Home / Inventory of spare parts

Methods of calculation for the coverage

What method of calculation for the coverage, it is convenient to use

Editing of the rotation for the calculation of the coverage

Calculation of the rotation on the basis of the movements of output

Best estimate of the levels of inventory on the basis of the rotation

Generation of the flow of resources to the calculation of the coverage

Understanding the coverage schedule

Introduction

The time coverage of the spare parts and consumables is a very interesting topic in terms of the module of inventory Levels, supply and requisition. The coverage allows us to know, and to display graphically the approximate time in days in which we will have stock of a particular replacement part or consumable.

Many times simply know the amount of stock that we have of a particular spare part, does not tell us whether the stock is sufficient or not to cover a certain period of time. However, having regard to the stock in time, allows us to forget about the amounts and rather worrying to whether the quantities that we have are sufficient to cover the next 30 days, 60 days, 90 days, etc If we know that of all the spare parts are covered at least for the following 30 days, and we are monitoring, we will be calm and carefree of having to make emergency orders.

Methods of calculation for the coverage

The coverage can be calculated in 2 ways:

1. By setting the average turnover that has the replacement or consumable daily basis, that is to say, by setting the average consumption journal of the spare parts or consumable.

In this case the coverage is calculated by dividing the stock between the rotation and gives us the days that we will last these stocks.

2. Based on the flow of resources from the planned maintenance program Maintenance Management. To use this method it is very important to preallocate resources that are used to perform each of the activities of maintenance of the equipment. (for more information, see Allocation of resources for equipment and maintenance activities)

As a requirement also, calculate continuously the flow of resources. This flow of resources considered in the Management program of Maintenance all maintenance activities that are scheduled for computers, and in this way, it is possible to know the amount of each resource that is scheduled to use for each day.

What method of calculation for the coverage it is best to use?

Calculation of the coverage based on the rotation. This way of calculating the coverage is useful when:

- It has a constant consumption of the spare parts or consumable.

- No resources have been allocated to the activities of maintenance of the equipment in the program of Maintenance Management.

Calculation of the coverage based on the flow of resources. This way of calculating the coverage is useful when:

- It does not have a constant consumption of the spare parts or consumable

- Resources have been allocated to the activities of maintenance of the equipment in the program Maintenance Management

For those cases where the consumption of the part is not constant (or, in other words, it is sporadic), and is also not assigned to the replacement of any maintenance activity on a computer, it is advisable in these cases to not use any method of calculation to avoid misinterpretations.

Editing of the rotation for the calculation of the coverage

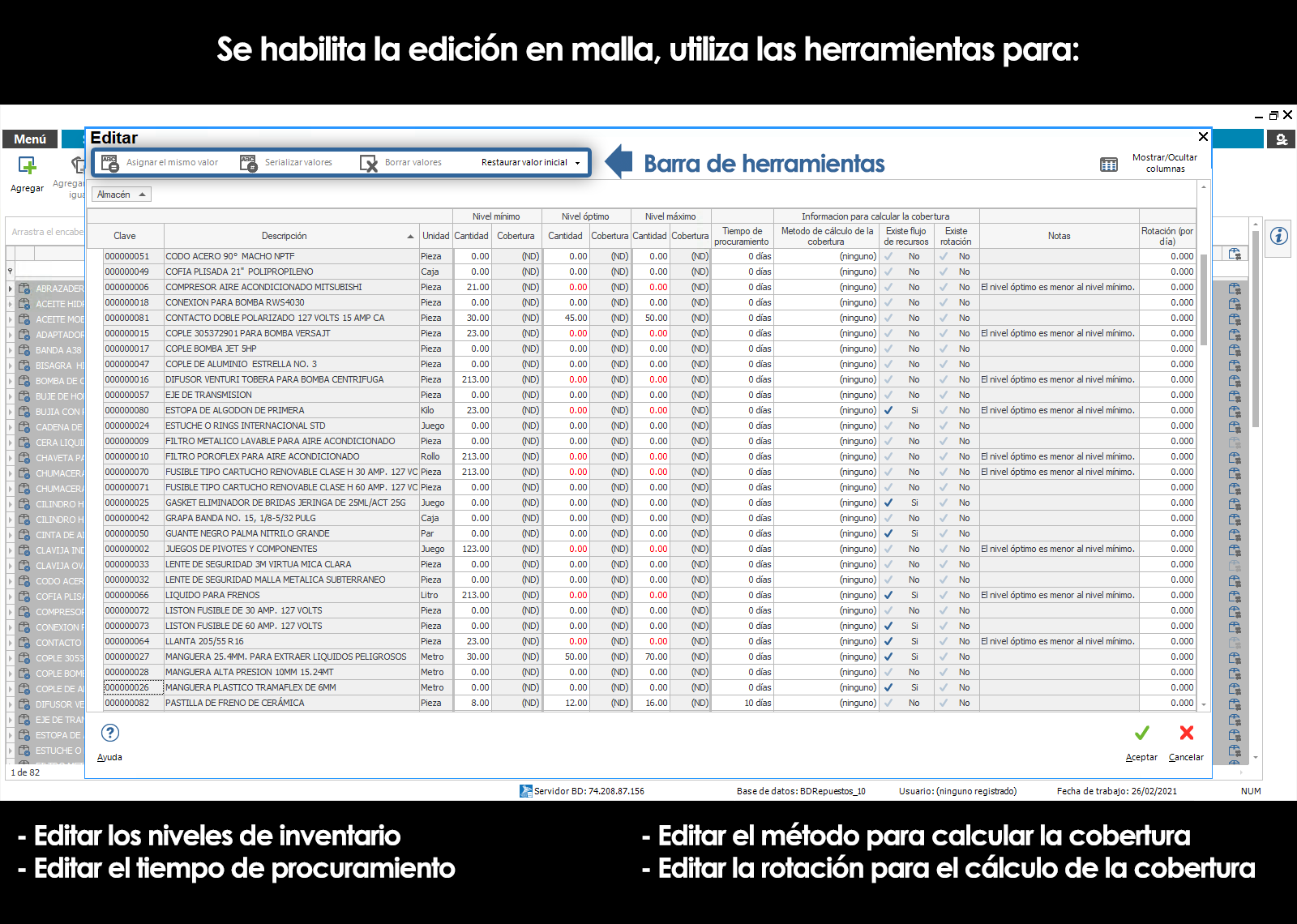

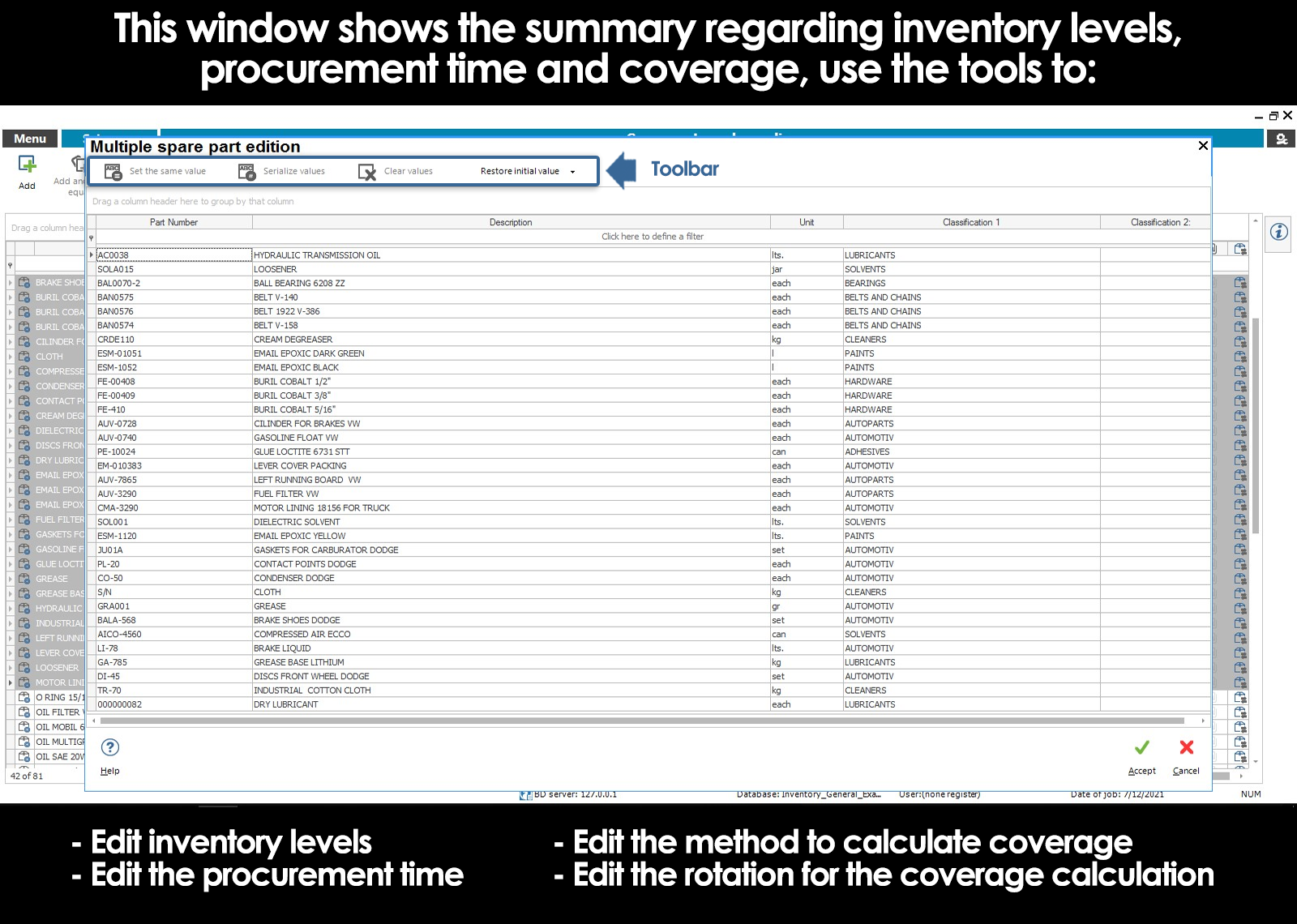

The rotation of the spare parts and consumables can be specified from different modules in the Inventory of spare Parts.

The inventory levels and the time of procurement can be specified from different modules in the Inventory of spare Parts.

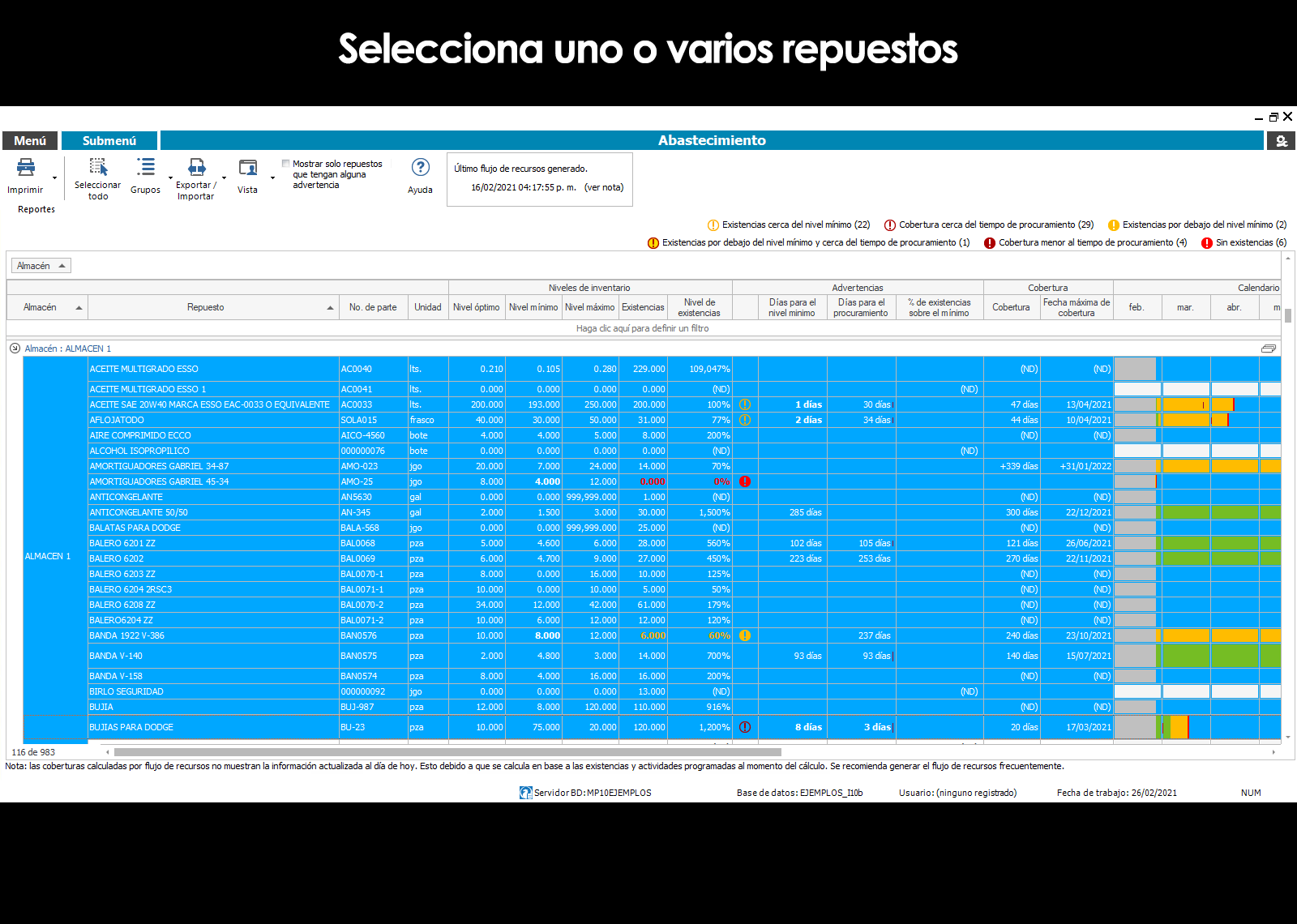

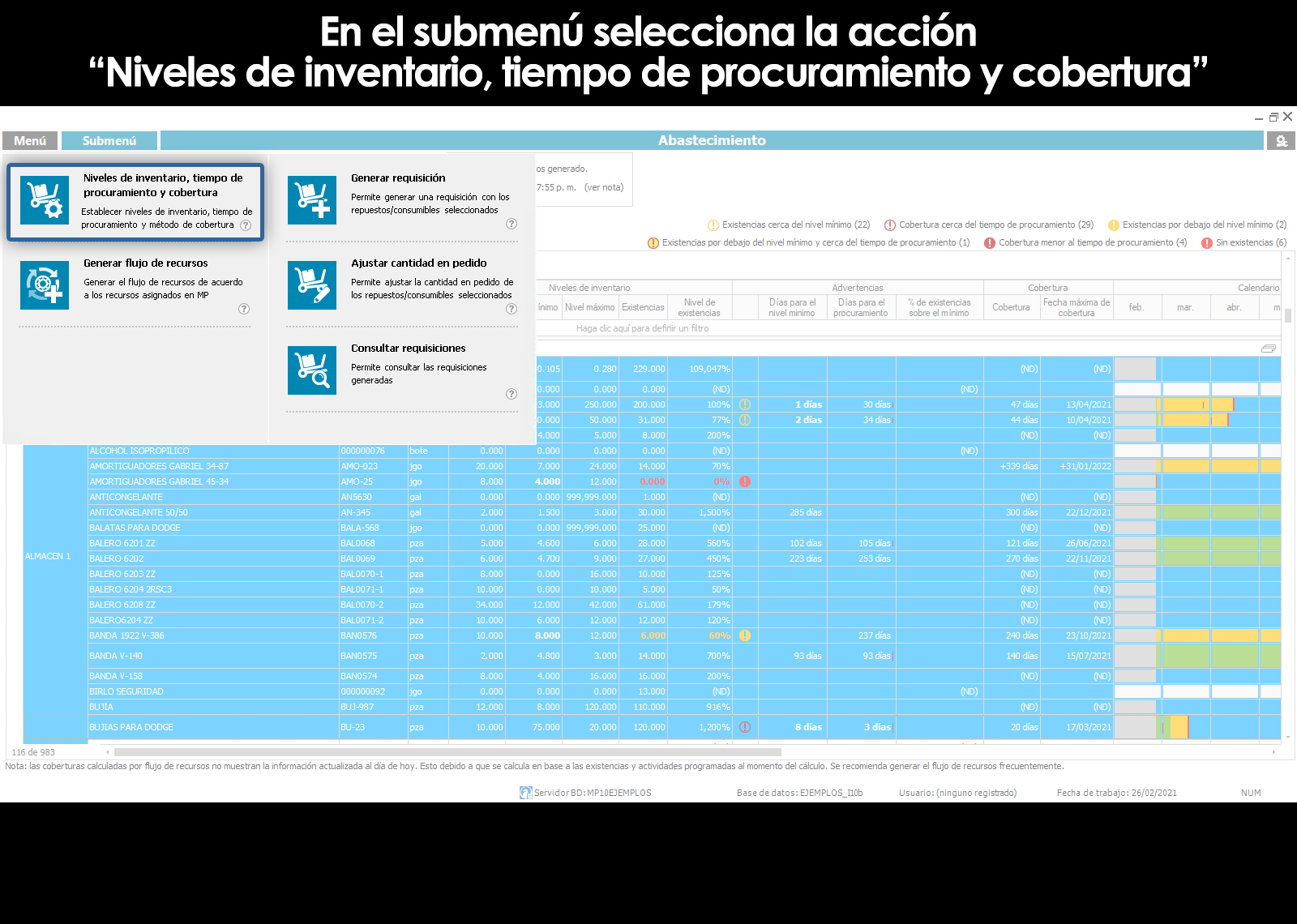

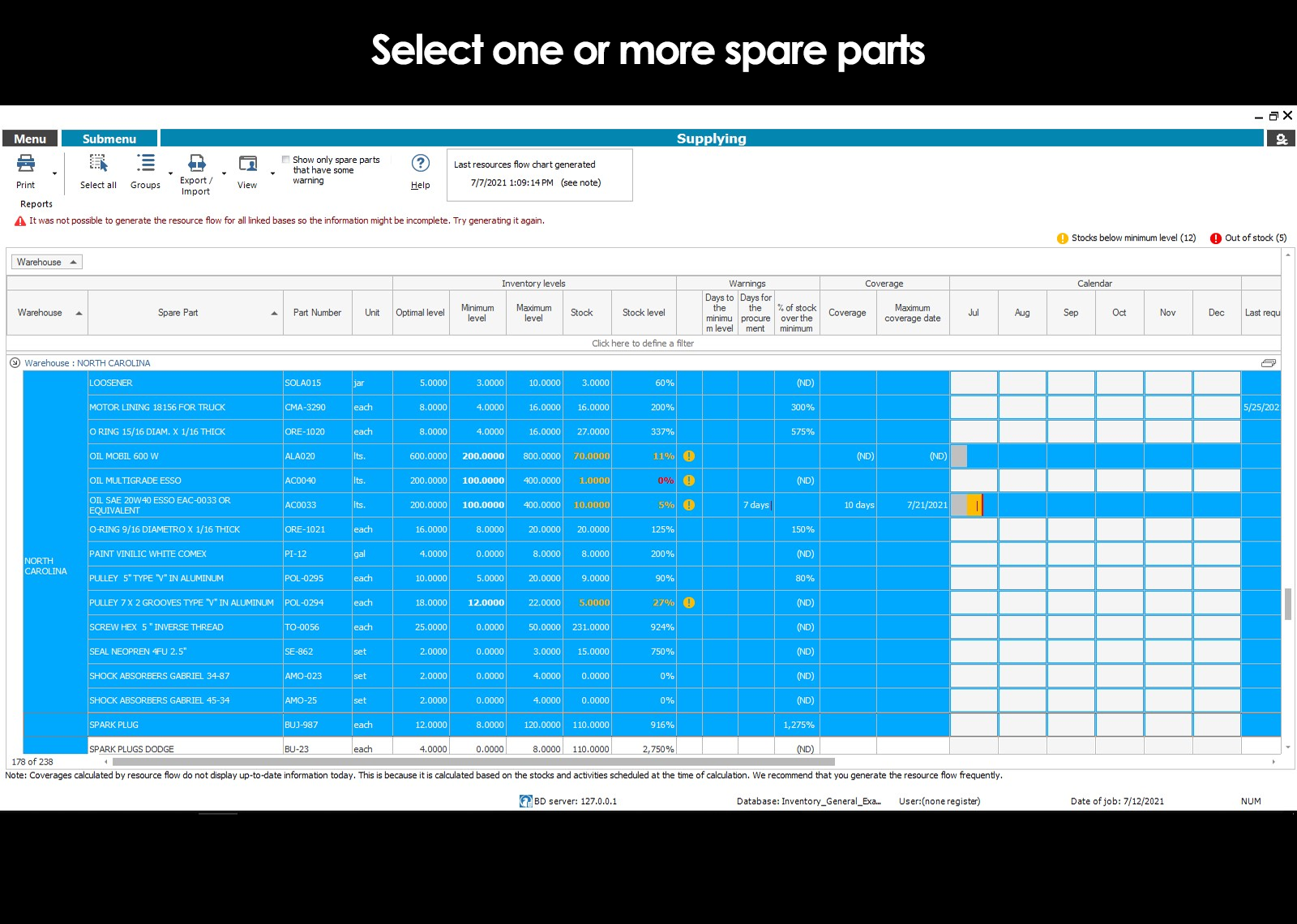

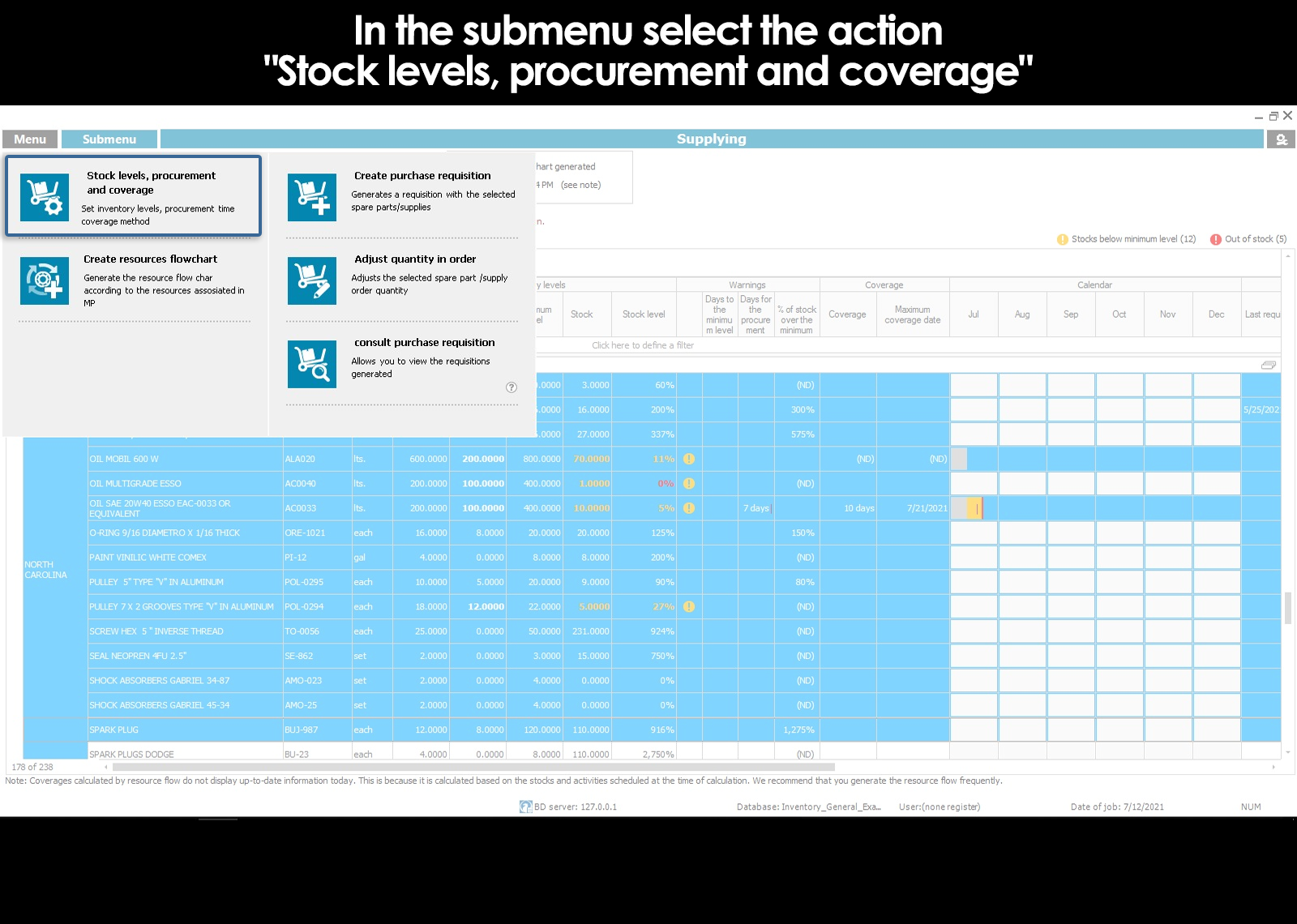

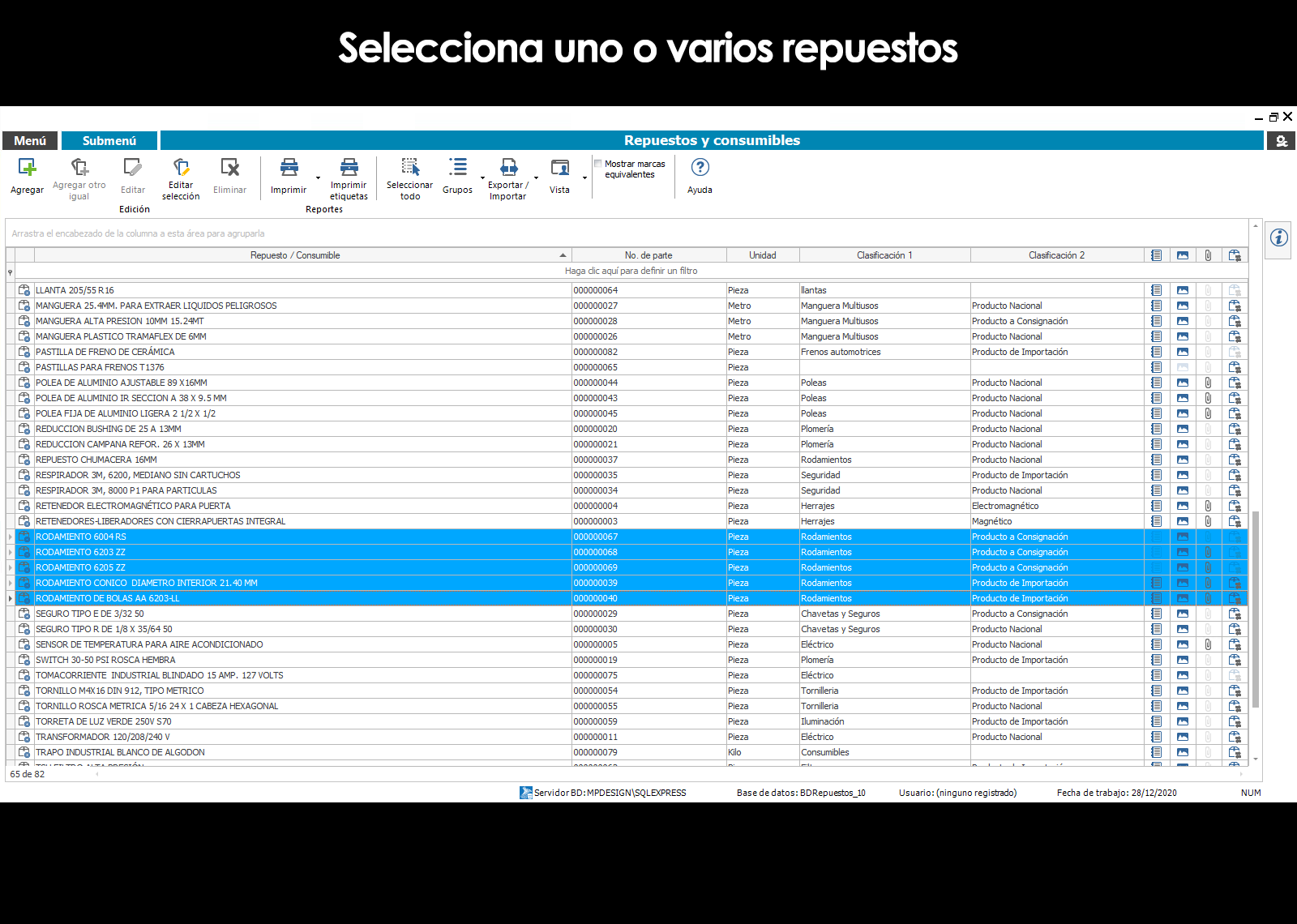

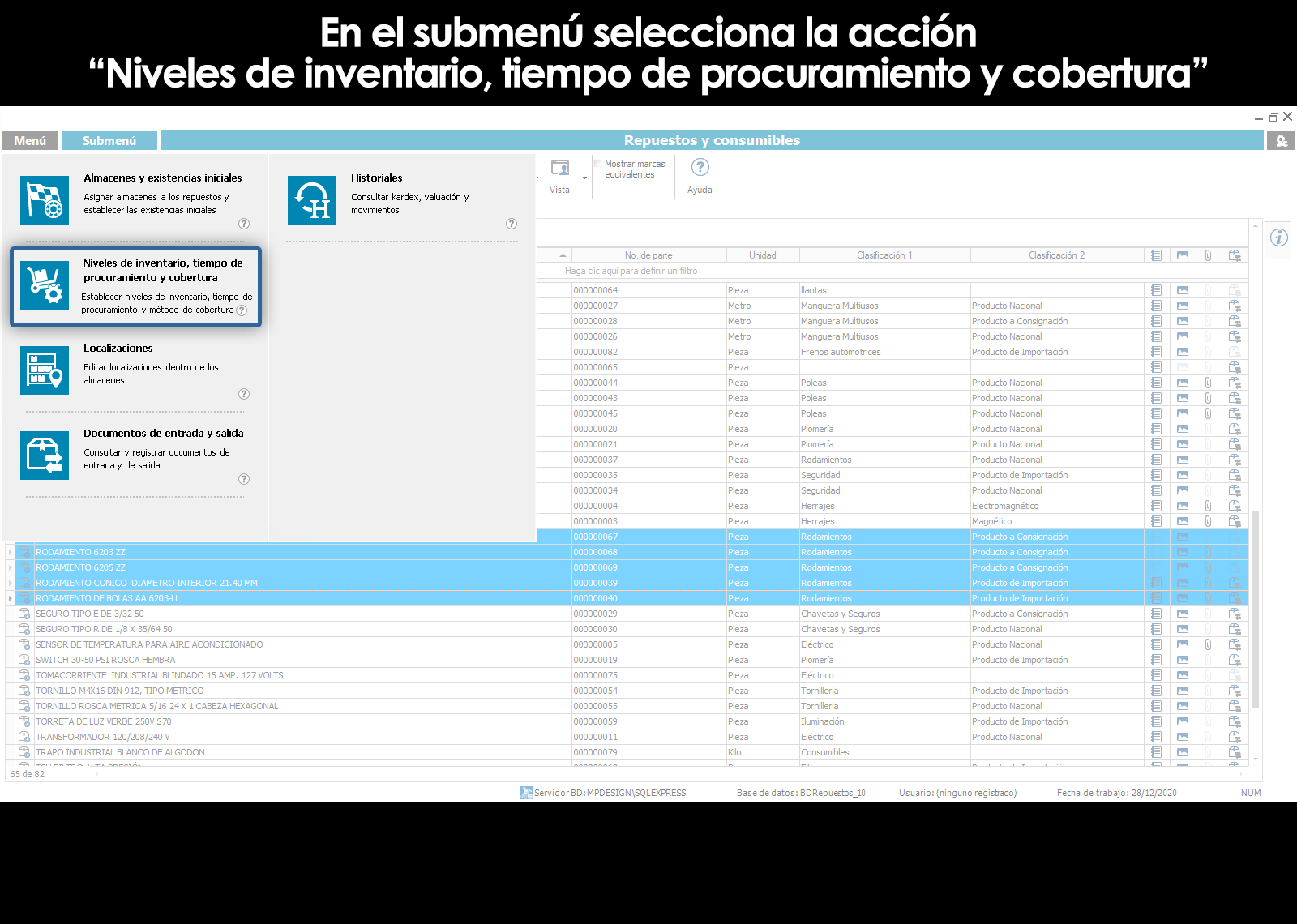

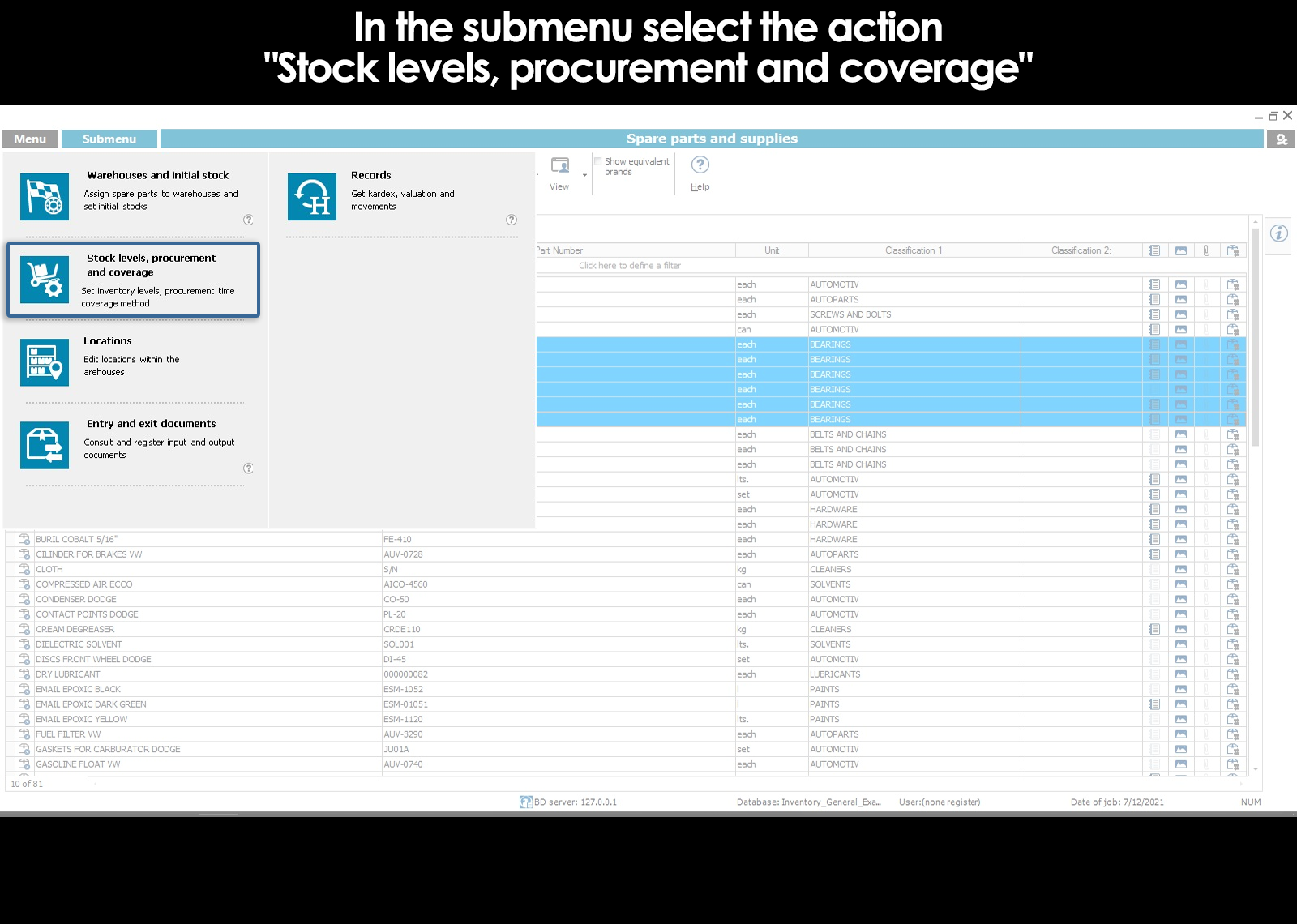

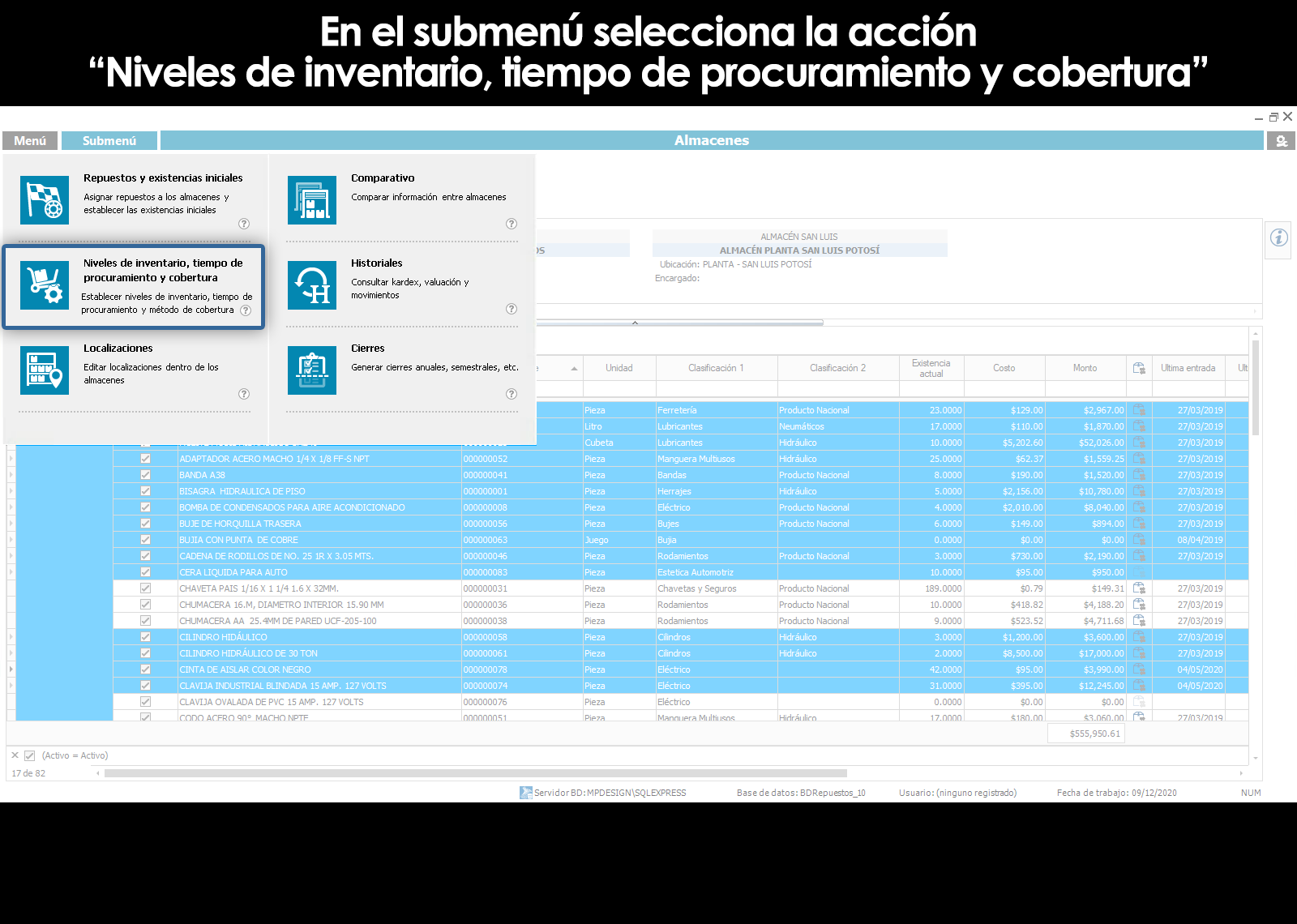

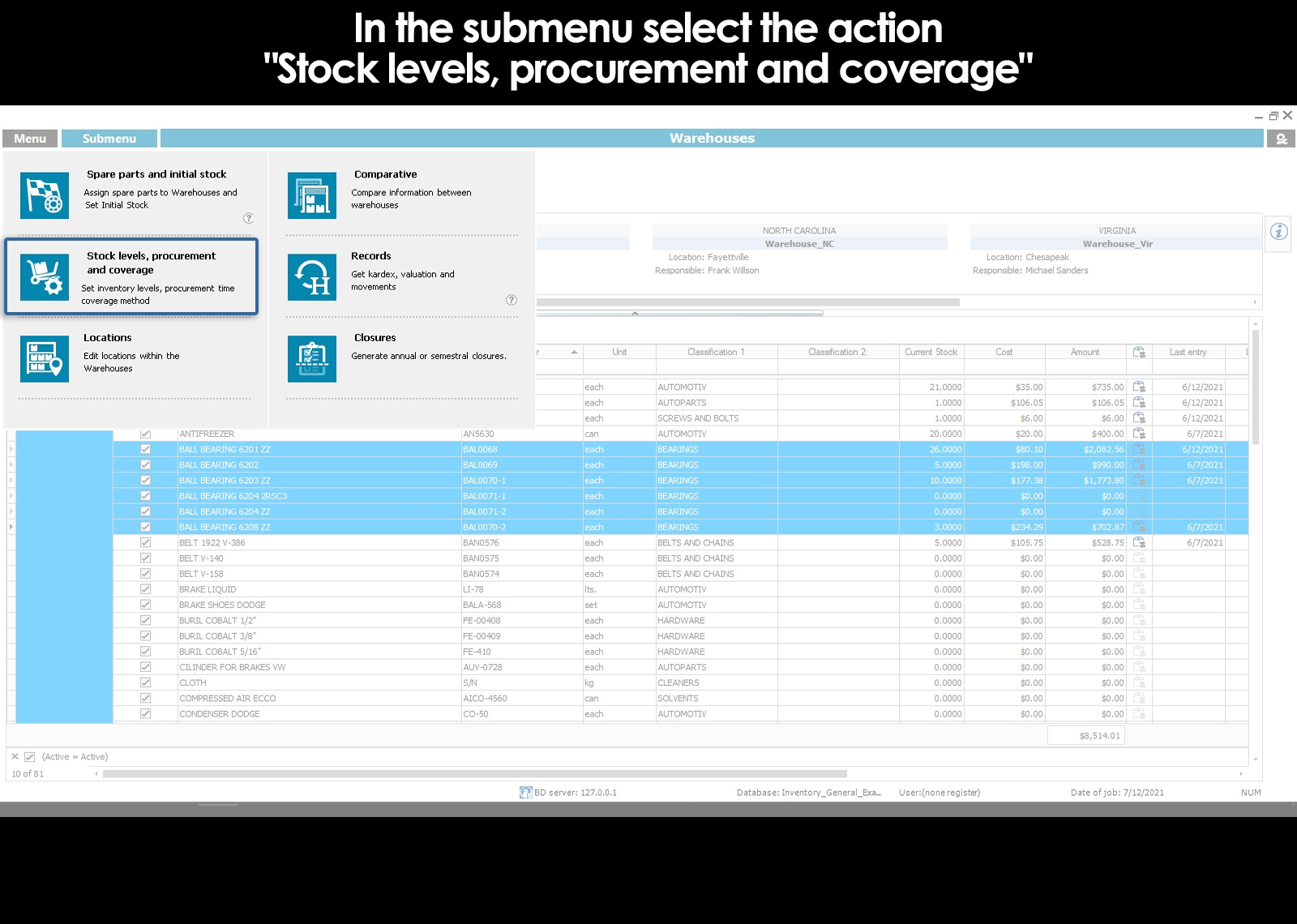

1. From the sub-menu in the module inventory Levels, supply and requisition

2. From the sub-menu in the module spare Parts and consumables

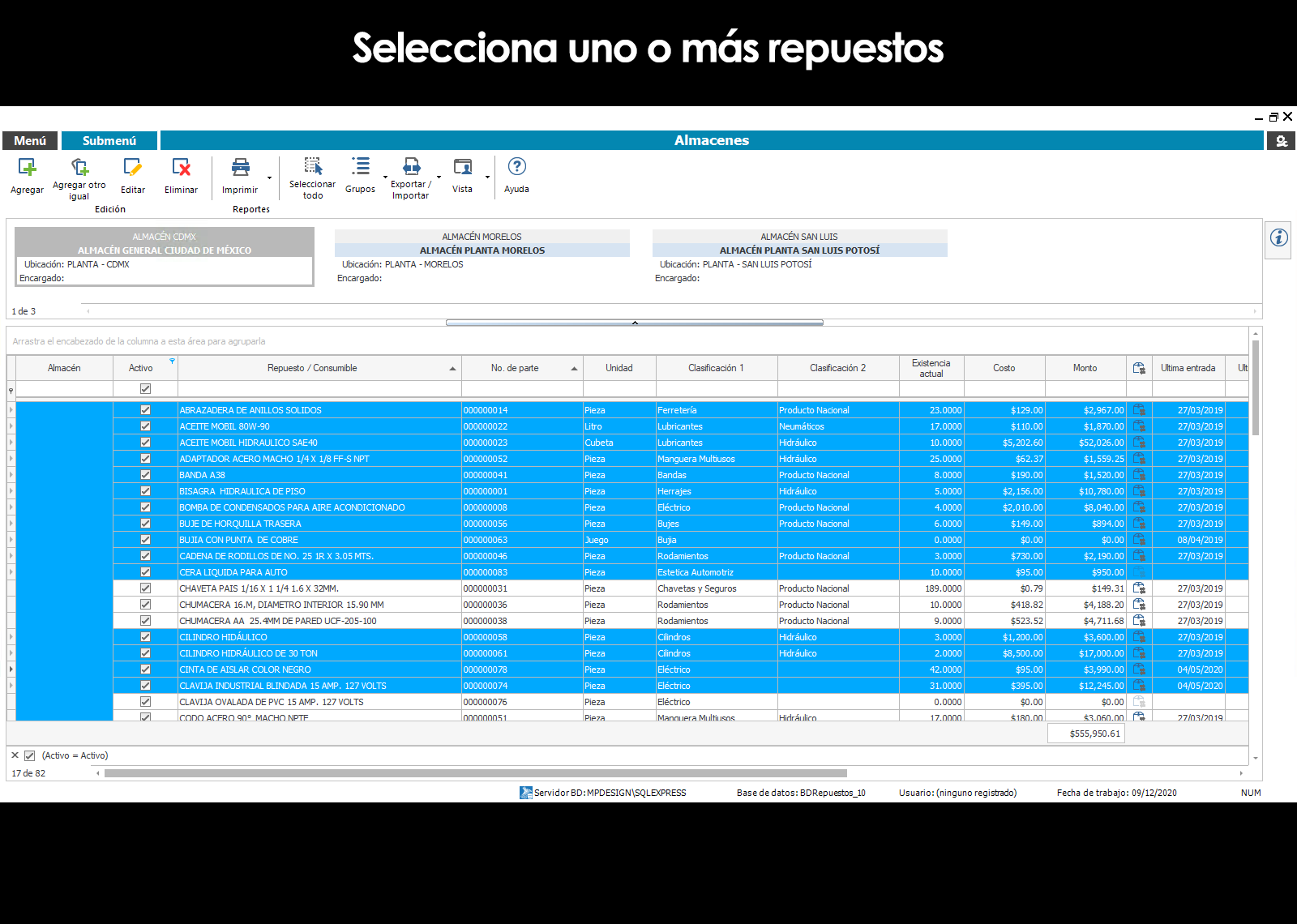

3. From the sub-menu in the module Stores

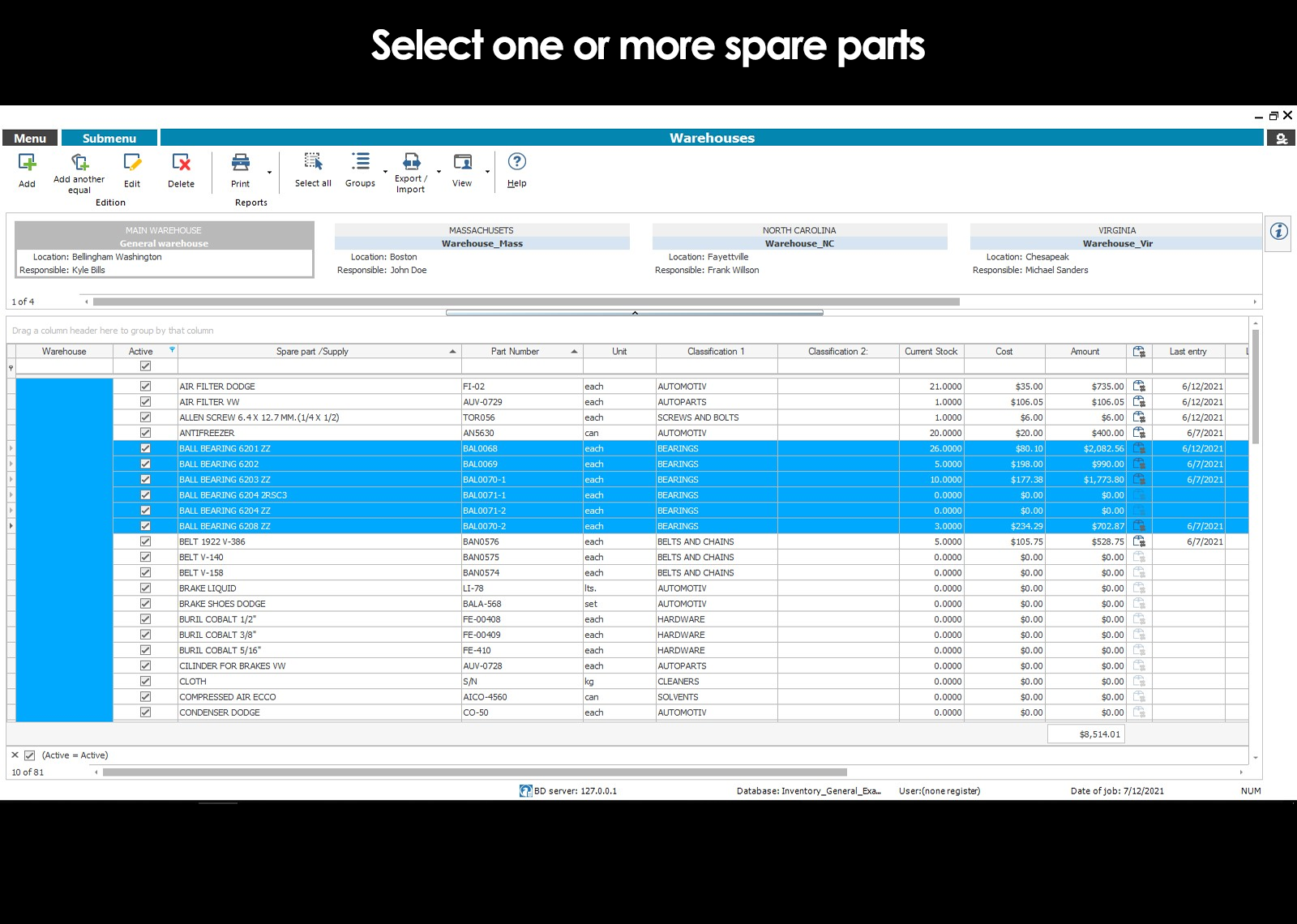

Previously you may have chosen a single-replacement, or, a selection of spare parts.

When presented with the screen you need to click on the edit button on the toolbar.

Calculation of the rotation based on the movements of output

A practical way to calculate the rotation of any spare or consumable is analyzing the movements of output that has had such replacement. The Inventory of spare Parts has a utility that allows us to easily calculate these values.

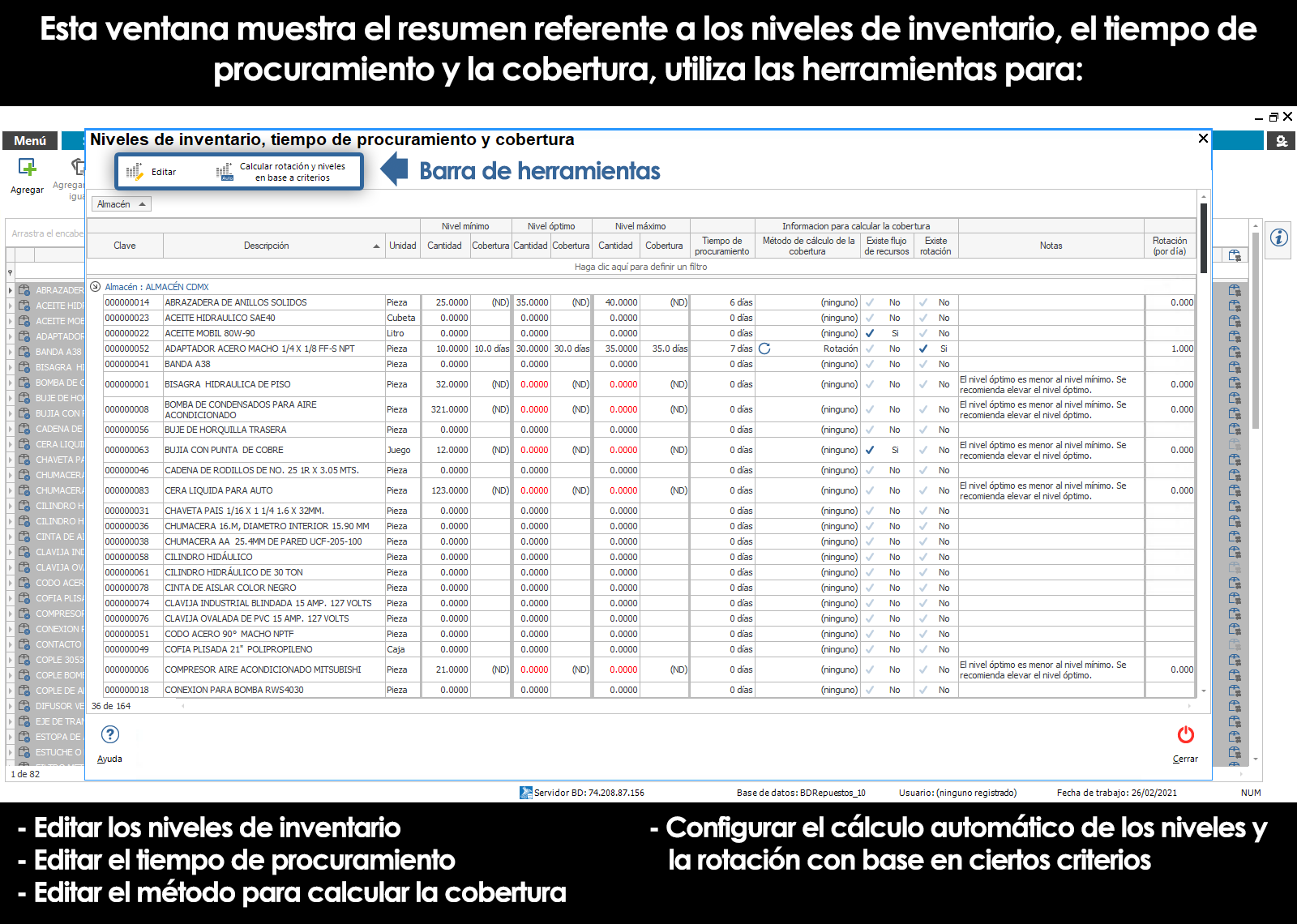

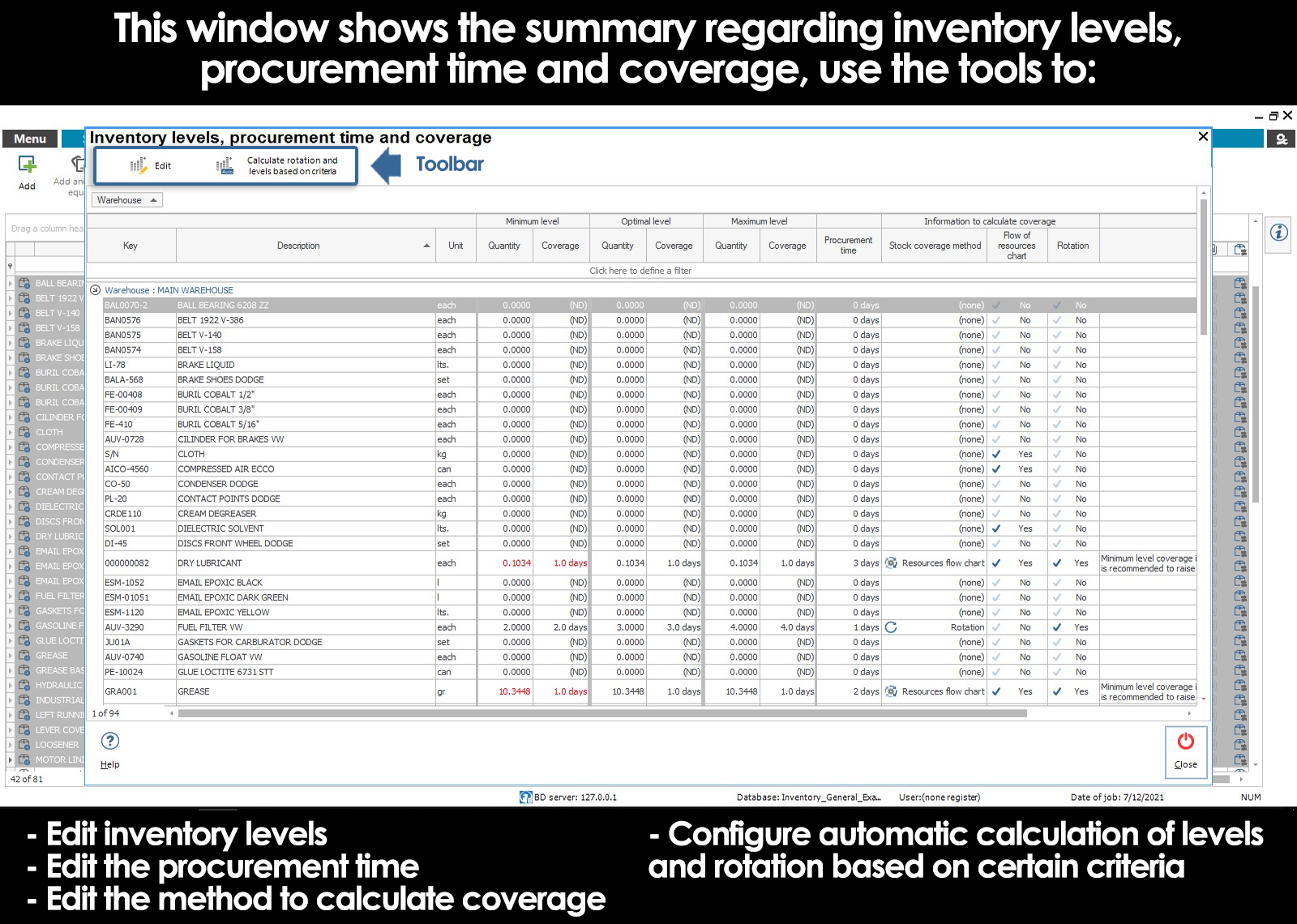

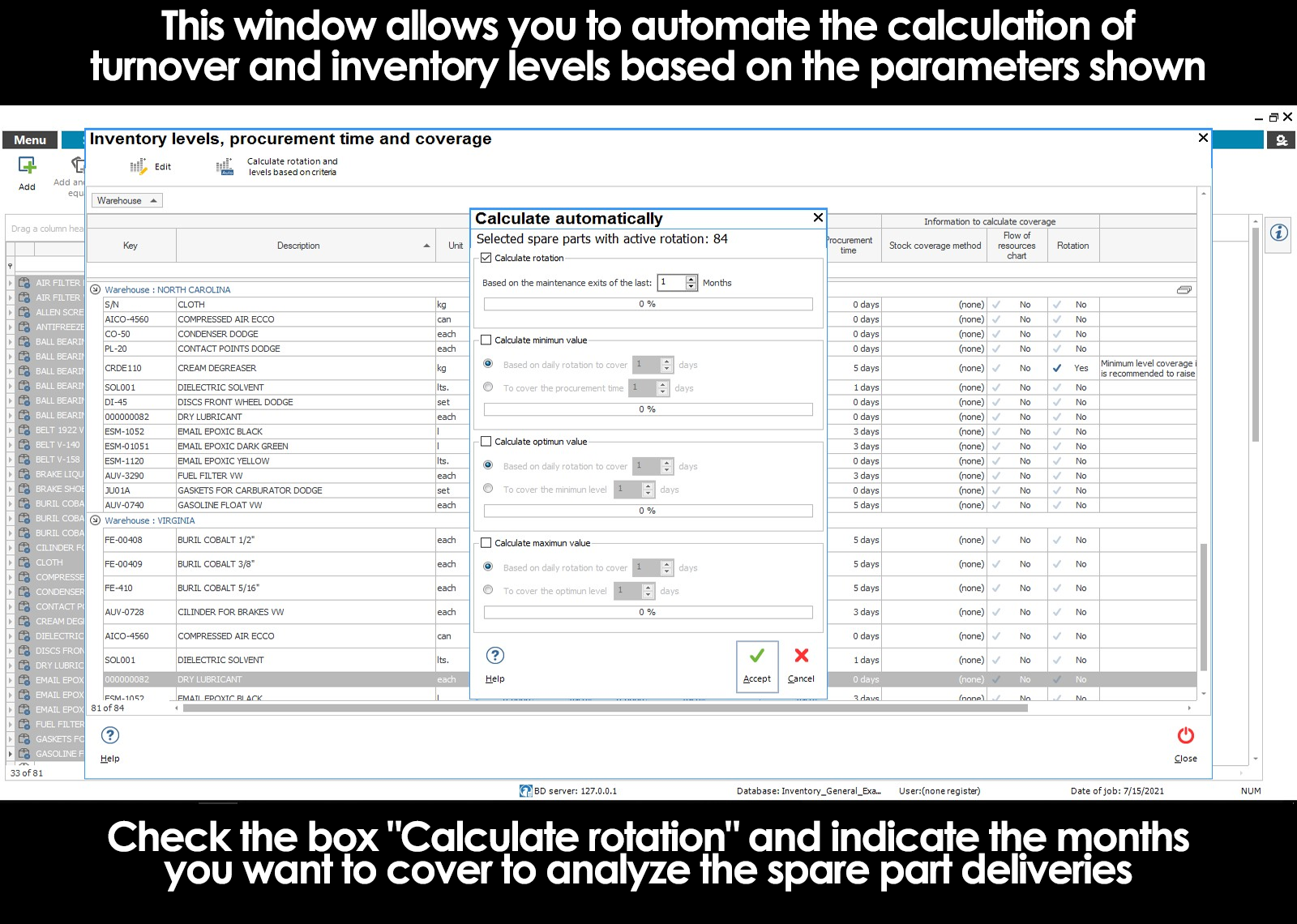

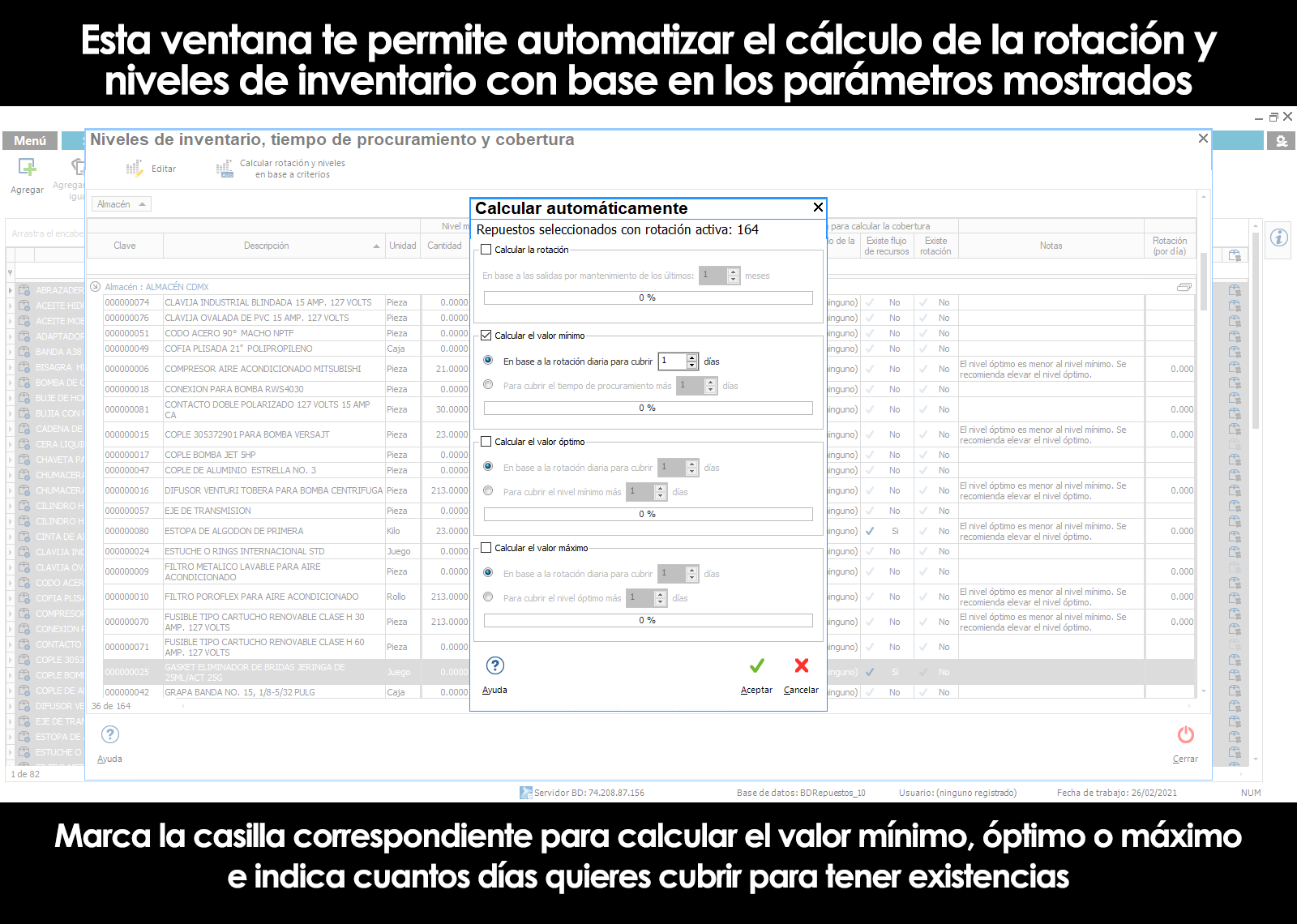

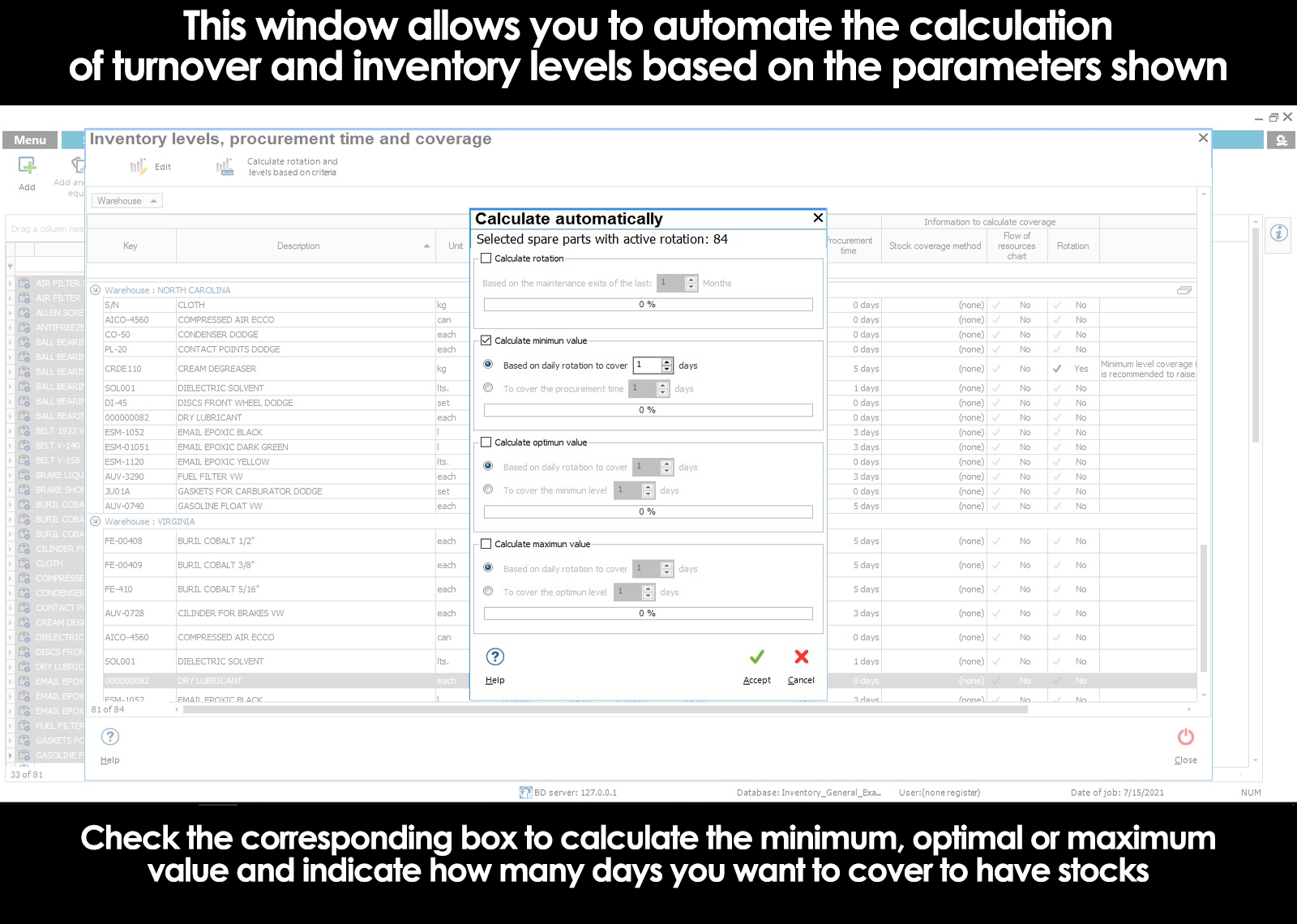

On the screen where it shows the summary of the inventory levels, time of organ procurement, rotation, and other, click on the button Calculate rotation and levels on the basis of criteria.

Select the months you want to include to analyze the outputs of the replacement, because, depending on the number of months you have chosen, the value of the rotation may vary.

We advise to calculate and use the rotation method for the calculation of the coverage for as long as the consumption of the consumable is more or less uniform. Otherwise, it is advisable to leave this value at 0 (zero) and use another method of calculation.

Calculating optimal inventory levels based on rotation

When we have to spare your rotation specified, when you edit the levels are minimum, optimum, and maximum, on the right side we see the coverage to give us a glimpse of the days that we would have covered in each case.

A practical way to calculate inventory levels is by using the rotation of each of the spare parts, or consumables. The Inventory of spare Parts has a utility that allows us to easily calculate these values.

On the screen where it shows the summary of the inventory levels, time of organ procurement, rotation, and other, click on the button Calculate rotation and levels on the basis of criteria.

Here we have the option of calculating our levels depending on how many days we want to cover to keep stocks and do not have to be making purchases continuously. This value is calculated simply by dividing the days you want to cover between the rotation, and that we are going to calculate the value of stock that is suitable for each replacement.

Another way to calculate our levels is based on the time of procuring of each part. As we said earlier, it is advisable to always that the minimum level is higher at the time of organ procurement for each product. In this way we will avoid running out of stock.

In each case, you select the days you want for each level and ready.

It is possible that, for each spare part or family of parts, the criteria for the calculation are different. Therefore, you can pre-select a group of parts and the use of a criterion. Then select another group of parts and use other criteria.

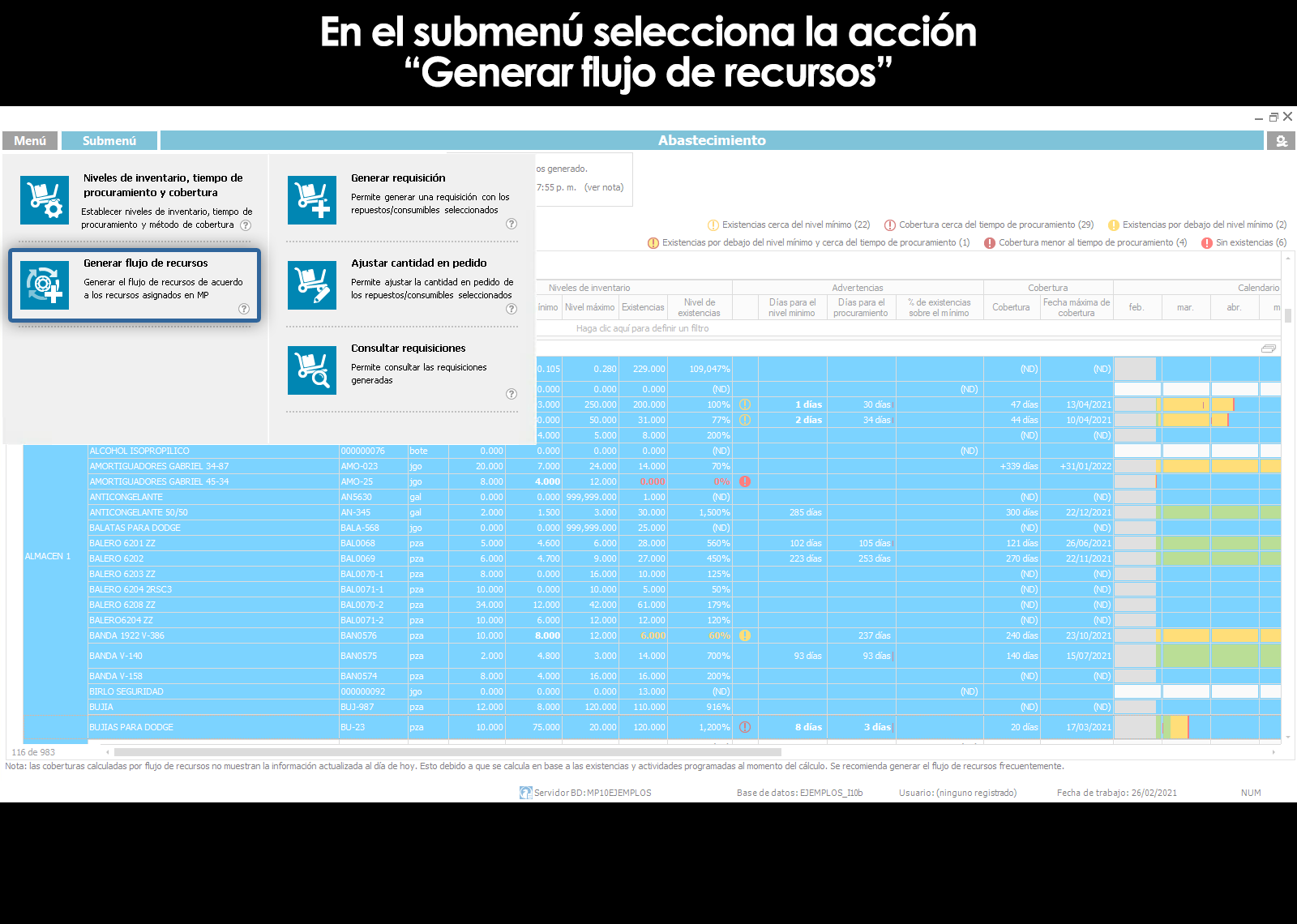

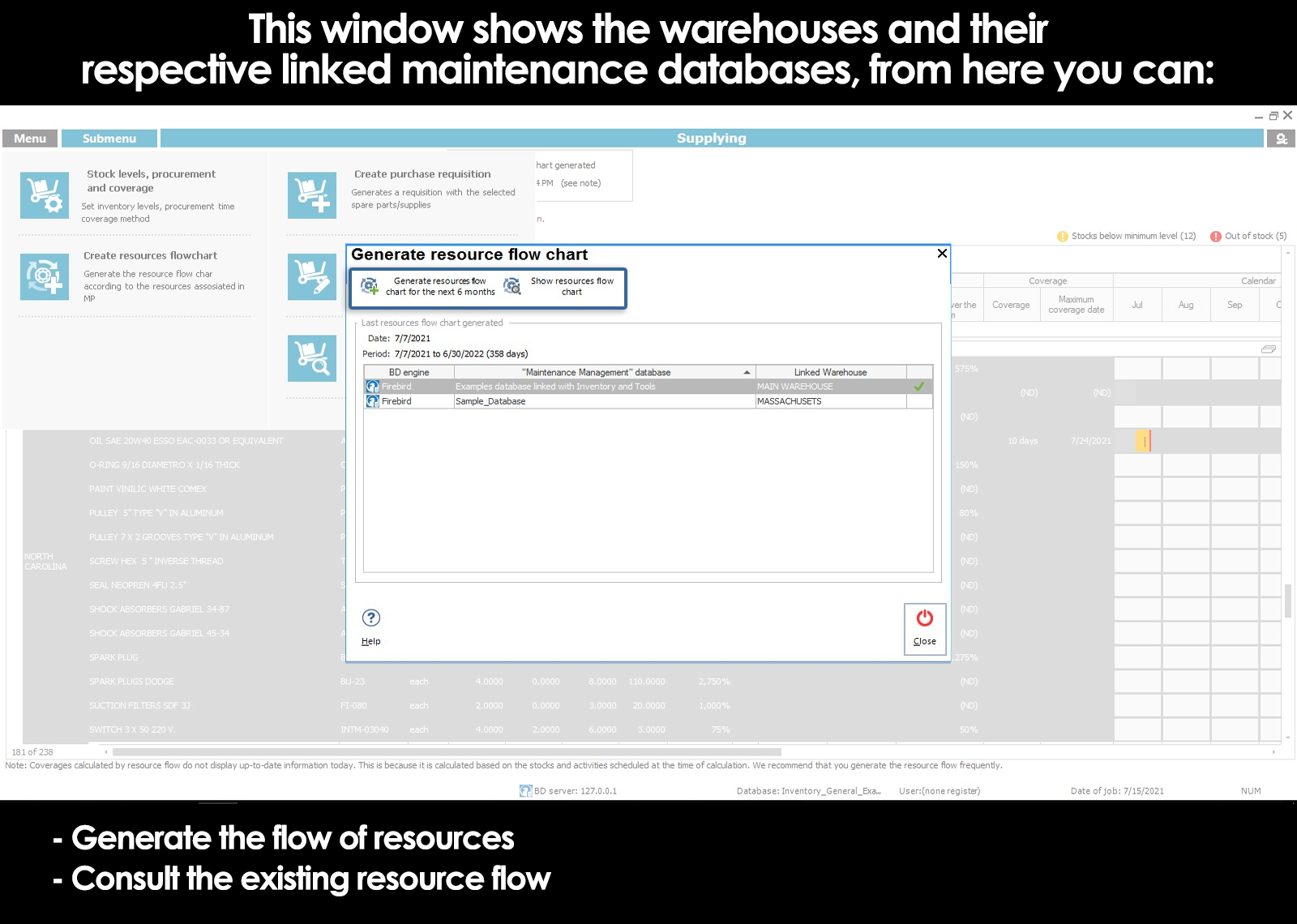

Generation of the flow of resources to the calculation of the coverage

Another way to calculate the time coverage of our inventory is through the flow of resources. The flow of resources considered in the Management program of Maintenance MP all maintenance activities that are scheduled for computers, and in this way, it is possible to know the amount of each resource that is scheduled to use for each day. This method is useful when you have properly allocated resources to the activities of maintenance since it will depend on the proper calculation of the requirements of spare parts in the future.

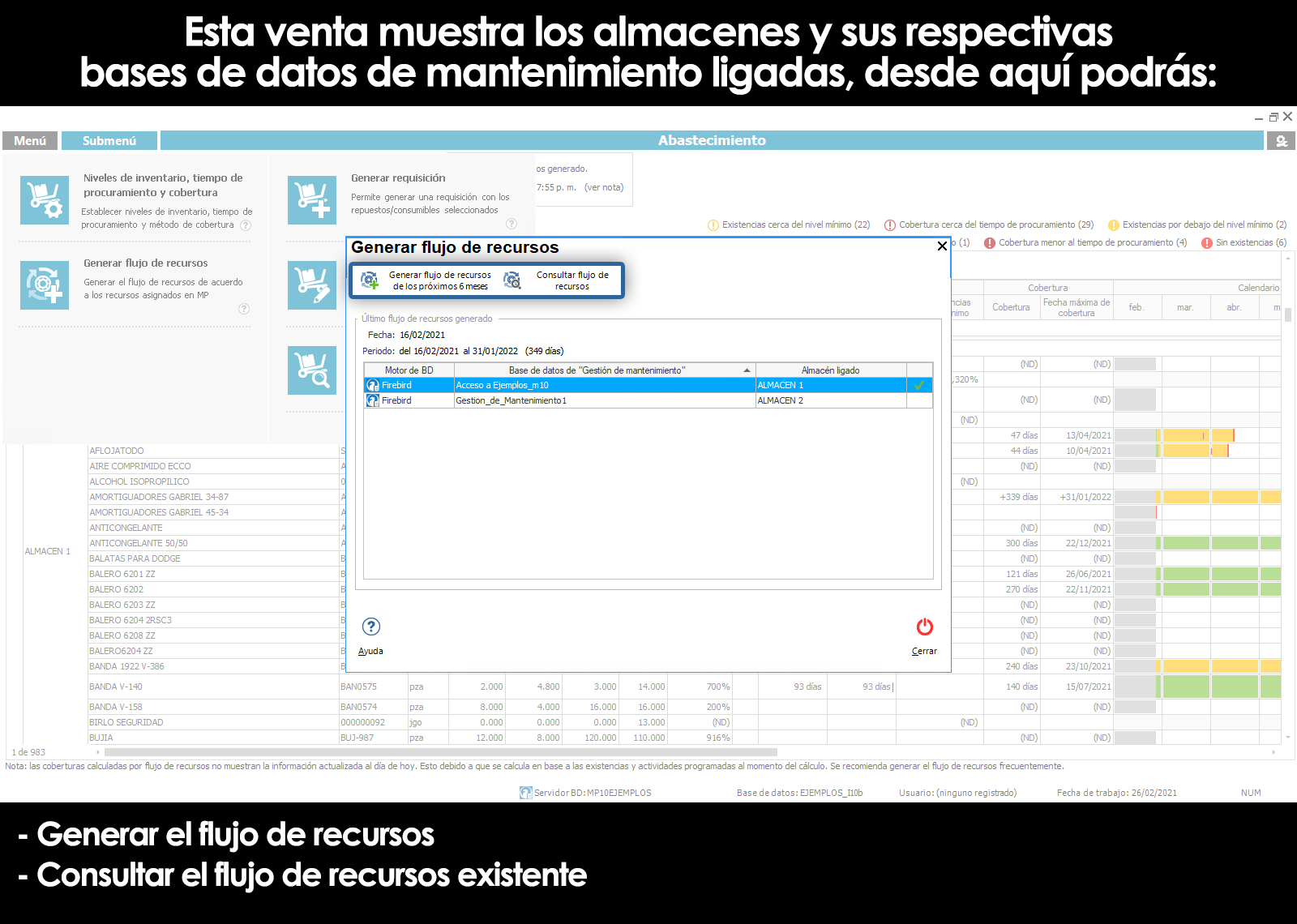

To calculate a flow of resources, you must click on the button Generating a flow of resources the sub-menu and then click on the button Generating a flow of resources.

The Inventory of spare Parts analyzes all of the stores and their respective databases of maintenance related. If you want to check the information of what was calculated, it can be queried via the button Consult flow of resources.

It is very important to be calculating continuously this flow, since the information varies with time depending on everything that has been updated in the program Maintenance Management MP. To do this, the window shows the date of when you performed the last calculation, as well as we will be notifying the program when it is convenient to recalculate the flow.

Take into account that the more often we are recalculating the flow of resources, the more accurate the schedule will be and the more accurate will be the estimate of the coverage.

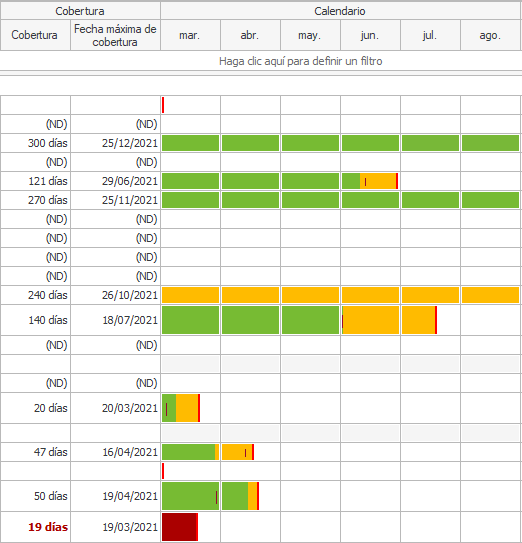

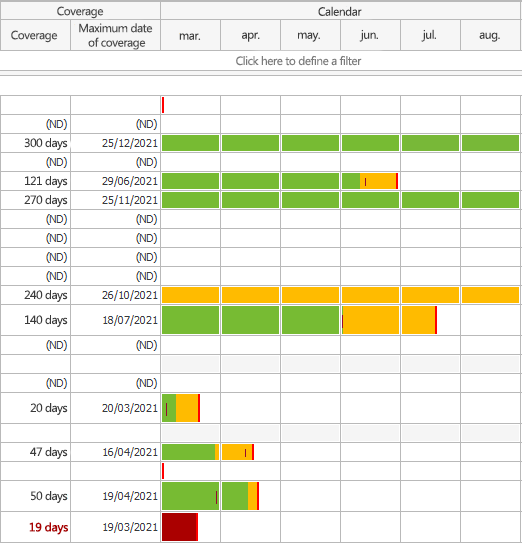

Understanding the coverage schedule

The following explains how to interpret the timing of the coverage.

Range in color green: is the range, as of today, in which our stock will be above the minimum level.

Range in color yellow: is the range, as of today, in which our stock will be below the minimum level.

Brand (small) color burnt red: indicates the point at which we will arrive at the time of procurement of the spare parts. This point is critical because, after this point, any order that we do subsequent to that date will not reach us on time, and very likely we run out of stock.

Brand (large) bright red: it is the day that our stock will be 0 (zero).

Can't find the answer to your doubts or questions?

Additionally, we offer training courses

Our flexible options of online training and face-to-face will provide you with all the knowledge necessary to understand and implement your software maintenance.