Home / Inventory of spare parts

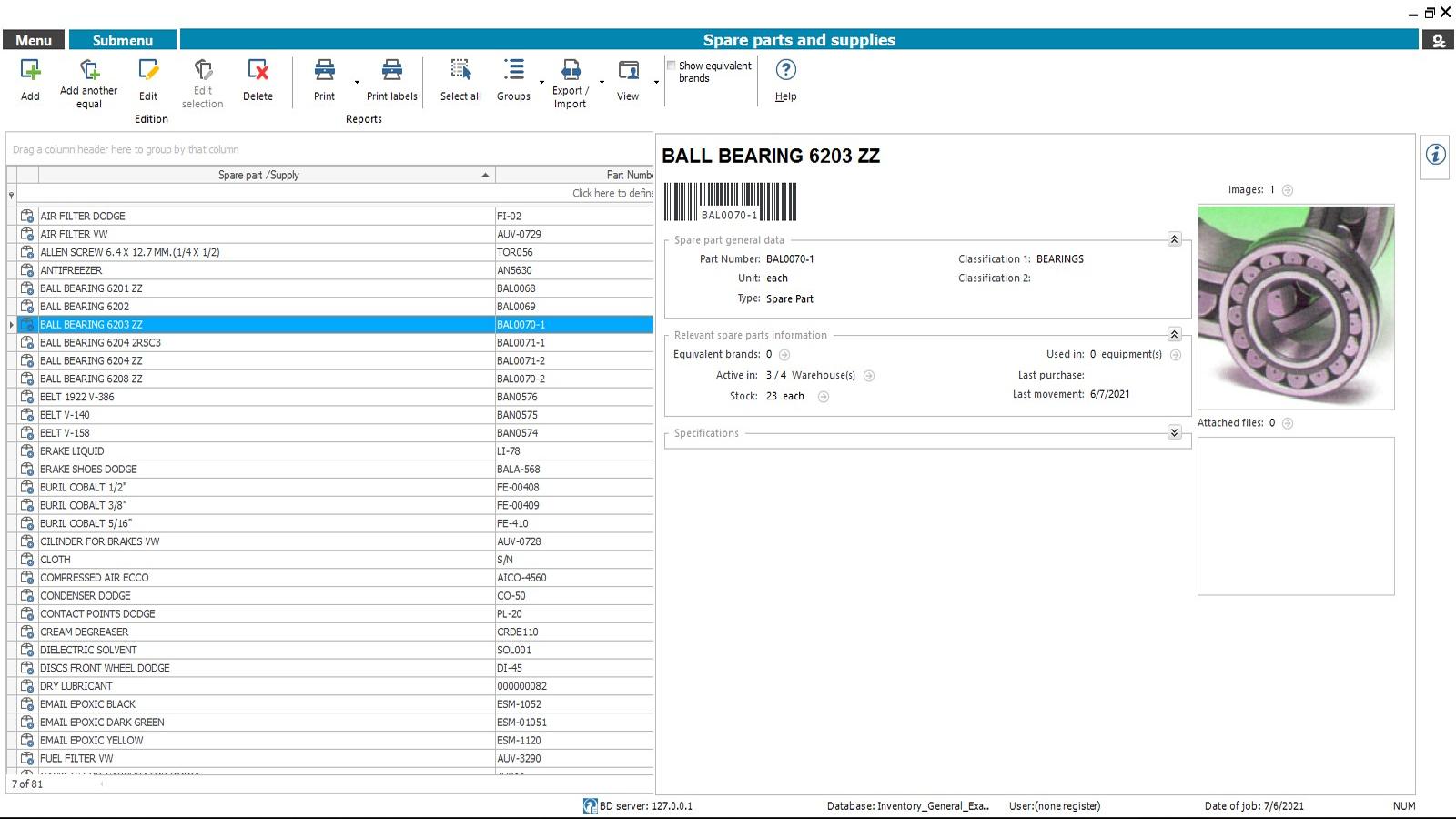

Description spare

Part number

Unit of measure

Classifications

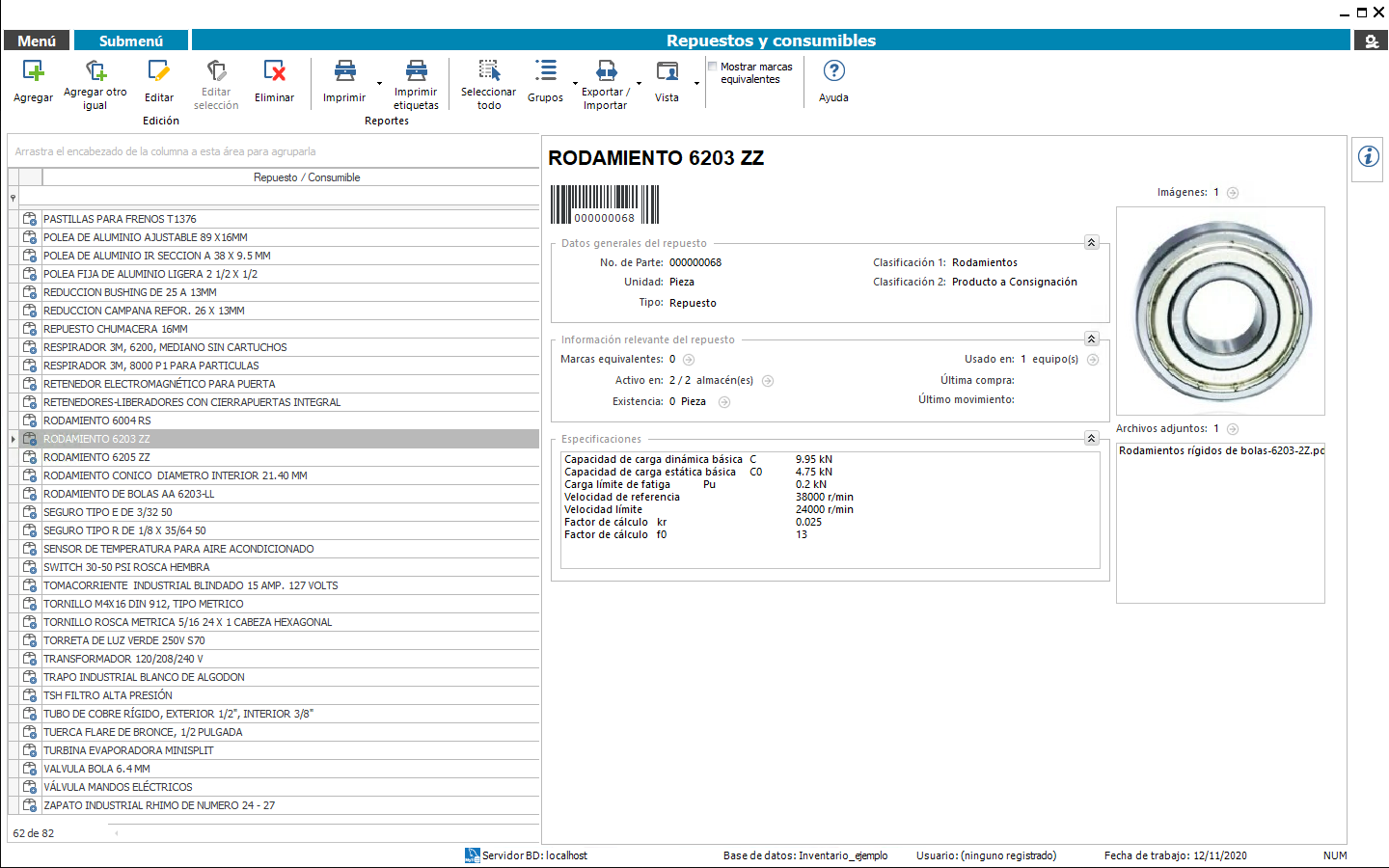

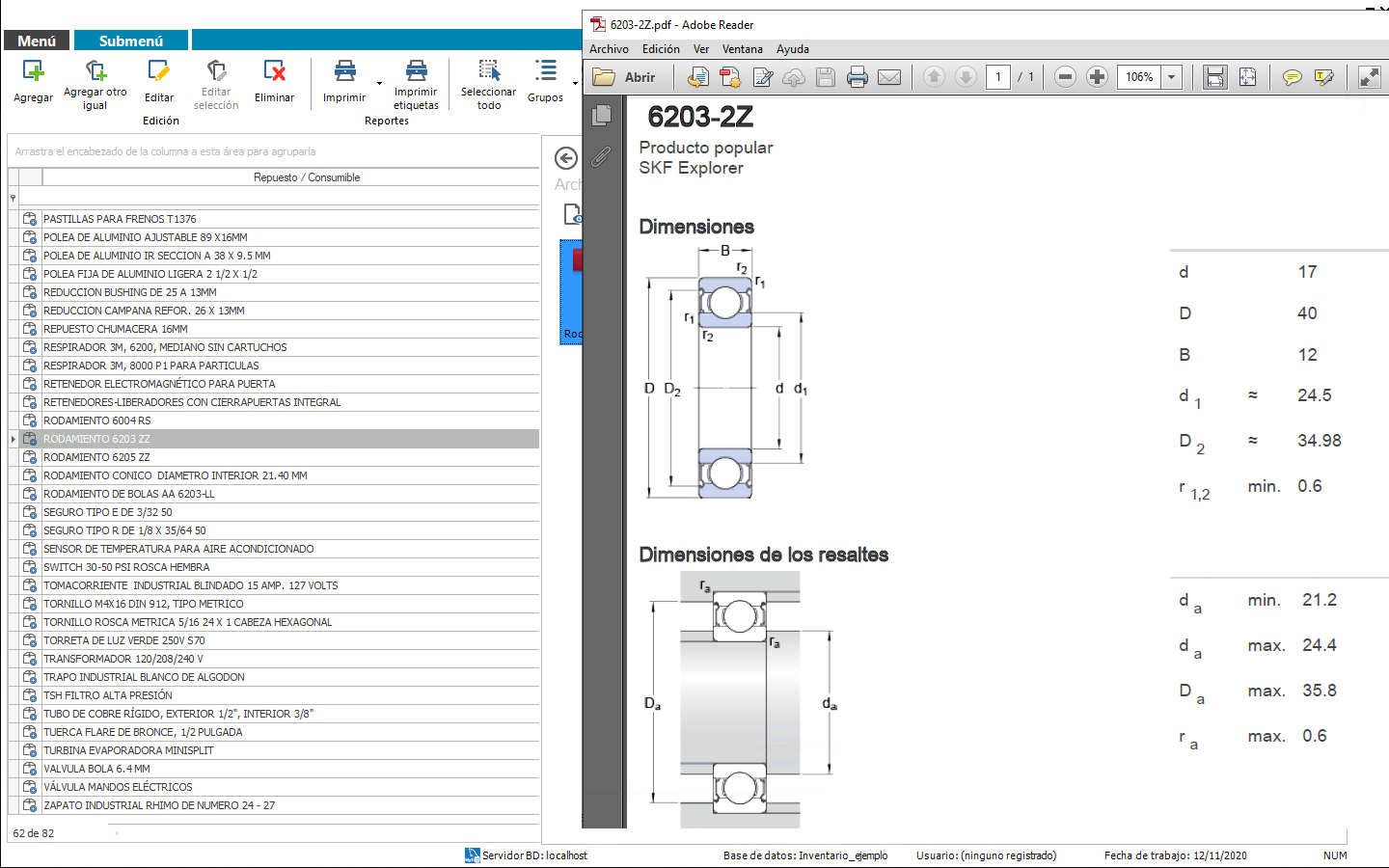

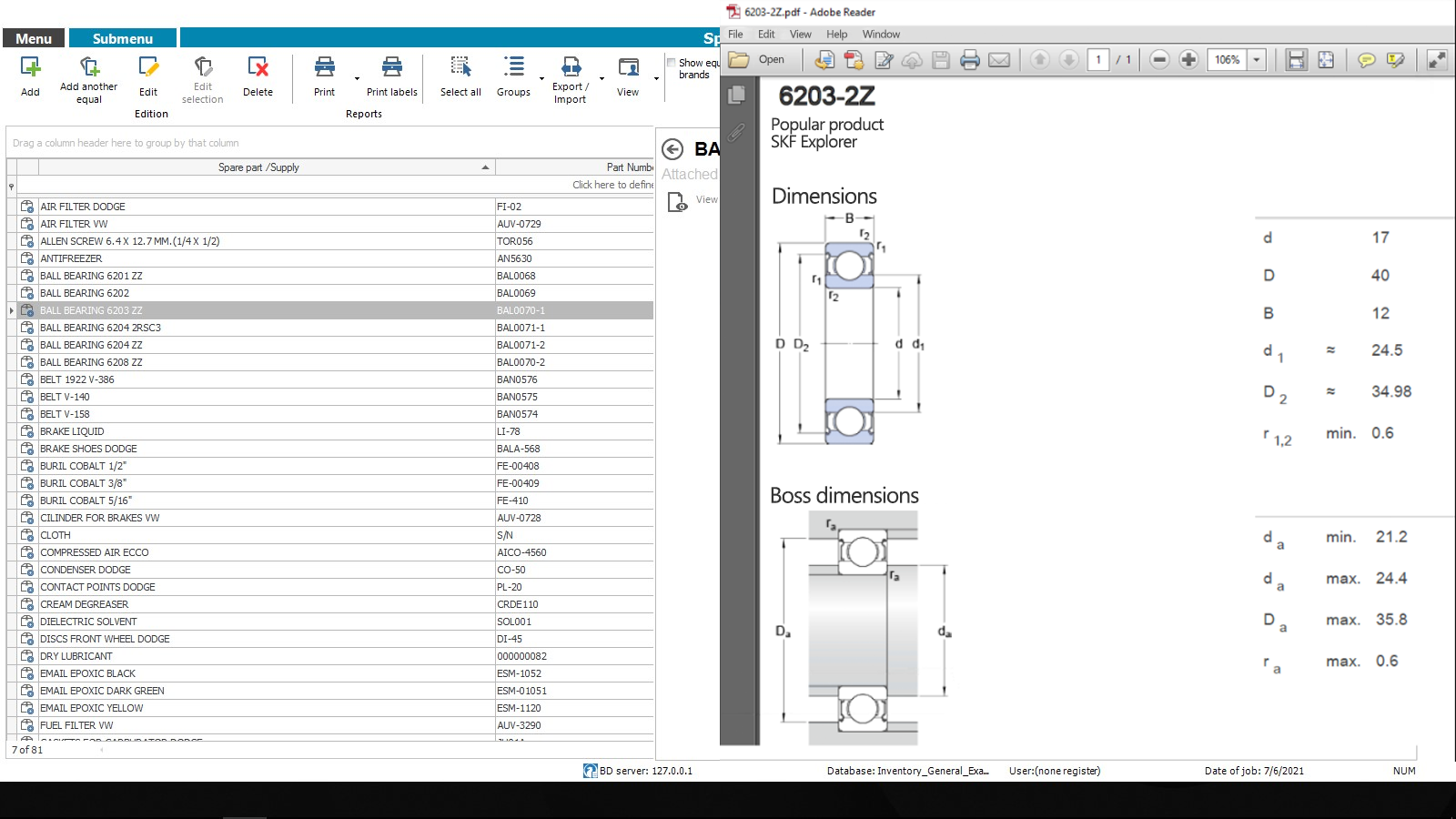

Specifications, images and attachments

Catalog auxiliary images

Catalog auxiliary attachments

Trademarks equivalent replacement

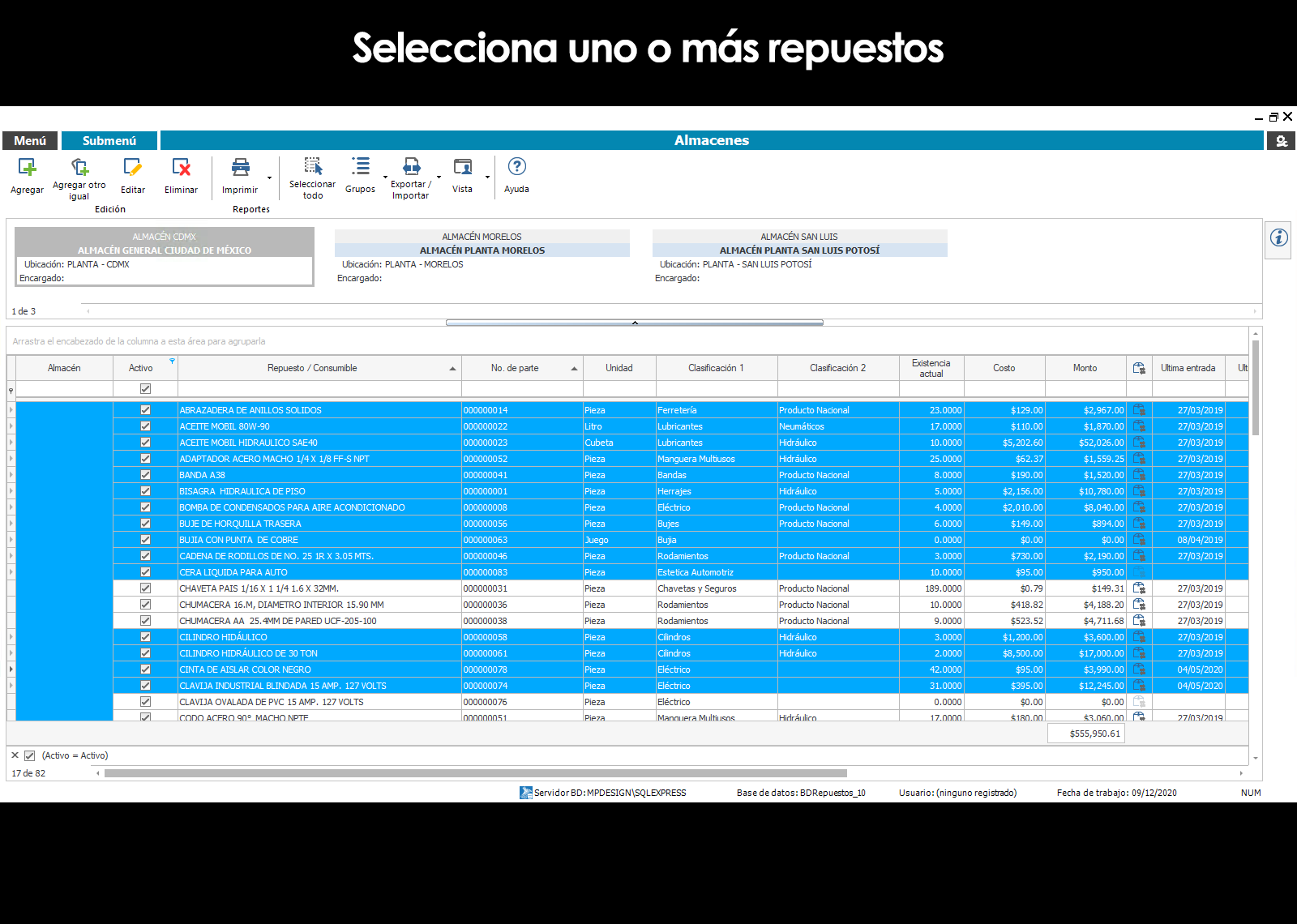

Warehouses that handle the replacement

Location in store

Levels minimum, maximum, and optimal

Time of procurement

Stocks and start-up costs

Related topics

▸ Introduction to the catalogue of spare parts

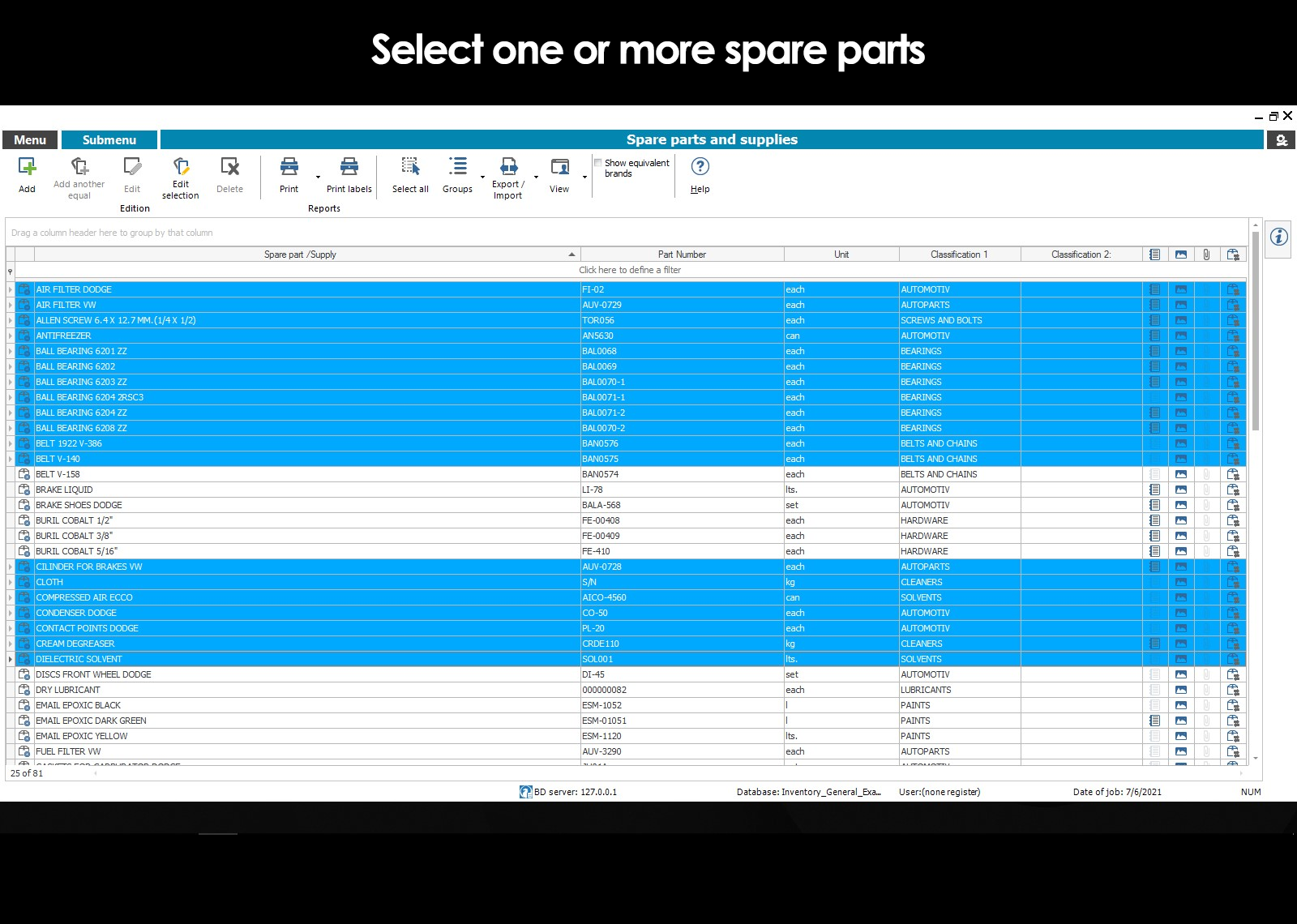

▸ View of the catalog of spare parts

▸ Information Panel spare parts

▸ Submenu of the catalogue of spare parts

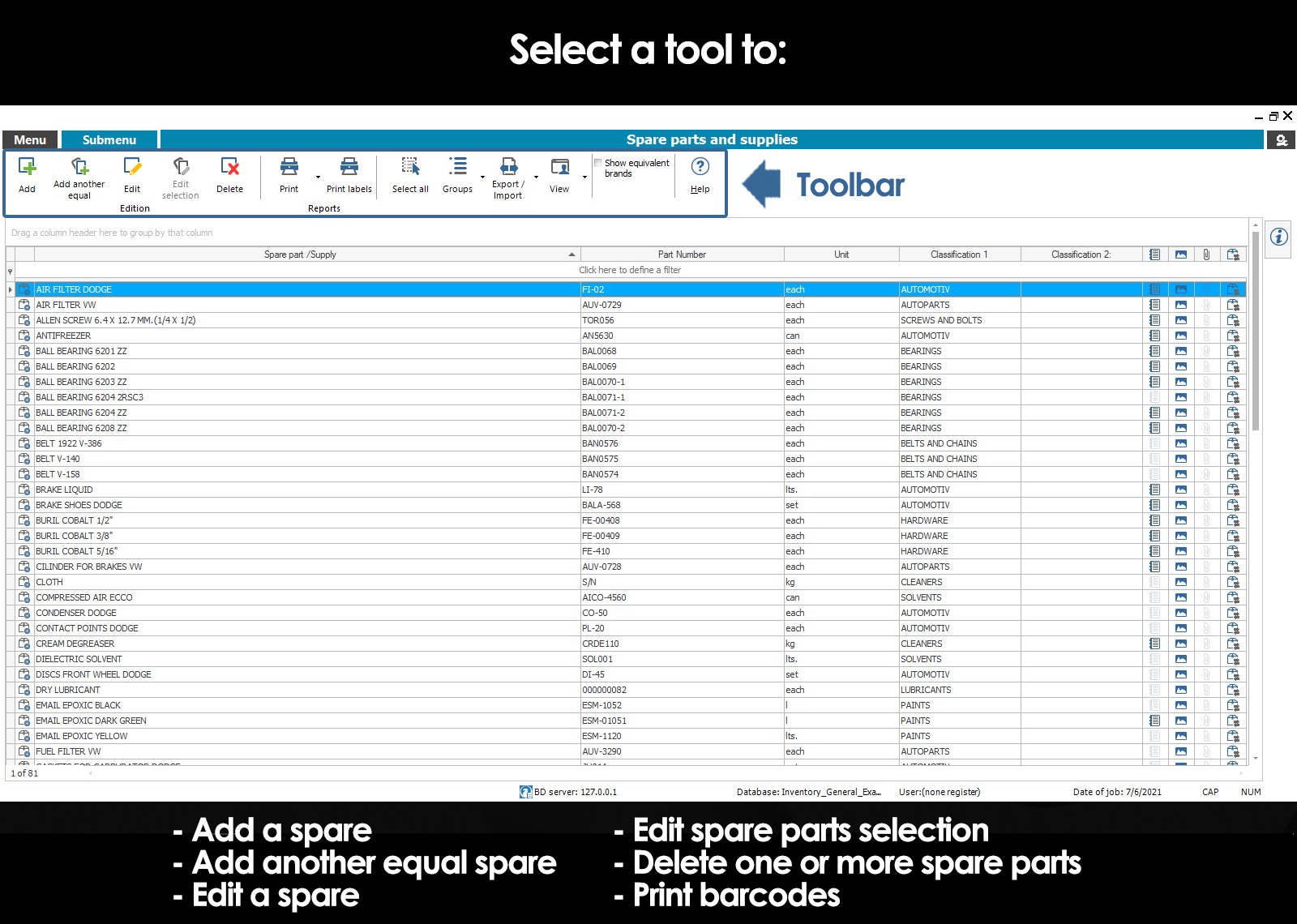

▸ Add a spare

▸ Add another one like it

▸ Edit a spare

▸ Delete a spare

▸ Editing multiple parts

▸ Printing of labels with bar code

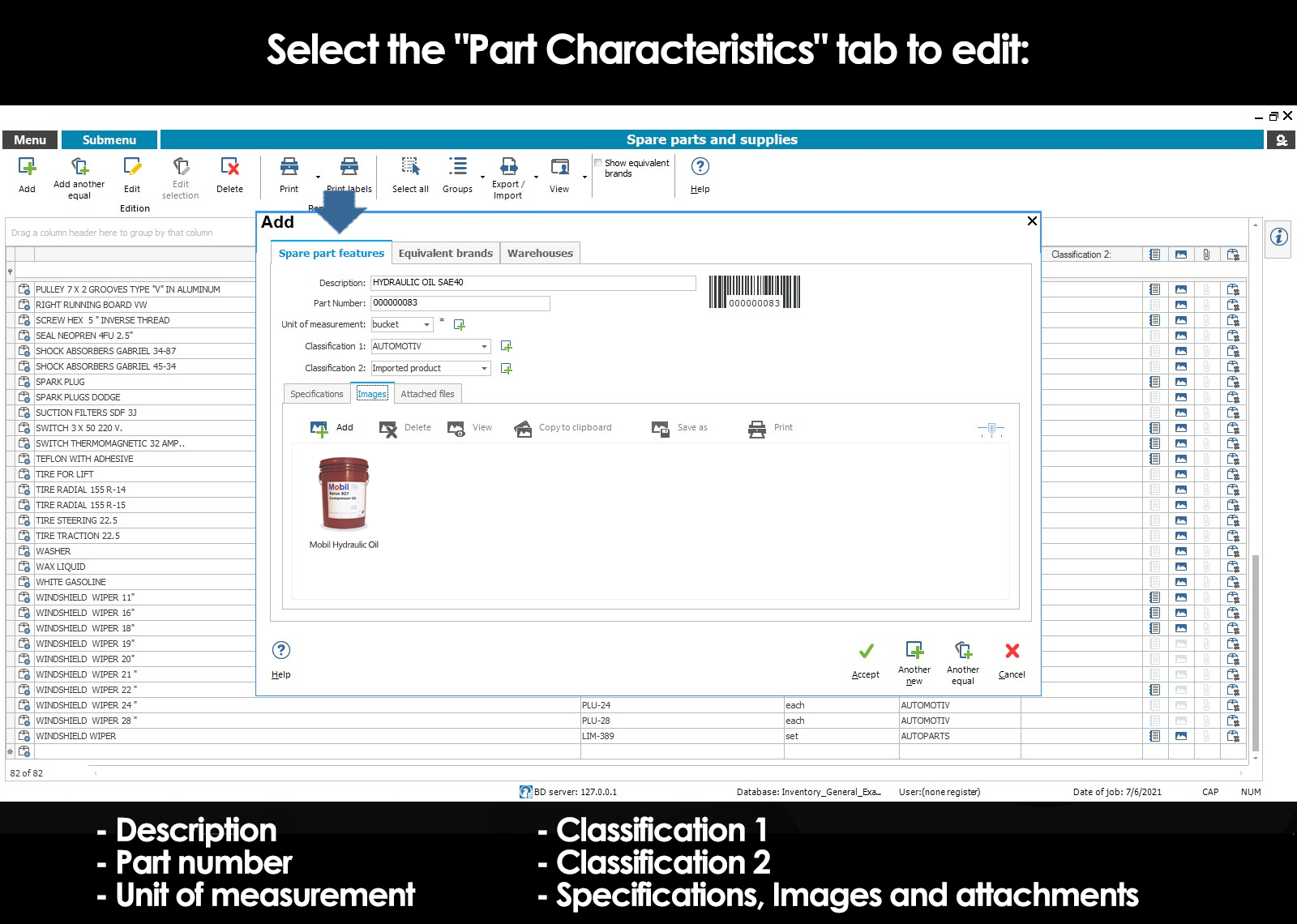

In the previous topic explains how to add or edit parts.

In this topic we focus on the specific explanation of each concept:

-

- Description

- Part number

- Unit

- Classification 1

- Classification 2

- Technical specifications, images and attachments

- Location

- Levels minimum, maximum, and optimum

- Trademarks equivalent

- Time of procurement

- Beginning Stocks

- Initial costs

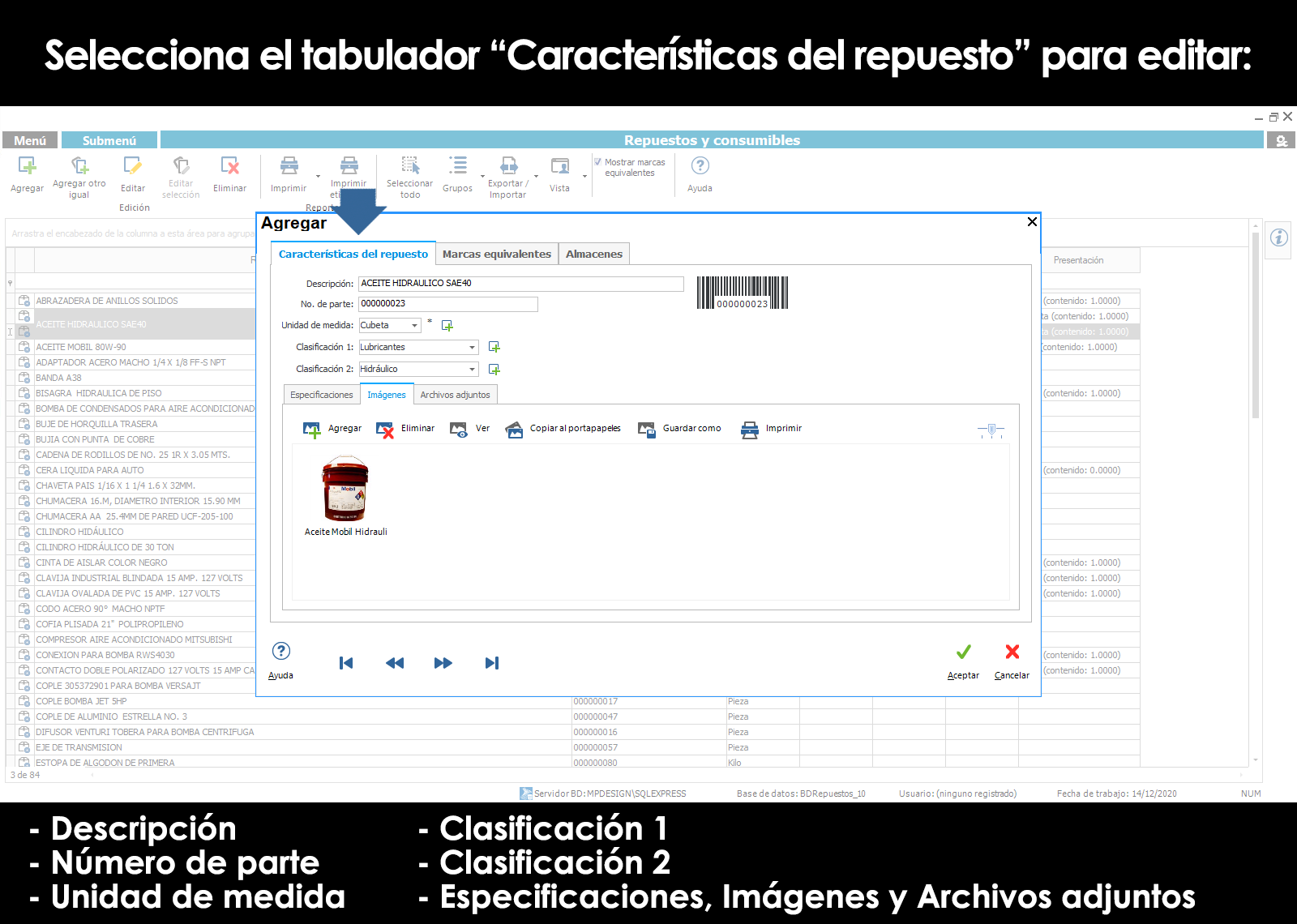

Description spare

Allows you to capture a brief description of the spare parts or consumable with up to 140 characters. If you require more space for more details of the product you will be able to use the field specifications.

Part number

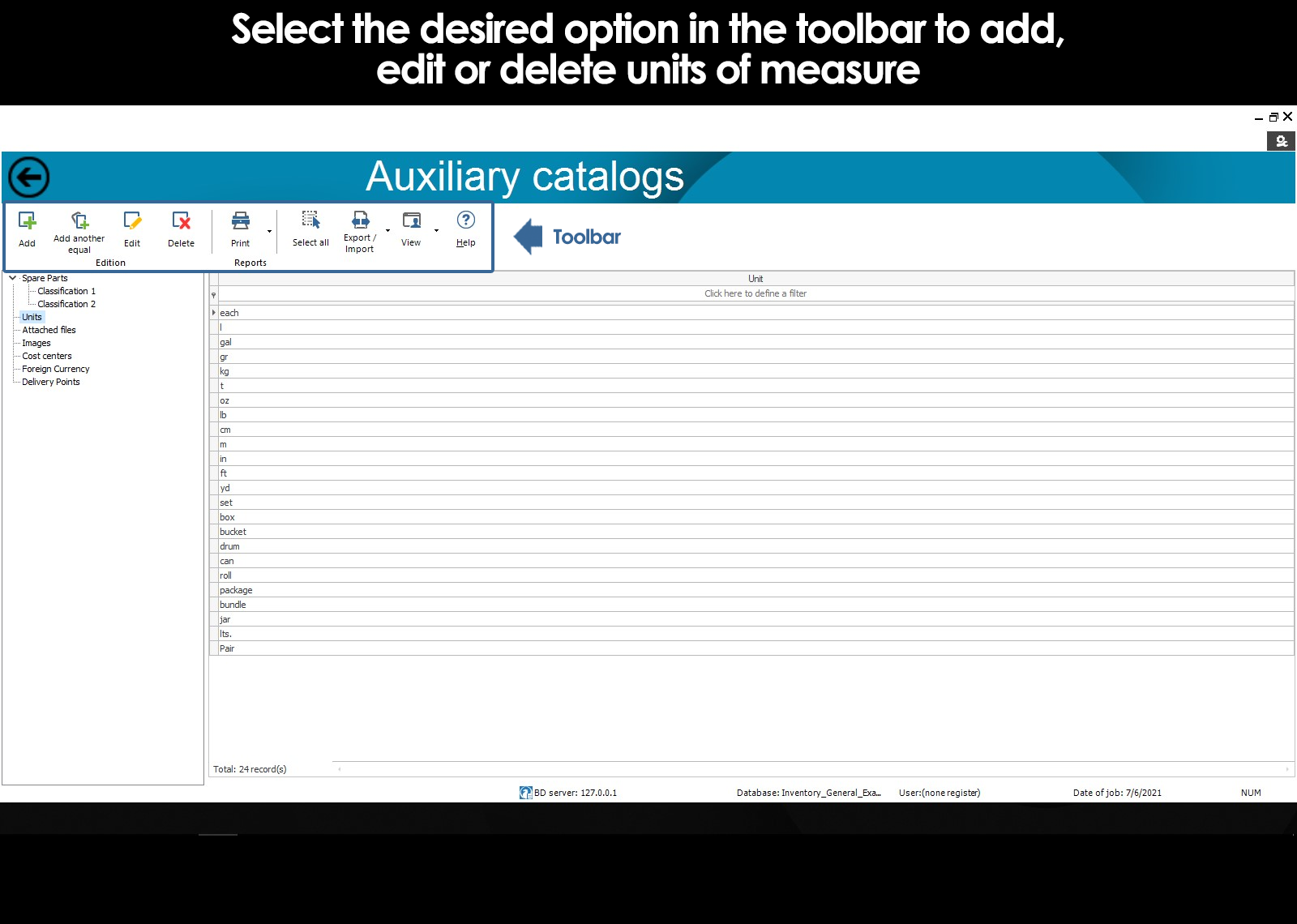

Unit of measure

The unit field allows you to indicate the unit of measure with which you will be able to quantify clearly the stock of our inventory, these provide us with the tools necessary for the correct interpretation of the quantities, the following are some examples of units of measure:

- Piece

- Game

- Roll

- Metro

- Liter

- Bucket

- Gallon

- Kilogram

- Etc.

At the time of editing a replacement, the unit of measure of the replacement is selected from a list contained in a catalogue auxiliary units. If the desired unit of measure is not yet registered, it is possible to add it to the catalog auxiliary units at this time, without the need to leave the screen capture of spare parts, by clicking on the icon To add to the catalog located to the right of the field.

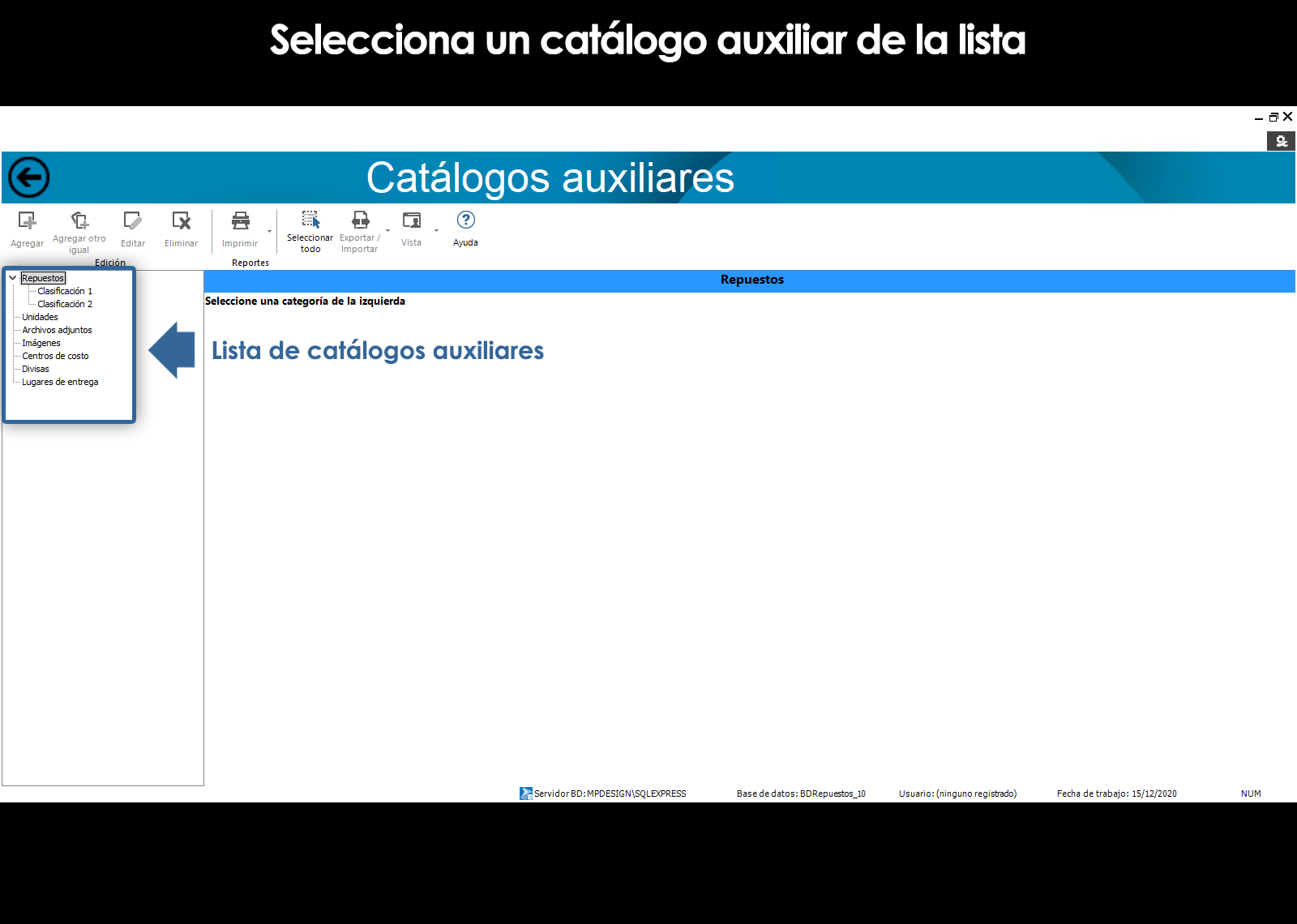

To edit or delete a unit of measure of the catalogue auxiliary inidades, it is necessary to go to the module Catalogs auxiliary.

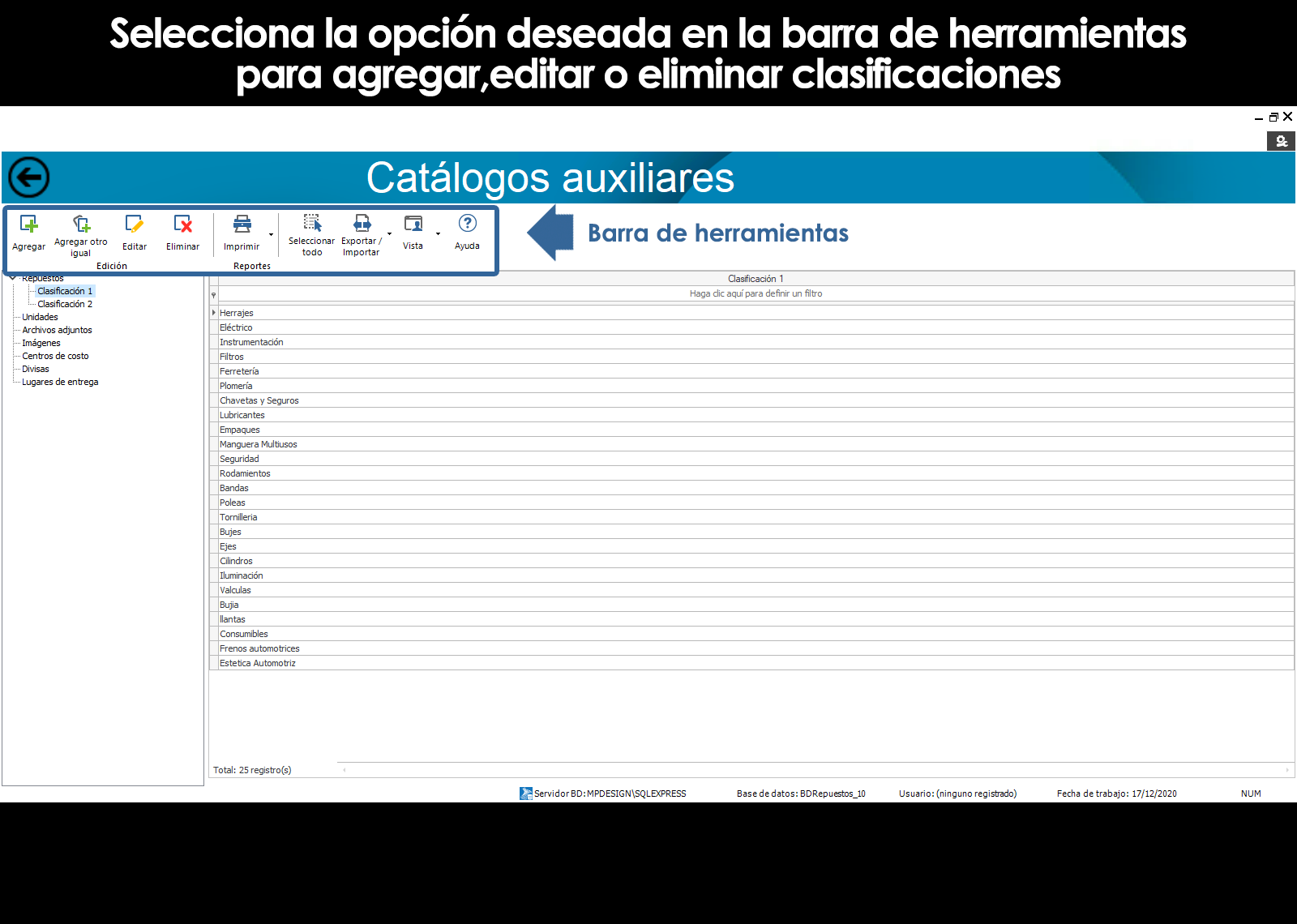

Classifications

The fields ' Classification 1 and 2” allow you to classify the spare parts by two different criteria that are set by the user according to their particular needs classification.

Example of a Catalog of Auxiliary Classifications:

| CLASSIFICATION 1 | CLASSIFICATION 2 |

|---|---|

| NATIONAL PRODUCT PRODUCT IMPORT PRODUCT CONSIGNMENT |

HARDWARE ELECTRIC INSTRUMENTATION FILTERS HARDWARE store PLUMBING PINS AND INSURANCE LUBRICANTS PACKAGING BEARINGS BANDS PULLEYS HARDWARE AUTOMOTIVE |

At the time of editing a replacement part, the rating of the replacement is selected from a list contained in a catalogue auxiliary classifications. If the desired rating is not yet registered, you can add it to the catalog auxiliary classifications in that moment, without even having to leave the screen capture of spare parts, by clicking on the icon To add to the catalog located to the right of the field.

A practical example of application of the fields of “Rank 1 and 2” could be seen in the grouping of the catalog of spare parts.

To edit or delete a catalog classification auxiliary classifications, it is necessary to go to the module Catalogs auxiliary.

Specifications, images and attachments

The inventory of spare parts allows you to supplement the information of your parts with specifications, pictures, and attachments, leaving this information available for rapid consultation from the information pane.

In the field of specifications, the program allows you to capture freely on text features and special details of the spare parts, which will be available from the information pane.

The images allow you to document the information of the spare with photographs, diagrams, etc you Can also associate files of Word, Excel, PDF, etc, with additional information as may be manual installation of the spare parts, technical sheets, etc, at The time of displaying file attachments, spares inventory will open the file with the application that is configured on the computer to open the default file type.

To associate an image to a computer it is necessary to first import the image to the catalog auxiliary images . Once the image is imported to the catalog is appropriate to associate with the team. This is because the images are saved in the database and this way it will not matter to move or delete the source of the images.

For the administration of the images and attachments, go to the module Catalogs auxiliary from the Main menu.

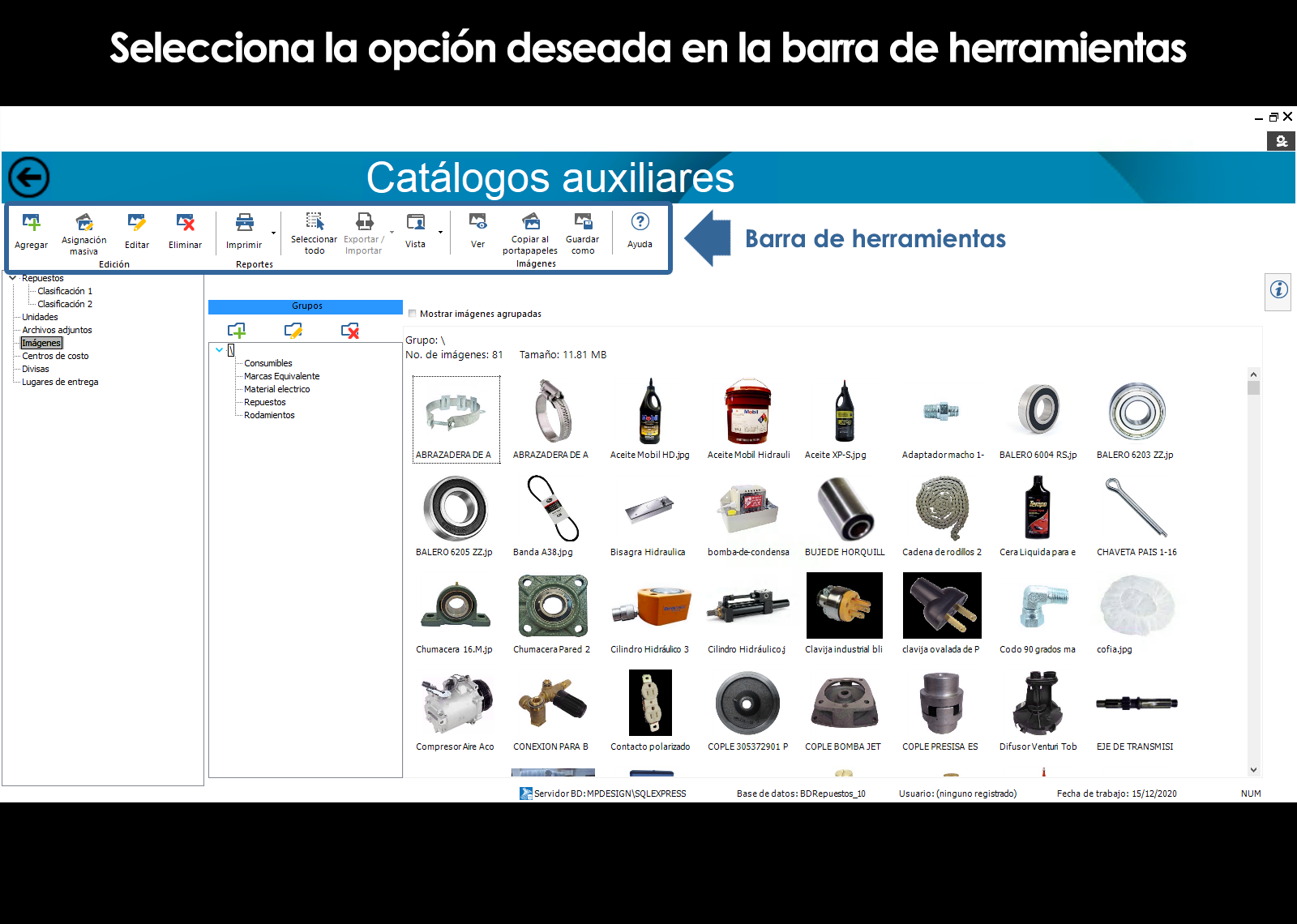

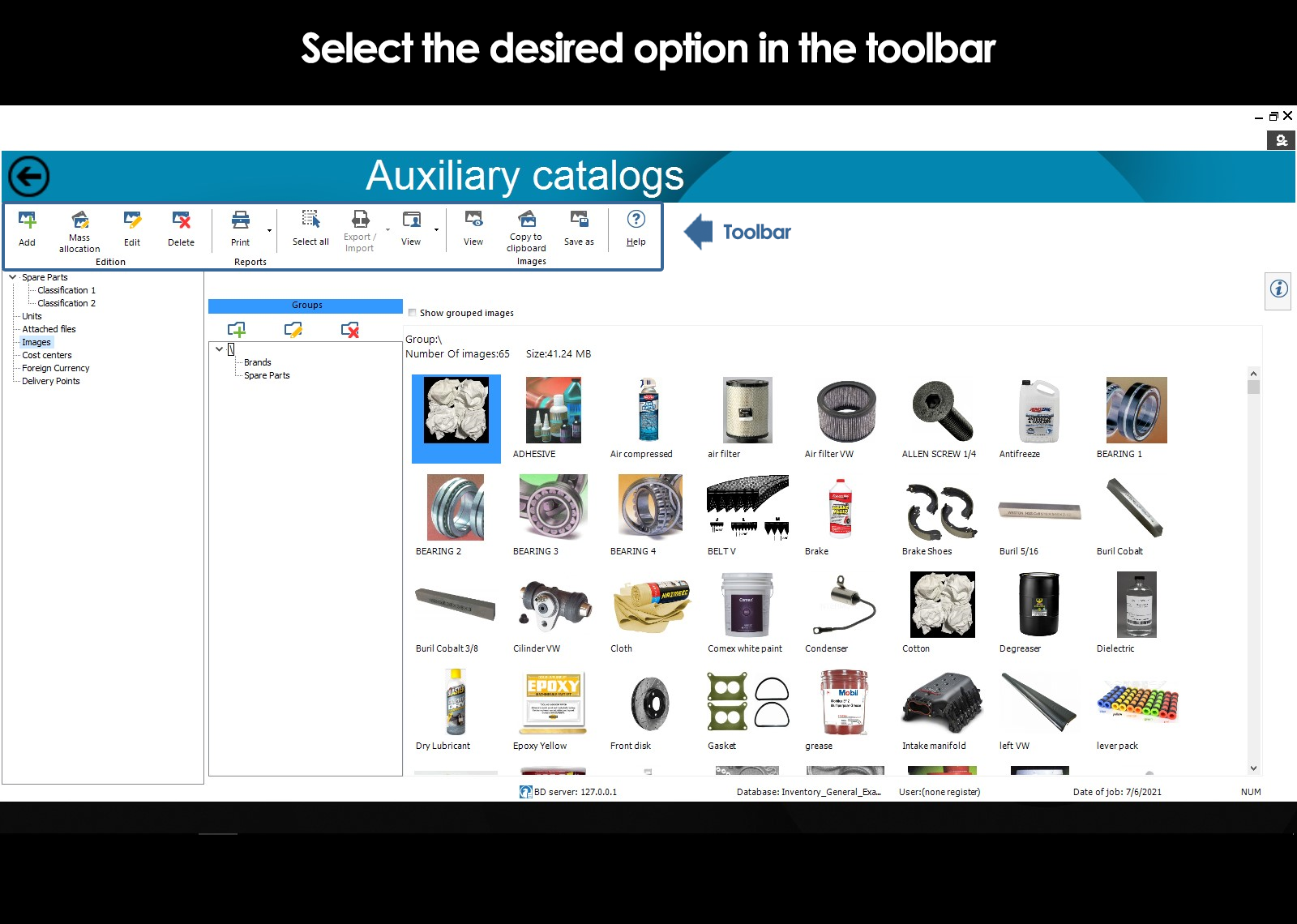

Catalog auxiliary images

The catalogue auxiliary image is formed importing images to the program Inventory of spare parts for the purpose of associating their spare parts. Just add it once to the database and will be available even when you delete, move, or lose the file of origin of such images.

The catalogue auxiliary of images allows you to group images, for example images of bearings, electrical equipment, bands, etc

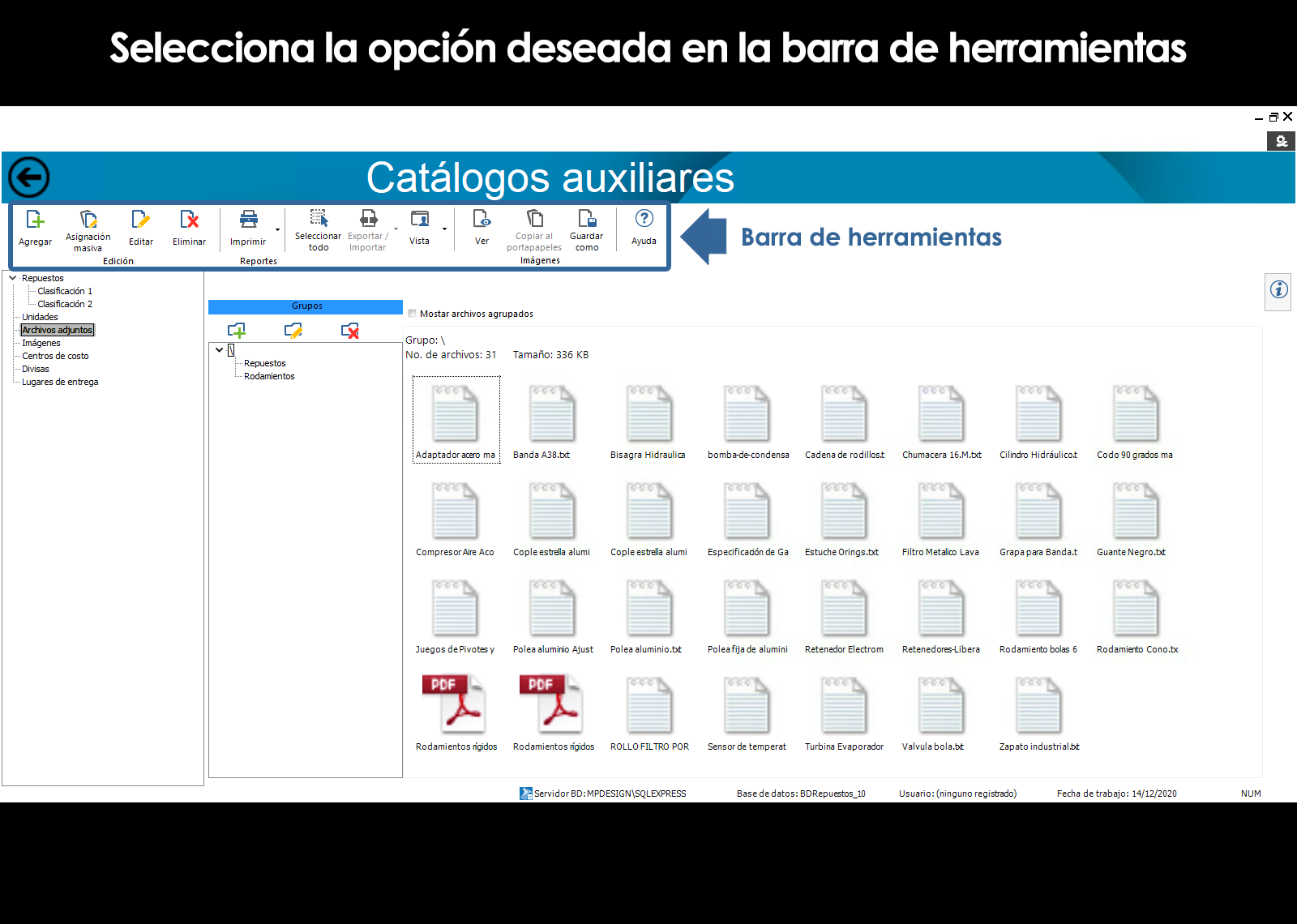

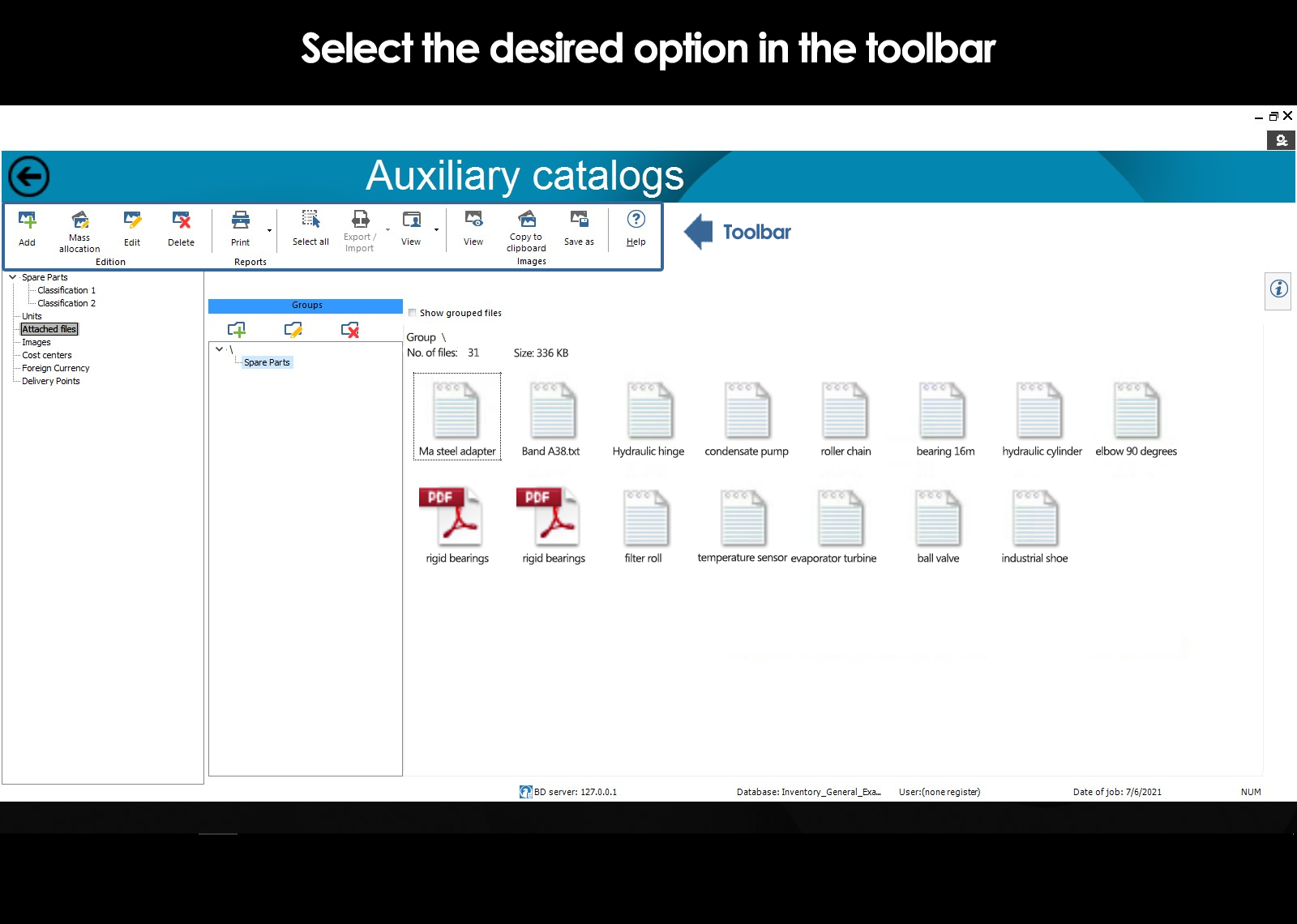

Catalog auxiliary attachments

All the attached files in the system are included in the catalogue auxiliary attachments, once loaded into the system, it is possible to assign them to different teams, locations, activities, maintenance, work orders, etc., attached files can be categorized according to their nature, as they can be, maintenance manuals, warranties, plans, or documents in general.

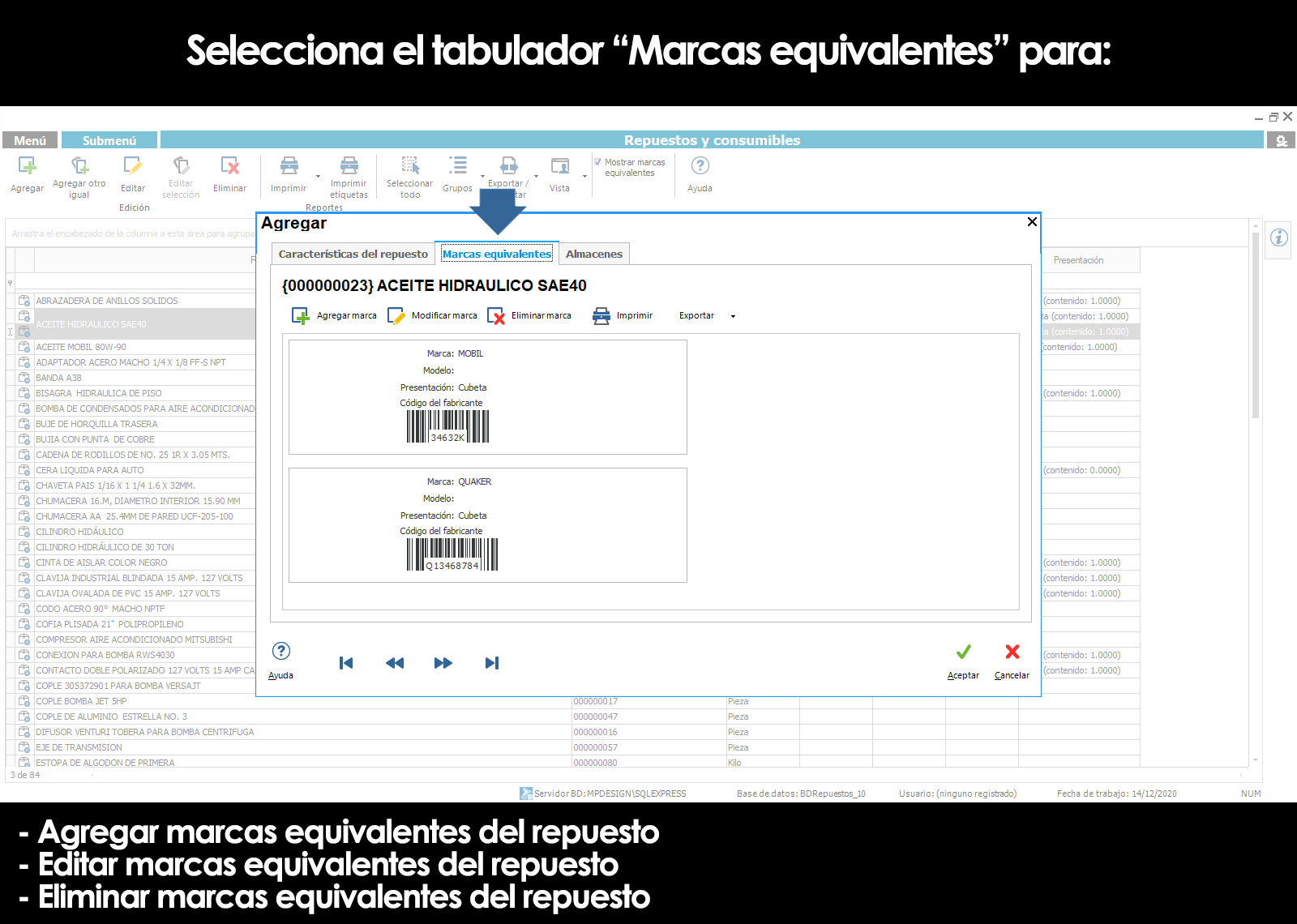

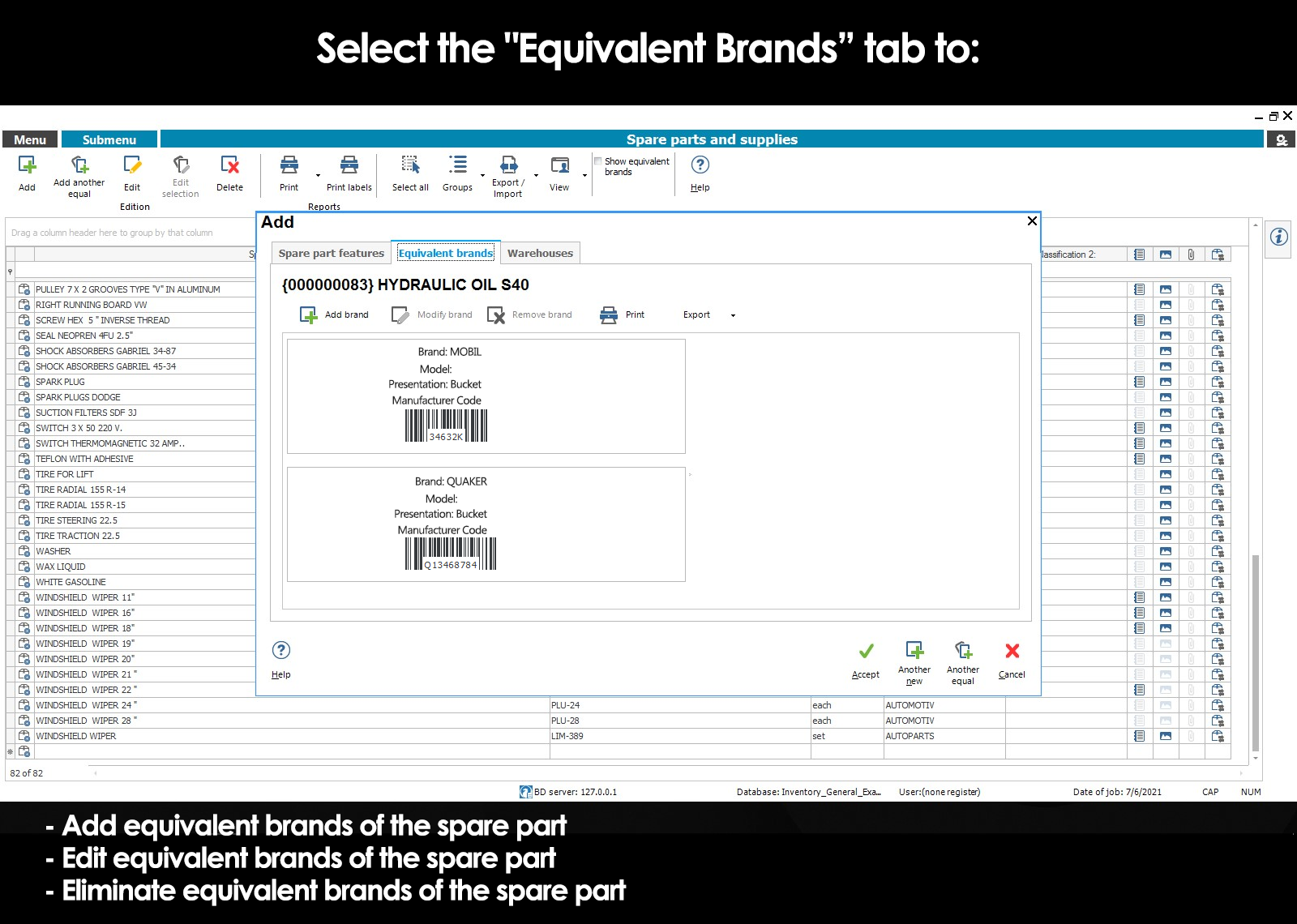

Trademarks equivalent

An important concept that differentiates a warehouse of spare parts and a store of a trade, for example, is that in the latter each product should be handled as different products. However, in a warehouse of spare parts, equivalent products can be managed as if it were of the same product.

As an example, we can mention that when out of stock of a product of a particular brand, that does not necessarily mean that we may need to re-supply the inventory, if we have stock of another product of another brand that is equivalent.

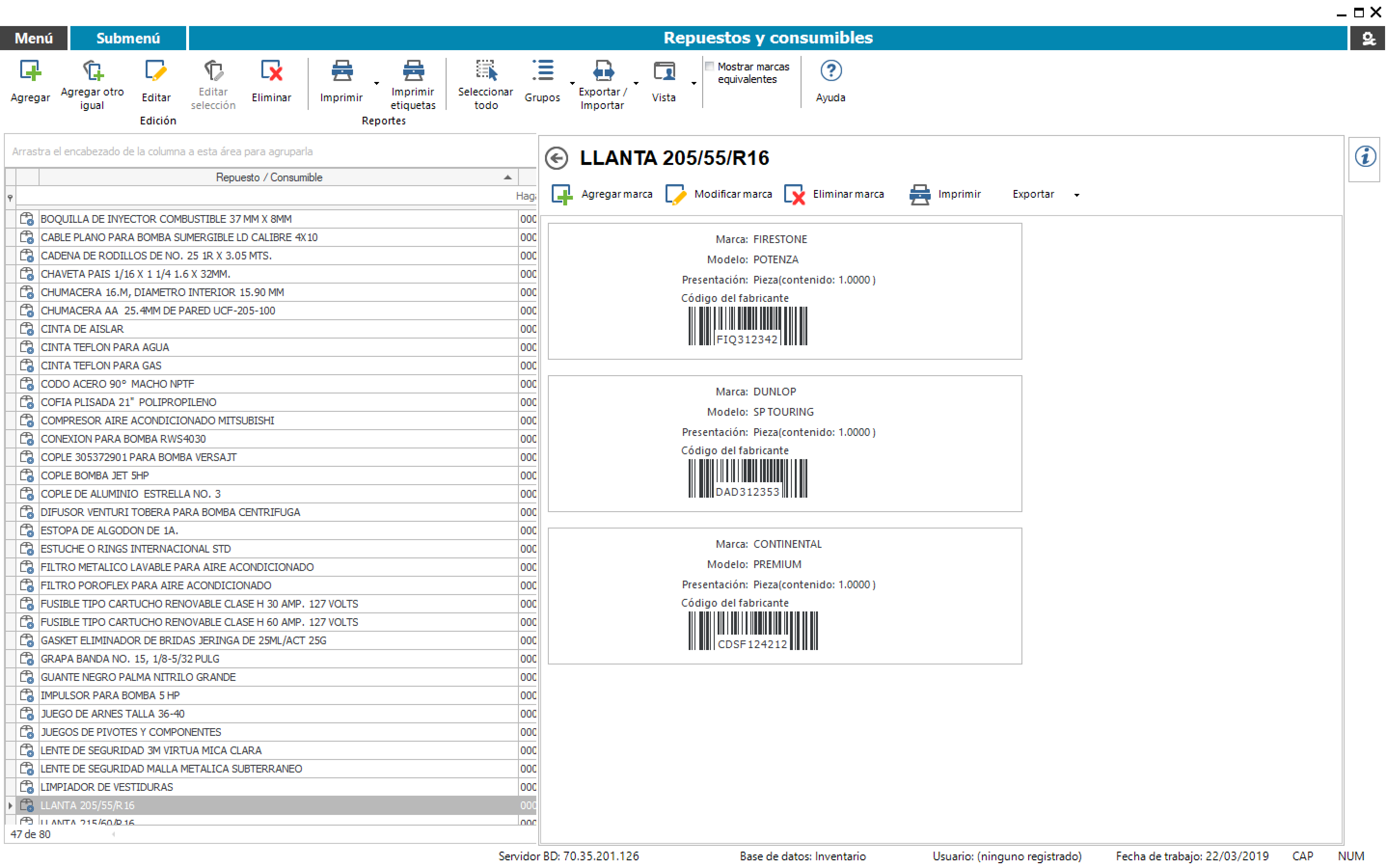

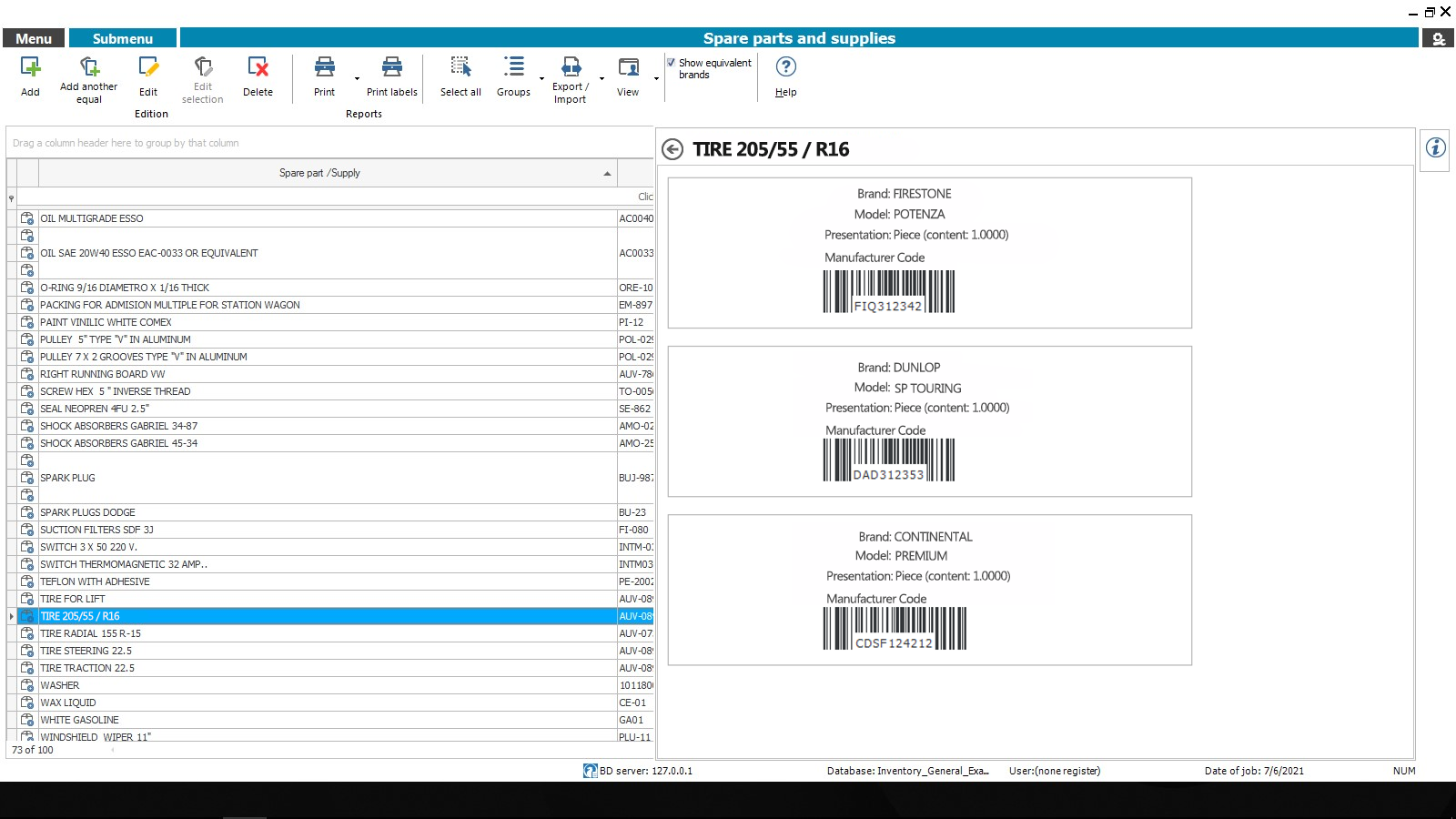

In the inventory of spare parts, you can generate a list of marks equivalent to each part in order to document the different brands of each part, thus avoiding the need in the catalog, spare parts repeated for each of the brands that produce them.

For example; assume that your store is required to have tires R16 R205 as a replacement for the vehicles of your company. There are different companies that produce this type of tires: Firestone, Bridgestone, Michelin, etc, Within their catalog of resources you will have the tire R16 R205 and also have the list of brands equivalent. So when you need to make the change of the tire, you will easily to the resource in its store, and you can use any of the brands that produce them, or, select a specific brand if required to do so.

To see the brands are equivalent select the tool to filter by brand equivalent that is located on the module toolbar of spare parts.

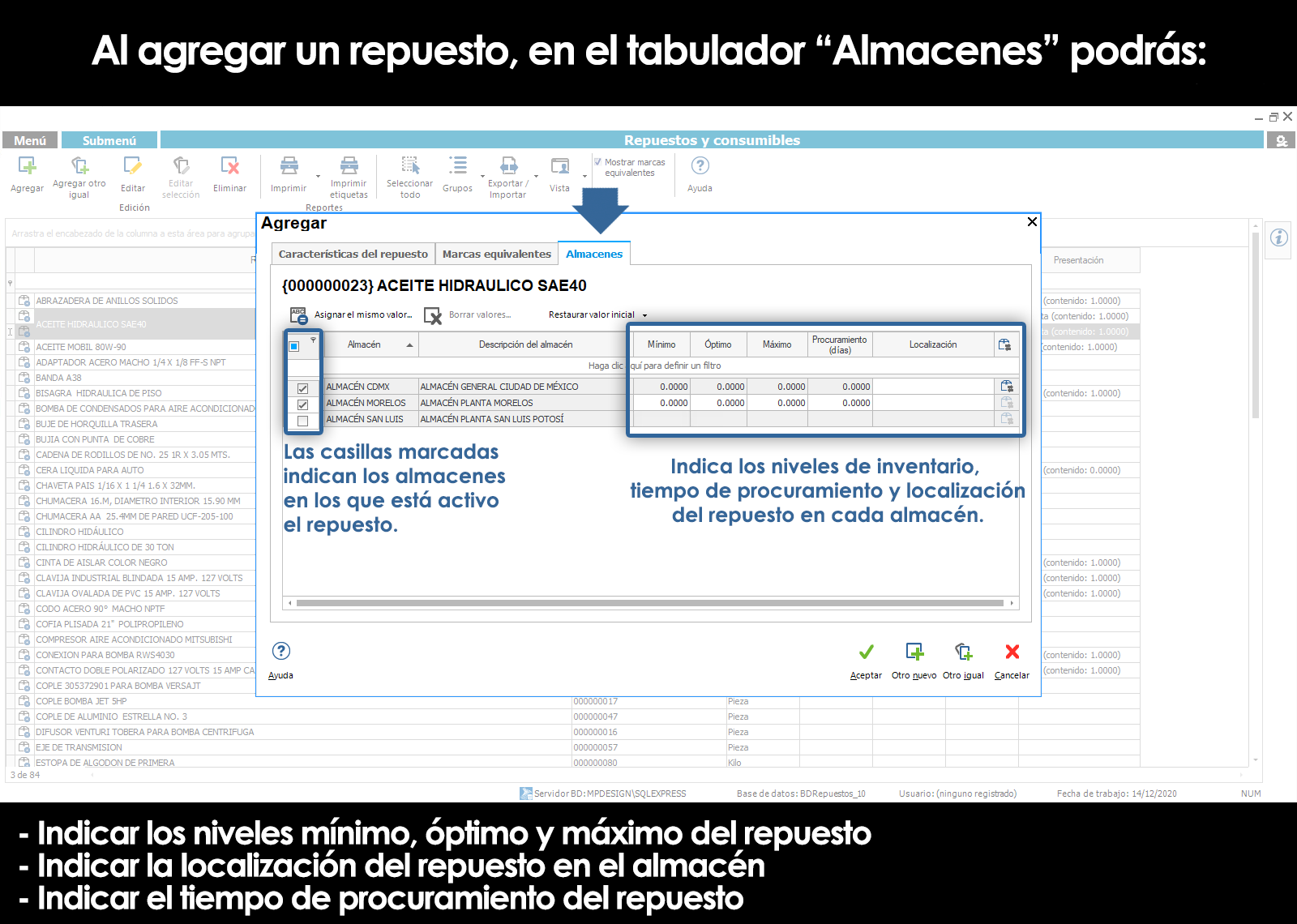

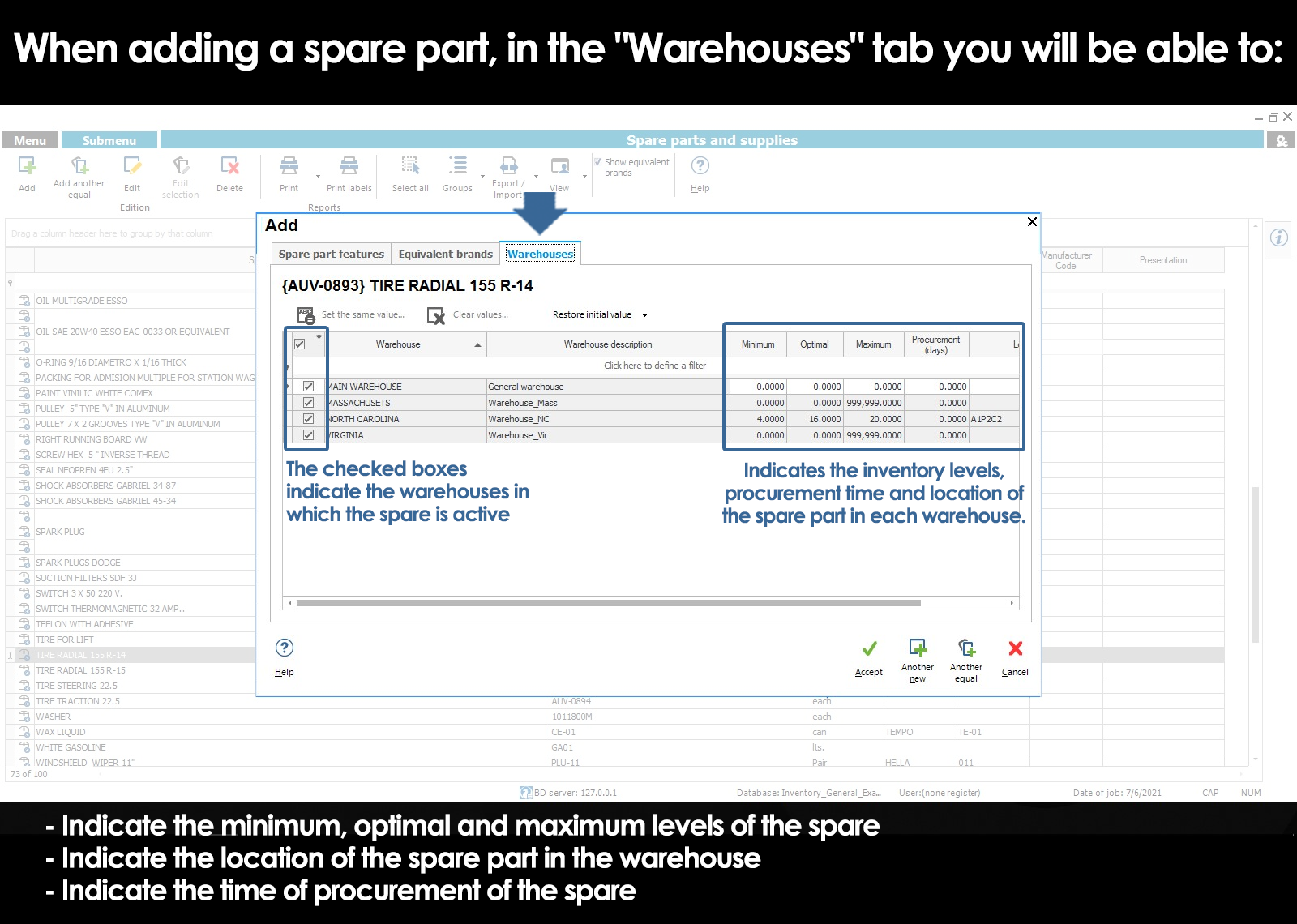

Warehouses that handle the replacement

The moment of adding a spare to the catalog, the program inventory of spare parts allows you to indicate on which stores will be active the spare. Then, in case you have more than one warehouse, we can choose the or the stores that will handle that part.

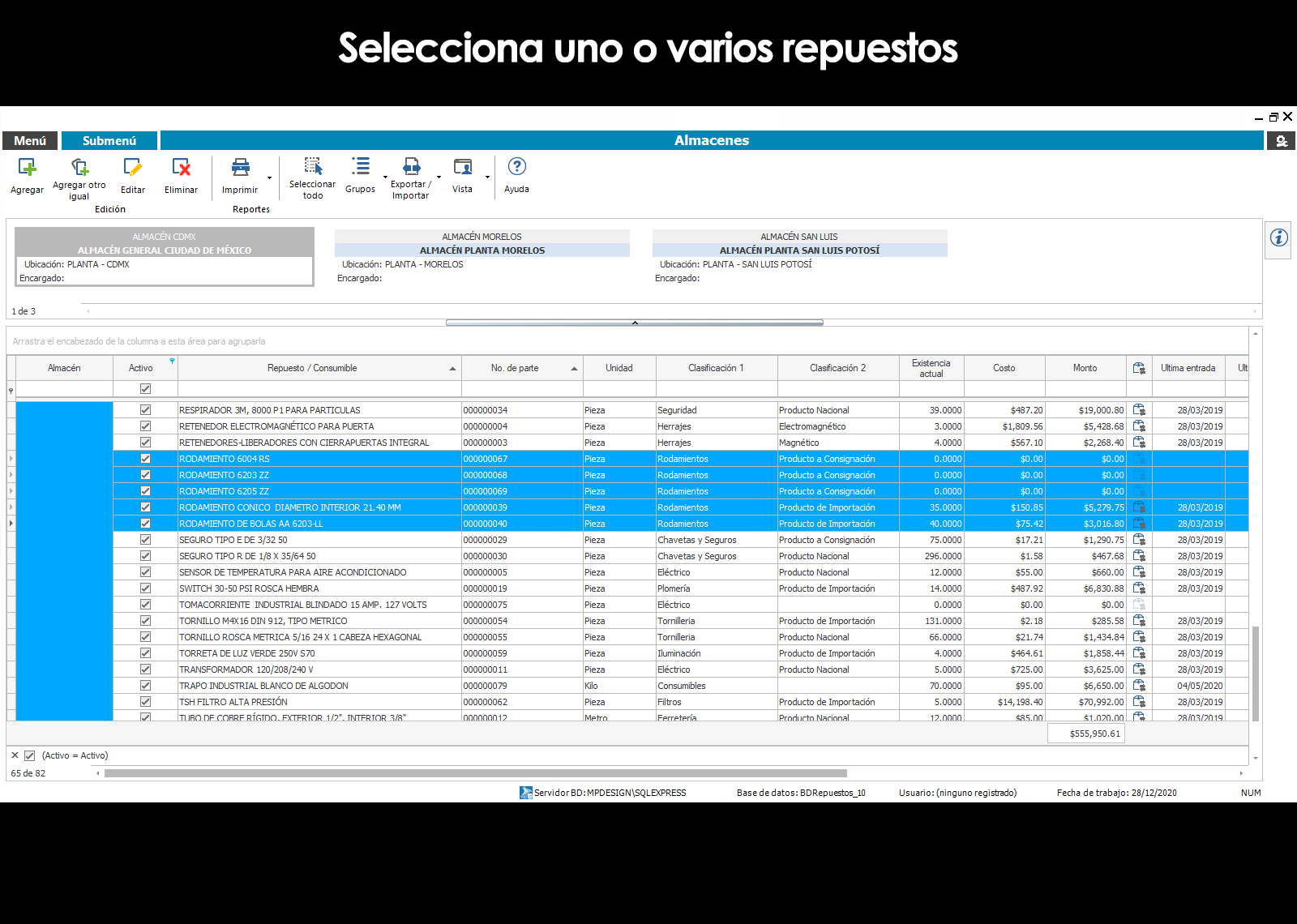

Location in store

The inventory of spare parts enables you to document the place in which they are physically located the spare inside the store (Eg. hallway, shelf or level), giving this location at the time of supplying the vouchers.

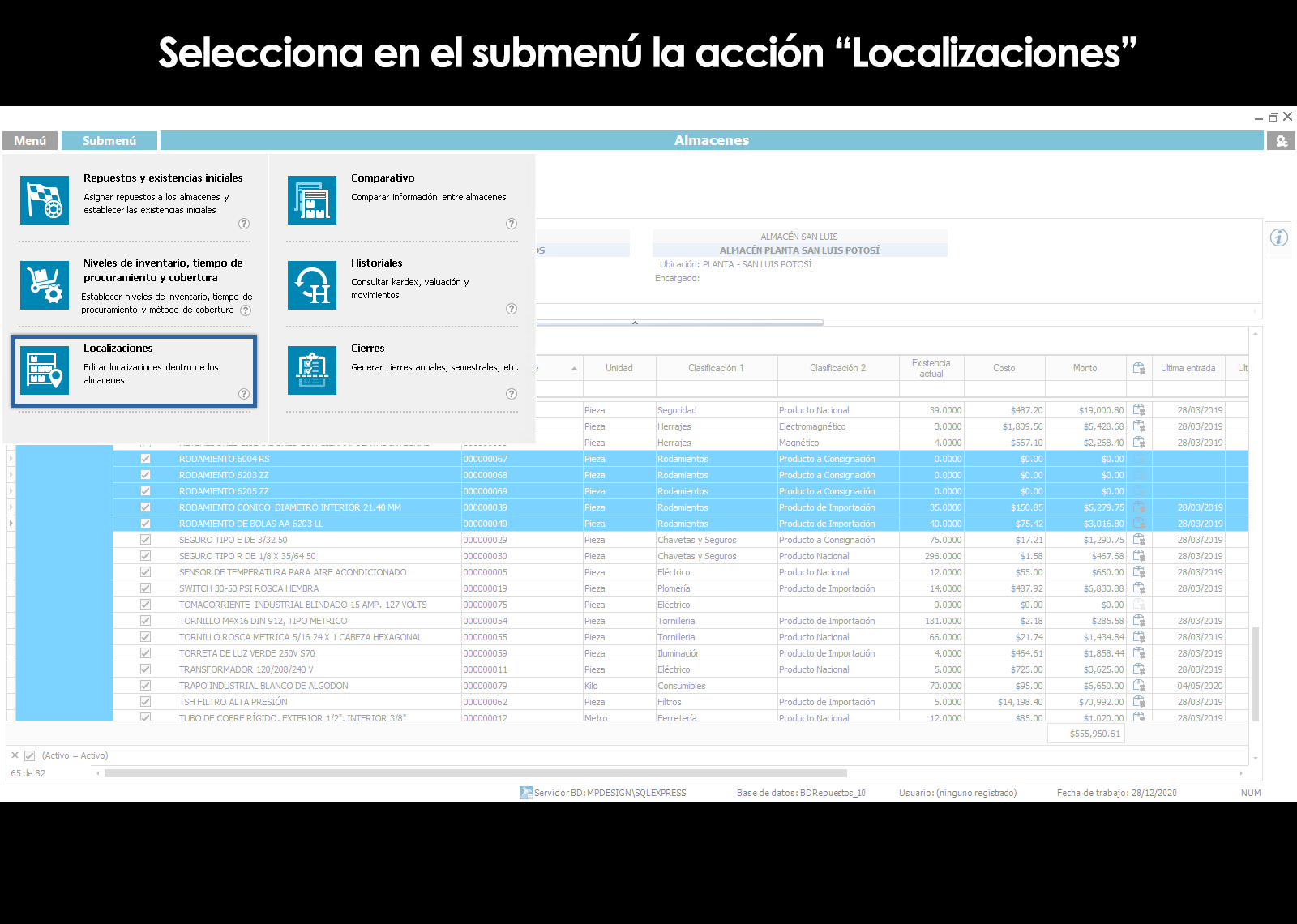

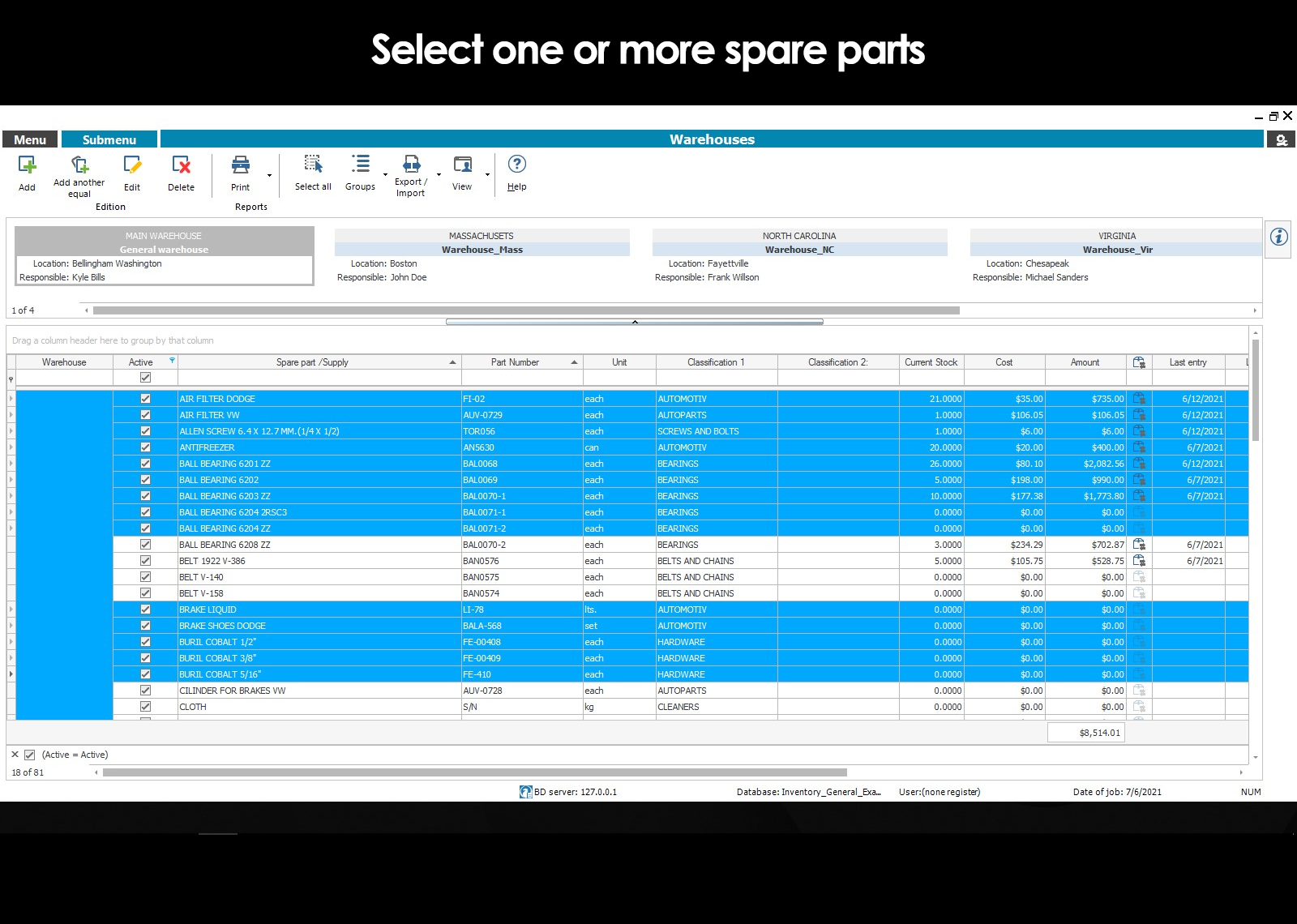

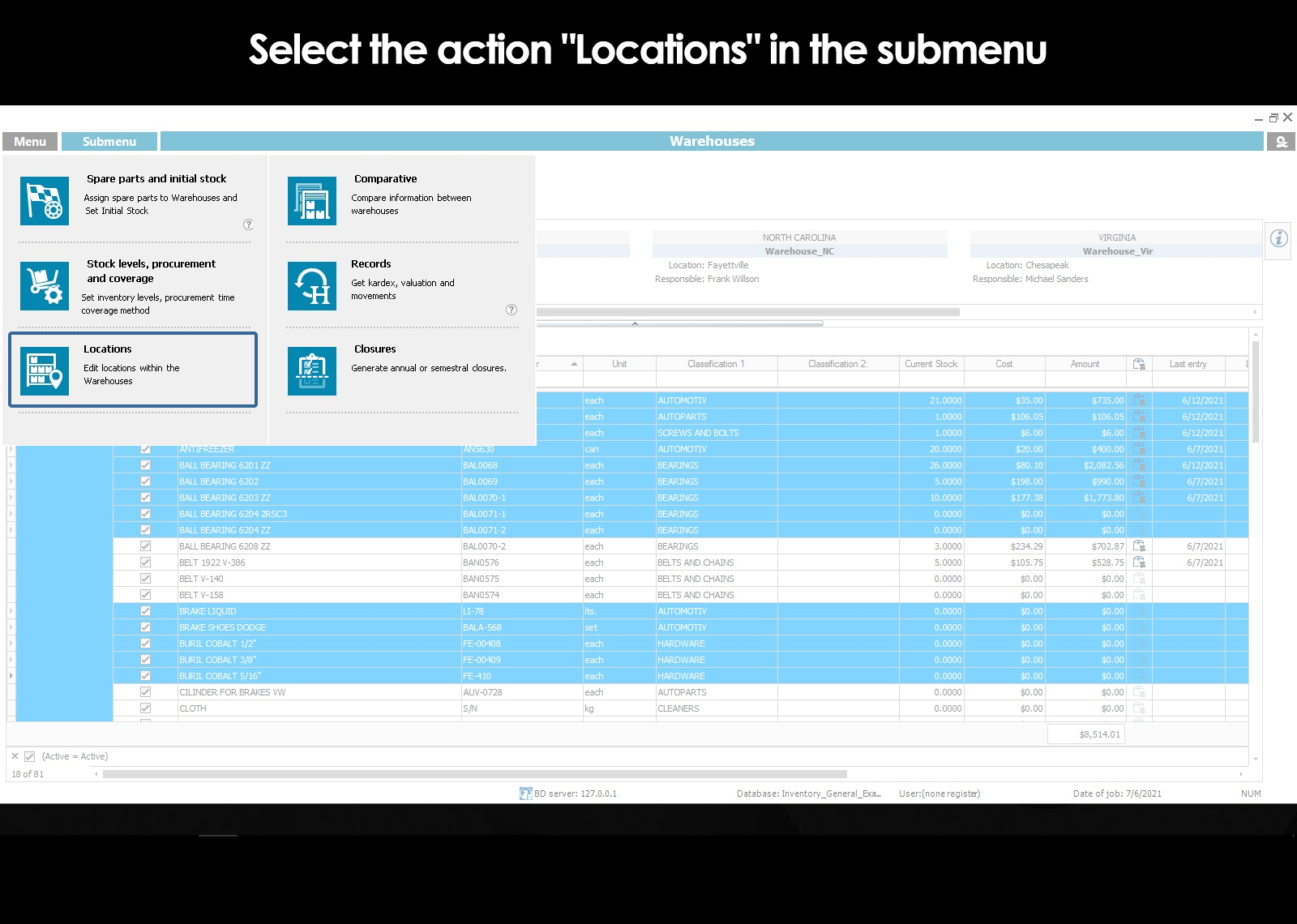

Another way to indicate the location of the parts is through the action of the submenu Locationsselect the parts of the mesh, and then select the action Locations within the submenu.

It will open in a mesh modifiable with the location field to capture the location of the parts in the warehouse. This location can be modified at any time.

The location of spare parts in warehouses can be edited from the module Spare parts and consumables, as well as from the module Stores.

Levels minimum, maximum, and optimal

The moment of adding a spare we can also indicate their levels of minimum, optimum, and maximum if we know them. Later, and based on the stored information, the program provides the option of calculating these levels by different methods.

Time of procurement

Is the estimated average time elapsed (in days) since the product is applied to the purchasing department until it is delivered to you by the supplier at the Store. This time of procurement is very useful to calculate the supply of products coming to use for maintenance, allowing the appropriate timing of purchases and the possibility of getting a supply under the concept of “Just in Time”, maintaining the stock levels at a minimum and without affecting the performance of the maintenance jobs that are scheduled.

Stocks and start-up costs

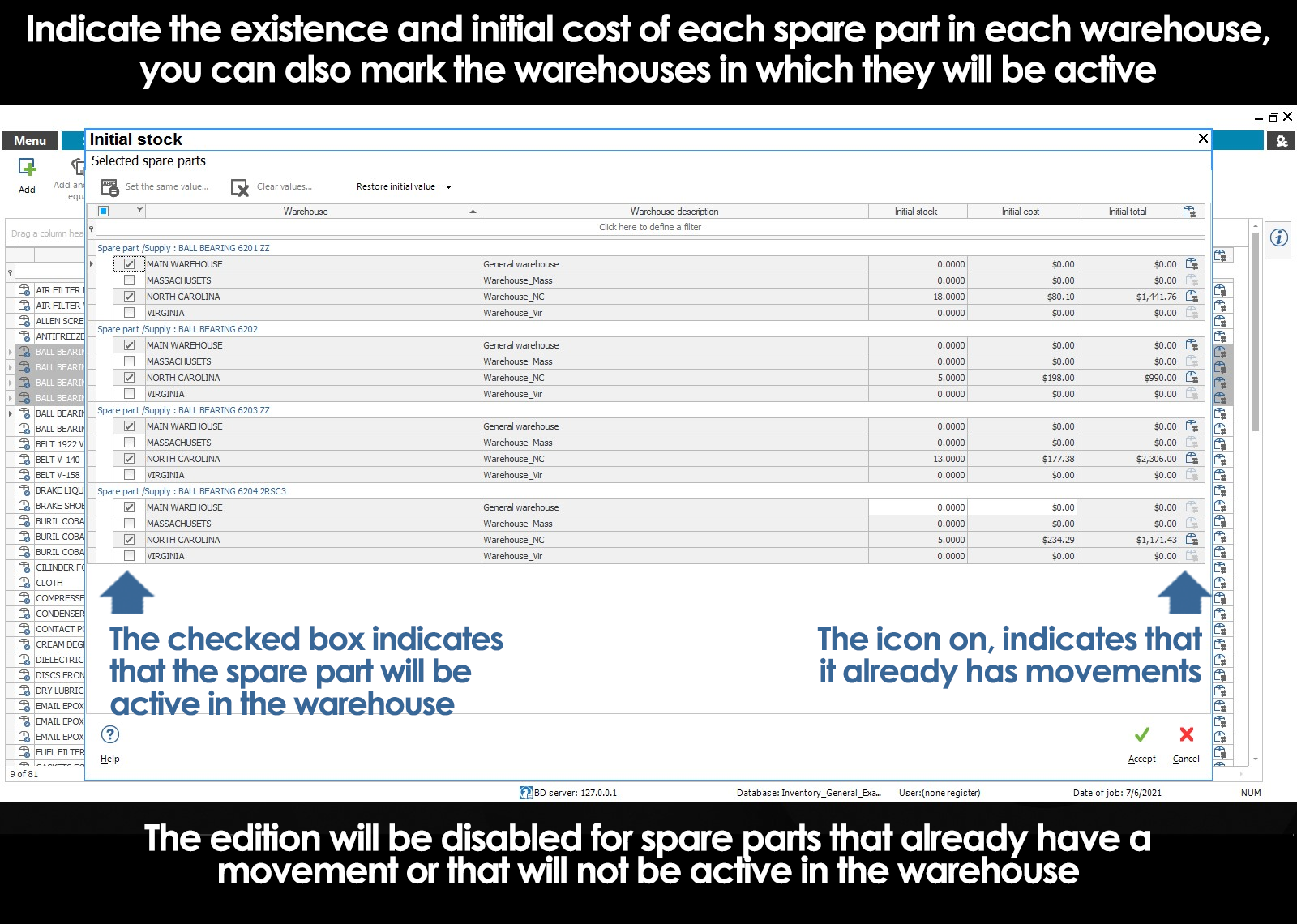

Stocks and initial costs of a spare part are variables in each store as its localization, minimal, optimum, and maximum, as well as the time of organ procurement.

The stock record and initial costs is the process with which the user indicates the initial condition of your inventory to be able to start to work and generate movements of input and output, calculate the supply, coverage, queries and be able to perform queries with the current values.

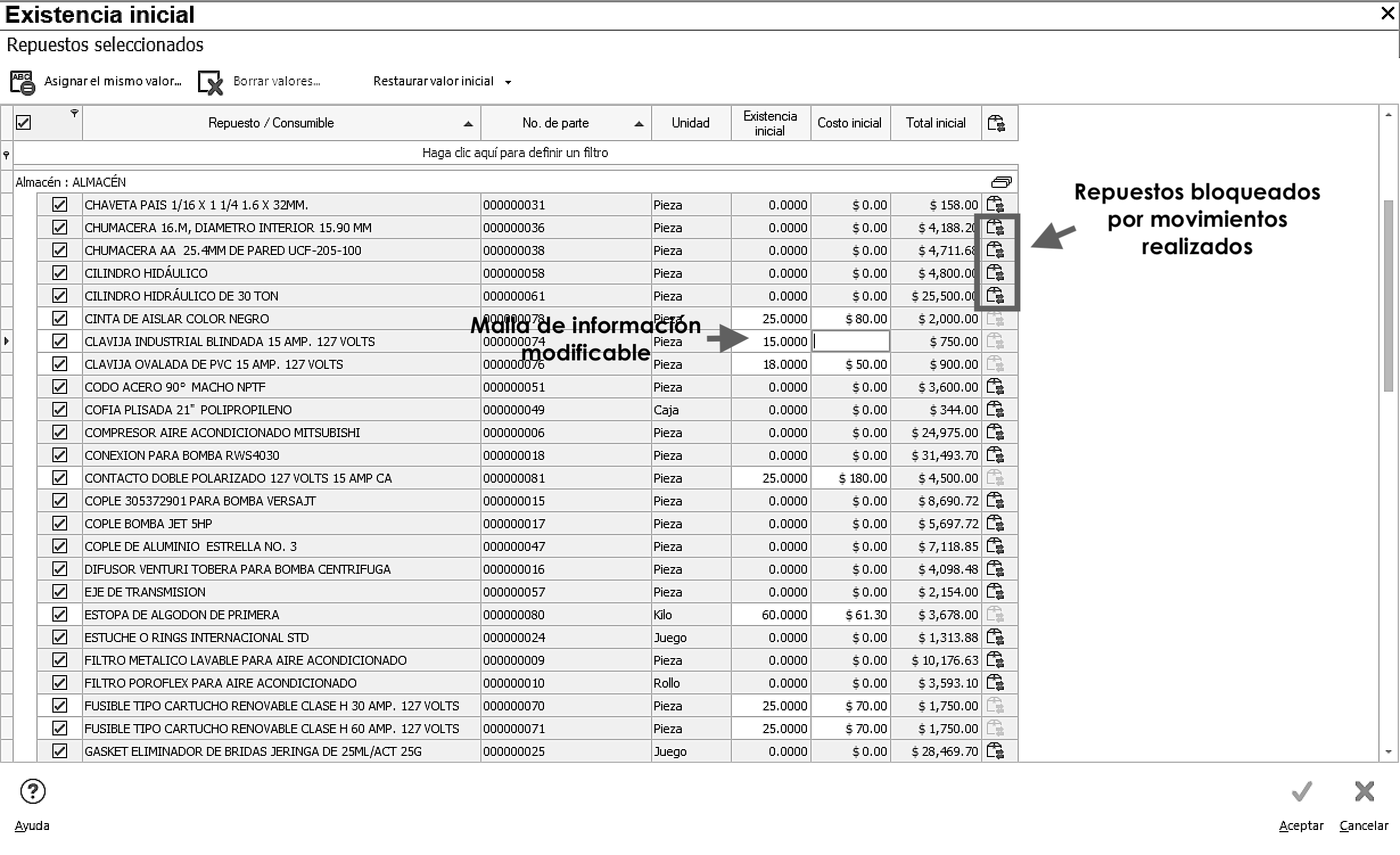

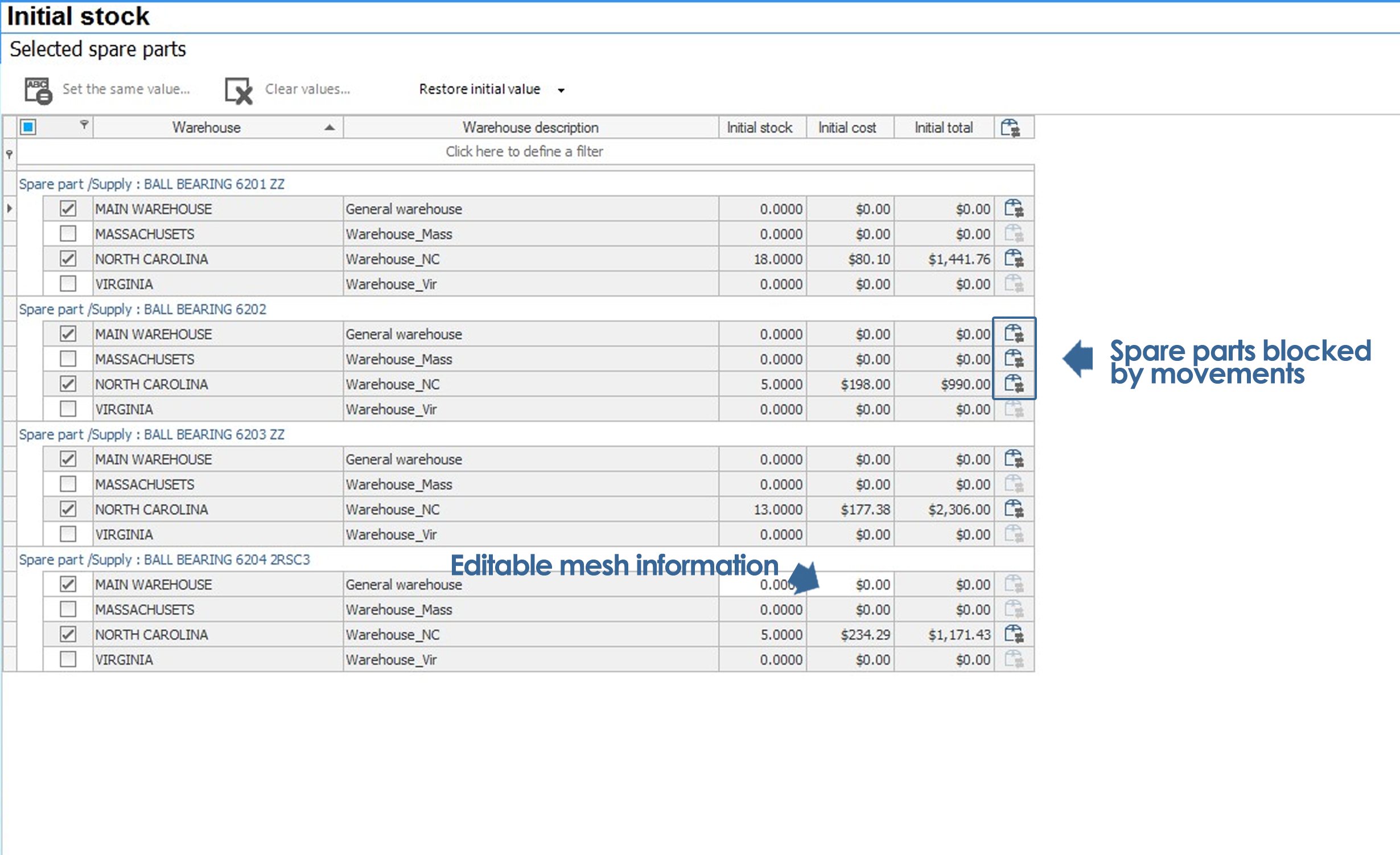

The versatility of the Inventory of spare parts of the suite MP version 10 allows you to record your initial stock at the time of creating spare parts and stores, or, later allows you to edit individually or in bulk stock: initial, initial cost, and location of the parts in the different stores.

Also for ease and agility in the implementation of the Inventory of spare parts, the user can start working with the parts to which they had captured their initial values, avoiding having to capture the initial values of all the parts to start using the program inventory. It is important to note that once there has been a movement with a spare, not be able to make modifications of the initial records (existence of initial and initial cost) of that spare in the store which made the movement.

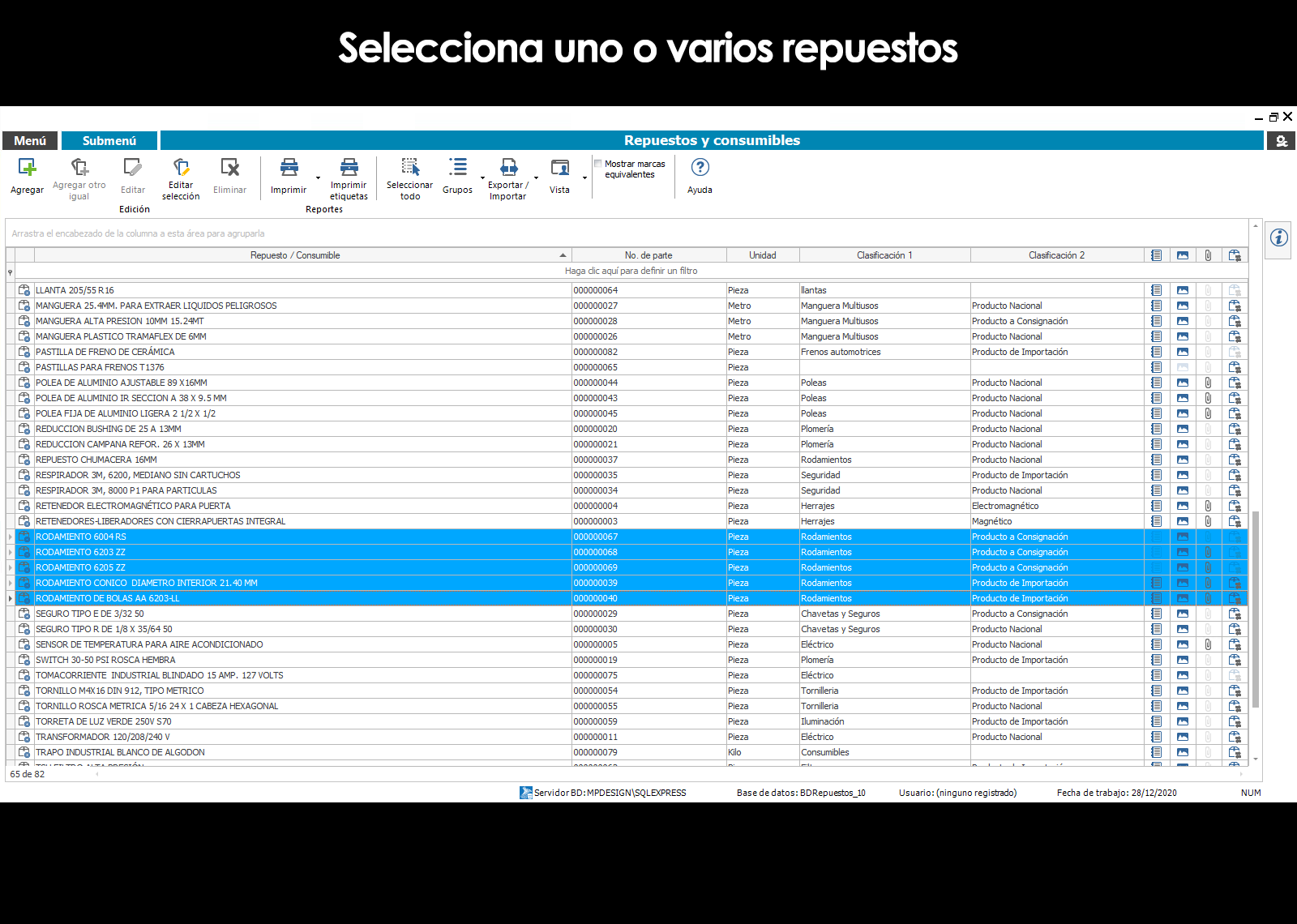

The log of initial stock can be done from the module Spare parts and consumables and from the module Stores.

From the module spare Parts and consumables can record the initial stock of spare parts in each of the stores; in contrast, the module Stores, records the existence of initial spare parts that are contained in the selected storage location.

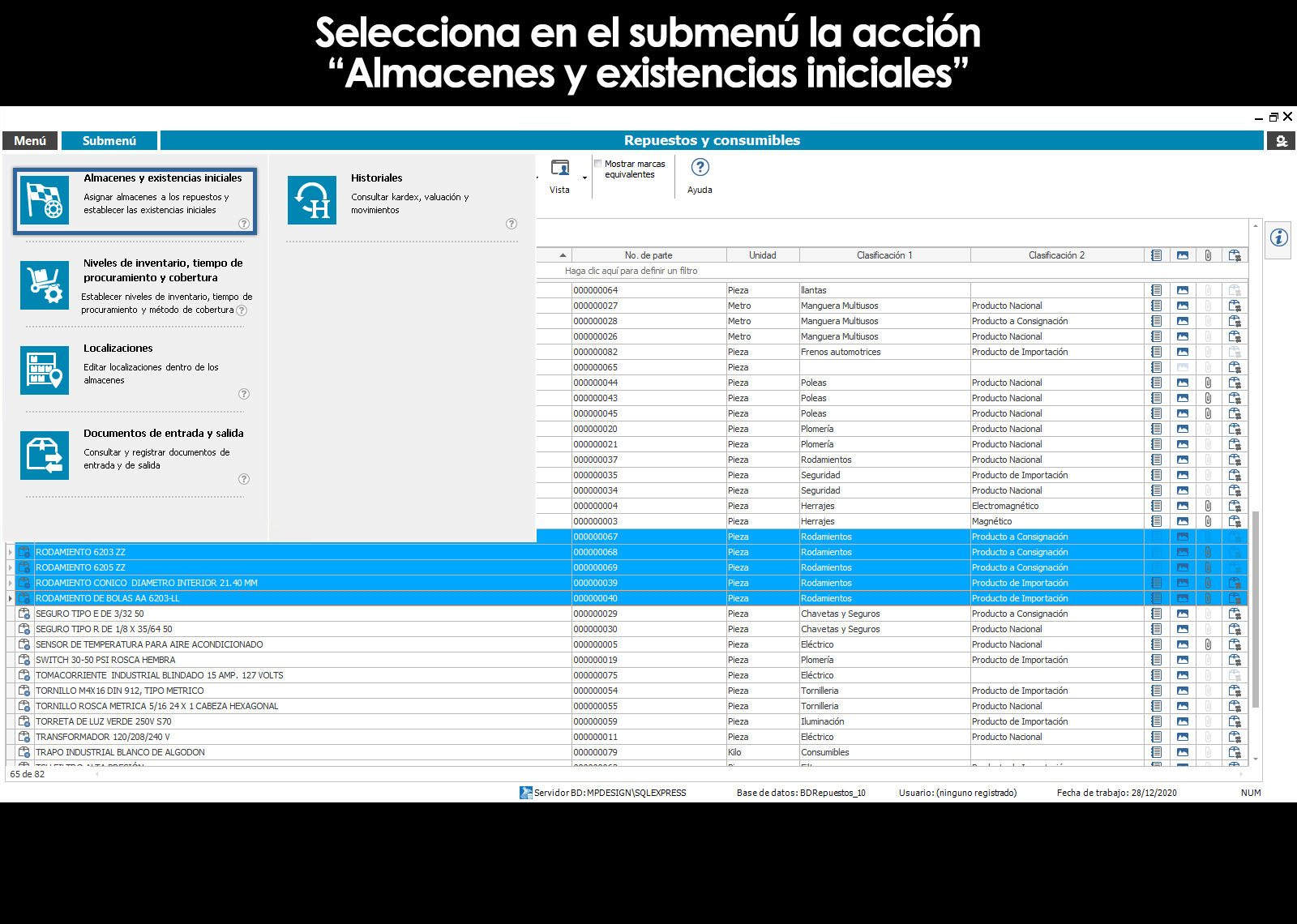

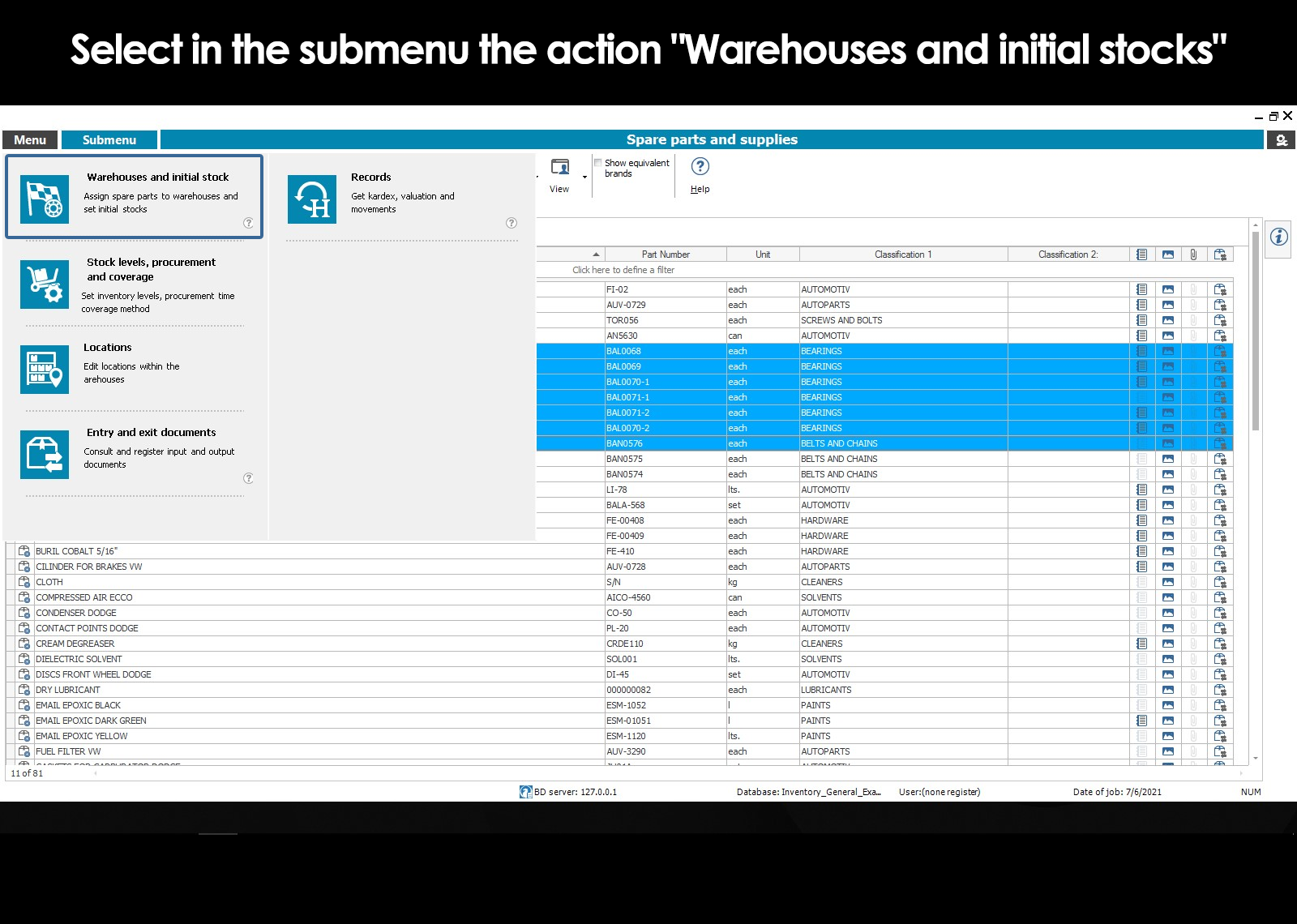

To capture the initial values of its parts from the module Spare parts and consumables and select in the submenu Stores and initial stock.

This will enable the multiple editing the mesh to register the information. This screen allows you to select the parts that you have in store by ticking the checkbox, edit the existence of initial and modify the initial cost of the parts selected. It is important to note that it is not possible to modify the initial values of the parts to which they have generated a movement and thus is found dialing the symbol of a movement.

Note: The spare locks only in the store from where it was generated the movement of output or input.

Can't find the answer to your doubts or questions?

Additionally, we offer training courses

Our flexible options of online training and face-to-face will provide you with all the knowledge necessary to understand and implement your software maintenance.