Inicio / Control de herramientas

¿Qué es un inventario físico?

Al igual que el programa inventario de repuestos, el sistema de control de herramientas cuenta con una función para facilitar la realización de inventarios físicos.

El inventario físico es un conteo manual de los productos que hay en un almacén.

Es necesario hacerlo cada cierto tiempo, de manera que se puedan identificar, revisar y contrastar las existencias que están registradas con las que realmente hay. Es decir, un inventario físico sirve para comparar el stock real con las cantidades que hay en el sistema.

La finalidad de un inventario físico es:

- Calcular qué partidas coinciden en número y cuáles no

- Localizar los posibles orígenes del descuadre

- Detectar pérdidas y artículos rotos o defectuosos

Dado que no se puede detener los trabajos de mantenimiento en una empresa, cerrar el almacén de herramientas por uno o varios días para realizar dicho inventario físico no es una opción.

La función para la realización de inventarios físicos resulta sumamente práctica, ya que permite realizar el conteo por partes sin paralizar el almacén.

Generar nuevo inventario físico de herramientas

El proceso para realizar un inventario físico desde el sistema de control de herramientas, inicia con la creación de un documento de inventario físico que contiene las herramientas que se van a inventariar. Podría ser por ejemplo, las herramientas localizadas en un pasillo o anaquel determinado.

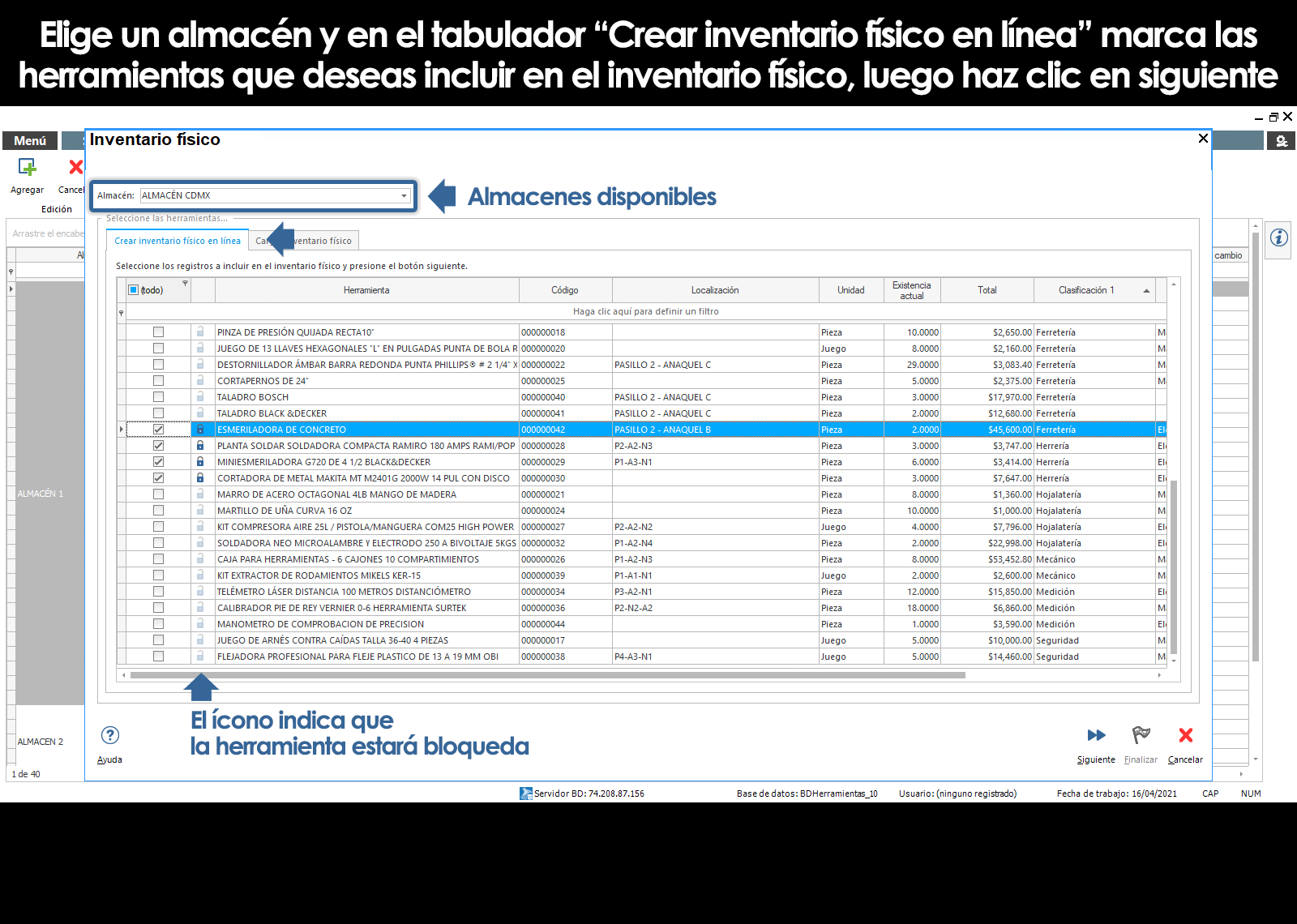

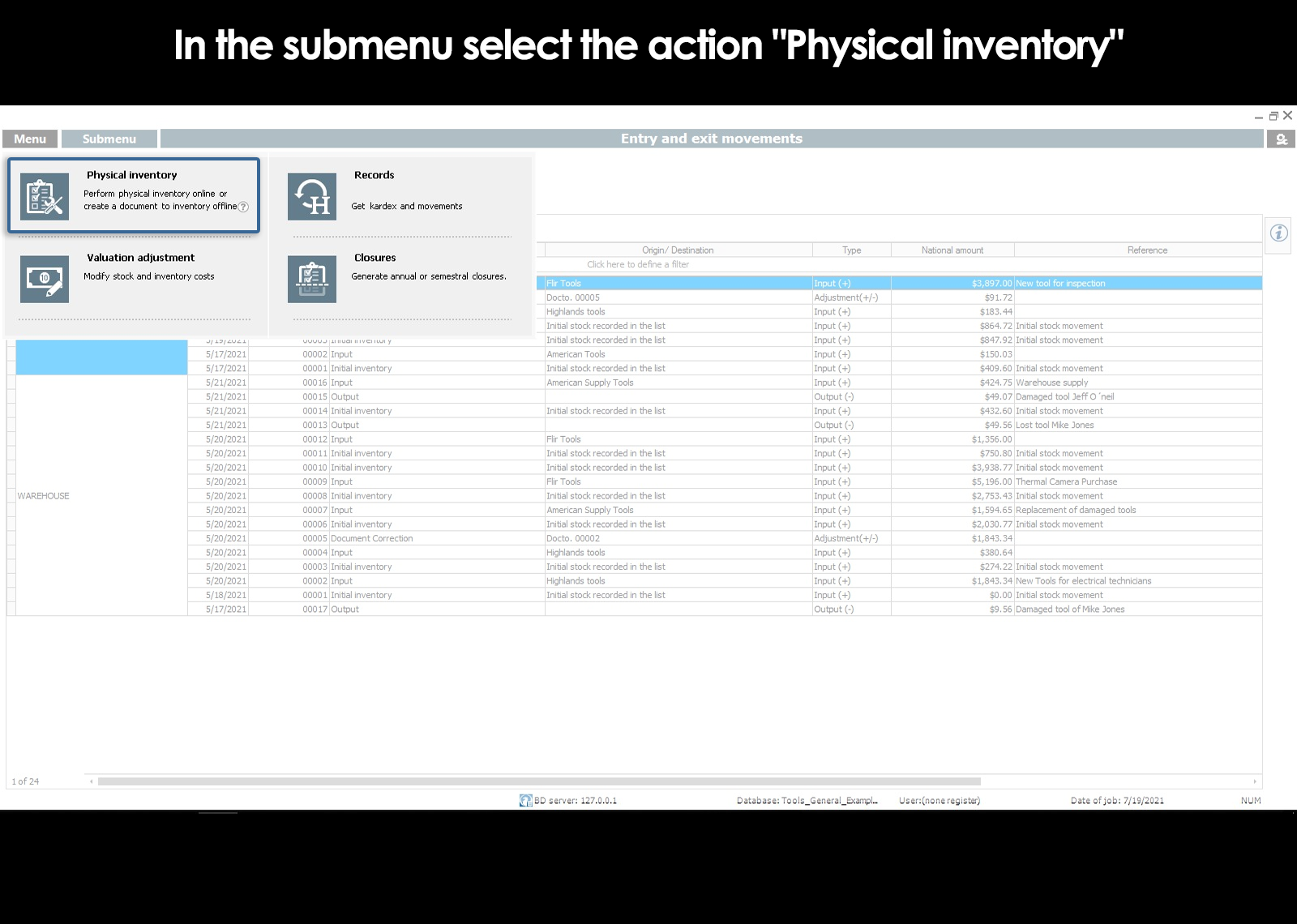

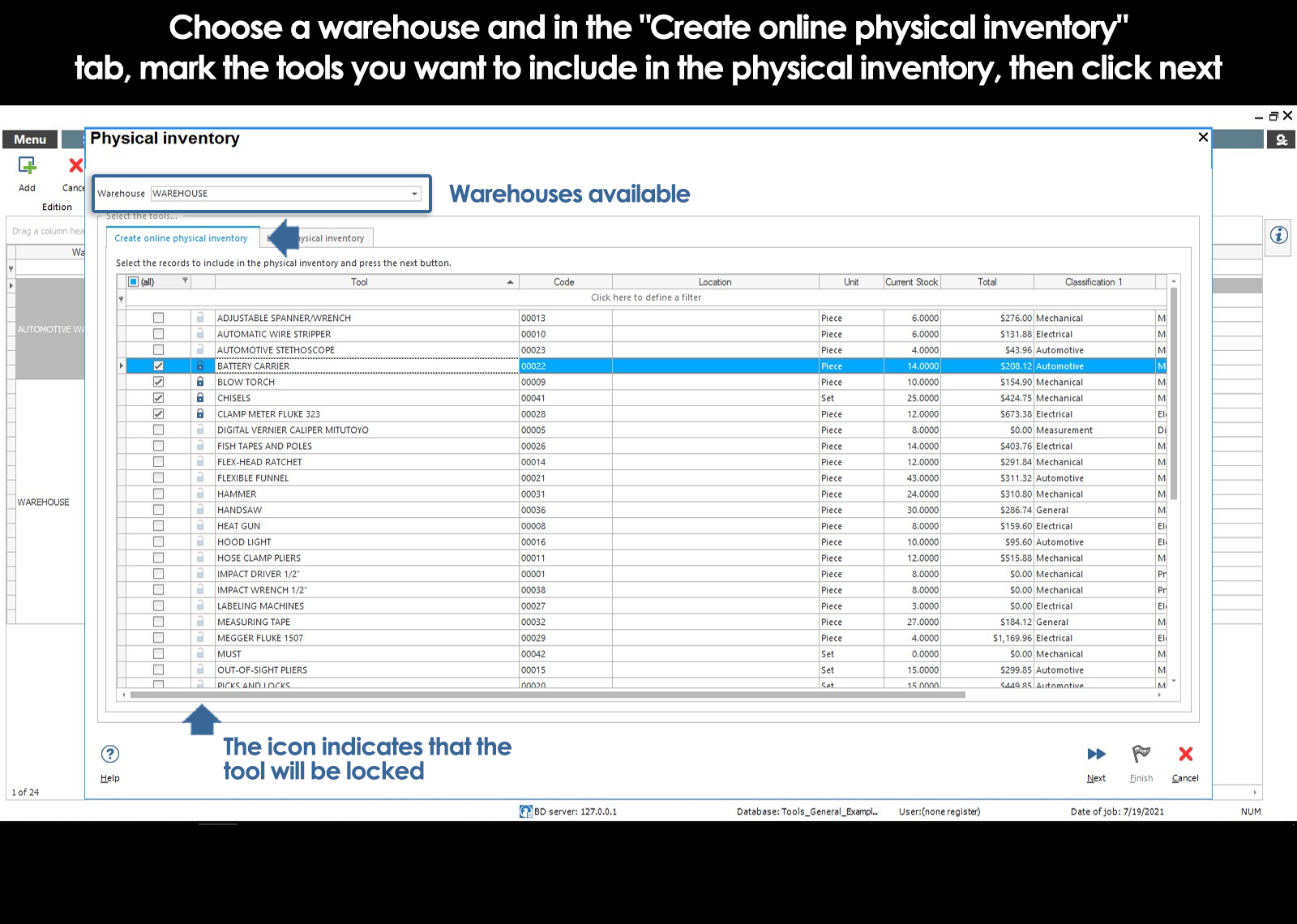

Para crear un nuevo documento de inventario físico, selecciona la acción de inventario físico que se encuentra en el submenú del módulo de movimientos de entrada y salida.

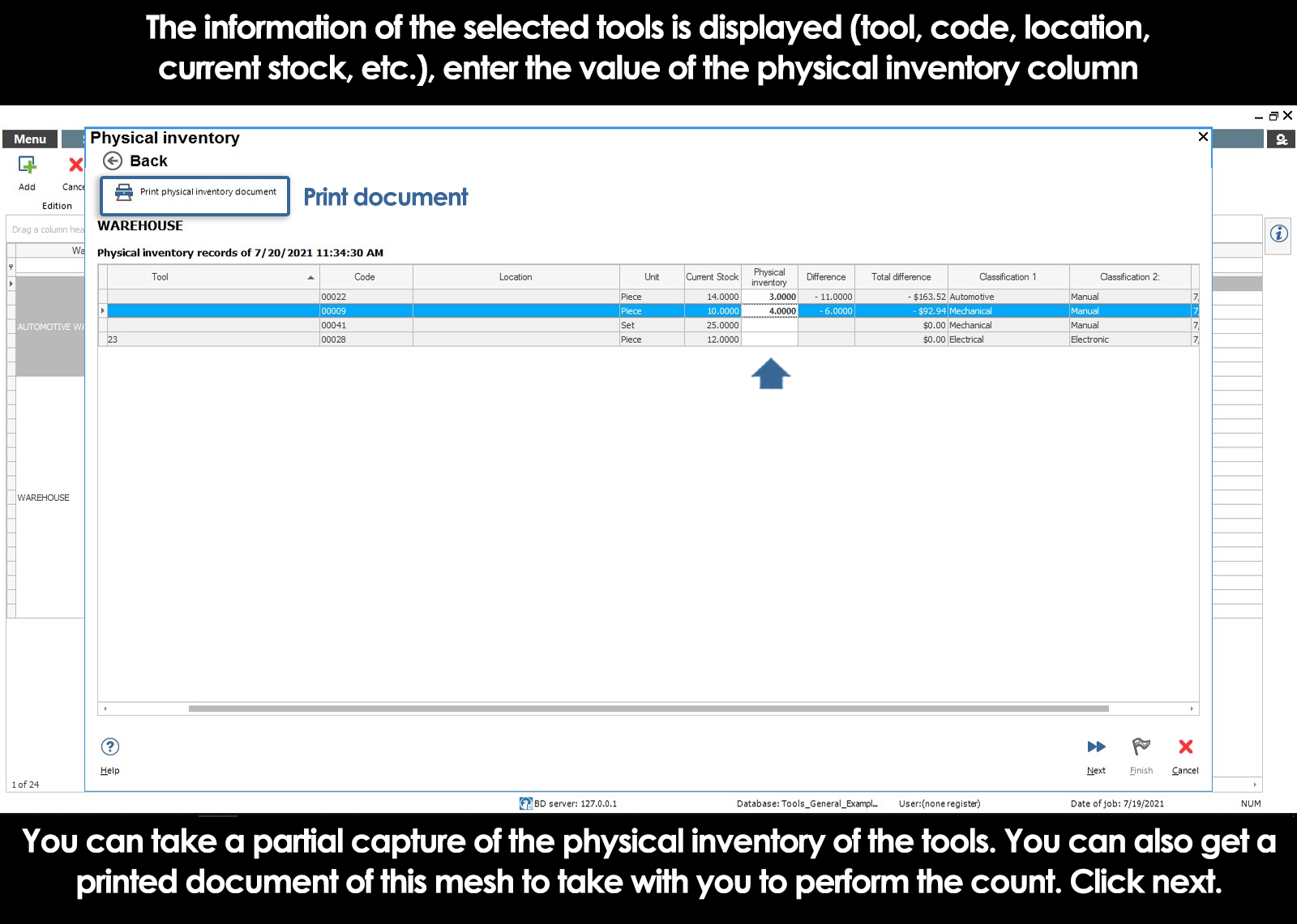

El sistema solicitará que indiques el almacén y las herramientas que deseas inventariar marcando la casilla de selección. Podrás imprimir un listado con las herramientas a inventariar para entregárselo a la persona encargada de hacer dicho conteo.

Las herramientas que se encuentren dentro de un documento de inventario físico son bloqueadas por el sistema. No obstante, si el almacenista requiriera o tuviera la necesidad de hacer un movimiento de salida puede hacerlo y en automático el sistema dará de baja la herramienta del listado de productos a inventariar e inventariarla más tarde.

El siguiente paso es registrar en el programa los datos obtenidos en el conteo físico.

Una vez registrado el conteo físico total o parcial podrás ir liberando las herramientas que ya fueron inventariados. Las herramientas liberadas desaparecerán del listado.

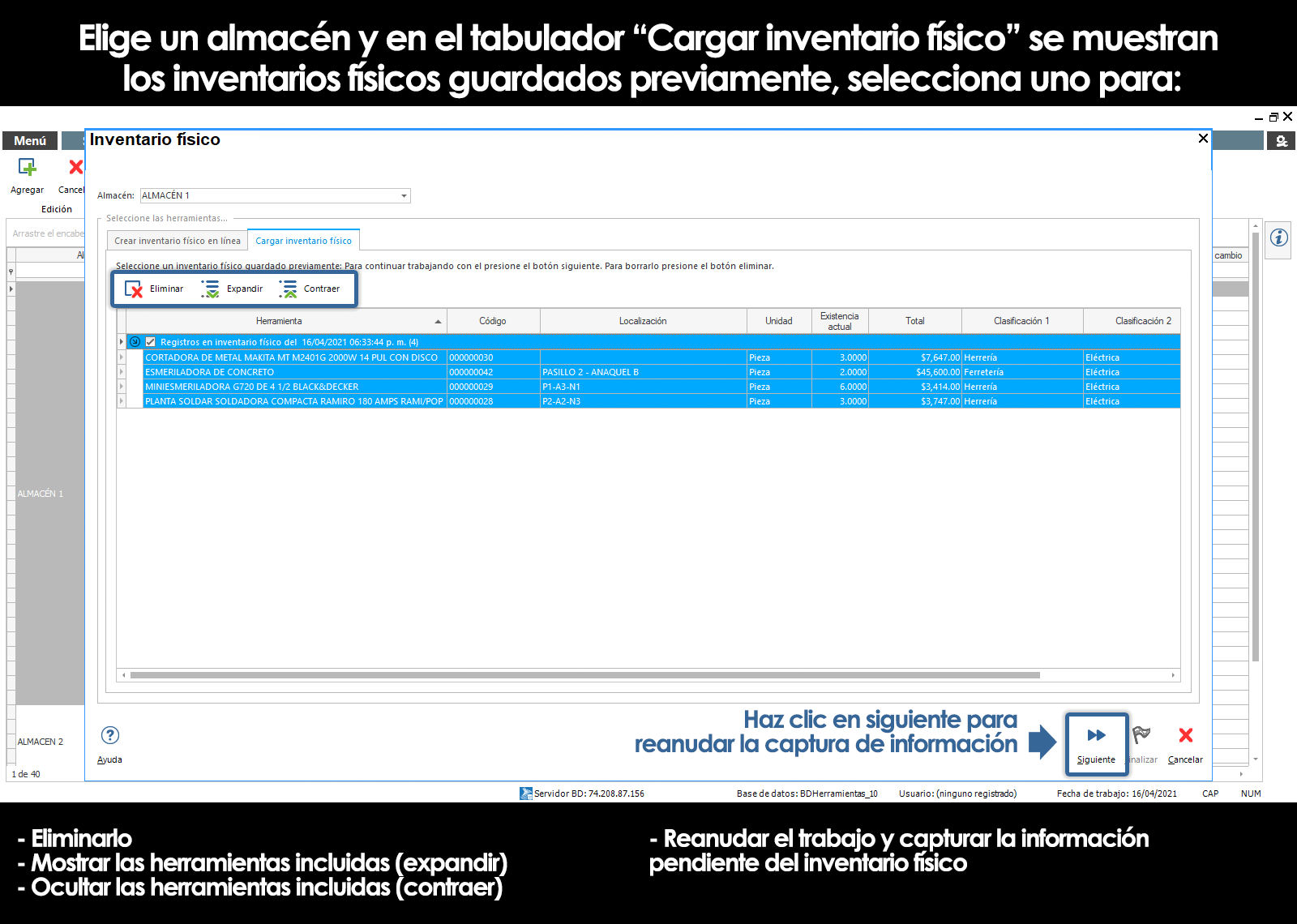

Podrás también guardar el avance en el inventario físico y reanudar posteriormente usando el tabulador “Cargar inventario físico”.

Liberar herramientas inventariadas y crear de movimientos de ajuste

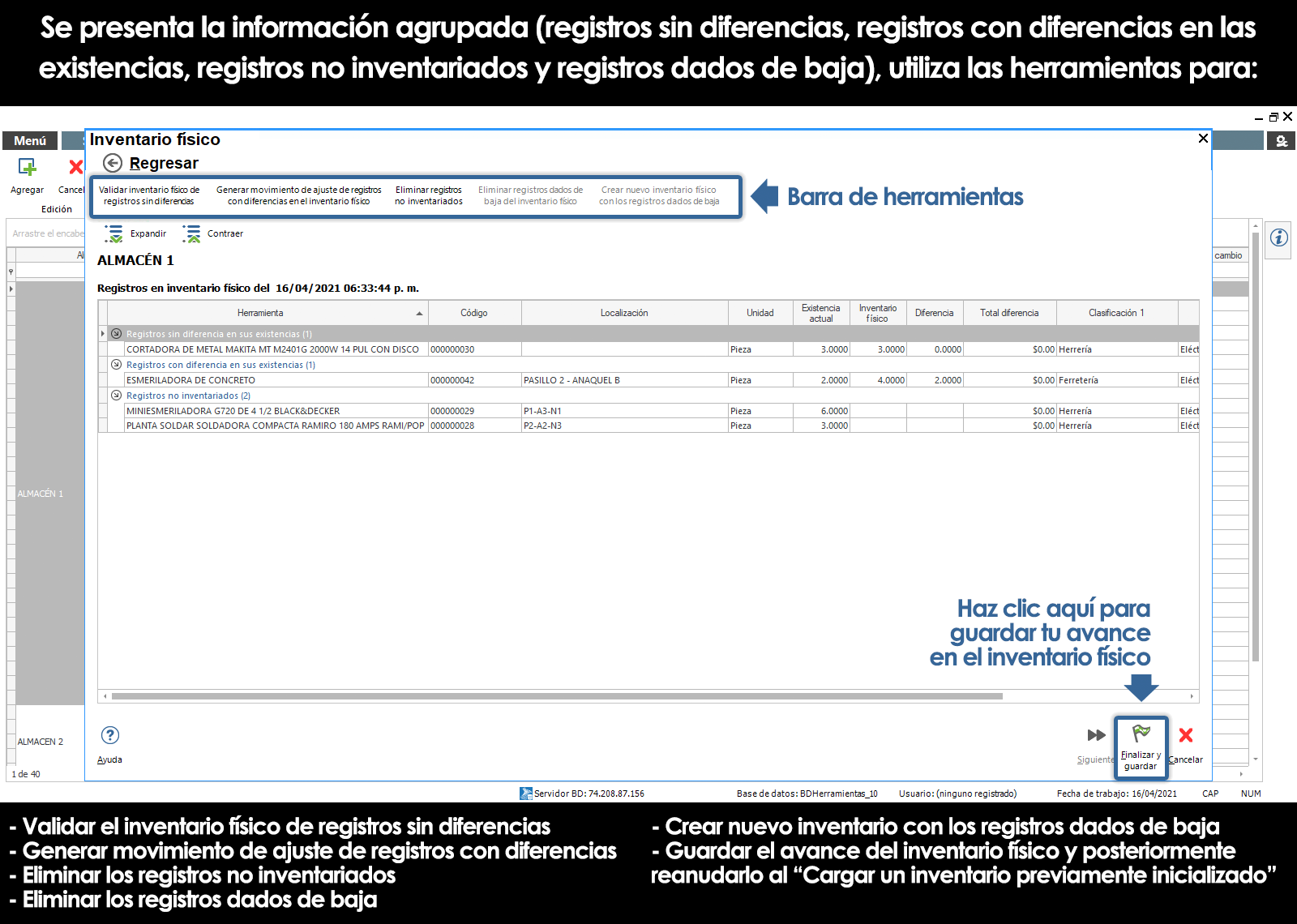

Conforme vas registrando las existencias resultado del conteo físico, las herramientas son agrupadas en 4 categorías:

| Categoría | Acción a realizar |

|---|---|

| 1. REGISTROS SIN DIFERENCIAS EN SUS EXISTENCIAS |

|

| El conteo físico es igual a la cantidad documentada en el programa. | Haz clic en Validar inventario fisico de los registros sin diferencias.

Todos los repuestos ya inventariados y que no presentaron diferencias serán liberados y eliminados del listado. |

| 2. REGISTROS CON DIFERENCIAS EN SUS EXISTENCIAS | |

| El conteo físico es diferente a la cantidad documentada en el programa. | Haz clic en Generar movimientos de ajuste de registros con diferencias en sus existencias

Se generará un movimiento de ajuste para hacer coincidir las existencias del programa con el stock físico. El movimeinto de ajuste utiliza el método de costeo predeterminado para calcular el monto del movimiento. Las herramientas involucradas serán liberadas y eliminadas del listado. |

| 3. REGISTROS NO INVENTARIADOS | |

| Son herramientas que no han sido contadas físicamente pero se incluyeron en el documento de inventario físico. | Realiza el conteo y registra los datos obtenidos, o bien, haz clic en Eliminar registros no inventariados para eliminar las herramientas del listado y liberarlos. |

| 4. REGISTROS DADOS DE BAJA | |

| Una herramienta se da de baja del documento de inventario físico cuando se genera un movimiento de entrada o salida que involucra dicha herramienta. Aún cuando las herramientas se bloquean por el sistema cuando se encuentran en un documento de inventario físico, la realización de los trabajos de mantenimiento no puede parar, por esto, cuando se genera un movimiento con productos que se están inventariando, el programa le muestra una alerta y le informa que la herramienta se encuentra en inventario físico. Si el almacenista decide continuar con el movimiento, el sistema dará de baja la herramienta del documento de inventario físico. | Haz clic en Eliminar registros dados de baja para quitar las herramientas del listado y liberarlos, o bien, presiona Crear un inventario físico con los registros dados de baja para quitarlos del listado y generar un nuevo documento de inventario físico con las herramientas que se dieron de baja del inventario. |

Cuando el listado de herramientas del documento de inventario físico se encuentre vacío, habrás concluido con el inventario físico.

Para cada herramienta inventariada quedará grabada la fecha y la hora en la que se registró en el sistema su último conteo físico.

Haciendo clic en Finalizar y guardar podrás guardar el avance en el inventario físico y reanudar posteriormente usando la herramienta “Cargar inventario físico”.

Cargar inventario físico previamente iniciado

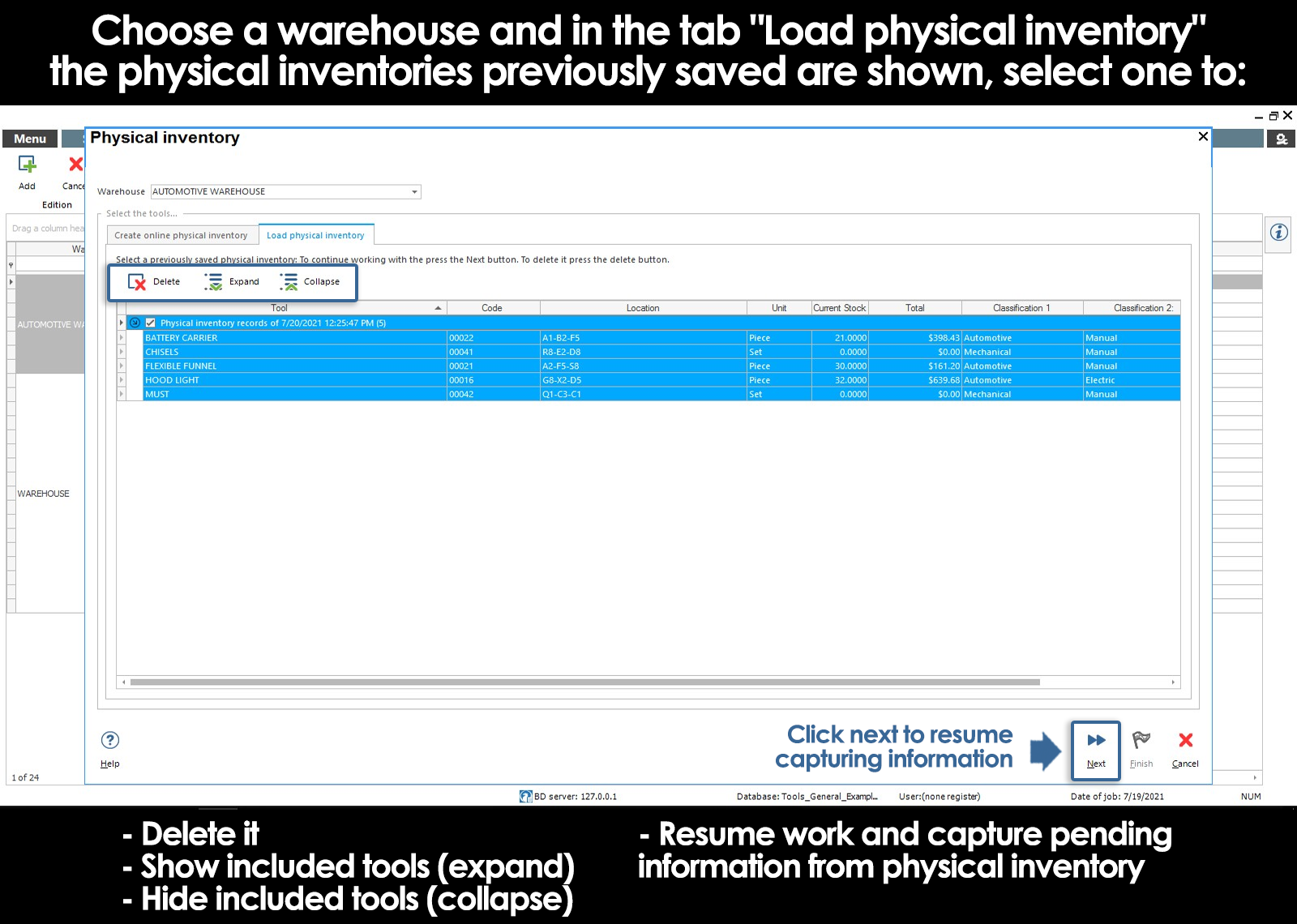

El inventario físico lo puedes realizar por partes, es decir, puedes capturar la información de un grupo de herramientas, guardar la información y continuar trabajando en el inventario físico en otro momento. También cuando se realiza el inventario físico llenando manualmente el documento impreso, debes ingresar al inventario previamente inicializado correspondiente para ingresar la información al sistema.

Dentro de la herramienta de inventario físico, selecciona la pestaña de cargar inventario físico previamente inicializado que se encuentra en la parte superior de la pantalla. Esta pestaña muestra todos los documentos de inventario físico que se encuentran abiertos. Los inventarios físicos se encuentran agrupados por la fecha de inicio. Al expandir el grupo podrás observar las herramientas que se contienen en ese documento de inventario.

Selecciona el documento de inventario físico que deseas cargar y al presionar siguiente se mostrará la malla modificable para continuar capturando el inventario físico.

¿No encuentras la respuesta a tus dudas o preguntas?

Contacta a nuestro equipo de soporte técnico

Ofrecemos servicio de soporte técnico GRATUITO vía:

✅ Videoconferencia

✅ Llamada telefónica

✅ Correo electrónico

✅ Whatsapp

✅ Chat

Preguntas frecuentes

Consulta nuestro sitio de preguntas frecuentes para conocer más sobre los esquemas de suscripción, nuestra amplia gama de opciones de conectividad, solución a problemas técnicos, etc..

Contacta a nuestro equipo de soporte técnico

Ofrecemos servicio de soporte técnico GRATUITO vía:

✅ Videoconferencia

✅ Llamada telefónica

✅ Correo electrónico

✅ Whatsapp

✅ Chat

Opcionalmente ofrecemos cursos de capacitación

Nuestras opciones flexibles de capacitación online y presenciales te brindarán todo el conocimiento necesario para comprender e implementar tu software de mantenimiento MP.

Opcionalmente ofrecemos cursos de capacitación

Nuestras opciones flexibles de capacitación online y presenciales te brindarán todo el conocimiento necesario para comprender e implementar tu software de mantenimiento MP.