Inicio / Control de herramientas

Temas relacionados

▸ Introducción a almacenes de herramientas (multi-almacenes)

▸ Agregar almacenes de herramientas (multi-almacenes)

▸ Determinación de herramientas que maneja cada almacén

▸ Consultar disponibilidad de las herramientas en cada almacén

▸ Consultar del valor total del almacén

▸ Comparativo de almacenes

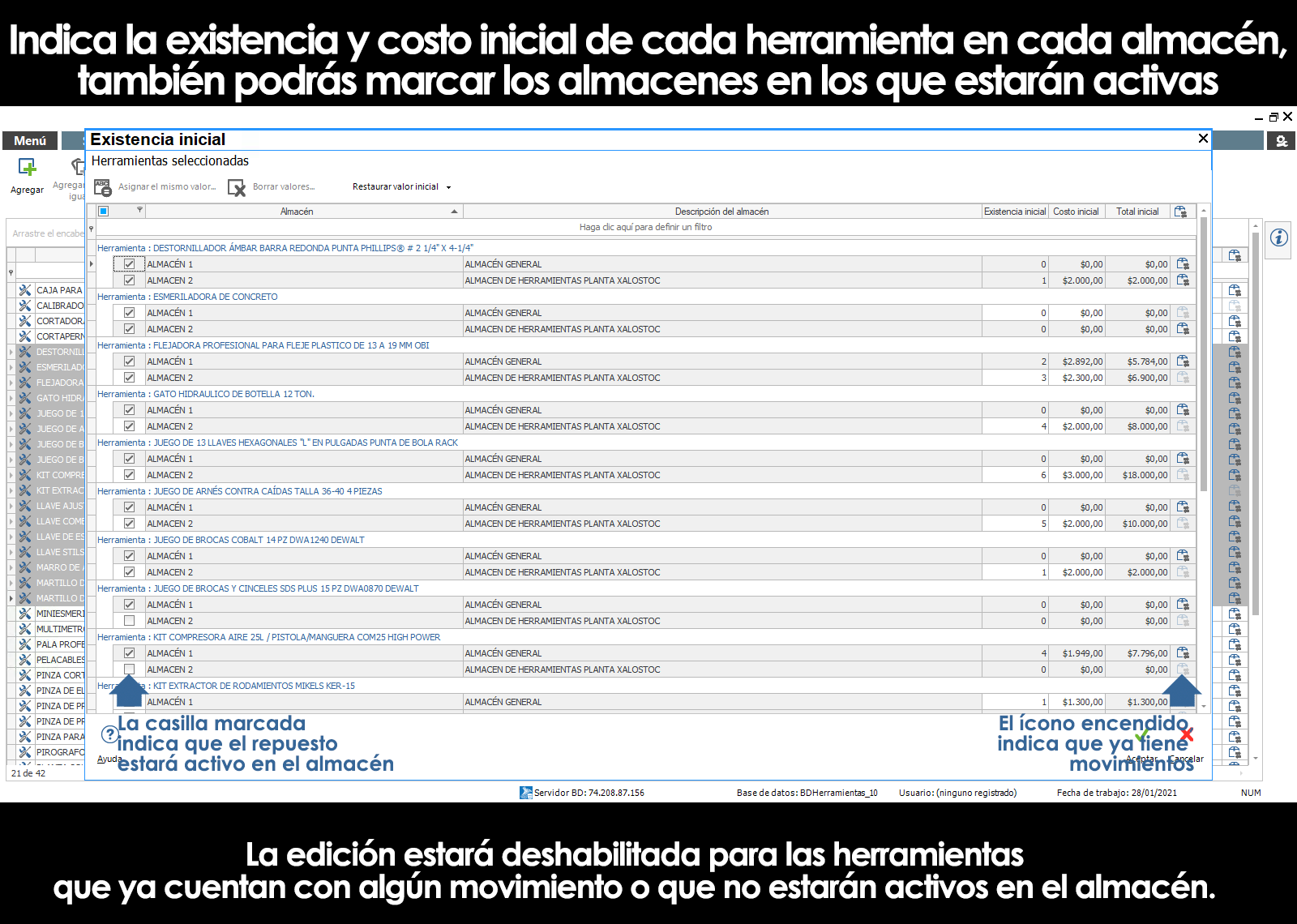

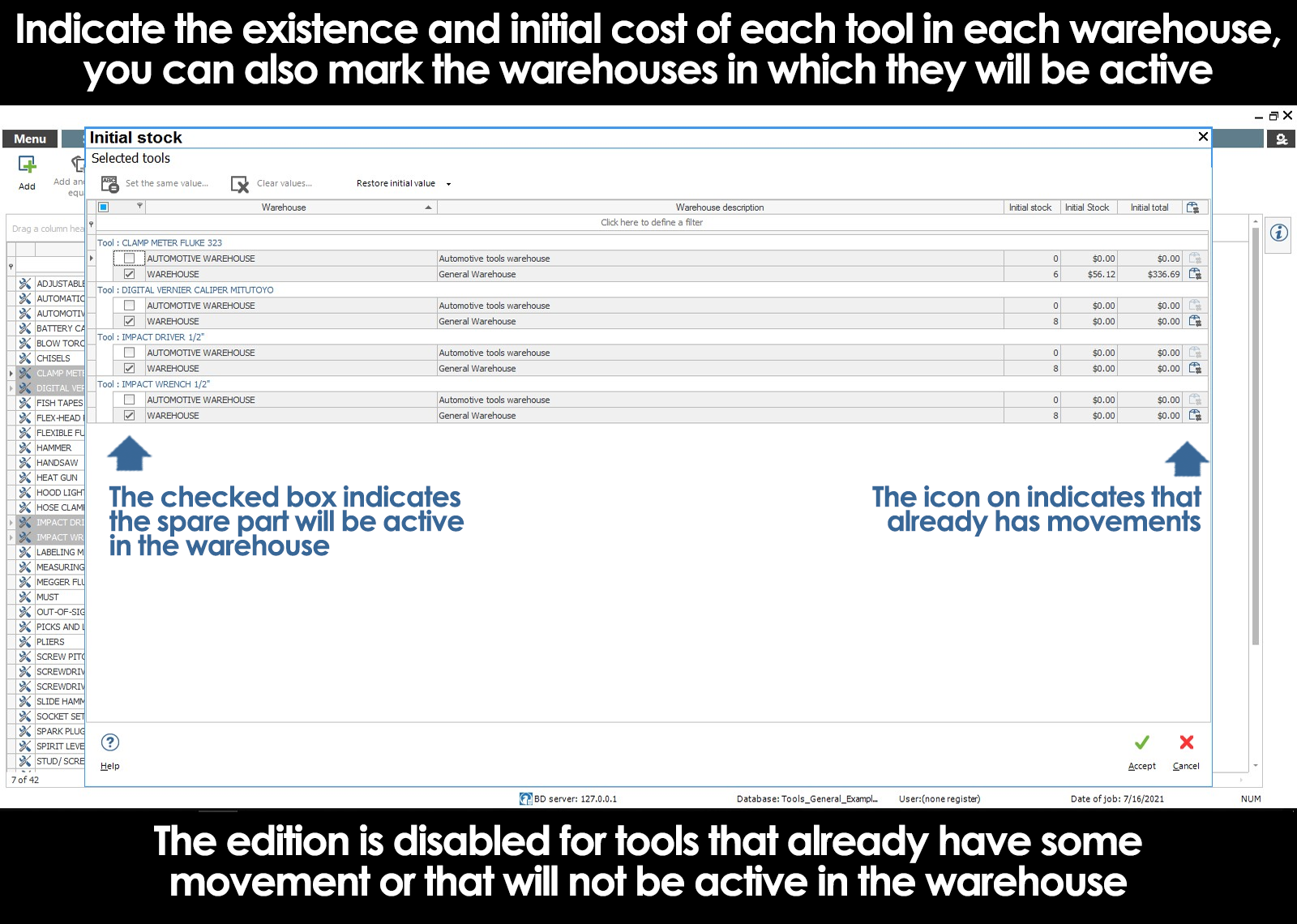

Las existencias y costos iniciales de una herramienta son variables en cada almacén al igual que su localización.

El registro de existencias y costos iniciales es el proceso con el cual el usuario indica la situación inicial de su inventario para poder comenzar a trabajar y generar movimientos de entrada y de salida, movimientos de resguardos y devoluciones, para poder realizar consultas con los valores actualizados.

La versatilidad del sistema de control de herramientas de la suite MP versión 10 le permite registrar sus existencias iniciales al momento de crear herramientas y almacenes, o bien, posteriormente permite editar de forma individual o masiva las existencias iniciales, costo inicial y localización de las herramientas en los diferentes almacenes.

También para facilidad y agilidad en la implementación del sistema de control de herramientas, el usuario puede comenzar a trabajar con las herramientas a los cuales les ha capturado sus valores iniciales, evitando así, tener que capturar los valores iniciales de todos las herramientas para comenzar a utilizar el sistema. Es importante señalar que una vez que se ha realizado un movimiento con una herramienta, no se podrán realizar modificaciones de los registros iniciales (existencia inicial y costo inicial) de esa herramienta en el almacén en que se realizó el movimiento.

El registro de existencias iniciales se puede realizar desde el módulo Herramientas y desde el módulo Almacenes.

Desde el módulo de Herramientas pueden registrar las existencias iniciales de las herramientas en cada uno de los almacenes; en cambio, en el módulo de Almacenes, se registra la existencia inicial de las herramientas que se contienen en el almacén seleccionado.

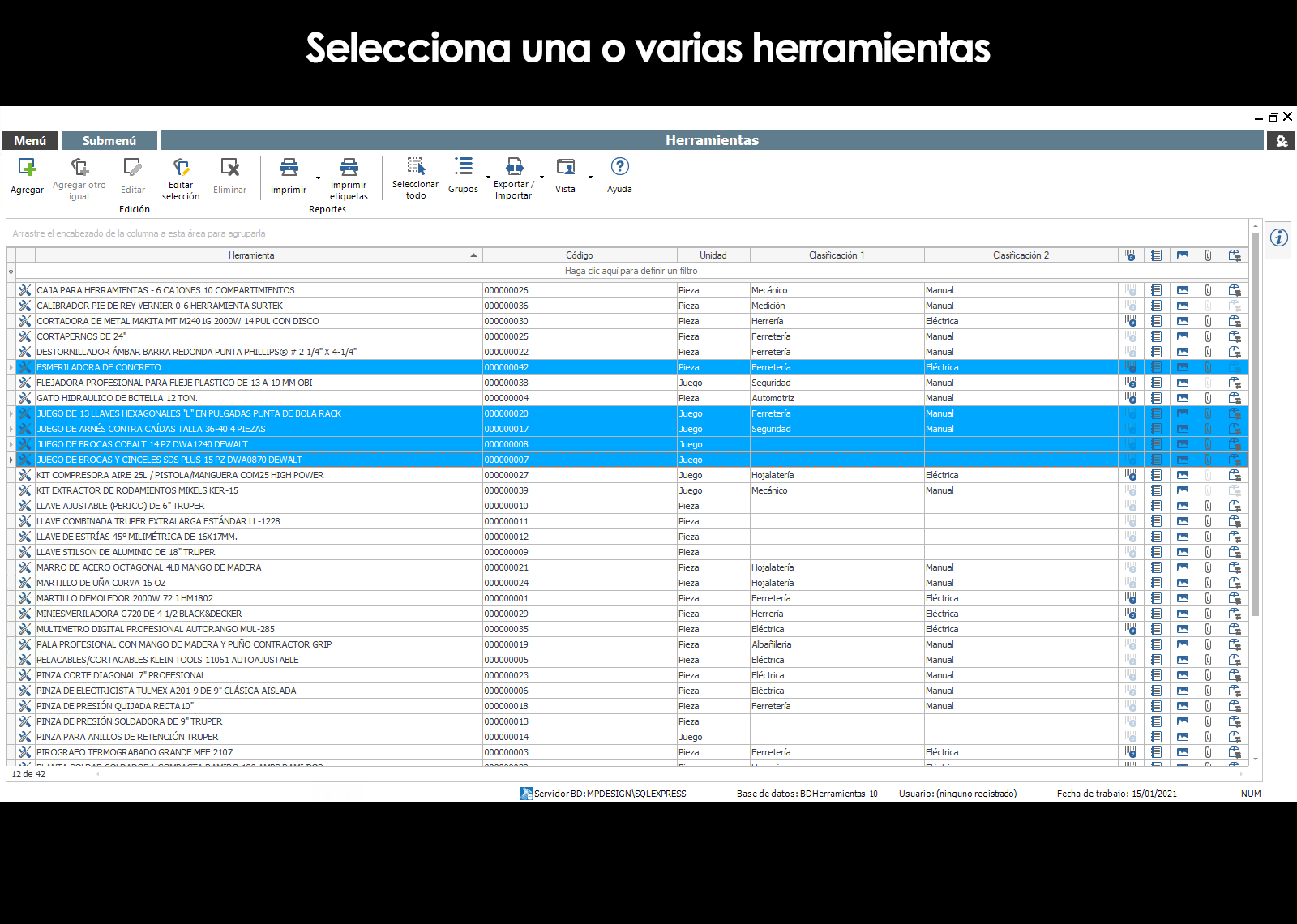

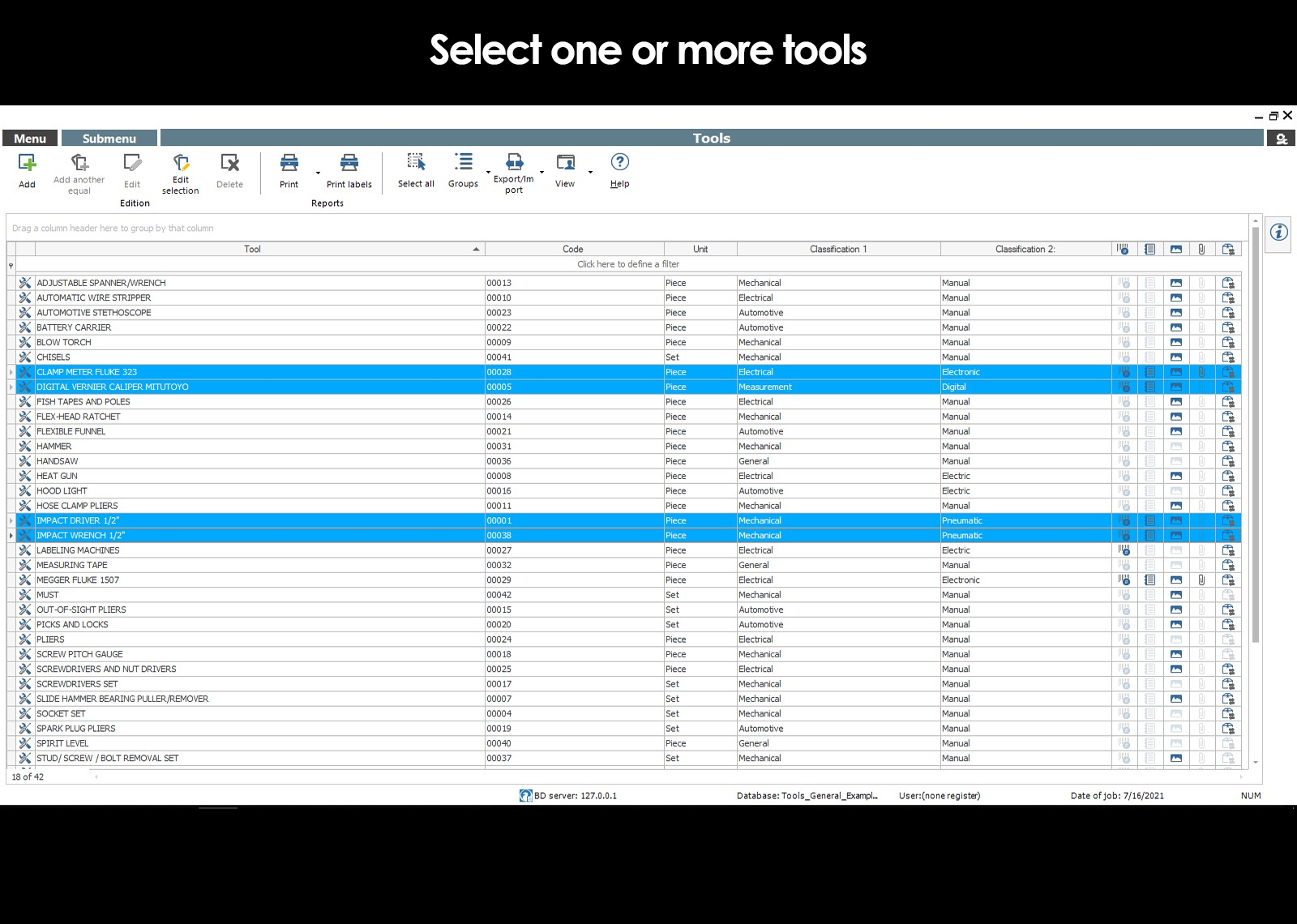

Para capturar los valores iniciales de sus herramientas desde el módulo de Herramientas y seleccione en el submenú Almacenes y existencias iniciales.

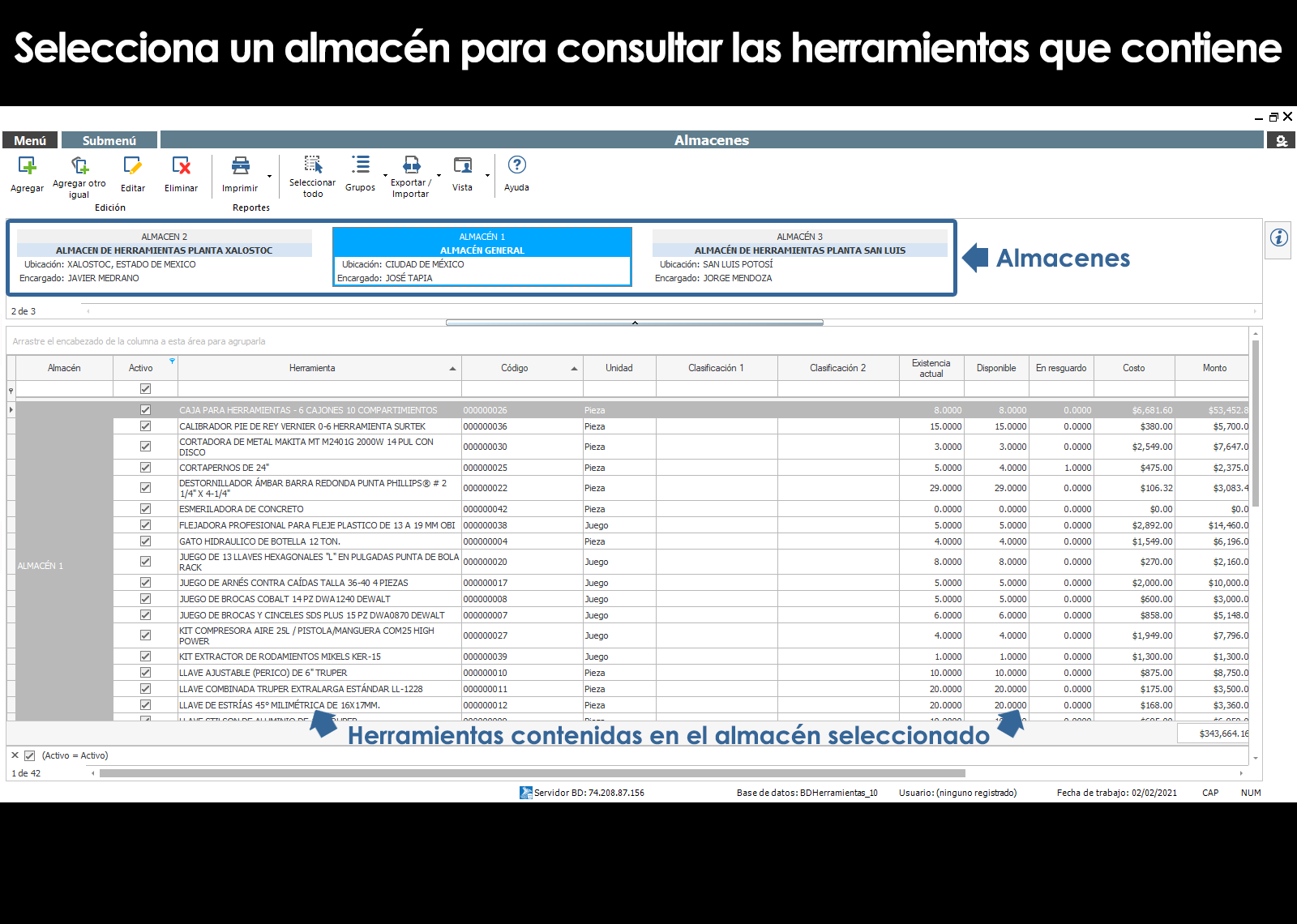

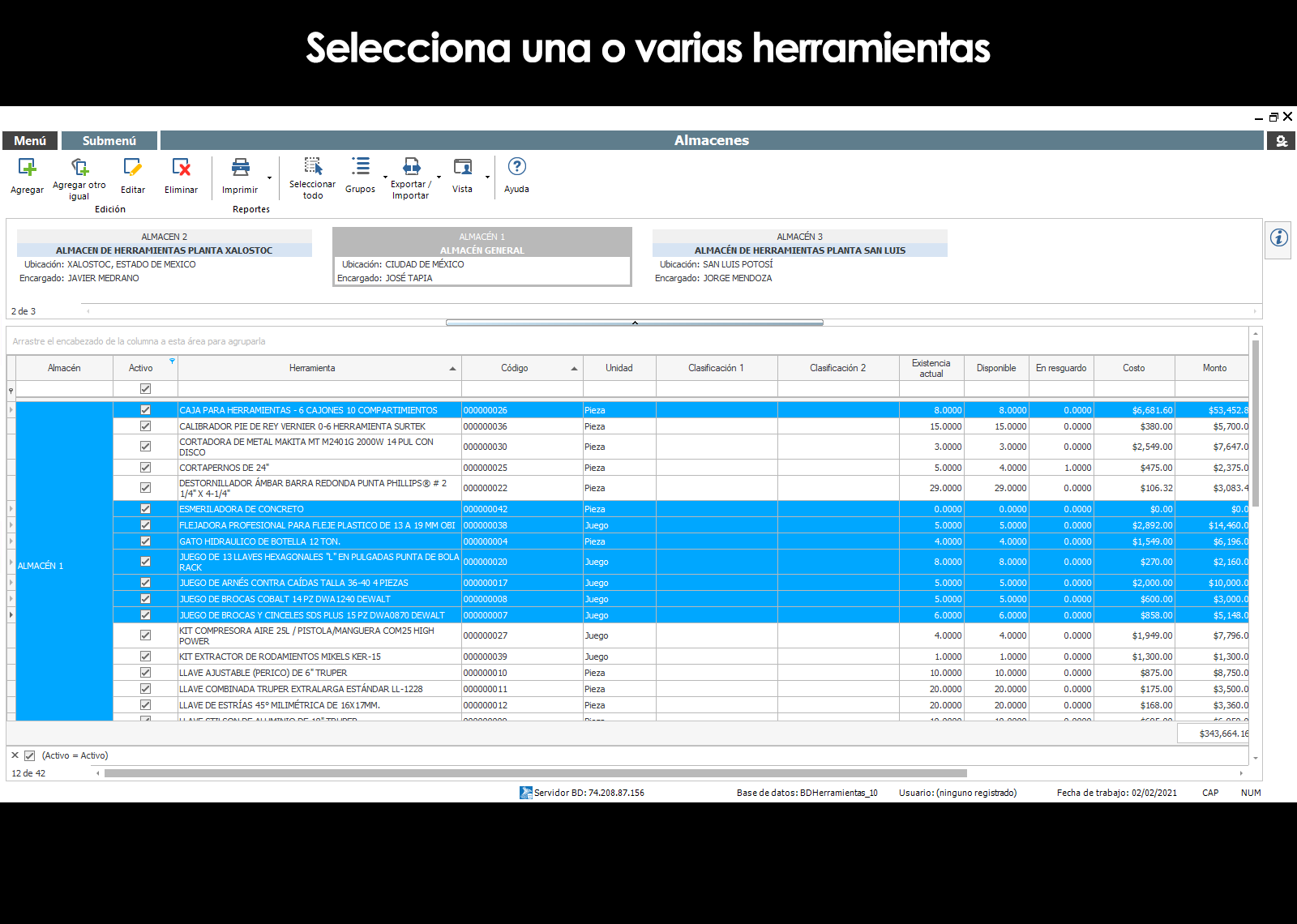

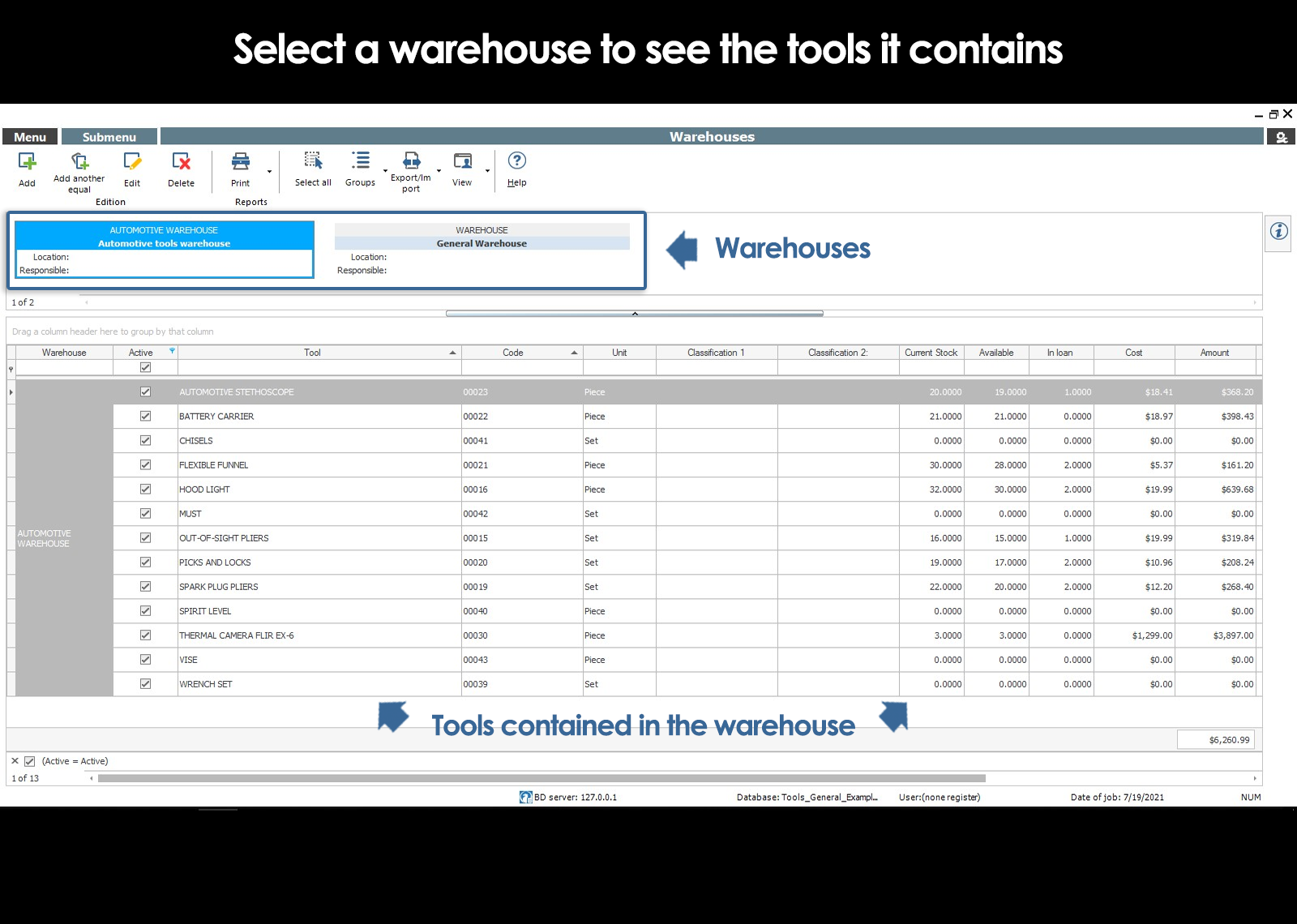

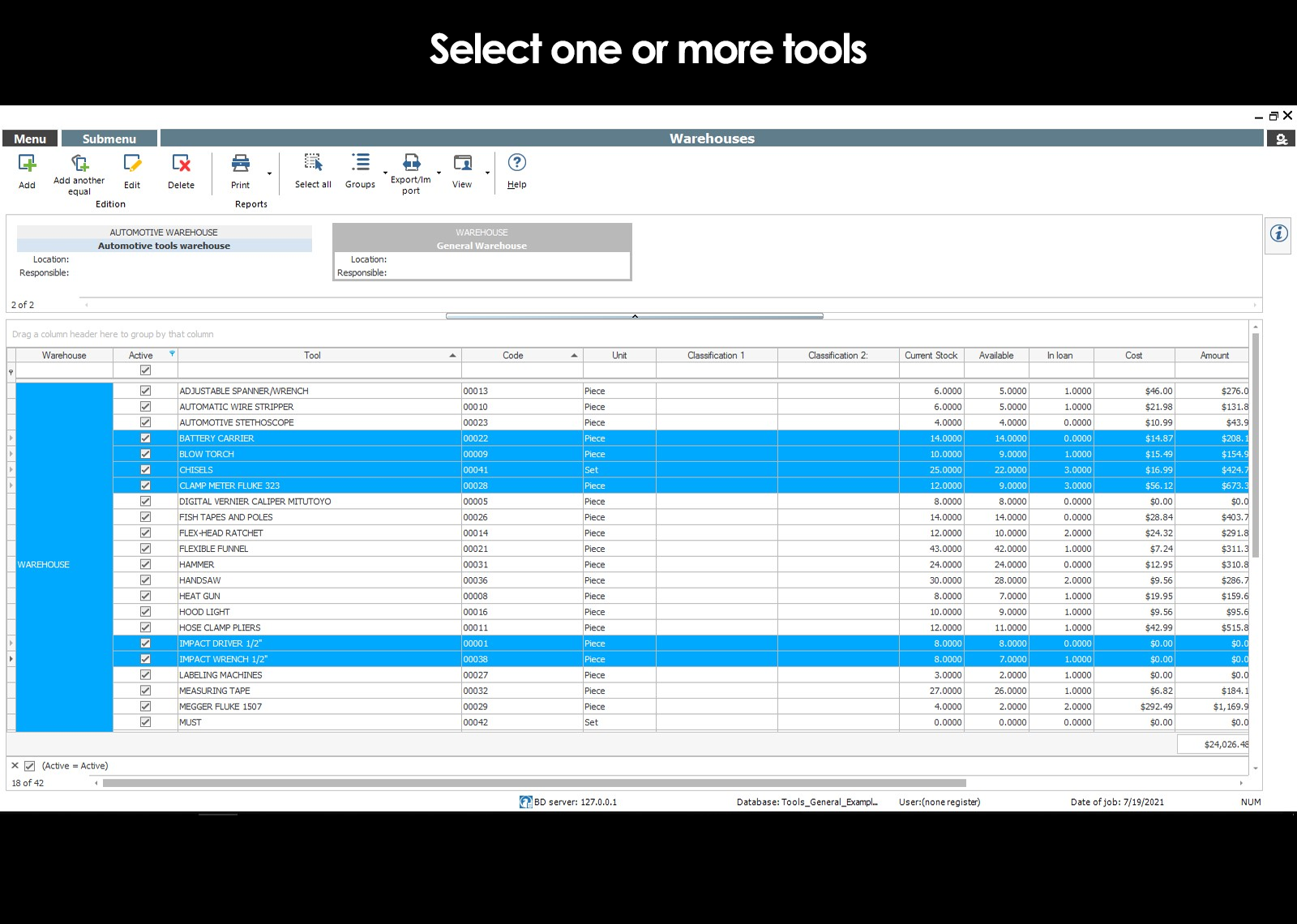

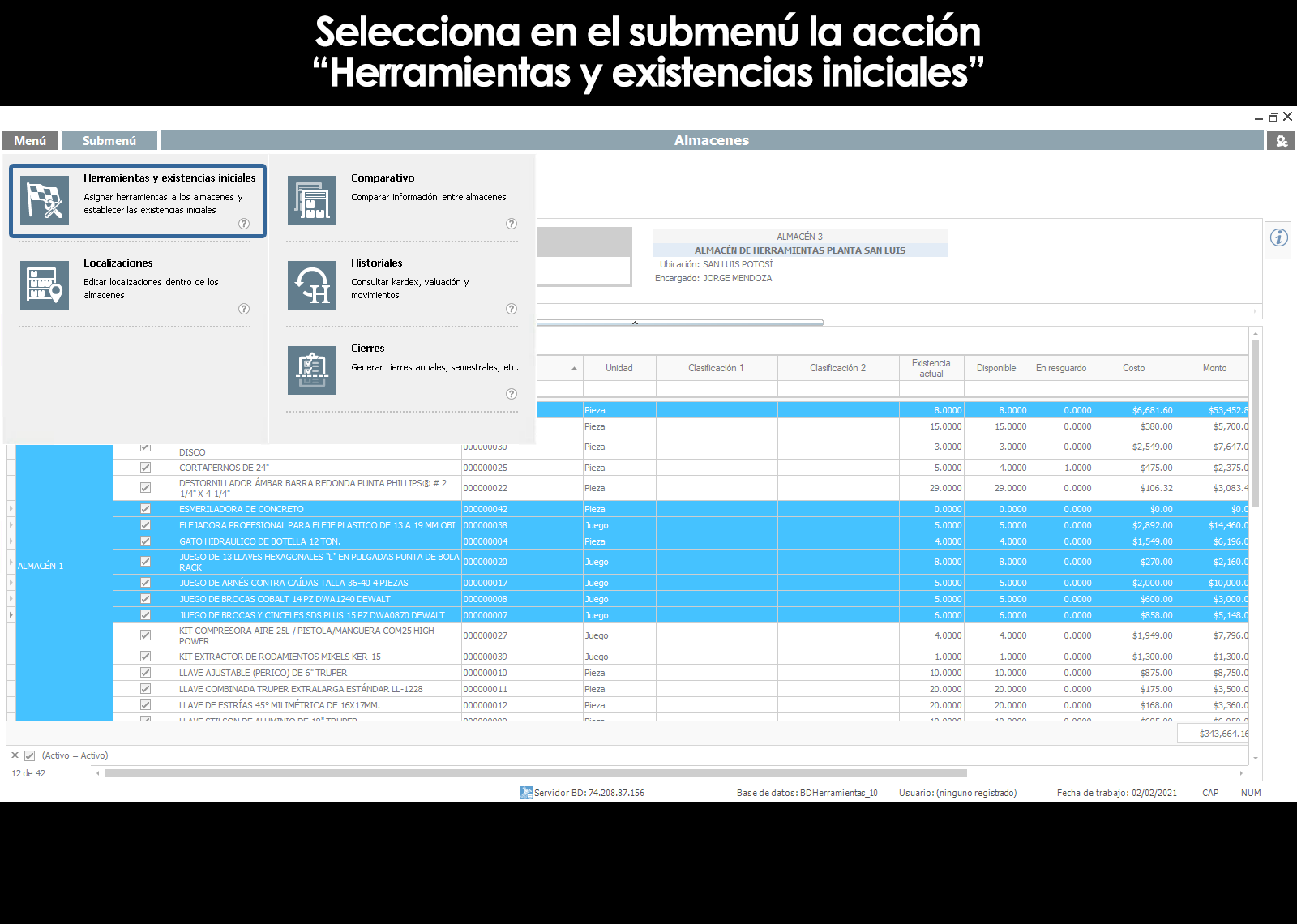

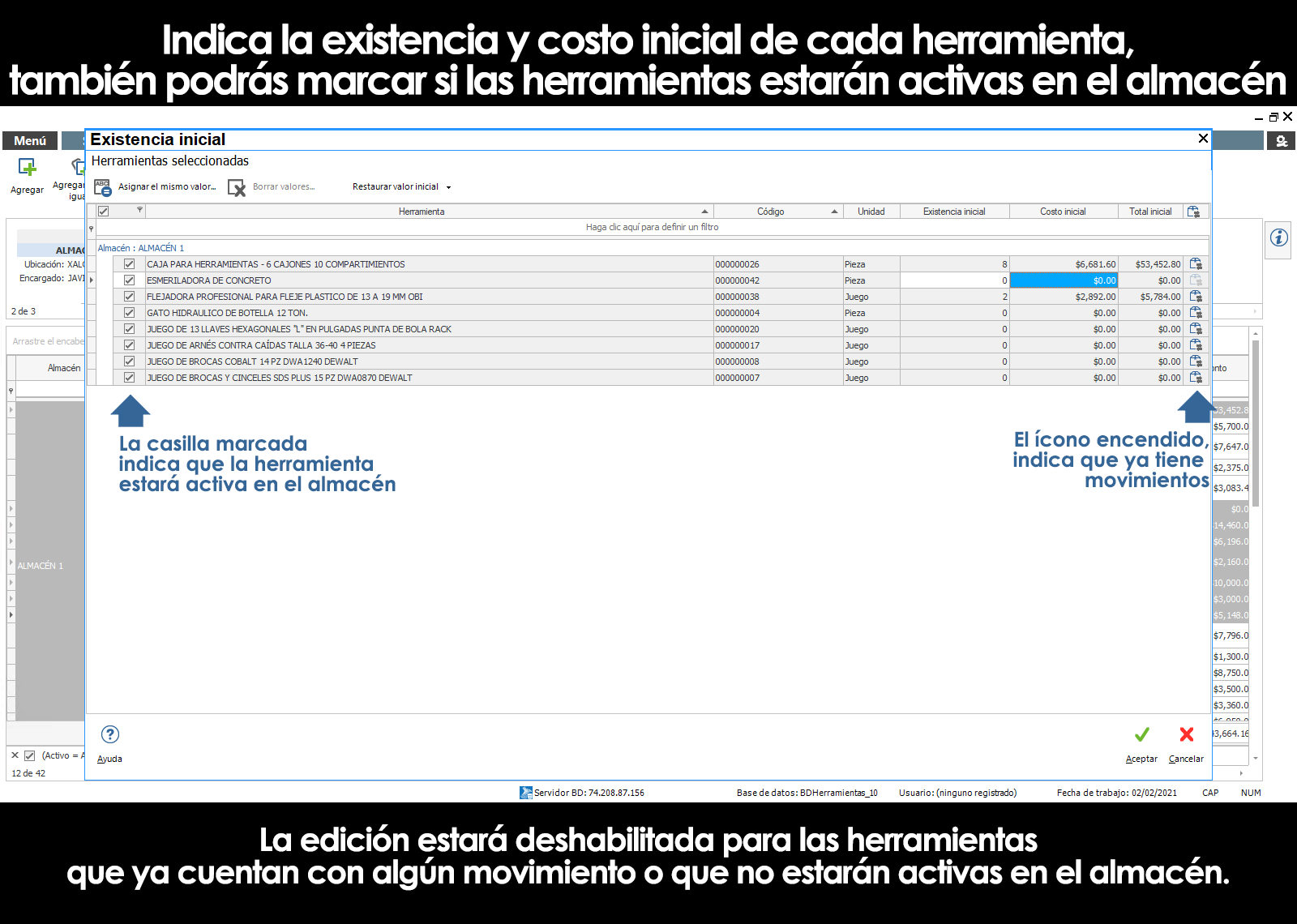

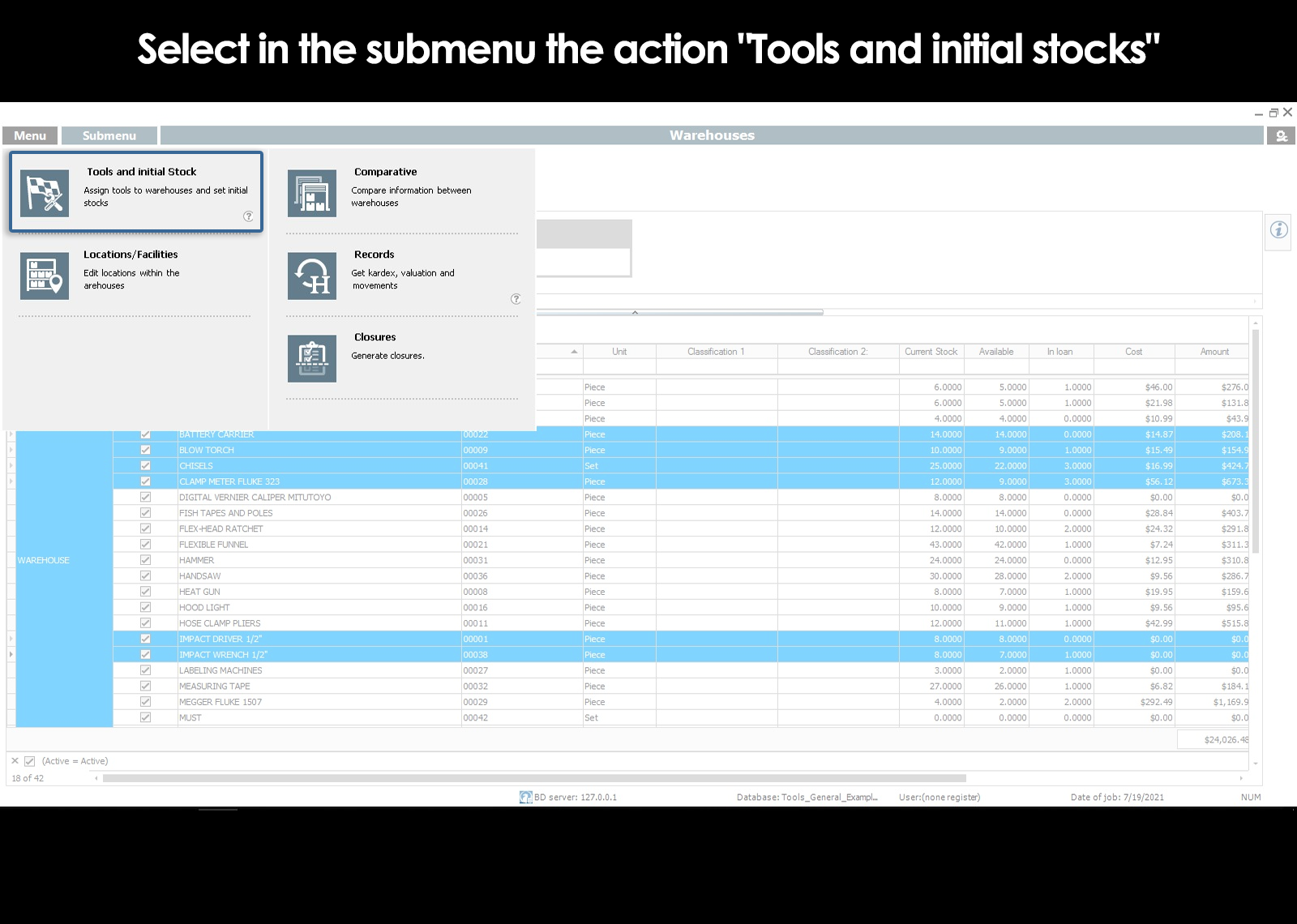

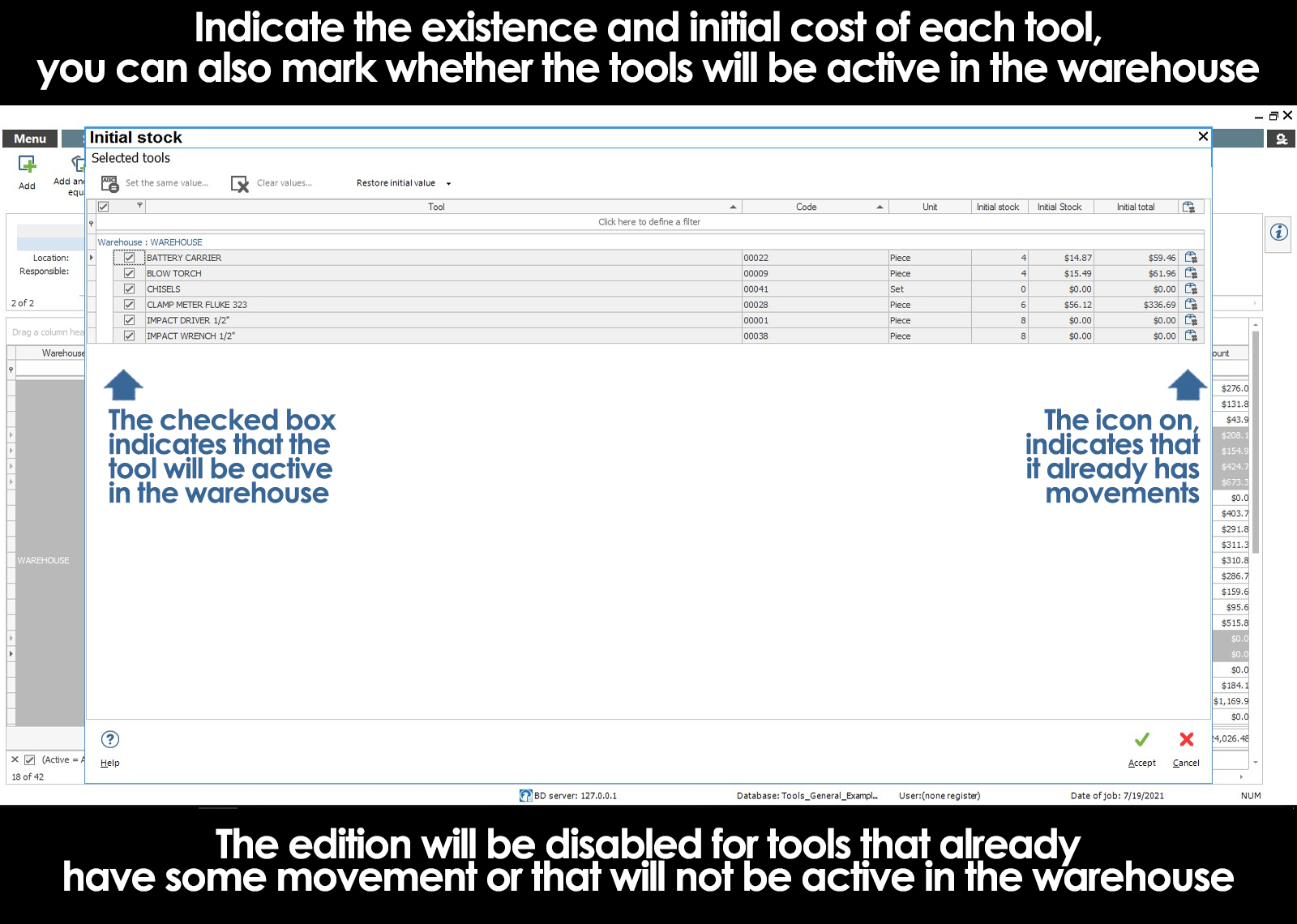

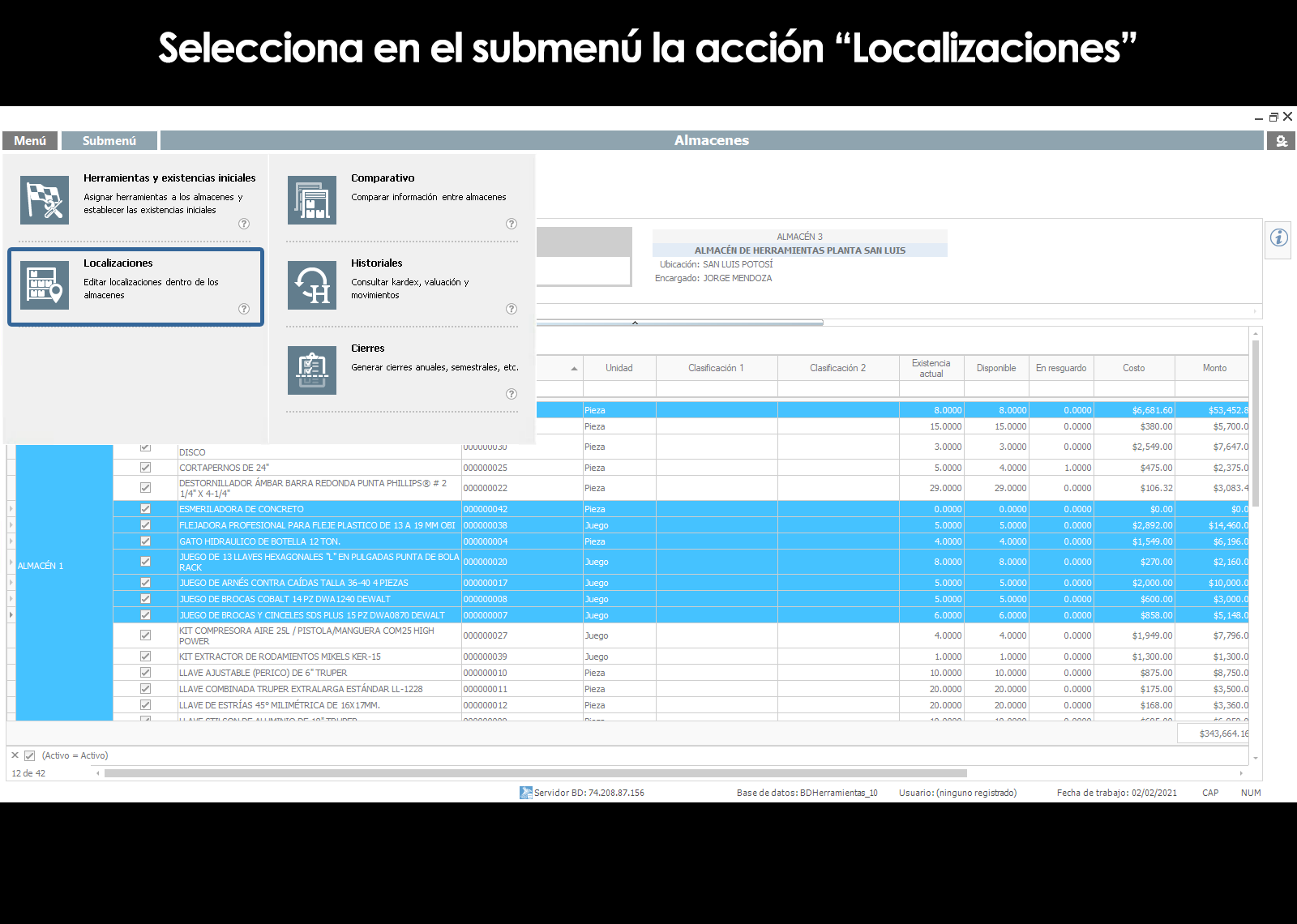

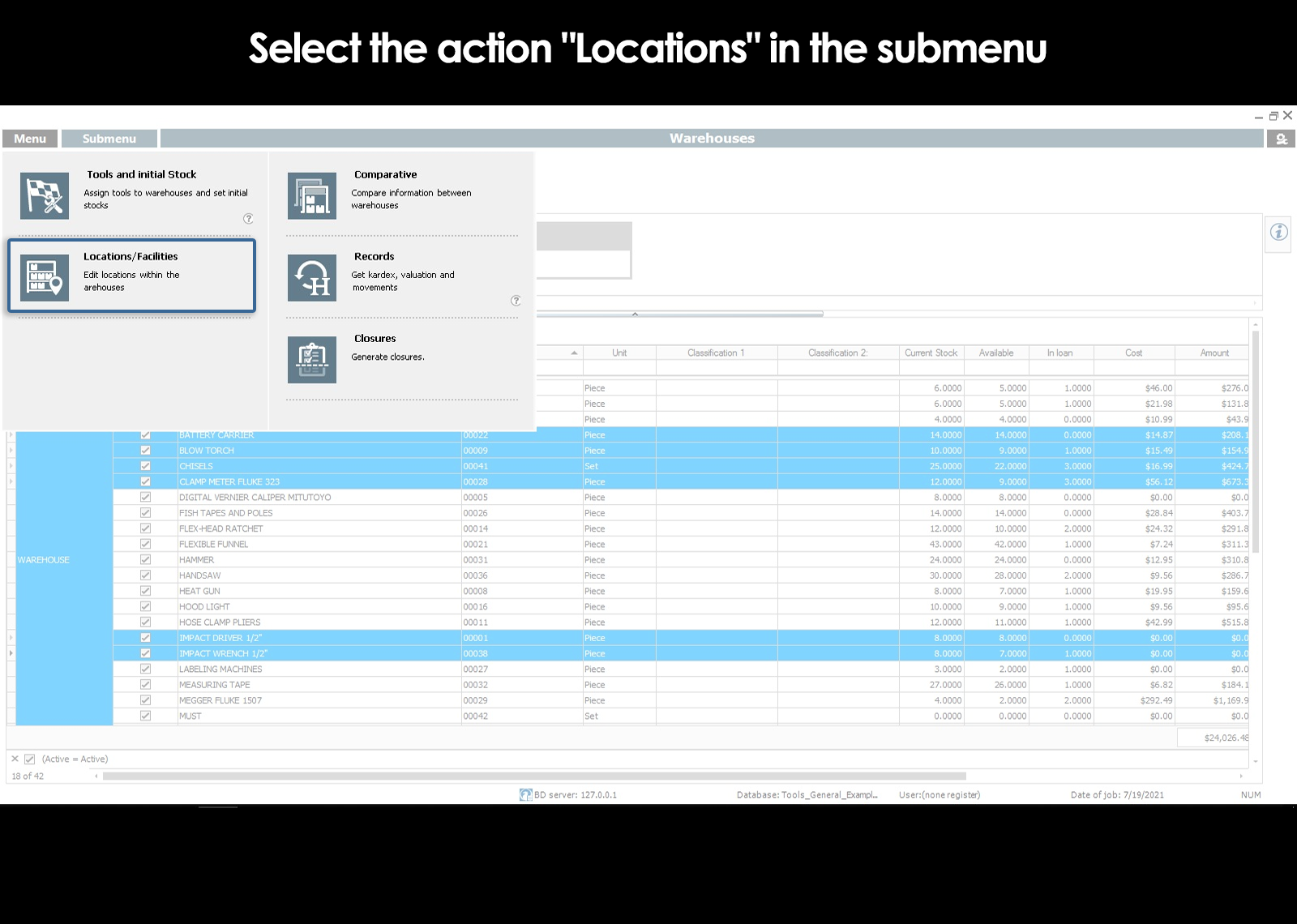

Para capturar las existencias desde el módulo de Almacenes ingrese a dicho módulo, seleccione un almacén en caso de contar con multi-almacenes y luego seleccione el o las herramientas que desea editar, posteriormente seleccione la acción Herramientas y existencias iniciales que se encuentra en el submenú del módulo.

En ambos casos se habilitará la edición múltiple en la malla para registrar la información. Esta malla permite seleccionar las herramientas que se tienen en el almacén marcando la casilla de selección, modificar la existencia inicial y modificar el costo inicial de las herramientas seleccionadas. Es importante señalar que no es posible modificar los valores iniciales de las herramientas a las cuales se les ha generado un movimiento y por lo tanto se encontrará marcado el símbolo de movimientos.

Nota: La herramienta solo se bloquea en el almacén desde donde se genero el movimiento de salida o entrada.

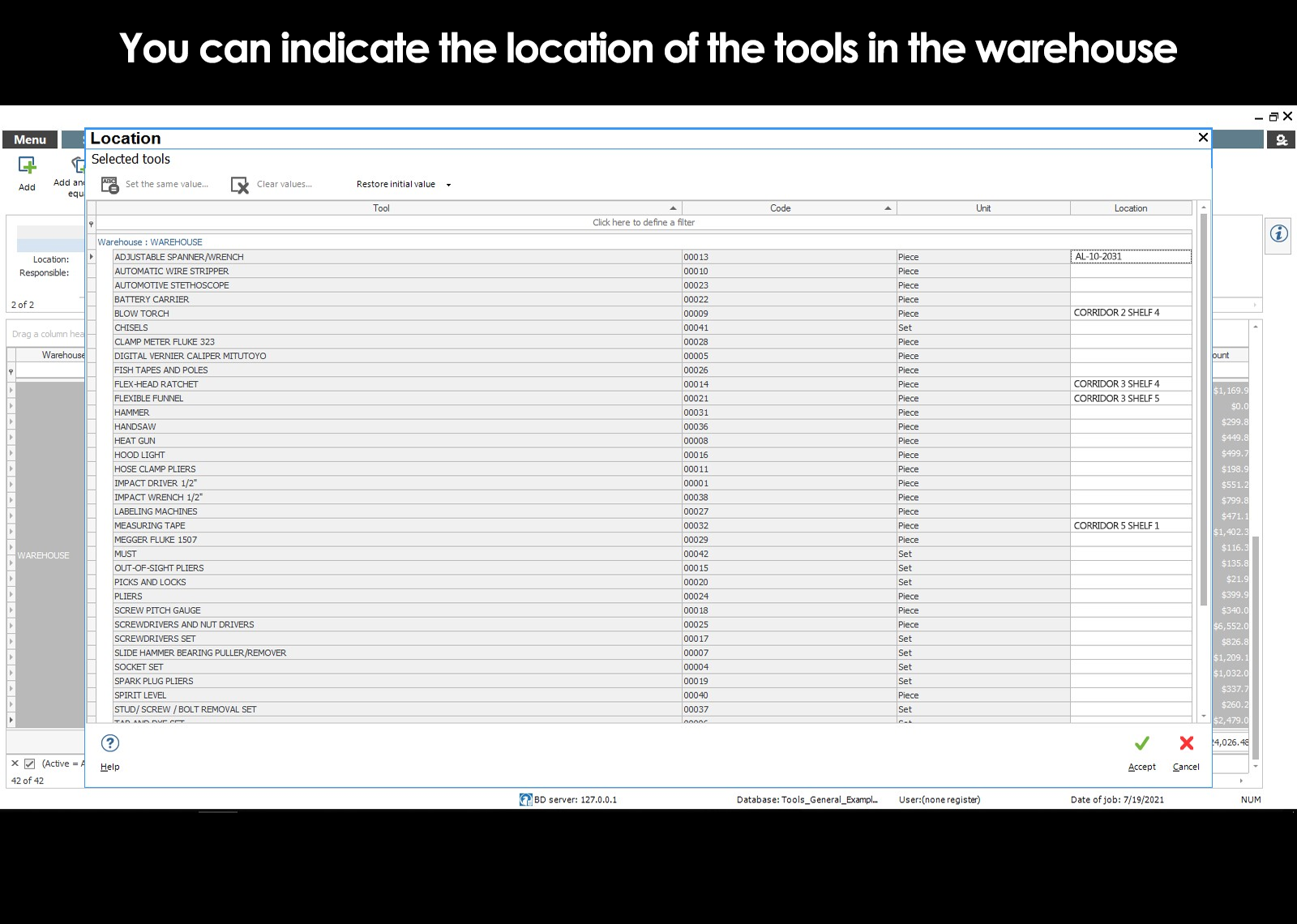

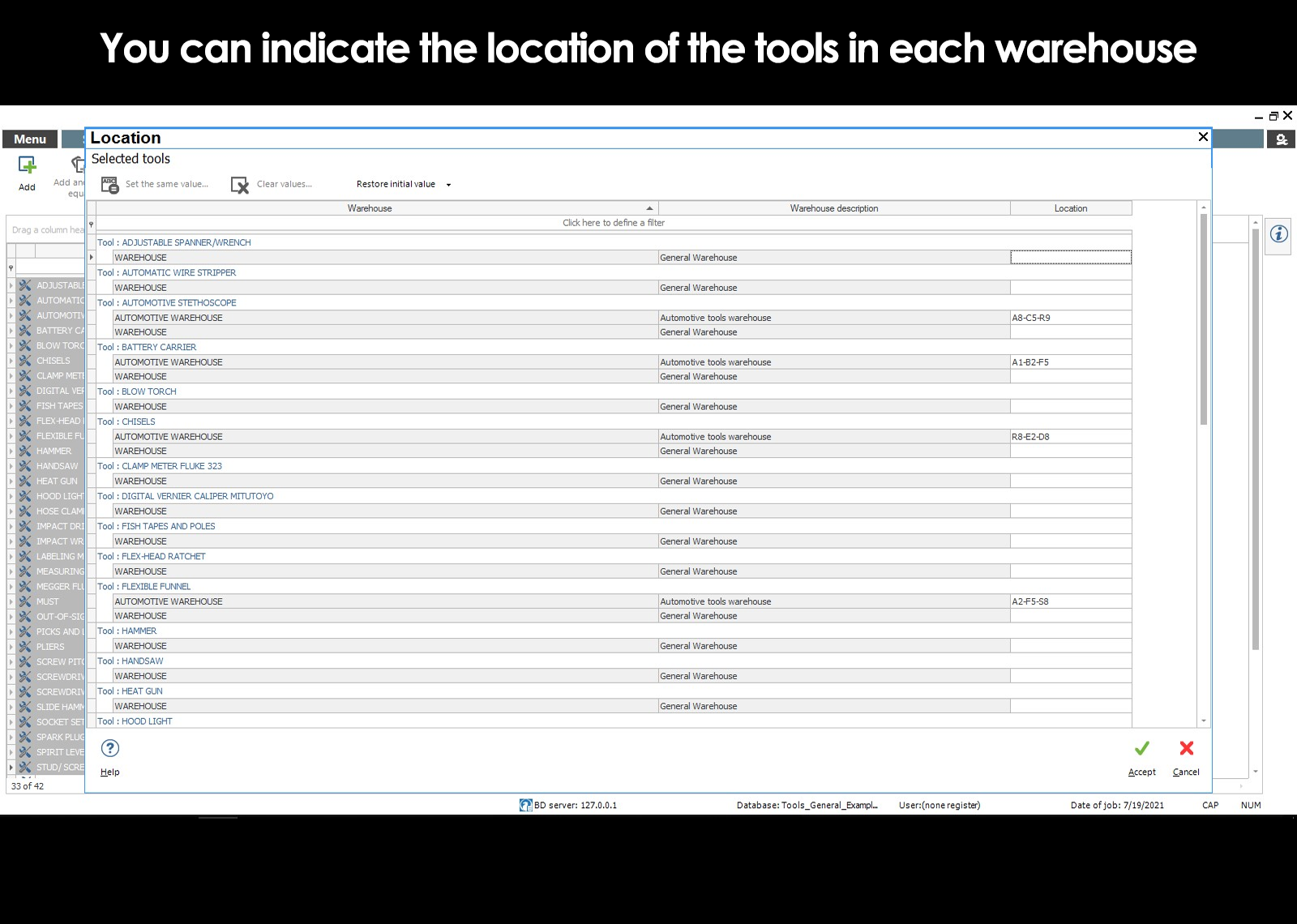

Localización en el almacén

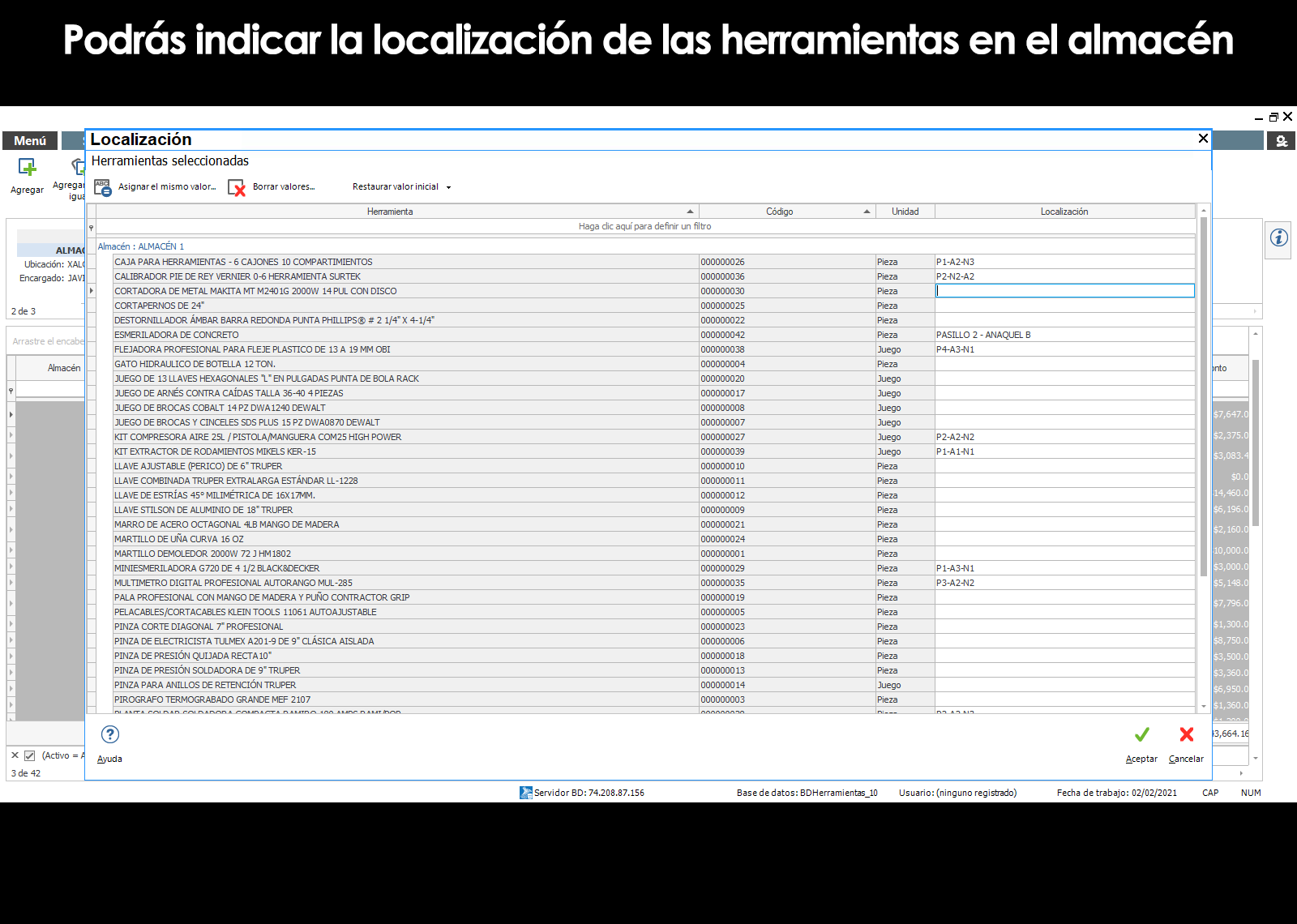

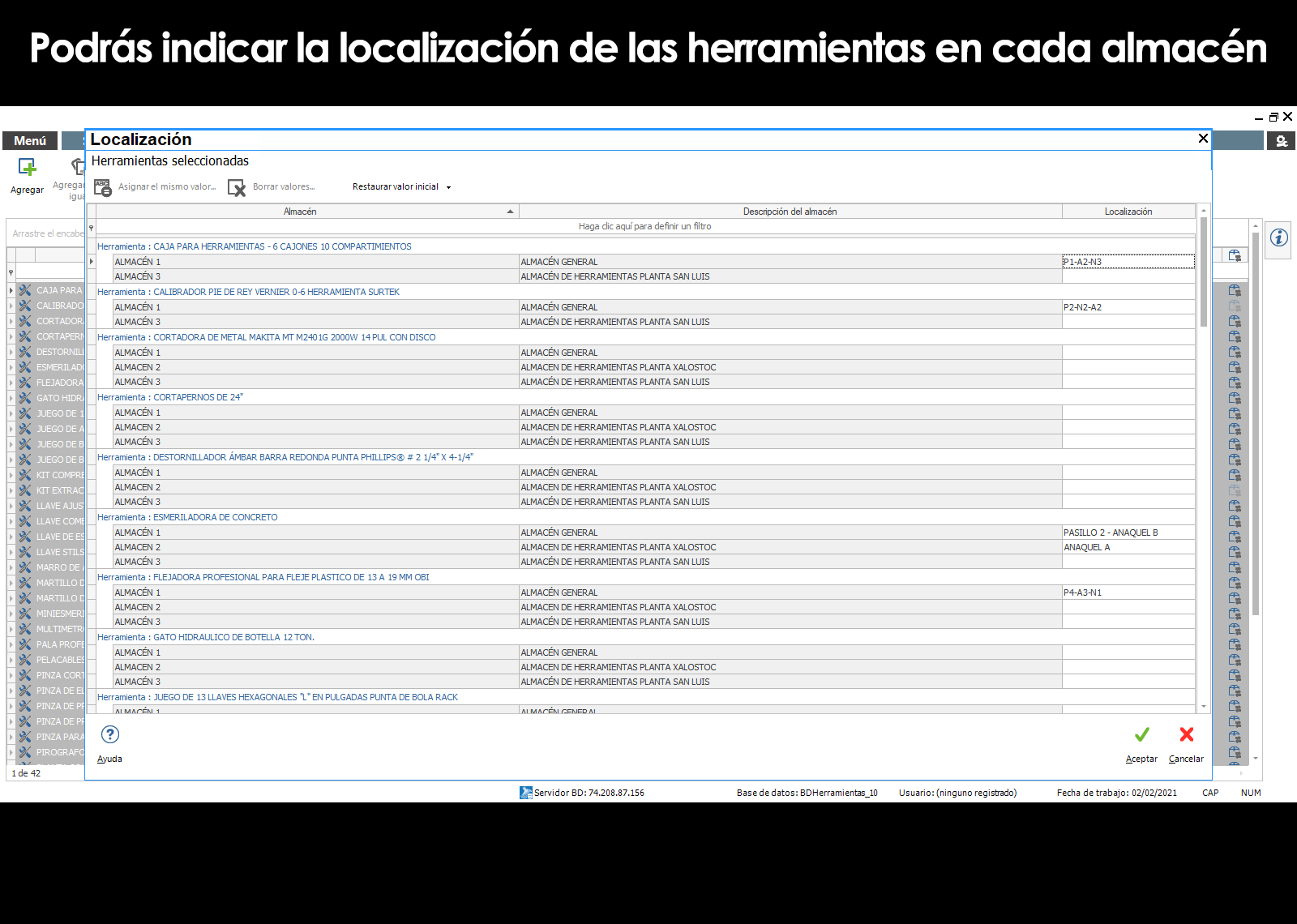

El sistema de control de herramientas permite documentar el lugar en que se encuentra físicamente la herramienta dentro del almacen (Ej. pasillo, anaquel o nivel), facilitando con esto su ubicación al momento de hacer el resguardo.

Al igual que las existencias y costos iniciales, la localización de los repuestos en los almacenes se puede editar desde el módulo de Repuestos y consumibles, así como desde el módulo de Almacenes.

Para indicar la localización de los repuestos, selecciona los repuestos de la malla y luego selecciona la acción Localizaciones dentro del submenú.

En ambos casos se abrirá una malla modificable con el campo de localización para capturar la localización de las herramientas en el o los almacenes. Esta localización puede ser modificada en cualquier momento.

¿No encuentras la respuesta a tus dudas o preguntas?

Contacta a nuestro equipo de soporte técnico

Ofrecemos servicio de soporte técnico GRATUITO vía:

✅ Videoconferencia

✅ Llamada telefónica

✅ Correo electrónico

✅ Whatsapp

✅ Chat

Preguntas frecuentes

Consulta nuestro sitio de preguntas frecuentes para conocer más sobre los esquemas de suscripción, nuestra amplia gama de opciones de conectividad, solución a problemas técnicos, etc..

Contacta a nuestro equipo de soporte técnico

Ofrecemos servicio de soporte técnico GRATUITO vía:

✅ Videoconferencia

✅ Llamada telefónica

✅ Correo electrónico

✅ Whatsapp

✅ Chat

Opcionalmente ofrecemos cursos de capacitación

Nuestras opciones flexibles de capacitación online y presenciales te brindarán todo el conocimiento necesario para comprender e implementar tu software de mantenimiento MP.

Opcionalmente ofrecemos cursos de capacitación

Nuestras opciones flexibles de capacitación online y presenciales te brindarán todo el conocimiento necesario para comprender e implementar tu software de mantenimiento MP.