuestra atención y cuáles no.

Bueno, con todo lo anterior, otra funcionalidad del módulo es saber fácil y rápidamente que productos son de los que nos debemos abastecer. Utilizando una serie de filtros con las que cuenta este módulo, es fácil filtrar y saber todos los productos a los cuales debemos o queremos generar una requisición para que el departamento de compras correspondiente proceda con su compra.

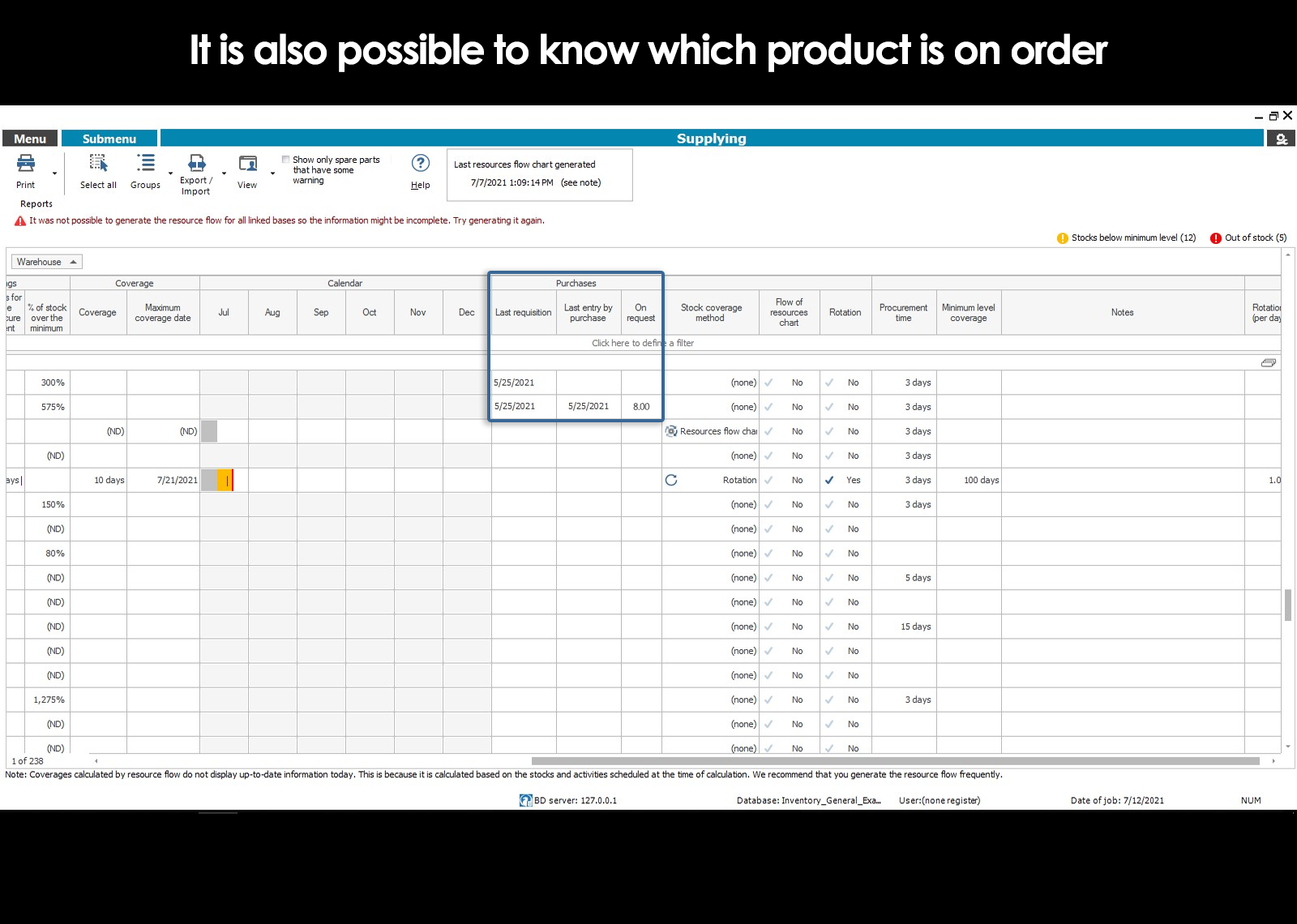

El último punto sería la de generar las debidas requisiciones. Una vez que filtramos y decidimos qué productos debemos o queremos comprar, podemos generar una requisición. La idea es que esta requisición se le pase al departamento de compras encargado para que ellos tramiten la debida compra con el proveedor que a ellos les convenga. En este módulo es posible saber que productos se encuentran en pedido para poderles dar seguimiento junto con el departamento de compras.

¿No encuentras la respuesta a tus dudas o preguntas?

Opcionalmente ofrecemos cursos de capacitación

Nuestras opciones flexibles de capacitación online y presenciales te brindarán todo el conocimiento necesario para comprender e implementar tu software de mantenimiento.